Why does that IR speak to me? Second that on the flame thrower bungs. ![]()

¯\_(ツ)_/¯ wrote: This thing was already cool but that exhaust exit has put it over the edge into perfection- is the plan only autocross? You can probably run hillclimbs with that cage.

Hillclimbs are a consideration, but it will be an autocross car 99% of the time.

I'm fan of how you have routed that custom exhaust.

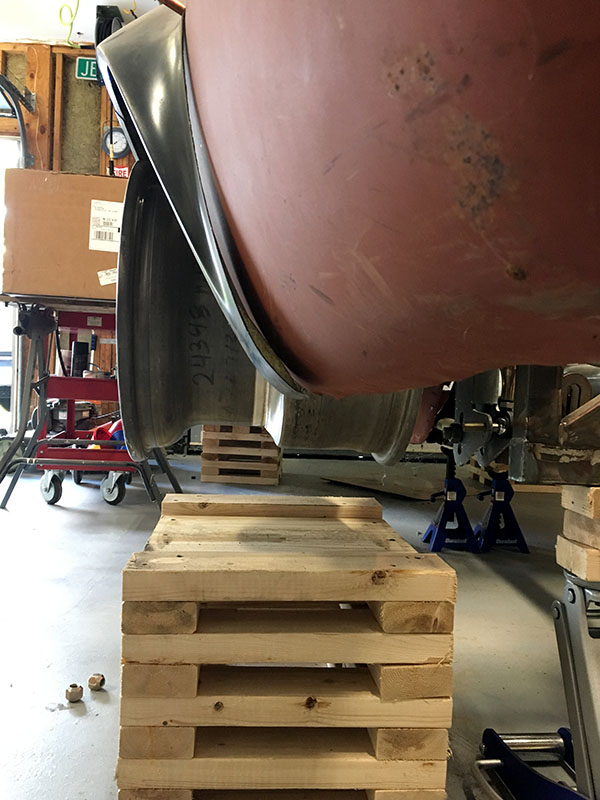

I also like the wood plank stacks you have for putting the car up on. Did you make those yourself?

TIGMOTORSPORTS wrote: I'm fan of how you have routed that custom exhaust. I also like the wood plank stacks you have for putting the car up on. Did you make those yourself?

Thanks! The exhaust turned out better than I could have imagined. I'm looking forward to hearing how it sounds.

As far as the blocks, yes, I built the cribbing myself. It's just 2x4s glued and screwed together. It's super stable and gives me lots of room to work underneath.

Dusterbd13 wrote: Ive seen that cribbing in other places. My question is how do you get it up there???

Two floor jacks, some jack stands, and a little patience. If I had a really high lifting jack I could have done it in one shot.

I just got the car up about halfwayish on the jackstands, then moved it up the rest of the way on jacks. With the shock "simulators" in place I don't have any droop travel, which helps.

After waiting for what felt like forever (Real kept delaying), my new rear wheels have arrived. Ron and Sonya Ver Mulm from R&S Racing are awesome (some of you may know them from their own crazy Camaro). Sonya was extremely patient with me when I emailed once a week trying to find out when they would arrive.

16x14 with 7" backspacing. Dogs for scale.

I don't have time to mount the radial slicks yet, but I couldn't resist bolting one up to check it out.

I have some exhaust stuff to wrap up, then it's off to finish the welding and prep for firewall panels, then a self imposed paint jail. I'm starting to see some light at the end of the tunnel.

Gimp, you may have mentioned this earlier (being lazy here), but what is the plan for the 'T' tops? Dzus infused removable panels?

Ron and Sonya are really sweet people in real life. Sonya hugs my wife and I every time we see them.

759NRNG wrote: Gimp, you may have mentioned this earlier (being lazy here), but what is the plan for the 'T' tops? Dzus infused removable panels?

Get wet?

I thought about the Dzus removable panels, but then I couldn't figure out why. Even with those in, there are no side windows, etc. Rain either means I get wet no matter what, or I drive the Miata. I guess my real solution is a removable seat cover and weatherpack connectors.

Gimp wrote:759NRNG wrote: Gimp, you may have mentioned this earlier (being lazy here), but what is the plan for the 'T' tops? Dzus infused removable panels?Get wet? I thought about the Dzus removable panels, but then I couldn't figure out why. Even with those in, there are no side windows, etc. Rain either means I get wet no matter what, or I drive the Miata. I guess my real solution is a removable seat cover and weatherpack connectors.

My Camaro was a solid roof car, but with no side windows, you still get wet. Been there, done that. May I suggest a couple small drain holes in the lowest part of the seat, just in case. I also left out the rear floor drain plugs, too.

You could put some snaps on the top and snap in a vinyl or canvas cover over the t-top area, or just tough it out.

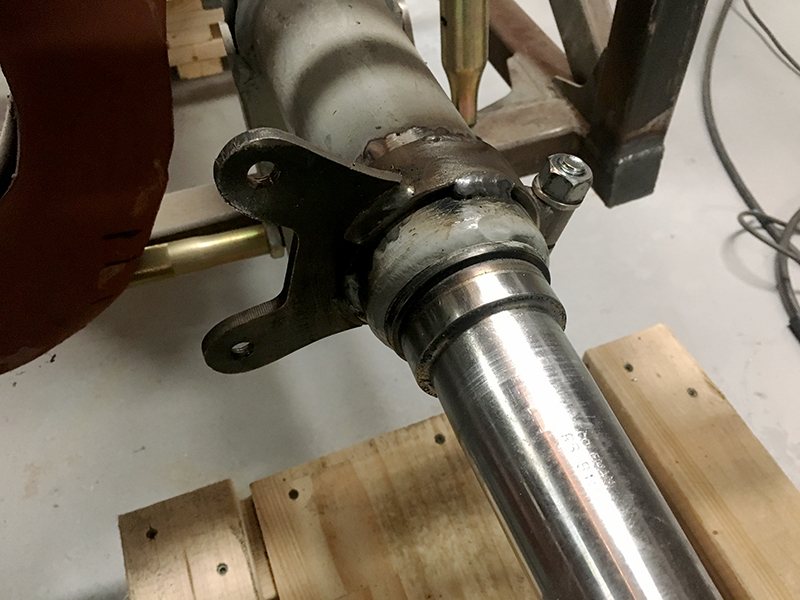

Micro-update. I like my legs. I want to hang on to them as long as possible, so I added a little protection.

This also provides a little strength to the middle of the car where I cut through for the trans tunnel. The driveshaft isn't fully in the trans in this photo (due to an issue with yoke length), but it has plenty of clearance.

I also buttoned up some clearance related stuff on the exhaust, and when I get back from vacation it goes off to get tigged up by Larry.

With the x pipe and trans tunnel loop, you should be good if the front joint breaks. I always have a fear of pole vaulting.....

Dusterbd13 wrote: With the x pipe and trans tunnel loop, you should be good if the front joint breaks. I always have a fear of pole vaulting.....

Same. I have room to weld in some flat stock under the car to save the X-pipe should something fail. I may go there. I'm also going to add some sort of hoop at the rear if I have room.

Instead of welding the flat bar after the driveshaft think about holding it for the floor pan instead so it's removable. Take that from experience.

Small update to show I'm still alive. Kicked the Miata out of the garage to get back to work on the Camaro. Wheels and tires are off getting mounted, and I have this box of goodies waiting to go on this weekend.

I know it's a ways away, but when you get this bad boy sorted out check out Kevin Gale and Challenger392 threads for some possible different venues .....yes I know it's not in your back yard, but these hill climbs are way WHACK!!! And you'd fit right in blastin' all those little carz!!!

Apexcarver wrote: In other news, this hockey player seems to have stolen one of your rims...

Impossible. That thing has never been this close to DC.

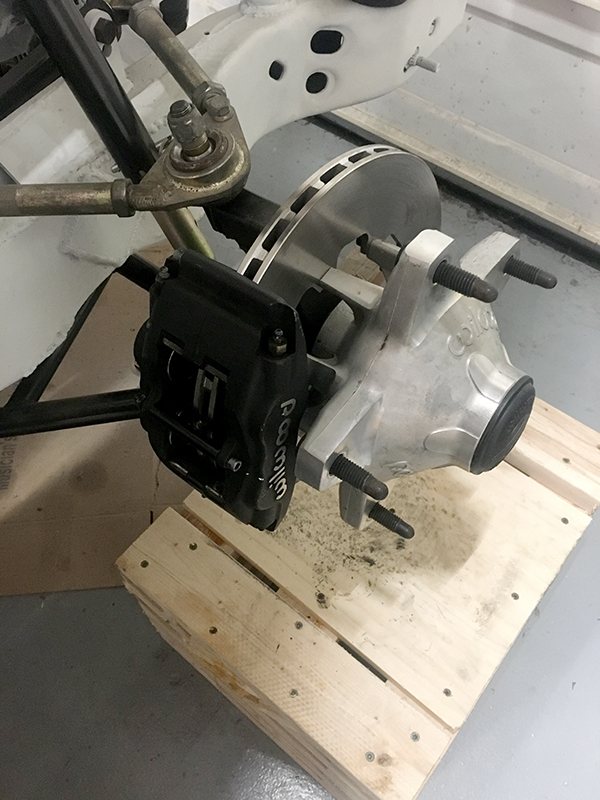

Worked on the new front brake setup. Originally I was using a 12" rotor and a GM style caliper, but Ron at RS Racing recommended I move up to a 13" rotor and some Wilwood Superlite calipers.

It's a tight fit inside the 16" rim, but it works.

I'll need to machine about 5mm off of the large caliper spacer I have to center them up on the rotor, but it all works for now.

I'll be moving to the rear brakes next, and those come with some new gumballs.

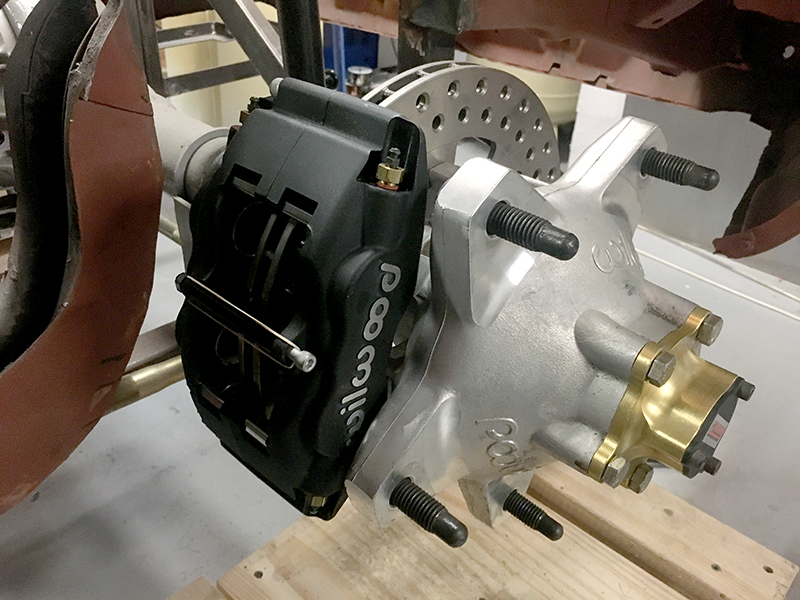

Moving on to the rear of the car, the brakes were a little less of a bolt on affair. The rear end housing had no bracket on it, so I had to add one. I opted to go with a bolt on bracket. Even though it bolts on, it still requires a quick weld to keep it from rotating under braking force. The nice part about it is that since it doesn't have to be fully welded, you don't risk warping the housing.

With that sorted, I could put the full 11.75 disk that used to live on the front on the rear, and bolt up the hub and caliper.

Now I could get to the really fun part, mounting up the new 16x14 and radial slick. The tire itself is taller than the bias plys I have been using, and that was expected. What surprised me was how much wider the tire appears due to being better supported on the 14 inch rim, vs the 12.

The new rear wheels from RS Racing are so shiny and fit perfectly.

I will need to do a little bit more clearancing, but that was expected.

You'll need to log in to post.