Because what I really needed was another project.

This car came up on our local Craigslist early last week and, after a short conversation and some cursory research, we both agreed that we should drag it home. The previous owner bought the car June 1st 1990; We took deliver 25 years later, to the day! It was parked in 1996 after the head gasket popped and was put into storage until last week.

This thread should move fairly quickly, unlike some of my others. I'm jumping straight into the rust repair before doing too much with the mechanics. The car is scabby, but very solid, so there might not be too much in the way of sheet metal work here. I'd like to have it ready to go off for paint in two weeks, barring any extreme rust that I've yet to uncover.

The immediate plan calls for a X19 1.5, 5 speed, and L-Jetronic swap, rabbit struts and coilovers up front, wagon leaf spring and new dampeners out back, fresh paint, and some lows on steel wheels. Obviously brakes and steering components will also be freshened up as things come apart.

Nice project,I grew up with fiats,they are without a doutbt the most underrated and misunderstood car in the in the industry,mostly due to improper maintenance and shoddy service ,can anyone deny the handling and fun factor of the most mundane of this cars?,on one of my many trips back to my native italy many many years ago when I thought that I had what it took to be the next Mario Andretti ,I would rent one of this cars and drive it all over italy and enjoying the fantastic mountain roads that are home to legendary hillclimbing races and even entering local autocrossing events which in italy they are called gymkanas by the way and of course the always popular locally organized rallies which were actual performance events, I had a blast,winning quite a few events, having the time of my life and those cars never let me down ,always brought them back to the rental agency in one piece, at time it was Maggiore being the big player in the italian rental car industry ,im sure they loved me after the cars went through service checks and wondering why new brakes and cv joints were needed at such short intervals,if they only kewew ,any way I'll follow your project have fun and let you imagination and creativity wonder with this wonderful cars

Right, so I had almost forgotten that we are going to track the budget on this car like the Dusterbd13. So, here's our baseline:

$800, not including transport and the usual dinner + drinks bribe for the truck owner -

$0.47 and an 80's Molson or Labatt's bottle cap. So, $799.53 is our official starting point.

It's easy to tell that you're in the PNW when you say that you expect your newly purchased Fiat to be ready for paint in two weeks.![]()

In reply to bgkast: You'll be the first to know, should I need a hand with anything.

In reply to Woody: It surely is a wonderful place to live. Too bad "it rains here constantly". ![]()

This car is going to be more Russian Lowrider, less stripped out racer. That doesn't mean that it's not going to end up with big sway bars and sticky tires, it's just not going to look like a boy-racer.

Think a subdued version of this:

But in Volkswagen's Chrome Yellow:

Why the color change? There's a spot of rust in the forward section of the driver's door jamb. To do it right, we'll need to pull the doors. If we're pulling the doors and the engine is out when it goes to paint, I see no reason to not jamb it, shoot the trunk, and the engine bay. Plus, the painter says it's what he would do if it were his car and that's the color the lady wants ![]() . It's going to be a Driver+ quality, not a 100 point restoration.

. It's going to be a Driver+ quality, not a 100 point restoration.

In reply to pizzaman1:

Fiat advertising of the era claimed that Enzo Ferrari's DD was a dead stock 128.

https://www.youtube.com/watch?v=lQSac0Jpz0Y

I follow the IG acct that posted that Russian lowrider above. Almost everything they post is amazing, and I can't wait to see you do something similar.

Burrito wrote: Because what I really needed was another project. This thread should move fairly quickly,.... I'd like to have it ready to go off for paint in two weeks, ....

OK, this I have to see![]()

I have you in the Outlook calendar for the 23rd at 6pm to check on progress. I feel like a free range escargot compared to the pace some of you guys maintain.

Cool car, looking forward to seeing what you'll do with it. I owned one in the exact same color, gosh, probably about 25 years back.

NOHOME wrote:Burrito wrote: Because what I really needed was another project. This thread should move fairly quickly,.... I'd like to have it ready to go off for paint in two weeks, ....OK, this I have to seeI have you in the Outlook calendar for the 23rd at 6pm to check on progress. I feel like a free range escargot compared to the pace some of you guys maintain.

I guess I should specify that I hope to have it ready to go to the paint shop in 2 weeks, not ready to paint in 2 weeks. Those are two vastly different things.

I am working with the painter to do kind of a work study thing. He's going to show me what to do and how to do it to cut down on his labor. I'm going to do a few small mechanical jobs for him to keep the costs even lower.

It's also worth noting that the paint shop is literally next door to my shop. Like, we share a wall next door, not down the street next door. So, "going to the paint shop" really just means "rolling it outside".

128s are amazing little cars. As a long time X1/9 owner, I always wanted one, as they share a lot of components. I'll never forget the first time I drove one. It's faster than the X as it weights a lot less, and it corners pretty well too. It's no wonder they were so successful racing.

As Jumper K. Ditchdigger noted, this was originally a rubber bumper car. The PO converted it to chrome bumpers at some point during it's tenure with him. As grateful as I am for that fact, there are a few remaining relics of it's previous life as a big-bumper car.

Just look at all those reflectors, the giant license plate holder, and the scabbed on reverse light. Since we are going for the "Cleaned" look, all this has to go.

Since we are lucky enough to have the early bumper, the plate light and reverse light will be easily relocated to their proper locations. The license plate lights are available new for about $25 to my door and the reverse light will be a universal unit unless I stumble upon an early piece for cheap.

Here's an example of the earlier rear end:

Much better!

So, lets tear it down and see how many holes we have to deal with.

Ok. Bumper off, lights removed, and a quick roll call for the newly uncovered holes. 2 for each reflector, 5 for the plate holder, and a biggy for the reverse light. A nice even ten hole job.

The Darwin fish might make a reappearance later on in this cars life (it is dated 1990, after all), or maybe we will see if there's a booming market for pseudo-vintage Darwin fish on eBay.

All of the small holes (about 3/8" and under) were filled in with the welding spoon thusly.

After a spell we had nine holes filled in, and nine welds ground flush.

Awesome, already looking much better. I may have stuck a few of my VTO wheels on there to check clearances, ignore that for now.

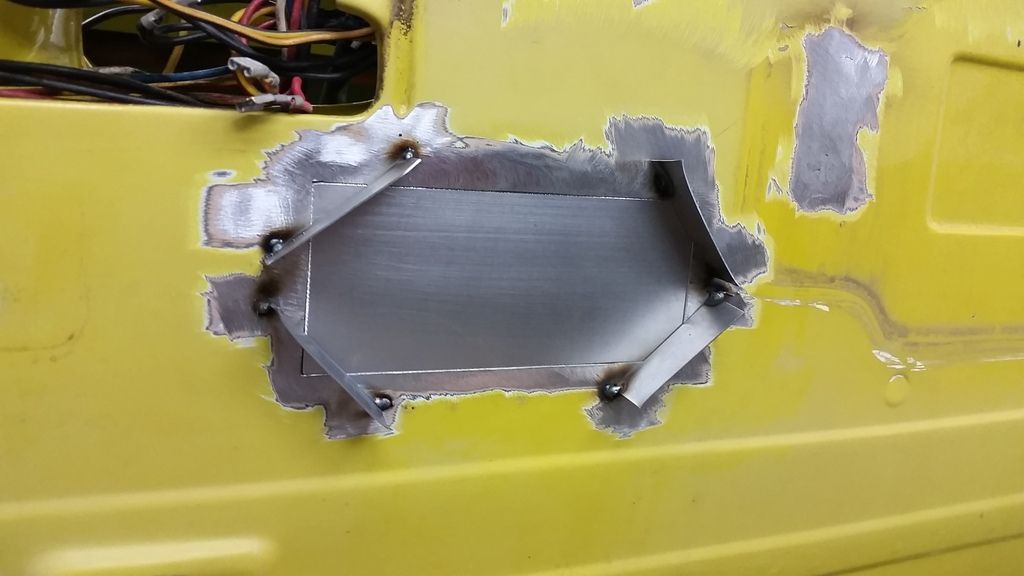

Onto the big hole for the reverse light.

I opened the hole up a bit to get rid of the two proud mounting ears.

But at some point during the move into the new shop I lost my little surface mount clampy things and the last one of my rare earth magnets. Queue ingenuity.

I don't need no stinking magnets or cumbersome clamps.

I gave the patch a little curve to match the rear panel.

After a hundred or so pulls of the trigger and more than a few short breaks for beer and panel cooling we are all welded up.

And good penetration on the backside (heh).

After about a decade with a the grinder, again moving slowly to not warp that wide flat panel, we are all ground off flush. There's a little bobble on the top seam. Nothing a skim of filler can't hide. ![]()

That pretty much rounds out the rear panel until I find a plate holder I like (or fabricate something). Next step is rear corner marker shaving and rear quarter panel rust repair.

$799.53, not counting consumables and sheet metal until I have to purchase more.

I still think Egyption badges for that car would be awesome.

Still, great find for the Burrito Bride, I look forward to seeing it progress!

In reply to bgkast:

Yeah, but thats not it. Mine is torn down into about a thousand little pieces.

This one is my shopmates Seca.

I wondered if that was a Seca, or a 70's Yamaha 850 triple...

On topic, the cleaned up look on the tail is a huge improvement... and the wheel mock-up looks like a winner.

I know nothing about them but I'm sitting here fascinated to watch the mechanical bits get removed and re-installed. Good show.

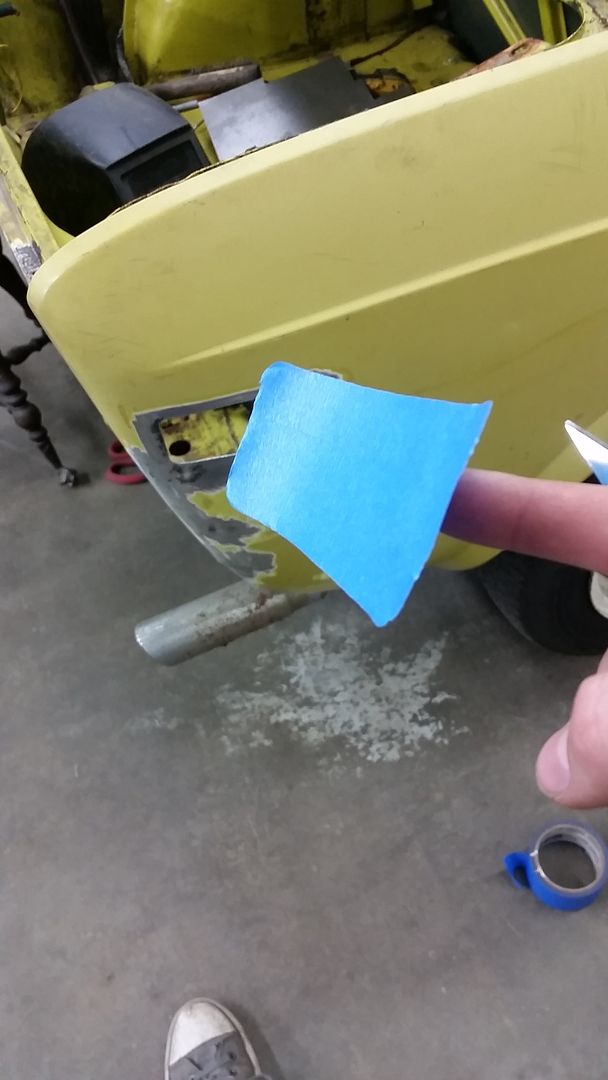

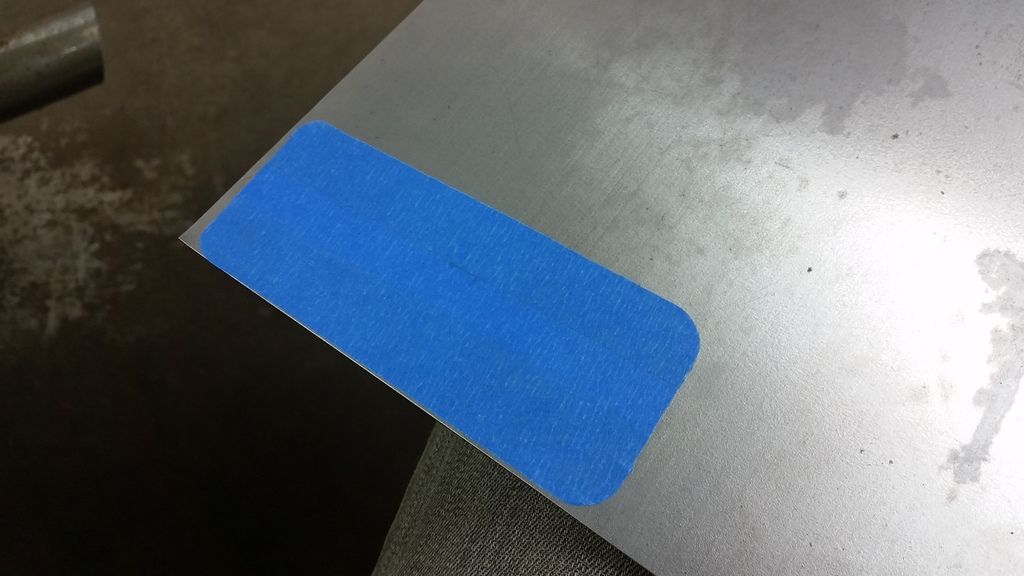

So, continuing on with plugging up the holes. I made my typical tape template (big thanks to NOHOME for that tip).

Stick it on some sheet and snip it out.

As a flat sheet it well and truly doesn't fit so well.

So, naturally, hit it with a hammer until it does.

Side B fits pretty dang well.

Side A does, too.

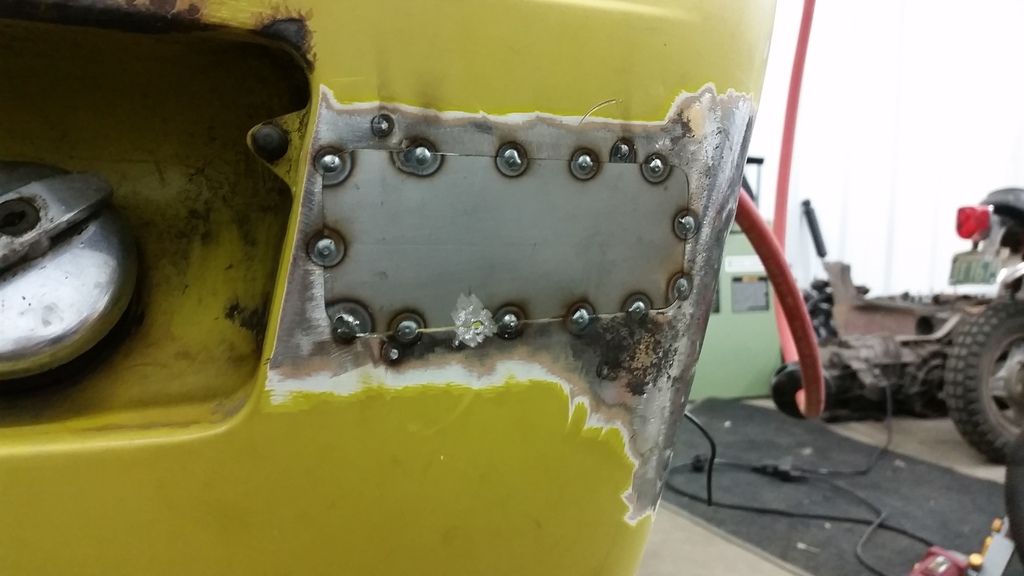

Side A all welded in.

Looks good on the backside.

All ground off. Again, a little wave, but well within reason. I think I warped it in the grinding process, I will take a little more care on the opposite side.

Side B is left at this point for the night.

Hopefully tomorrow I can get it all welded in and ground off before moving down to the rear quarters / trunk corners.

$799.53, ain't sheet metal work grand?

You are absolutely correct ,mario andretti also did some printed ads for my favorite 128 the SL saying that he wished the car that had 100 hp more to scare the hell out the Ferrari drivers ,I'm sure he wasn't joking and was right in his assumptions ,especially with him.driving it ,keep up.your good work on the project .

You'll need to log in to post.