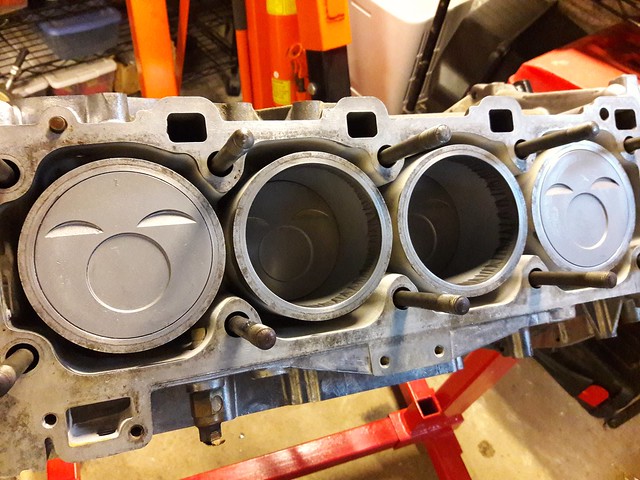

I tapped the four pistons in, careful to protect the cylinder walls from the edge of the rod end with a piece of cardboard. After the first piston went in, I found it difficult to reach my fat fingers past the crankshaft to seat the rod bearing in the rod.

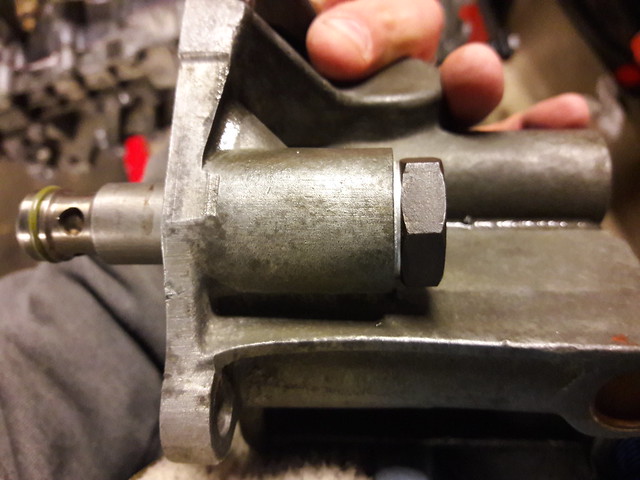

So I had the brilliant idea of putting the bearing in the rod before tapping it in. That was brilliant. Putting a smear of assembly lube to give it some "stick" so it wouldn't fall out while tapping in was not so brilliant.

Supposedly the back side of the bearing is supposed to be dry. The guys on Rennlist scolded me for that. Said it might result in a spun bearing.

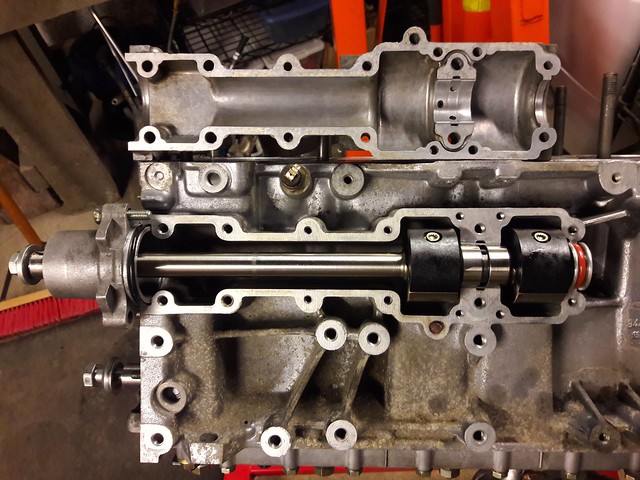

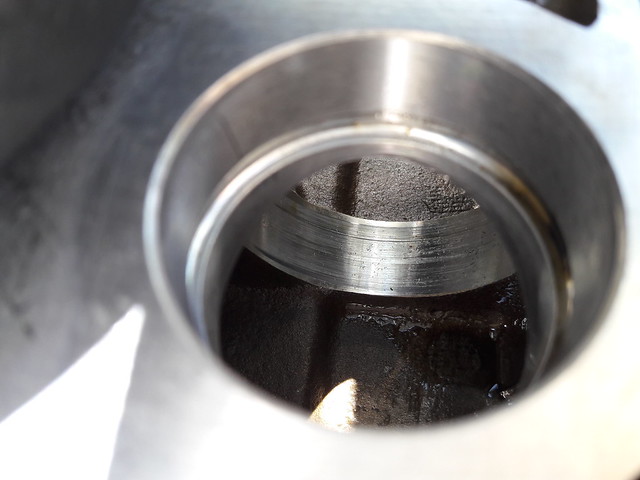

I'm not so sure about that. That's what the little tangs in the corner of the bearing are for! Plus, my bearings have a hole in them where pressurized oil is constantly forced. Admittedly, there's nowhere for it to go, but it seems to me there's going to be oil behind there eventually. Both halves of each bearing have the hole:

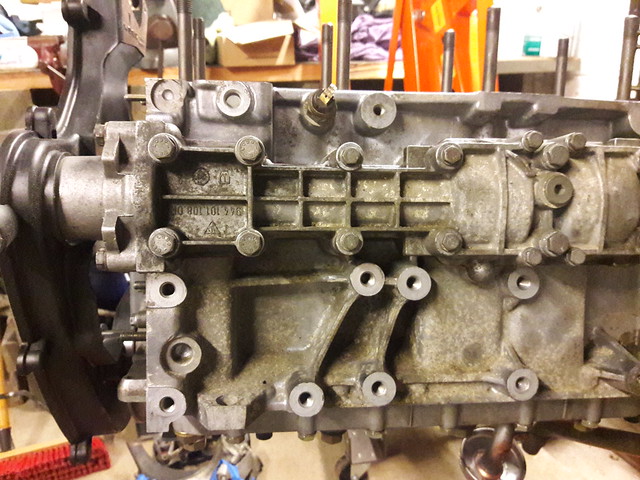

The bottom line is that all four pistons are in, and all four rods are torqued down. And I'm not taking the one-time-use nuts off again to clean off the back sides of three bearing halves that already have a hole in them. That's the decision I have made.

Edit: ...Until I change my mind.