Easy night, but it took a long time.

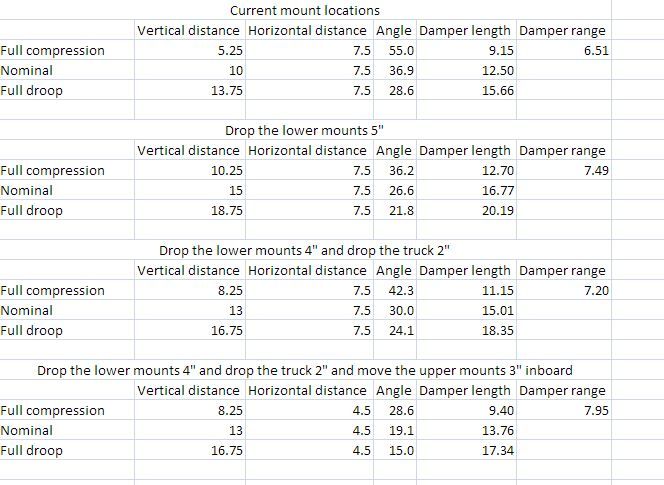

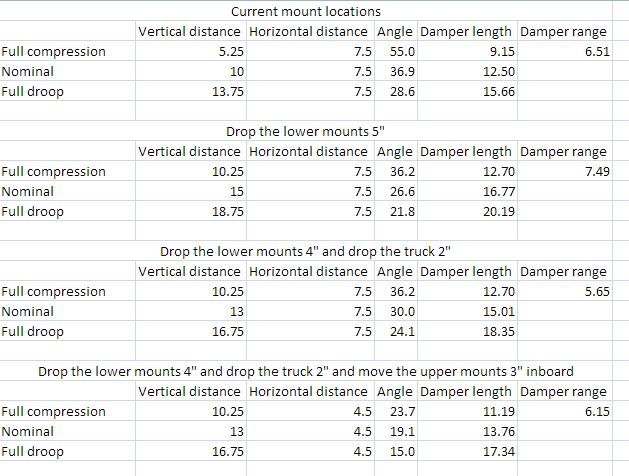

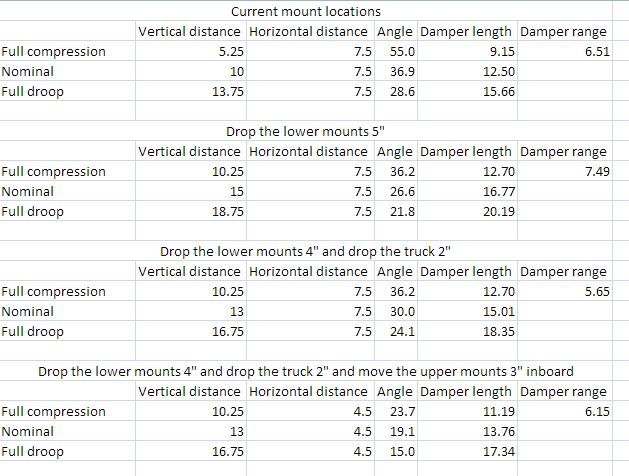

First off, to update the calculations. Here it is, I actually reduced the damper range required because I am giving up 2" of compression travel by lowering the truck. It's reasonable now, and I can proceed knowing that dampers exist for this application.

So I mounted the one bracket, flipped R to L, so that it's a bit more than 3" closer to the axle centerline. And then I lined up the other one. The bracket itself will be roughly 6" closer to the axle centerline. Since this side was originally in front of the axle and is now behind, the mounting location for the damper is away from the axle since I switched them R to L. Here are some pictures to illustrate.

This is the drivers side on the passenger side frame rail. See how the mount is closer to the axle?

Now this is the other side sitting there. See how it is now, after being relocated behind the axle, farther away by the offset?

Actually. I just thought of something. I am not sure which damper traditionally is forward and which is backwards. I ought to try and replicate the normal GM stuff. Let's look.

OK, it looks I did it properly. Drivers side damper behind the axle.

I know it doesn't matter functionally, but it ought to look stock-ish.

So then I turned my attention to the new bracket and marked the frame rail in preparation for the right angle drill/unibit solution (shipping)

And then addressed the old crossmember. I had to remove the exhaust to mount it (and the old exhaust was a temporary solution to having two open pipes exiting beneath the seat). here it is. Much will not be re-used.

Drilling these four holes stuck more metal in my arms and fingers then I can remember from any other drilling ever. It must be because I was under the truck. Ick.

It's in. Moving right along....