... because it won't be my money.

We kinda talked about this in reverse with a car hauler that someone wanted to have a deck that lowers with an articulating axle. I want to do the opposite.

I want a deck-over trailer that lifts on demand to meet a commercial 4' dock. Before you ask, it has to be a deckover because it needs to be 8' wide, and also before you ask... yes, it needs to meet up with a 4' dock. These are not optional. Also, before you ask... GVWR might as well stay at it's current 10k in case it needs to be used for heavy work, but in all honesty it will likely never see more than 5k.

So help me get there. I have the trailer. It's an 8' x 24' with dual axles, bumper tow. Critique my ideas. The first picture is more or less how things are now. It's a leaf spring axle setup. The second photo shows my first idea. It would add a subframe hinged at the back onto which the axles would attach. Then between the subframe and the trailer frame I would put some kind of lifting mechanism; possibly airbags, a hydraulic ram to a bellcrank, or some kind of scissor jack.

The current deck is 32" off the ground, but it also has monster balloons for tires (mobile home axles) and they are also about 30 years old, so careful choice of tire replacement could make the deck no higher than 32" for easier loading when NOT at a dock. Then to get up to the 48" dock, I need 16" of lift at the tail which (guessing) would mean 10-12" at the axle.

The thing I'm thinking about this design is that the trailer frame would lay flat on the subframe when in the down position and therefore take it out of play as part of the suspension. I could make a little cup or pin that holds it in place. This way the only thing the subframe needs to actually support is a triangulated load when the lift is activated during loading and unloading.

In this last picture I went really quick and couldn't figure out how to rotate the axles, but you get the idea of what it would look like in the up position.

Is there a reason that a ramp on the back of the existing trailer wouldn't work? Does the entire bed need to incline?

I believe Streetwiseguy's idea is how an airline catering truck operates a combo of hydraulic and scissors to lift the box up to the plane. May one enquire as to the purpose of this contraption?

If I'm not mistaken, doesn't 10k and more pound capability of the trailer put you in "CDL required"? Are you okay with that?

I think that even though you may not actually be hauling 10k pounds on the trailer, I think the fact that it CAN haul more than 10k pounds is what forces the CDL.

I would think if you need to load or unload 5k# you will want the deck as flat as possible. That incline will.make it tough to move on/off. Scissor lift contraption seems like it would be the way to go, possibly an easier option.

CJ said:Is there a reason that a ramp on the back of the existing trailer wouldn't work? Does the entire bed need to incline?

I'm trying to duplicate the function of a stake bed or box truck. Roll big scenic elements on with dollies, pallet jacks, etc. I need the bed to be flush with the dock and not have major angle changes. This is going to be a general purpose trailer 5% of the time, but 95% of the time it will be used to transport a large theater set from A to B, where both docks are a "pit" ramp. I don't mind a 10 degree uphill or downhill of the deck (a box truck points uphill and this trailer will likely point a bit downhill) but I can't have big ramp angles.

An example... the last show I moved A to B had a big "box" that was 14' long, 8' high, and 4' wide. It was a no-brainer on a stake body. I put a heavy dolly under one end and the pallet jack under the other and rolled it on. Remove wheels, tie down, go, reverse at destination.

John Welsh said:If I'm not mistaken, doesn't 10k and more pound capability of the trailer put you in "CDL required"? Are you okay with that?

I think that even though you may not actually be hauling 10k pounds on the trailer, I think the fact that it CAN haul more than 10k pounds is what forces the CDL.

Although I am licensed CDL, this will not require it. CDL for trailers is (from the DOT website) "if the tow-vehicle manufacturer’s assigned GCWR exceeds 26,000 lbs. (as shown on its cert label) and the trailer’s GVWR exceeds 10,000 lbs. If there is no assigned GCWR, the FMCSA requires a CDL only if the sum of the GVWRs of the tow vehicle and the trailer together exceeds 26,000 lbs. and the trailer’s GVWR exceeds 10,000 lbs. In either case, the driver will need a Class A CDL." In a nutshell, CDL is only required for over 10k if the tow vehicle is GVWR of over 26k

I own multiple 10k trailers and none require a CDL. It is common for trailer GVWRs to be upwards of 20k without needing a CDL.

Streetwiseguy said:

Here is the basic idea. Remove the parts you don't need.

No articulation. That would lift the entire trailer straight up parallel to the surface below it. I would need it to account for the fact that the trailer tilts up at the back while the street tilts down toward the back.

I'd suggest checking out commercial car haulers (5-10 car) for ideas.

Boydstun and Cotrell have decks that move vertically, and do it with hydraulic rams and tube within a tube design for the verticals sliders.

The high mount trailers typically use an electric pump, so no need for a truck mounted PTO. Some of the newer trailers use a screw system to lift instead of hydraulic pistons, so that may eliminate plumbing.

I'll try to visually demonstrate.

Box truck in the dock looks like this. It's about a 7 degree angle up to load scenic elements (none of which weigh 5000 lbs each)

Trailer in the dock looks like this

Lifted trailer in the dock will look something like this:

If you aren't trying to lift the whole deck flat, then why not make it a dump trailer with the tongue at the wrong end?

I could see your last photo working but I am trying to imagine the force required to actually lit 5K lb's at an angle like that. Now I could see something like two skyjacks on the end of the ramp, and just a hinge articulation to bring things up because using hydraulic's at an angle like that would require some serious throw.

I was thinking mechanical jacks like this on the end. You could do straight up hydraulics but they would stick up at least 6-7 feet to get the lift you want from the top of the bed and that would be horrible

for unloading.

No Time said:If you aren't trying to lift the whole deck flat, then why not make it a dump trailer with the tongue at the wrong end?

That's more or less what I'm attempting, but a dump trailer typically lifts just the bed leaving the frame and suspension in place.... which is what you want - the most possible angle for full dumping. If I do it the way I pictured, it articulates between the absolute tail and the hitch ball, making the shallowest angle possible.

But yes. I'm looking for ideas on how to lift it. I could do airbags, but that would require an air supply. I could do hydraulics and I have a few 5hp motors sitting around so I would just need the pump and rams.

wearymicrobe said:I could see your last photo working but I am trying to imagine the force required to actually lit 5K lb's at an angle like that.

Theoretically, if the axles were at the midpoint I would need double the weight, or a total force of 10k. I would have to do the calculations and factor in a little extra, but since the axles are behind center it would actually be a little less than double. I haven't delved into that rabbit hole yet, but I know that my 6.5 hp log splitter is a 20 ton, but not sure how they rate that... if that's psi at the cutting head, or a physical linear force, or some other calculation.

Come to think of it... maybe a used log splitter could supply my lifting force.

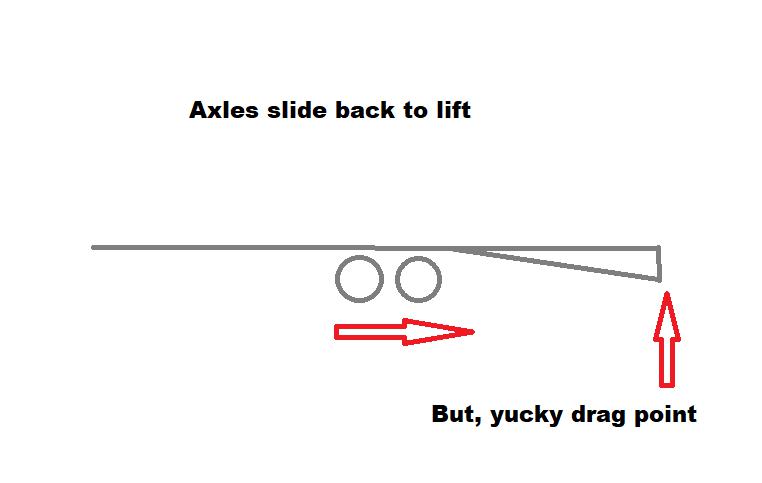

I also thought about a reverse of a container trailer. They use a 5hp engine to roll the axles forward until the tail is on the ground. I thought about doing something like shown below, but I think I would have dragging problems.

Here's a photo showing how the upper deck at the tail end of a 6/7 car trailer is set up.

It can raise and articulate, so the angle can be lowered to drive the car on and then raised and pinned in place so you can put another car under it.

You could potentially do something similar for the whole deck with vertical motion at the front and the pivot at the rear to have the deck level and flat with the dock.

So far, all of the ideas I've had.

No Time said:Here's a photo showing how the upper deck at the tail end of a 6/7 car trailer is set up.

It can raise and articulate, so the angle can be lowered to drive the car on and then raised and pinned in place so you can put another car under it.

You could potentially do something similar for the whole deck with vertical motion at the front and the pivot at the rear to have the deck level and flat with the dock.

This is a fantastic idea, and I'm into it, but I'm struggling to account for the vertical space that trailer has to work with. I will have very little vertical space to get the angles needed to duplicate this without bellcranks and possibly more engineering calculations than I can accurately do.

This would also require a complete subframe engineered to be it's own trailer. In my original idea, the subframe is as simple as some 2x4 1/4" wall steel tubing as trailing arms that articulate. When it's down, they are simply static and against the frame so they aren't structural. When it's up, it is simply carrying linear loads.

I do like the idea of a flat (level) deck, but I'm not sure the engineering required to achieve that is proportional to the benefit.

In reply to Curtis73 :

I would approach it as adding an articulating deck built on the current trailer.

-Add vertical posts at the front corners of the current deck to use for the raising and lower of the deck. You could use U channel to connect the deck to the movable upright, allowing the pivot and cylinder to be mounted higher than the deck so you don't lose ground clearance.

- modify the existing frame to add dropped mounts for the rear cylinders (see area right behind the tandems in photo), to allow for a better angle.

- Most of the tube used on that car trailer is 3/32" wall.

Another way to approach what you are trying to do is the way the mid decks work(I don't have a good photo) in the car trailer:

-Imagine a 4 post lift mounted rigidly to the current fixed trailer deck. The posts are connected to the moving deck by pins so you can raise each end different amounts

Rons said:May one enquire as to the purpose of this contraption?

Yup. 7 degree "pit" style docks at both point A and point B. Similar situations anywhere else I would go.

I build set pieces in the shop at point A. I typically rent a 26' box truck, but trying to build this trailer to replace those rental fees. I construct the set in a "touring" style so they get broken down into large chunks that fit on the transport. They get transported to point B; a large theater downtown (about 5 miles away) where they are unloaded on at their dock for re-assembly. After the show is done, reverse process.

From time to time, I also might rent a set piece from another theater (with or without a dock, but forklifts are involved). I sometimes might get a phone call where someone is donating a piano, or 6 couches, or I need to transport a scissor lift.... It just needs to be an all-purpose trailer. But 95% of it will be transporting large, bulky (but not necessarily heavy) set pieces from dock A to dock B.

In the example below, Note how this large set piece was constructed in 5 sections, each of them 6-8' long and 9' tall. They came apart using hasp latches and were wheeled onto a stake bed truck and transported. Then they were wheeled onto the stage and re-latched for the run of the show.

No Time said:In reply to Curtis73 :

I would approach it as adding an articulating deck built on the current trailer.

-Add vertical posts at the front corners of the current deck to use for the raising and lower of the deck. You could use U channel to connect the deck to the movable upright, allowing the pivot and cylinder to be mounted higher than the deck so you don't lose ground clearance.

- modify the existing frame to add dropped mounts for the rear cylinders (see area right behind the tandems in photo), to allow for a better angle.

- Most of the tube used on that car trailer is 3/32" wall.

Another way to approach what you are trying to do is the way the mid decks work(I don't have a good photo) in the car trailer:-Imagine a 4 post lift mounted rigidly to the current fixed trailer deck. The posts are connected to the moving deck by pins so you can raise each end different amounts

I can totally picture what you're suggesting, (I have operated car transports before) but I don't think the complexity/weight is proportional to the benefit. I'm trying to keep it as simple as possible or it will never get done.

In reply to Curtis73 :

Understood.

I've gone through similar thought exercises trying to figure out how to double stack snowmobiles when trailering to make use of the existing 2 place trailers I have.

Too much complexity cancels out any benefit.

I'm sure I'm missing something here, but I can't help but wonder; if it's beneficial for it to be simple, what's more simple than a pair of ramps at the bottom to raise the height of the trailer to the edge of the dock?

A rental truck is so, so cheap that I can't imagine ever actually saving money with this. It might be more convenient but that's a totally different calculation!

Floating Doc said:I'm sure I'm missing something here, but I can't help but wonder; if it's beneficial for it to be simple, what's more simple than a pair of ramps at the bottom to raise the height of the trailer to the edge of the dock?

That is simple until you consider that they'd have to be sturdy enough to hold the trailer and about 10' long, and they would have to be transported with the trailer to every dock I might visit. Then, depending on the type of dock (pit, flat, uphill) it might take 8 or 10 tries to place the ramps at the right spot to get the deck just right.

You'll need to log in to post.