loosecannon wrote: Here is more info on the Golden Ratio: https://en.wikipedia.org/wiki/Golden_ratio

Tiny little update.

My new trans mount arrived:

It still requires the crossmember to be flipped 180 to work with the Jerico, but it's bolted in now and the engine is sitting at a better angle.

I also got 1" spacers to test wheel backspacing. Looks like going to a 6" backspace will give me all the inside and outside clearance I need.

Nothing too glamorous to show work wise after the weekend, but I have mentioned piles of sand before. This car was sandblasted well over 10 years ago, and ever since I've always found little piles of sand under the car when working on it. Over the years the amount has diminished, but it has never quite stopped.

While crawling around on the ground doing some work, I noticed two body plugs in the rear quarters.

For those that aren't familiar with these cars, the trunk floor doesn't extend all the way to the fenders. There is a 1/2"ish gap on either side. Back when this was a street car, the trunk would leak through the spoiler holes, and I would find those little yellow ear plugs surfacing after the rain. This went on for years, with me pulling hundreds of ear plugs out of the car. Well...

For those that don't want to sit through a 2 minute video, just make sure you pull the body plugs if you ever have a car sandblasted.

Oh, and those ear plugs? I had to pull them out of he drain hole with needle nose pliers. Once I did, the sand started flowing.

I still haven't gotten everything cleaned out, but just reaching in the passenger side turned up this:

I was wondering where that went...

In reply to Gimp:

But now you'll need to add ballast to meet minimum weight? ![]() At least you won't need to buy any oil-dry for a while though!

At least you won't need to buy any oil-dry for a while though! ![]()

So I've been slowly tackling the exhaust on the car, but working with the car on just jackstands A) wasn't easy because it wasn't high enough B) never felt safe enough to me at the height I need the car, so I built some cribbing.

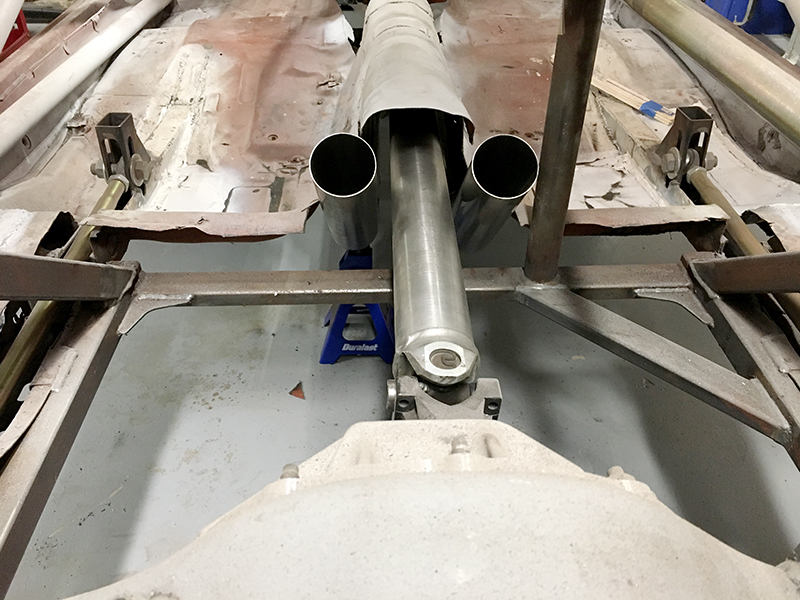

Now, with the car higher up, I can start laying things out. I started with a Pypes 3" X-pipe kit and a set of 3.5" to 3" necks to connect to the headers. I've had to do a few funky things to mate the exhaust up, but I'll show you that next time. For now, here are two teasers.

And there is still room for them to go up. I should be able to keep the entire 3" dual exhaust above the frame.

And there is still room for them to go up. I should be able to keep the entire 3" dual exhaust above the frame.

Had to laugh at the sand thing. It really never goes away. I bought the Volvo after it had already bee sandblasted and it was full of sand, and even after having removed the entire underside of the car and replaced all the wheel tubs and sills, and chased it with an air-hose in every cavity I can find,I still get a sandcastle when I flip the thing on the rotisserie.

I still remember hauling this car on an open trailer a few hours on the highway soon after it was blasted.

We had a sandstorm following us. Fun way to prevent tailgaters.

First autocross runs should be fun. I suggest goggles.

Apexcarver wrote: I still remember hauling this car on an open trailer a few hours on the highway soon after it was blasted. We had a sandstorm following us. Fun way to prevent tailgaters. First autocross runs should be fun. I suggest goggles.

It had already been on a trailer once before that. The people that were behind us that time were probably buried.

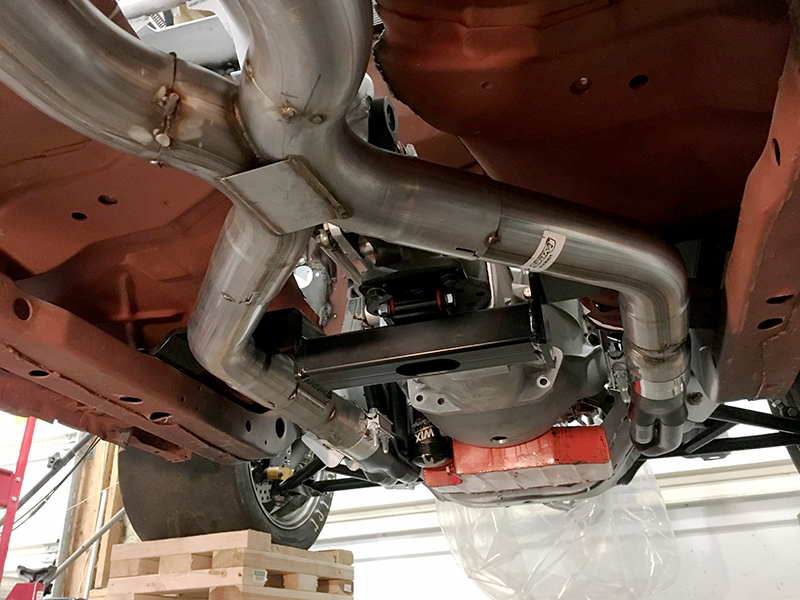

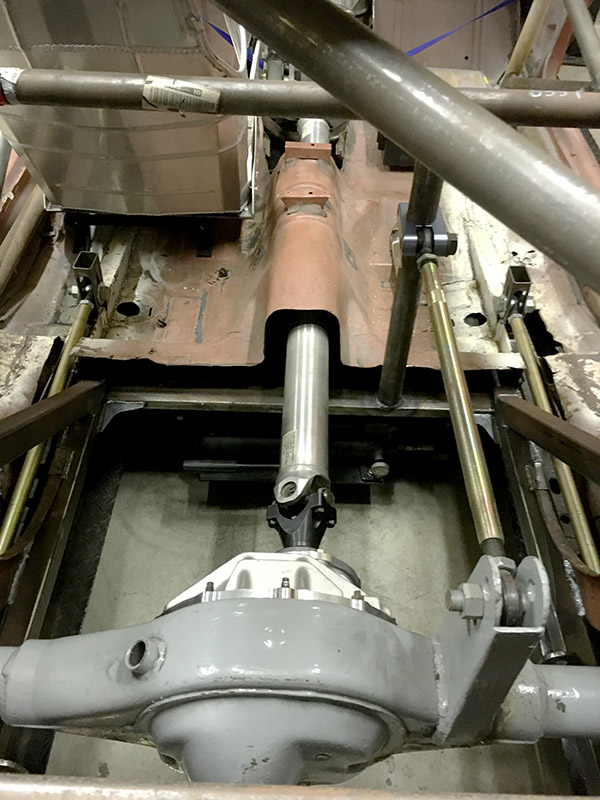

Made some more progress on the exhaust, and I'm pretty happy so far. Tucking 3.5" collectors and a 3" dual exhaust above the frame is a bit of a challenge, but I'm figuring it out. I'm still going to have to either take a little out of the top of the pipes where they go through the trans crossmember, or be less civilized and use a BFH. They don't touch, but they are super close.

I started with a universal Pypes x-pipe kit that was designed to "tuck" into the driveshaft tunnel, but like anything else on this project, some modification was required. Since my driveshaft sits much higher than stock (due to lowering the car so much), I have more room in the tunnel than most. To take advantage of this, I sectioned out a little bit of the bends after the x-pipe and narrowed up the exhaust by a total of 4 inches so it can tuck right into the tunnel.

The hardest part so far was working with the passenger side header that Larry modified for me. When we had the mock up block in the car, that side hung way too low and was well below the frame. Larry modified it, but when I bolted them to the real motor, that header wound up being just a little too high up. No issue with modding the floor, but I did have to drop it a bit to get it under the crossmember.

I don't see it really hurting flow.

I don't see it really hurting flow.

Once that was done and checked I could get things aligned up and tacked so the tubes wouldn't rotate, etc.

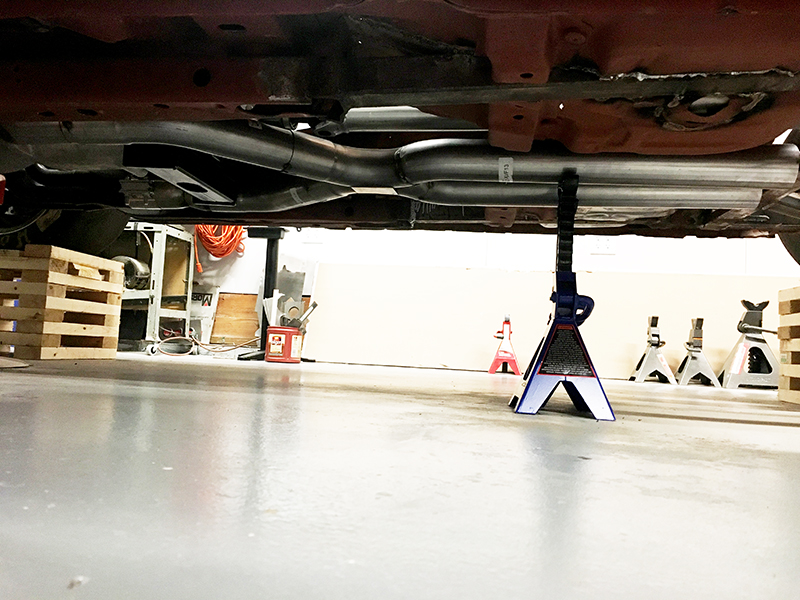

I'm super happy with how well this tucks up under the car. The bottom of the trans crossmember is lower than the exhaust, which is right at (or a little above) the frame.

The exhaust does drop down slightly towards the back of the car, but it shouldn't be an issue. Here's a look from below with it all tucked into place.

Next bit of the exhaust is going to get really interesting. Stay tuned.

That's awesome! We ran 3 Camaros and the exhaust was the lowest point on all of them. None of them were quite this low though.

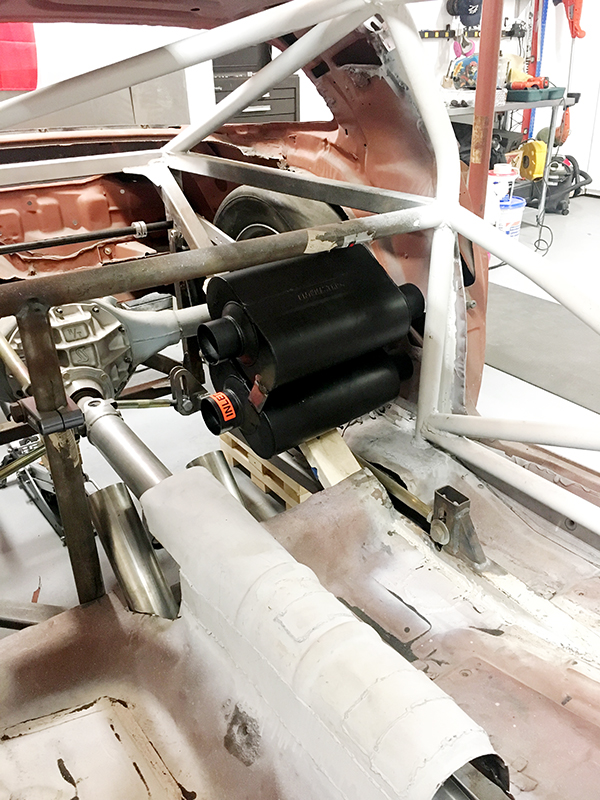

A little more exhaust work. This is where the routing starts getting weird.

No better way to get ground clearance than to go up.

Mufflers arrive this week, so hopefully I can show you guys where this is all headed soon.

When they Made us go to Mufflers at the Round track, We Merged into a single 4" pipe with A Single Muffler in the rear But we Didn't Have to use a stock Floor pan, no Issues with Flow, If You HAD to you Can Oval the pipes with no Flow Issues Either.

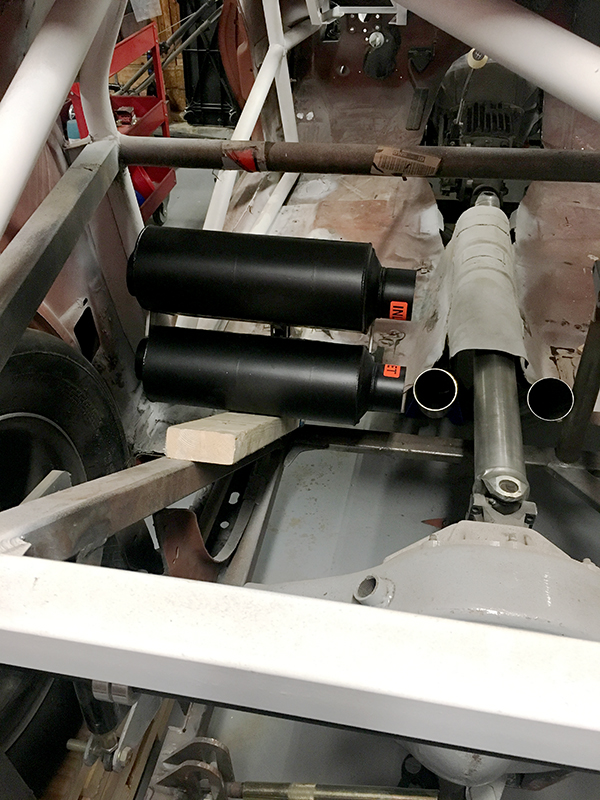

Brown Santa dropped off some goodies, so I quickly mocked some things up.

Mufflers are 3" in/out Flowmaster Super 40s. I went with these because their lack of packing means the sound will be consistent over the life of the muffler, and the Super 40s are quieter than the standard 40 series but supports the HP levels I'm shooting for.

Packaging, like everything else in his car is, interesting...

They are not quite where they need to be yet, as the "top" muffler needs to slide back a little to get things in line.

They are not quite where they need to be yet, as the "top" muffler needs to slide back a little to get things in line.

Aside from that minor tweak, things are lining up well.

The rear suspension is at full compression in these pictures, so the driveshaft is as high as it ever could be. I should have tons of room to take the passenger pipe over the shaft. The exhaust will exit out the body, right behind the front door. Should be sweet.

Hopefully more updates and a complete exhaust soon.

I think I would want to passengers side mount them. Weight distribution would be helped, and the hot exhaust would be further from the driver.

Is there a packaging reason why that couldn't happen?

Dusterbd13 wrote: I think I would want to passengers side mount them. Weight distribution would be helped, and the hot exhaust would be further from the driver. Is there a packaging reason why that couldn't happen?

Yes.

The third link (upper) is offset to the passenger side, so there wouldn't be enough room for them. I'll be running a full size battery in this car, and I'll mount that on the passenger side of offset the exhaust weight.

Weight distribution isnt a huge concern. Keep in mind hes going to have to add ballast, so as long at its low and central...

my thoughts go to maximum efforts for reducing in-car temperatures, but I obsess over racecar ergonomics. (if the driver is hot and worn out from noise/etc or uncomfortable, he wont perform as consistently or as well)

You'll need to log in to post.