Last night was dedicated to making the m10 flywheel work with the m42. With the m42 dual mass flywheel/pressure plate/bolts weighing in at 38 lbs and the m10 single mass stuff at 28 lbs, it's obvious this is a great idea. It doesn't cost as much as sourcing an m20 single mass, and actually weighs less. The friction surface for both the m42 and the m10 are the same, so I have high hopes this will be able to handle the small amount of boost I plan to add in the near future.

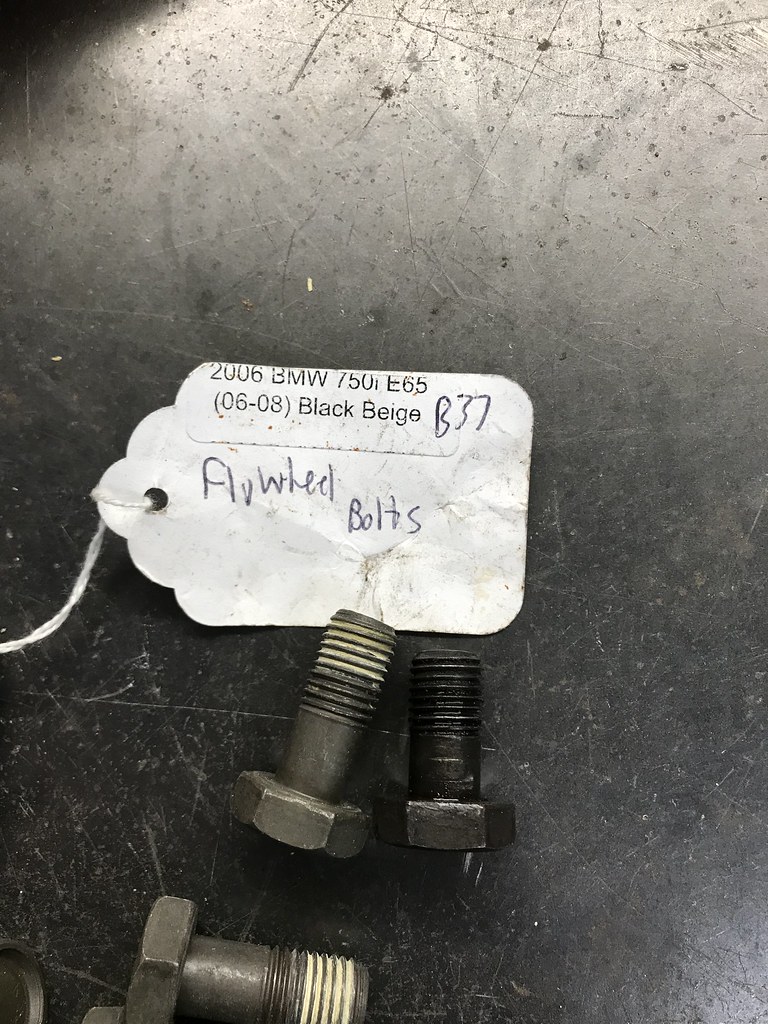

Anyway, three of the bellhousing bolts on the m42 trans didn't let loose and the heads were rounded off. BMW decided to start using these silly 8 point type heads, so it's not difficult to screw them all up. After welding nuts to all of them, they broke free and on to flywheel land. I'm pretty sure I can use all of the m10 hardware which are standard 6 point.

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

After pulling all the flywheel/clutch stuff it was time to compare the two. Just like mentioned elsewhere, it all looks doable. The difference in ring gear distance between the m10 and m42 is ~1.74mm with the m10 being closer to the block. The fork engagement with the throwout bearing is ~3mm shorter with the m10. If you try to mount the m10 flywheel directly to the m42 it immediately fouls the rear main seal housing bolts. They stick past the crank flange just ever so slightly.

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

My first solution was to try using some low profile allen heads I had laying around to see if they would clear. These are stainless, so they would need anti-seize or I should consider getting hardware that won't weld itself to it's little threaded friend hole.

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

I got out my feeler gauges to check bolt clearance to the flywheel and got .43mm. My first thought was that's great, but I still would like to get the m10 ring gear closer to the m42 distance. When you swap a single mass m20 flywheel, you drill a couple rivets on the m42 flywheel to remove a little spacer, and that is used as a shim for bolt clearance. So out came the drill. The spacer for this aftermarket LUK flywheel measured in at 2.79mm, which put the ring gear about 1mm past the m42 spot. I think that's a reasonable difference, and this allows me to put the stock bolts back to the rear main seal housing and skip the low profile stainless steel ones. Even better, is that the throwout bearing height ends up at the roughly the same as the m42 stuff. Yeehaw! This is going to work.

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Now the question is whether I want to try and swap the bendix on the m10 starter with the m42 one. They are slightly different tooth count and diameter. I'm half tempted to try the m42 starter as is with the m10. It's way lighter and smaller in size, making any future repairs much more manageable. The tooth engagement looks decent, but obviously not perfect. I meant to snap some pics of the differences, but it was getting late and my hands were filthy.

Does anyone have any pro tips on how to swap a starter bendix without destroying stuff? I don't see an easy way to get either one off without major surgery and I have found a couple cheap rebuilt starters that are supposed to be a drop in m10 upgrade with better starting power and lighter weight: the sr441x Bosch. With me needing to buy a full clutch kit the budget is getting thin, and the $62 starter put things too tight I think.