The Chevy Cadavalier racks mount the tierods in the center for some reason. Perhaps you could mount a plate to it like the one you have pictured

this entire thread makes my head hurt ... Maybe it'll make more sense when I'm at home and can read it again ... Gotta stop surfing the web at work ... too many interuptions!

Wally wrote: The Chevy Cadavalier racks mount the tierods in the center for some reason. Perhaps you could mount a plate to it like the one you have pictured

I've found a few examples now of either center steer setups like you describe with an adapter plate or end steer with the same adapter. In fact Flaming River makes them so Im guessing its not as cheezy of an idea as I first thought.

littleturquoiseb wrote: this entire thread makes my head hurt ... Maybe it'll make more sense when I'm at home and can read it again ... Gotta stop surfing the web at work ... too many interuptions!

It makes my head hurt too...but Im learning and a plan is forming.

I think I have to rule out rack A, which is kinda sad because the more I looked at the measurments the closer it appeared to be. But the range of motion is just not good enough. Its designed for a hardcore offroad dunebuggy which does not have to make tight turns so it only has about a 2 inch range of motion at each end.

In other news rack B turns out to be a rear steer....sigh, I coulda sworn the donor was a front steer but I see now that the brake rotors are on the leading edge so when I looked at photos and assumed the brakes were trailing that meant the rack was in front. Still at this point I dont see why I cant flip it upside down. Its a grease filled manual rack and it doesnt seem to care what direction it is oriented in.

More to come.

found it on another site i had posted it on...My desk top at home didn't crash but the my ducuments folder is now empty....12 years for racing info gone in a poof....WTF

This is going to take awhile to write so print it out and take it to the car and look at stuff.

1) measure the distance between the two inner ball joints (hiems) Lets say for example its 22 inches

2) look in catalogs that have rack dimensions for a rack with inner tie rods at 22 inches. You'd like to get as close as possible.

3) make sure the rack you pick you can get the steering shaft to with out going through the motor. Tried to help several racers fit racks that just didn't work.

4) Rack height. This depends on a few measurements so take you time and get it right! 4a) Measure from the outer ball joints center of swivel to ground. Becarfull if you use real ball joint like me it can be deceiving as to where the center of rotation is. Cut and old one to make sure. lets say its 8.0 4b) Measure from outer tie rod center of rotation to ground. Lets say its 8.5 4c) so you have a outer tie rod that 1/2 inch higher then the ball joint this means you rack need to be 1/2 inch hirer then the inner ball joints. This will set the angles of the tie rods the same as the lower control arms thus minimize bump steer.

5) I race pavement and have found some Ackerman to be a good thing. Most big car set the racks 1.5 to 2 inches off the center line of the outer tie rods In DWARFS 1/2 to 3/4 works good. 5a) Point both wheels straight now tie a string around the outer tie rode bolts measure to a cross member in-line with the inner ball joints let say its 12 inches. So if you have front steer spindles (most dwarfs do) you should set the racks center line at 11.5 to 11.25 from the cross member.

Keeping a rack in the right place is hard!! An easy way to help is this. Measure the rack diameter and find some tubbing that will snuggly fit over the racks ends now weld on some thin sheet metal to the tubbing this can be clamped to the 1x2 frame that comes out to hold the bumper.

So to sum it up you want the tie rod angles to match the lower control arm angles when viewed from the front and you want the rack set back toward the motor .5 to .75 from the outer tie rod ends.

Best of luck 44dwarf "Smok'in the competition NOT Tobacco"

"Transplant organs, Don't bury them!"

Center steer is a cheapo way of doing steering. GM and others did it in no small part because they put the tie rods WAY up on the strut housing, like making it part of the lower spring mounting plate.

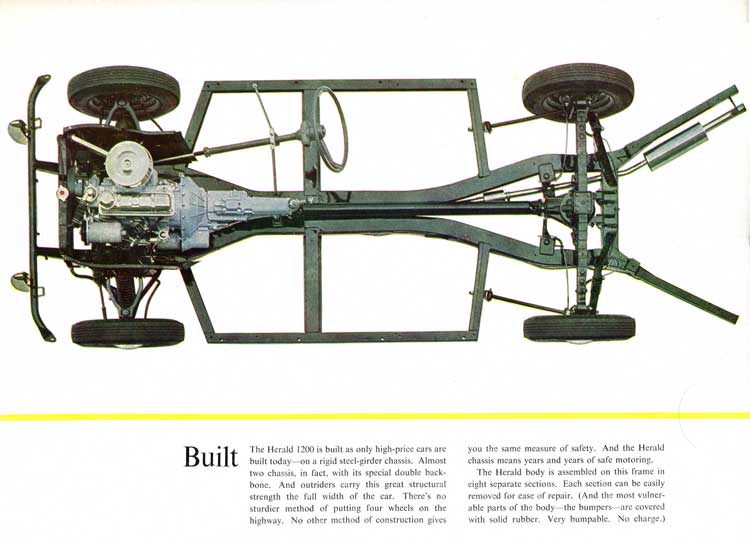

Here's a Chrysler setup, to show what I mean.

44Dwarf wrote: found it on another site i had posted it on...My desk top at home didn't crash but the my ducuments folder is now empty....12 years for racing info gone in a poof....WTF

DOH! Im paranoid about such happenings which is why I have everything duplicated in so many spots.

44Dwarf wrote: 1) measure the distance between the two inner ball joints (hiems) Lets say for example its 22 inches

19 inches

44Dwarf wrote: 2) look in catalogs that have rack dimensions for a rack with inner tie rods at 22 inches. You'd like to get as close as possible

. This is where Im having issues at the moment. Finding references for rack dimensions.

44Dwarf wrote: 3) make sure the rack you pick you can get the steering shaft to with out going through the motor. Tried to help several racers fit racks that just didn't work.

No motor up front :) But there are some clearance issues which make a rack with a center input shaft instead of offset better suited (not a common setup)

44Dwarf wrote: 4) Rack height. This depends on a few measurements so take you time and get it right! 4a) Measure from the outer ball joints center of swivel to ground. Becarfull if you use real ball joint like me it can be deceiving as to where the center of rotation is. Cut and old one to make sure. lets say its 8.0 4b) Measure from outer tie rod center of rotation to ground. Lets say its 8.5 4c) so you have a outer tie rod that 1/2 inch higher then the ball joint this means you rack need to be 1/2 inch hirer then the inner ball joints. This will set the angles of the tie rods the same as the lower control arms thus minimize bump steer.

Once we get the suspension out of "vice grips and spring clamps" mock up and welded in place this weekend I will feel better with these measurements.

44Dwarf wrote: 5) I race pavement and have found some Ackerman to be a good thing. Most big car set the racks 1.5 to 2 inches off the center line of the outer tie rods In DWARFS 1/2 to 3/4 works good. 5a) Point both wheels straight now tie a string around the outer tie rode bolts measure to a cross member in-line with the inner ball joints let say its 12 inches. So if you have front steer spindles (most dwarfs do) you should set the racks center line at 11.5 to 11.25 from the cross member

I did look at this tonite and we can set the rack back a bit further than I thought so we should be ok.

44Dwarf wrote: So to sum it up you want the tie rod angles to match the lower control arm angles when viewed from the front and you want the rack set back toward the motor .5 to .75 from the outer tie rod ends.

This is all doable, I can mount the rack to give the correct angle and offset toward the rear but its getting the inner pivots to match at that 19 inches that's the bear. I think I have a plan, I just have to let it marinate in my brain awhile first.

Thank you for the very informative and educational post!

Jensenman wrote: Center steer is a cheapo way of doing steering. GM and others did it in no small part because they put the tie rods WAY up on the strut housing, like making it part of the lower spring mounting plate. Here's a Chrysler setup, to show what I mean.

Dont you still end up with the same issues no matter how high up you put the steering arm?

getting a bit off topic at this point but my curiosity and need to learn are getting the better of me.

How does a car with a steering box rather than a R&P achieve anything close to a reasonable geometry?

Im used to VW bugs with their left mounted steering box with a short tie rod on the driver side and a long one on the passenger side. I haven't thought on it too much but I just cant wrap my head around how that works well at all (but it does)

Here's the best image I could find of the steering setup which leads to reverse Ackerman. See how the steering tie rods sweep back?

Yeah, no matter how high you put the steering arms you still wind up with weirdness. In a non high performance car with overboosted power steering and fairly limited suspension travel it's not much of an issue.

It's actually easier to work with 'parallelogram' linkage than R&P. The trick is to have the outer arms, the Pitman arm and the idler arm all describe the same arc.

The old short/long Bug steering (and also the very similar Twin I Beam Ford truck layout) was cheap but that's all it had going for it.

Ok, since I dont function without visual aids I thought Id toss this out here

Dimension from inner a arm pivot to ball joint

Distance between A arm pivots

Rack set in roughly the most rearward position we can get

Overhead view of same, as you can see the rack is a bit too long

and viewed straight on

My idea is to do something similar to the setup in earlier pictures (with the adapter bar, but because the rack shape in its inverted postion wont allow that I want to make something like this.

Really bad drawing but essentially Id put flats on the top and bottom of the rack output arms and create a box which slips over the output and is held on by a bolt which threads in to the area where the tie rod used to thread, this would allow me to bolt on a heim joint similar to what was shown in the earlier diagrams.

The rack position can go up or down, its resting on the frame right now but that point forward on the frame no longer supports any major weight (used to hold the engine) so I can notch the frame and sink the rack.

Thoughts?

Oh, one more thought. The steering rack output arms are internally threaded for the tie rods. They are 1.5 inches deep threaded. Probably too shallow to cut an inch off each side but it was a thought. Looks like it would take equipment beyond my scope to cut, drill and rethread, but it does look possible.

edit I took a moment and thought to measure the joint that goes into the rack and its only .75 inches deep which means I could effectively take .75 out of each side for 1.5 total so Id be at 20.5 against my 19" spacing and the steering arms do sit outboard of the balljoint by about .5 inches per side so that gets the a-arm to tie rod length just about equal....is this sounding close to where I need to be? At this point my brain is fried so I may be completely confused.

Okay. The rearward movement shown is going to be too much, but it's good to know you have that much room. Like dwarf says, around .75 setback from the centerline of the outer tie rod centers is just about ideal.

It's best if you lower the rack and put the outer tie rods on the bottom of the knuckles. You should be able to get the tie rod real close to the horizontal CL of the control arm that way, which is good.

Man, that is a funky lookin' rack. ![]() What in the world did it come out of? Are you sure you will need all the movement it has? Say it has 5" total travel but you only need 3", then you can whack off an inch per side easily. If you need all it has, is there any reason you can't cut off the outer ends of the rack housing? i.e. cut 1 1/2" off each end of the rack and a similar amount off each end of the rack housing. Looking at the wear pattern, it appears it doesn't go full travel anyway so I don't think you'll need to modify the housing. I also would, since there is going to be a bit of bump steer anyway, make the tie rod about 1/2" shorter than the CA measurement so any bump steer will be in the understeer direction.

What in the world did it come out of? Are you sure you will need all the movement it has? Say it has 5" total travel but you only need 3", then you can whack off an inch per side easily. If you need all it has, is there any reason you can't cut off the outer ends of the rack housing? i.e. cut 1 1/2" off each end of the rack and a similar amount off each end of the rack housing. Looking at the wear pattern, it appears it doesn't go full travel anyway so I don't think you'll need to modify the housing. I also would, since there is going to be a bit of bump steer anyway, make the tie rod about 1/2" shorter than the CA measurement so any bump steer will be in the understeer direction.

Your pic shows 13.5" from the center of the lower pivot bolt to the center of the bottom ball joint. Ideally, the center of the outer TR will be the same distance from the pivot bolt. If it is .5 outboard, then you can heat/bend the arms to bring it in. You can also twist the arms to help with positioning (see your Miata's setup again).

Before doing that (or for that matter anything!), lock the steering in the straight ahead position. I did this on the Abomination by mounting short pieces of angle steel on the hubs with an equal amount sticking out front and rear (I drilled holes to match the bolt circle and clamped it down with the lug nuts), then used another piece of angle and Vise Grips across the front. Level the whole car front/rear/side/side, then level the control arms, then measure between the front and rear of the angle steel on the hubs the same way you'd check toe. When the measurements are equal, now it's in the straight ahead position.

Once that is done, check the measurement all the way across between the tie rod holes. Then check the measurement between the inner pivot bolts. Use center to center measurements. Now subtract the pivot bolt measurement from the total width measurement, then subtract 1" from that (so each tie rod will be about 1/2" shorter than the CA), divide that measurement by 2 and that is how long the tie rod will need to be center to center. You use this measurement to decide how much to cut off of the rack.

Remember when figuring the cutoff amount to allow for the distance from the center of the inner tie rod ball to the flat part of the mounting. On most inner TR's I have seen, this will be somewhere around 3/4". That means you take the center to center measurement found above, then add 3/4" (or whatever the center measurement turns out to be) double that (for two tie rods) and subtract that from the full width measurement. That's how long the rack needs to be. It's probably going to be right around 18 1/2" rack length from flat to flat so that when the inner tie rods are bolted up the measurement from center to center will be right at 20". Like may dad used to say: 'Measure thrice, cut once'. ![]()

Cut, drill, rethread: Cut it with a chop saw. Do it slow, take your time. Drill: chuck it in a lathe so the new hole will be dead center. Rethread: make your hole a bit deeper than the length of the tie rod thread (for instance if it's 3/4" long, add about 3/16") then start the threading with a standard hand tap. Cut until the tap bottoms. Then switch to a 'bottoming tap' and finish the threads.

The heim joint adapter will cut down on rack travel a lot so I'd think carefully before doing that. Plus, heims have limited movement compared to the factory tie rods so there is a real possibility of them bottoming out.

In reply to Jensenman: Not to be a buttinski, but I thought Ackerman could be achieved by mounting the rack ahead of, or behind a line between the steering arms. Are you saying that pushing the rack forward gives reverse ackerman effect? Thanks in advance, I'm learning tons from this thread.

Yes, on a front steer car pushing the rack ahead of the centerline of the outer tie rods gives reverse Ackerman which gets worse the further forward it goes. If the tie rod sweeps back when in the straight ahead position, the wheel on the outside of the turn turns in too much as the steering rack movement increases. R&P setups have sorta odd Ackerman anyway, even when mounted correctly (rack behind the tie rod centerline for a front steer car).

Rear steer R&P cars are the opposite. They have better Ackerman than a front steer car if the tie rods sweep forward at rest but it still isn't ideal. In both cases, the rack should be ~ 3/4" closer to the axle centerline as measured from a line drawn between the outer tie rod mounting point centerline. On rear steer cars that can be pretty tough as non essential bits like the engine tend to be in the way. ![]() That has a lot to do with the center steer rack setups used by GM and Chrysler.

That has a lot to do with the center steer rack setups used by GM and Chrysler.

Think of Ackerman like this. In front steer if the rack is set behind the outer tie rods as the steering is turned to the left the left spindel arm get shorter inrespect to the rack thus the tie rod seem like it gets longer. All due to the arc's the steering arm scribe.

To test you work you can make some homemade turning plate out of cheap plastic cutting boards from the dollar store! buy 4 ultra thin cutting boards the paper thin ones. stack two under each wheel use a sharpie to mark the sheets turn the wheel and add second mark measure the space betwwen marks on both sides the inside wheel should turn more.

44

You'll need to log in to post.