I used fire caulk to seal up mine. It is old and crusty and isn't sealing anymore. You may not need anything. If you dump more Btu's into it than it can shed, the temp will go up.

Curtis73 (Forum Supporter) said:In reply to alphahotel :

Just the stuff on the shelf at HD? Like this? If so, I have a few dozen rolls of it. Most of them say they conform to [insert code here], but they all refer to a code that calls out 250F as the max.

Yes, that's the stuff. It's been a few years, but IIRC the inside of the cardboard box was lined with aluminum foil and the edges of the foil sealed with the tape. They definitely got up to 350-400 degrees if you properly modulated the airflow. We roasted turkeys in them. Set a pan of charcoal on a couple bricks, prop a rack on a couple more bricks, put the turkey on the rack. If you didn't keep on top of the temp and the charcoal your turkey would be, um, sushi-like.

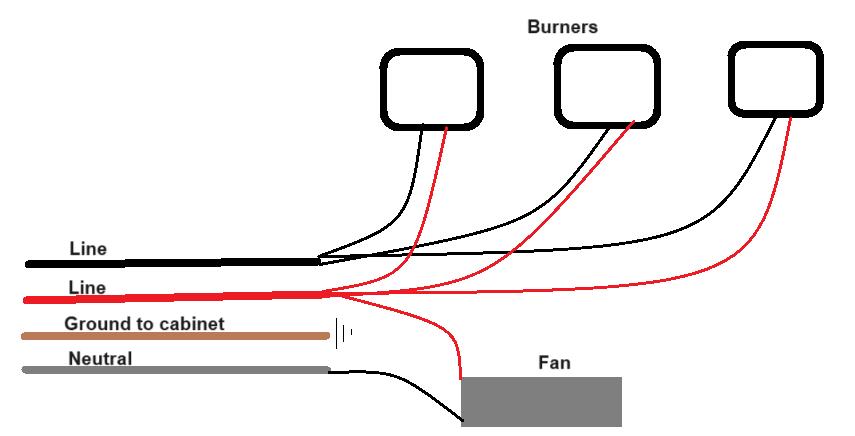

QUESTION OF THE DAY: Can I jack a line within one appliance? The oven elements are obviously 240V but I can't find an oven/fireplace fan in anything but 120V. I considered one of those heat-powered fans, but they're pretty bulky. Is it kosher to pull off one leg to power the fan?

Amperage draw would be tiny at 0.3A

Add another $57.07. Bought a PID, SSR, thermocouple, circulation fan, and a 40A two-throw breaker.

My cousin may have some fiberglass insulation he can throw in. He enclosed his patio a few years ago and he said he has "some" left, but wasn't sure how much. Here's hoping for a possible freebie.

Update. Between Turkey day festivities and hunting season, I haven't done a ton, but I have the burners fabbed into j-boxes, the studs on the exterior. I also taped all of the seams and started a little of the insulation.

Question of the day: How long does it take for insulation to "inflate?" The R-13 I put in is leaving a 1" gap between the cabinet walls and the fiberglass. It was a roll that was a few years old, but will it fluff up?

Got my circulator fan in the mail today.

I asked a question earlier and no one took a swing at it.

I know this isn't kosher, but can I borrow from one leg and the ground to get a 120v source for the fan? I won't be able to ground the cabinet this way unless I get some 8/3 WG and step up to a 4-pin plug instead of the 6-50 that I have. I know it will physically work, but will it rip a hole in the space-time continuum? Thoughts?

This would be with the four conductors. Is this kosher? Or at least not going to kill anyone? The fan is 0.3A

In reply to Curtis73 (Forum Supporter) :

The 4 wire way would be the better of the two "not kosher" options. In the day a lot of HVAC techs would use alligator clips on the end of an old extension cord and go from one leg of the 208 V in the disconnect switch to ground to make 120 for the drop lights / drills and vacuum pumps. That works until you try it in a building that has a GFCI trip on the main breaker and you dump a whole building. (Never happened to me but I know a couple of guys that found out the hard way).

In reply to 11GTCS :

Your words are wise. At this point for simplicity I'll probably just wire the fan separately and use an extension cord for it. I was trying to avoid two cords, but it isn't the end of the world.

(unless I go deeper and decide to add a 120v transformer)

If you have a router speed controller you might want to run the fan on it. I had a pair of blowers like yours, but bigger, on mine for a while. I hung them outside on the back and ran some 6" HVAC pipes from the bottom of the oven up to feed them. It was an experiment and I didn't insulate the pipes. They ended up moving too much air in the oven and as a bonus they acted as a radiator.

Curtis73 (Forum Supporter) said:This would be with the four conductors. Is this kosher? Or at least not going to kill anyone? The fan is 0.3A

Do it. It'll work just fine. I've got a welder that has 110v receptacle on the front that's doing exactly this with the 220v it's fed with.

Good feedback, thank you all.

Ironically, buying the SJO and receptacles/plugs will be the most expensive part of this project

Will the backing on that fiberglas insulation burst into flame near the elements? I'm not saying it will, just asking the question. 400-plus degrees would seem a good bit hotter than its usual application.

In reply to 1988RedT2 :

Let's find out.

It shouldn't. Ignition temps for paper are 400-450F. The oven will likely not ever go over 450F internal, so with the steel cabinet protecting some, and R13 fiberglass, my guess is the paper will take about 7 hours before it gets to a dangerous level. I've seen other builds with kraft batts, and one video showed the guy putting his hand on the outside of his steel sheeted oven describing it as hot enough that he couldn't leave his hand there, but not like it was painful.

I'm going to fire it before I put the outside sheathing on it. I can test things. If it stays as cool as I expect, I'm skinning it with Luan.

I also suppose if I'm concerned about it, I can take it outside and intentionally burn off the paper with a propane torch. I would just need to find an alternate way to hold the fiberglass in place. Right now the only thing preventing it from jiggling down is the paper attached to the studs.

Why is it you always have to buy another roll of insulation because you're short 1 foot. Literally.... one foot short.

Other than that last cavity, I have it all insulated I built a door frame that will hinge over the double doors of the cabinet, and I made a little stud box for below the door.

Got the circulation fan in. I put it on the bottom shooting up which isn't ideal. I would have liked it at the top blowing down, but it's just big enough that I predicted whacking it with the freshly powdered part as I put it in the oven. Ordered some 8/3 SO cord and got a 6x6" J-box to put the PID/relay/rheostat for the fan.

So the plan is to finish up the wiring and fire it up - burn off the paint and make sure it gets up to temp. I think I'll hang a steel pipe in it so I can use an IR thermometer to check if it's heating parts in a somewhat uniform fashion. I'll also check on paper temps before I skin it.... and I know skinning it will frustratingly raise the temps on the paper by an unknown amount.

QUESTION OF THE DAY: If the paper temps behave, I plan on skinning it with Luan unless you all have another brilliant idea on something rigid and durable that might be better. The steel studs are pretty flimsy and I figured Luan would really tie it together. I also have a truckload of Masonite. Less rigid, heavier, and more aromatic, but I honestly have about 50 sheets of it. Luan, Masonite, or....?

Cool project Curtis!

There's no dang way I would skin that thing with anything combustable, and I'm pretty reckless!

Your shop reminds me of the ol Mythbusters shop!

In reply to gsettle :

It's pretty easy to pull off the paper, I just need to find a way to hold the glass in place so it doesn't jiggle out the bottom.

Curtis73 (Forum Supporter) said:In reply to gsettle :

It's pretty easy to pull off the paper, I just need to find a way to hold the glass in place so it doesn't jiggle out the bottom.

I was more talking, well typing, about skinning it with luan or masonite.

Maybe you could use the skin from a couple old dead refrigerators?

The only issue I can think of with luan would be the heat conducting through the steel studs. If your shop starts to smell like a camp fire, stop for a while and let the whole box cool down.

I have used a chunk of 2x4 to hold some bike spokes and it didn't burst into flames. You could smell a hint of burning wood though. I had to come up with a way to mask the threads and hold them for the whole process. I drilled a bunch of holes in the wood the diameter and depth of the threads and stood them up. I cranked the powder system to 100K and had enough static to get through the wood so the powder would stick.

You'll need to log in to post.