And I'm sure for a car like this only needs a minimal battery that should be fairly light.

Apexcarver wrote: Weight distribution isnt a huge concern. Keep in mind hes going to have to add ballast, so as long at its low and central... my thoughts go to maximum efforts for reducing in-car temperatures, but I obsess over racecar ergonomics. (if the driver is hot and worn out from noise/etc or uncomfortable, he wont perform as consistently or as well)

Probably not that big of a deal for 60 seconds at a time, but definitely something to consider for endurance cars.

Ian F wrote: And I'm sure for a car like this only needs a minimal battery that should be fairly light.

Very true, but this car is already going to be underweight as is, so I'm going with a full size Optima style battery as I need the weight and this will be as low as I can get it and inside the wheelbase.

I've done the high compression V8 with tiny battery. Push starting the car before every run on hot days is dumb.

Why not exit the exhaust straight up thru the rear deck lid? Keeps your exhaust paths a more equal length. Plus, youll get a little bit of Db insurance - vertical exhaust is harder to hear at ground level.

4cylndrfury wrote: Why not exit the exhaust straight up thru the rear deck lid? Keeps your exhaust paths a more equal length. Plus, youll get a little bit of Db insurance - vertical exhaust is harder to hear at ground level.

Harder to hear, maybe, but it will more easily peg an DB meter. If I can use the ground to absorb (using turn downs) I should stay lower in the DBs. The length isn't all the far off either, once you consider that the passenger side header collector is quite a bit further back than the driver's.

That said, some diesel flaps could be cool.

People have experimented at Nationals with exhaust direction and down at the ground is bad, the sound waves just bounce off pavement. Sending exhaust up is quieter.

loosecannon wrote: People have experimented at Nationals with exhaust direction and down at the ground is bad, the sound waves just bounce off pavement. Sending exhaust up is quieter.

I'm actually considering putting v-bands on the tips so I can rotate them and/or add something to quickly cut sound should I ever go over. This is good to know.

it's unfortunate i didn't have more time and the mufflers weren't there when i was, or we could have knocked it out.

i love this car, and have ever since the first crappy weld i put on it back when we were barely out of our teens.

When I was racing SCCA I put a turned down tip on end of exhaust with a muffler clamp so we could direct it away from side of track where db meter was located.

In reply to Ovid_and_Flem:

One season we put new exhaust on both of our Circle Track cars with side exits. Same parts just new, and exiting the passenger side. Both cars got dinged for db infractions from sound bouncing off the wall despite having replaced the burnt out glass packs.

All we had to do to get back into spec was chop off the side exit and put a turn down just after the muffler.

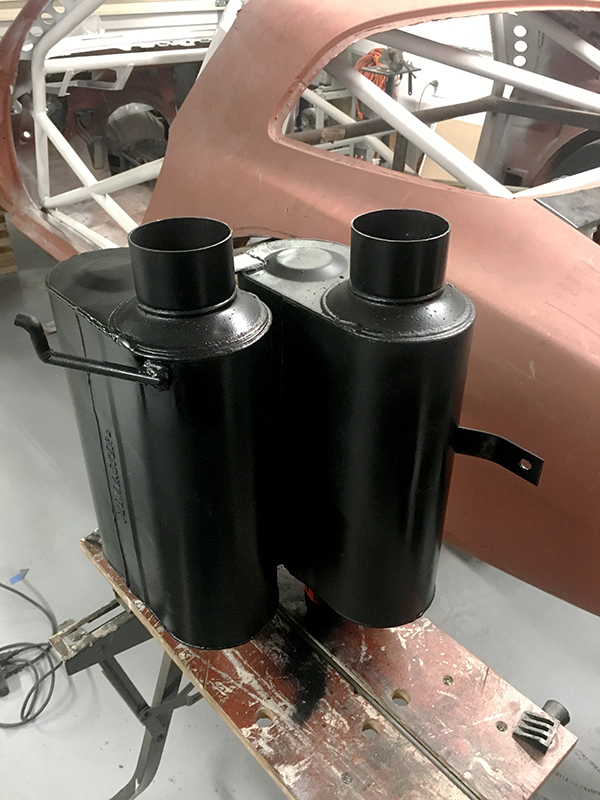

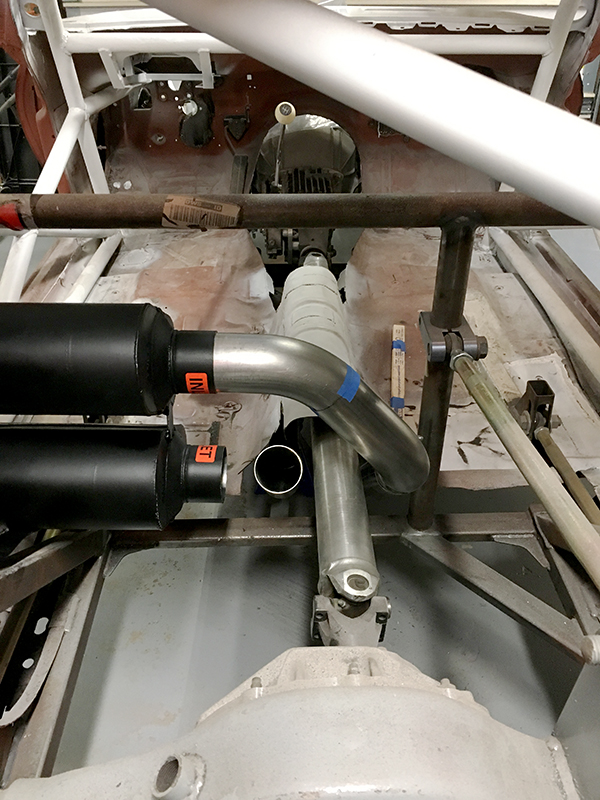

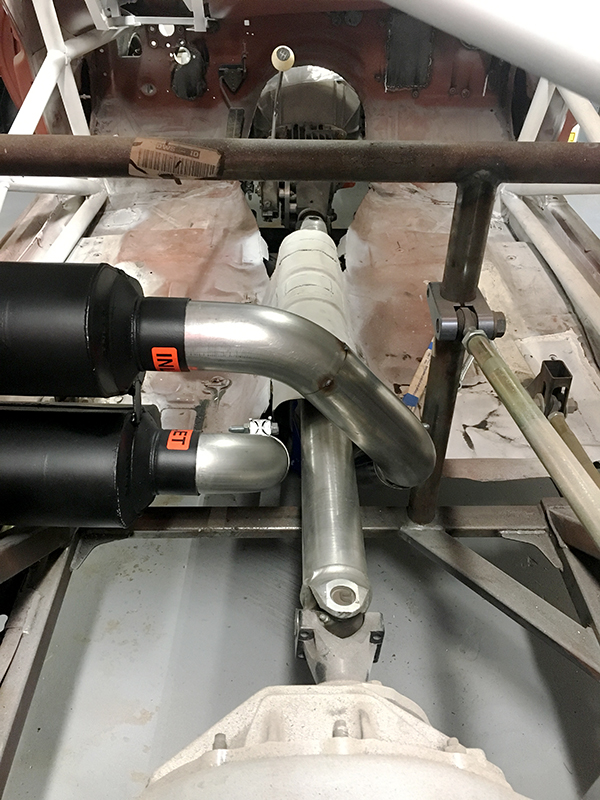

A little more progress on the exhaust. I got the mufflers fully welded together in the right position, and added the mounts to attach it to the chassis.

Then I added some studs to mount the bottom of the mufflers to the car.

And then made my own hangers out of some solid steel rod to keep the top in place.

The red bushings are Energy Suspension sway bar bushings, so I'll have the best handling mufflers money can buy.

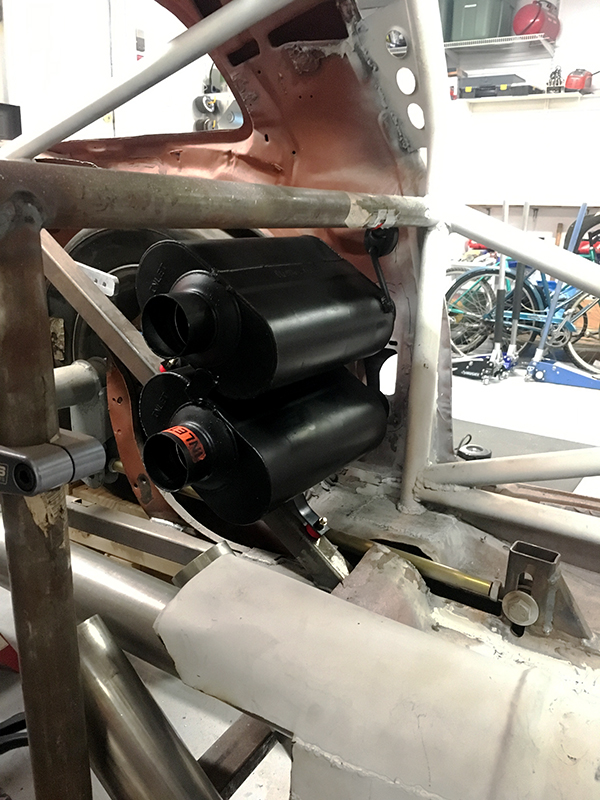

After that, since I'm waiting on some more exhaust tubing to arrive, I decided to take the plunge and cut the hole in the side of the car where the exhaust will exit. Overall that went really well and I'm super happy with the placement.

I still need to trim the inside panel, but just looking in from the outside you can see how well the mufflers are lined up for an easy exit.

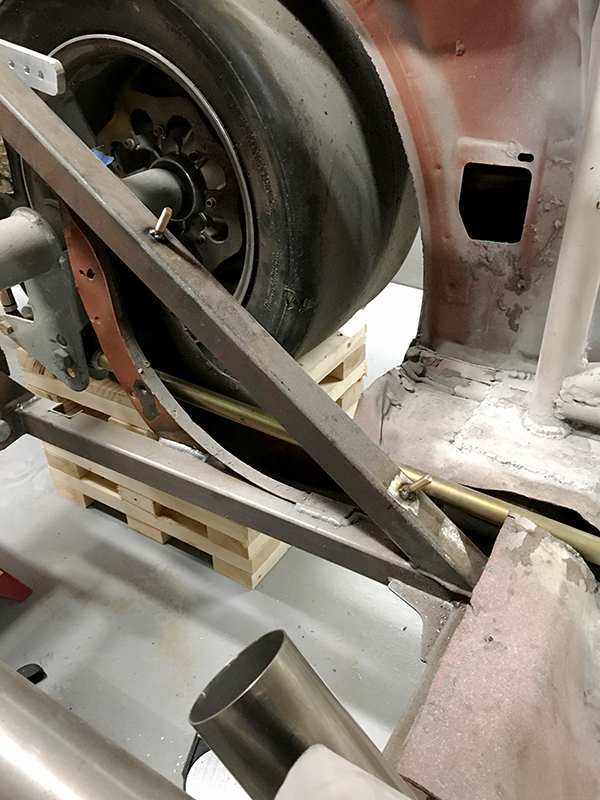

Slight update. I opened up the inside of the car to work on the path for the "tailpipes." Here is a shot looking in from the hole in the body.

I then started working on connecting the exhaust to the mufflers. I 3" radius 90 degree bend on order for the driver's side, but I did get the passenger side mocked up.

The blue tape will have to suffice for now, as I ran out of shielding gas putting things together and probably won't get a chance to refill until next week.

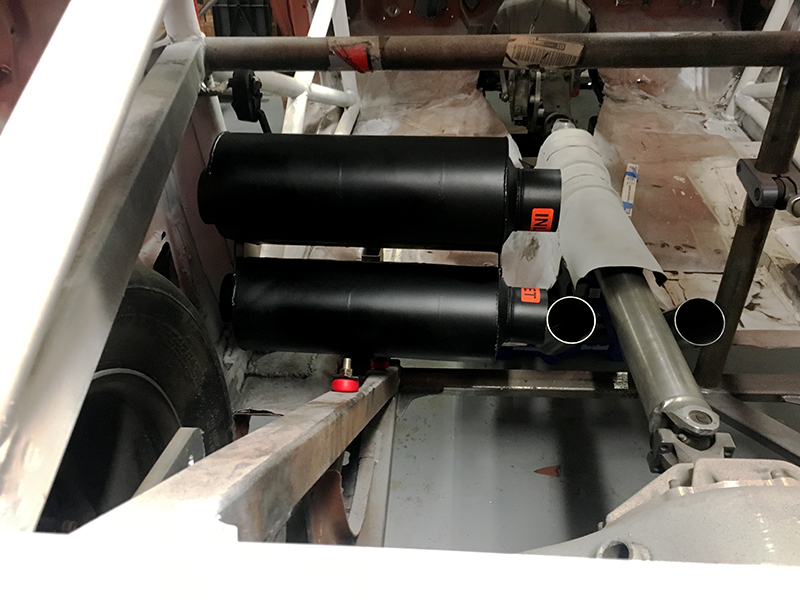

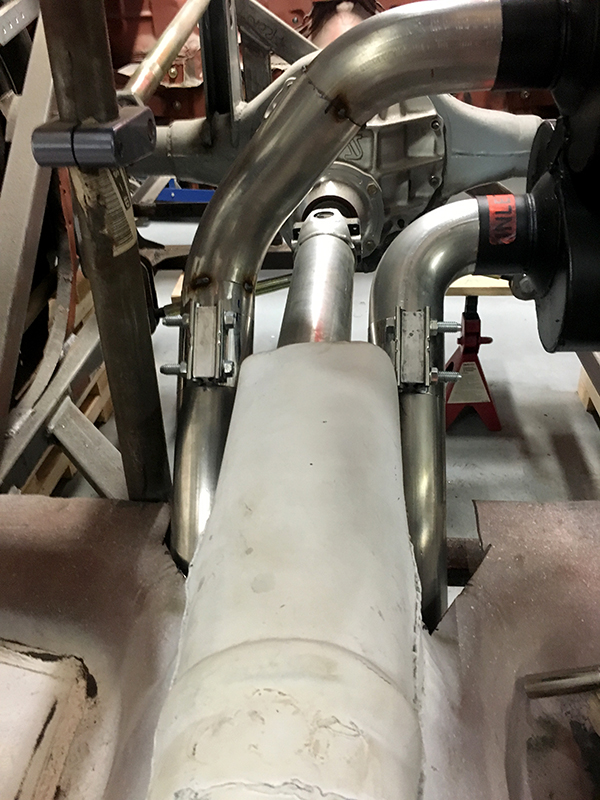

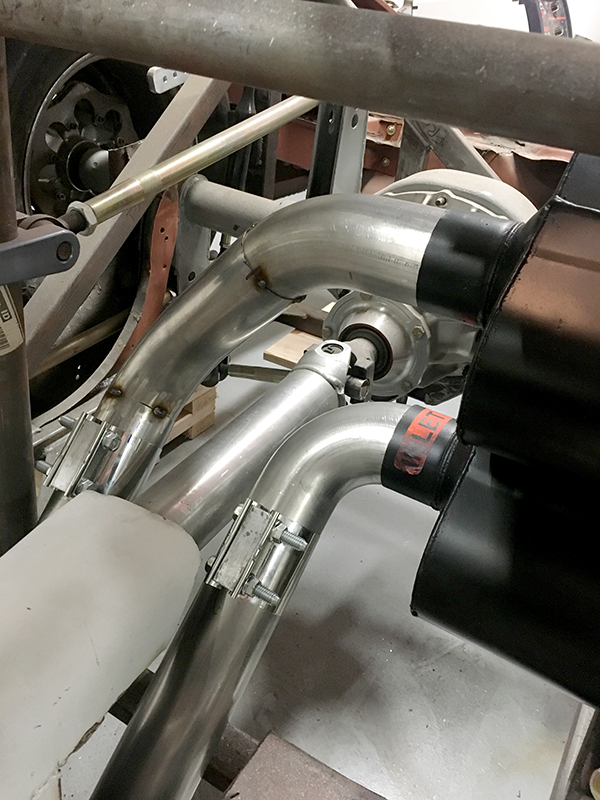

Aside from a few small tweaks for clearance, etc, and final welding, the exhaust is all wrapped up.

Got my tight radius 90 for the drivers side in the mail, and refilled the gas to tack things together. Keep in mind that as you look, the car is currently at full compression, so the driveshaft is up as high as it will ever go.

Once that was taken care of, I could work on getting the exhaust out of the car. The "tailpipes" actually came together pretty well and I'm really into the look.

I then bolted up the flare and clearanced it. I will be adding a SS heat shield to protect the paint and fiberglass.

759NRNG wrote: Radiant heat blanket on the bulkhead panel behind your 'chair' ?

That, lizard skin, and a whole bunch of anything else to keep me out of the "hot seat."

Gimp wrote:759NRNG wrote: Radiant heat blanket on the bulkhead panel behind your 'chair' ?That, lizard skin, and a whole bunch of anything else to keep me out of the "hot seat."

Anyone else smell bacon?

I love when this thread jumps to the top. I get to look at all the cool pictures again. ![]()

My first time in a CP car the owner says "don't touch that, or that, or that......just keep your hands in your lap". Everything about the car was hot and dangerous, I loved it.

You'll need to log in to post.