Sorry for the multipost Picture dump. Bring the thread up to speed here.

I got this truck 10 years ago from my Grandfather when he passed away. I documented me doing a partial restoration on it then.

The truck has been sitting for a couple years, so I decided it was time to dig back in. Go big or go home. Its not a dedicated drag racing truck, but I am going to try to run some times with it.

Truck Specs Currently:

1992 C1500 Work Truck RCLB

350 H.O. Crate

Vortec Heads

Comp Beehives

Threaded Rocker Studs

Valve Guide converted

Scorpion 1.6 Roller Rockers

LS7 Lifters

Comp Pushrods

Comp XR282HR Camshaft

Double Roller Timing Set

Edelbrock RPM AirGap

.015" Head Gasket

.030" Decked Heads

Long Tubes

750 Holley

HEI

Original 5 speed trans with updated Clutch.

275/55/15s

The Plans:

Convert Truck to RCSB

Full 2x4” by 11 guage CNC bent rectangular tubing frame

1-5/8” .083” Chromoly Cage (NHRA 8.5 Sec spec)

Tied cage sections through the firewall and back glass that will stiff the truck up.

Front Suspension;

Wilwood Pro Series Spindles

Fox Body Manual Rack

Wilwood 15” Hat mounted Rotors, 6 piston front brakes

QA1 Coilovers

Splined, Through Chassis anti-roll bar with 5 location to vary stiffness

Adjustable chamber

Adjustable Upper Control Arm mount location (roll center)

Adjustable Toe

Adjustable AntiDive

Rear Suspension:

3 Link Design (doesn’t bind)

Ford 9” Center Section, maybe a winter's 5063 if I come up with the cash.

Grand National (the racing league, not the Buick lol) full floater bearing ends.

QA1 coilovers

PanHard Bar design (**** tons of adjustability in the brackets, perks of being able to just draw it and cut it out)

Same antiroll bar as on the front.

Motor:

Gen 5 Aluminum 5.3

Stock Crank

Howards Billet Rods

Diamond Pistons

Built to spin 7500 rpm

Twin Turbo

ECU:

Leaning towards a MaxxEcu

Transmission:

Its a surprise.

The above is the wish list. Im sure it will change as i go along but that is the idea. I recently started actual work so check it out.

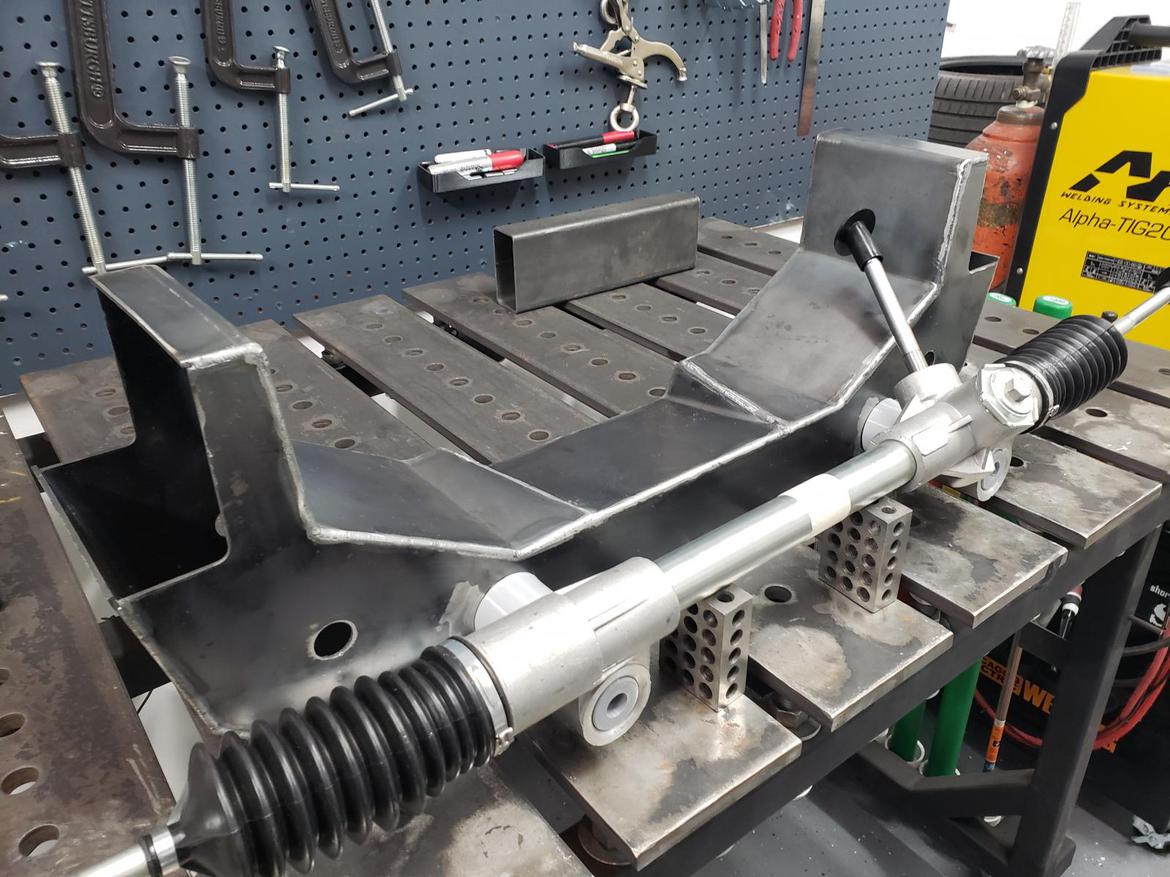

I got my fixture plate made up for the lower control arms. Looking nice. The 3D printed bits have tabs on the bottom that locate their position in the plasma cut slots. Next week I will be picking up some tubing and will be taking the virgin run on my JD2 bender.

The steering rack is on. It's a quick ratio fox body rack... I plan on running an electric assist column. If it sucks I'll convert to hydraulic later.

Moving along...

https://www.youtube.com/watch?v=Ld_nIAMZnJQ

Last week I got the cross shafts for the lower control arms. I couldnt fit standard bolts in past the steering rack, and I didnt want to pull the rack in order to adjust the lower control arm lengths.

Completed the lower control arm fixturing as well. My 3d printer is going on the fritz. Yay!

I got my tubing bender set up and some 1.25" DOM ready to go.

Lower control arms will be done soon.

https://www.youtube.com/watch?v=uVjocf_lJ3U

Solidworks designed CNC plasma cut frame - Check

3D printed Jigs - Check

Ridiculous truck with LS - Check

I think we have another deranged engineer with a thing for sport trucks. Welcome to the asylum.

More pic dumps.

I ordered and picked up the steel to start building out my frame table.

The frame table will be made of 2x4 .120w tubing, bolted and shimmed together (in order to remove the chance of warping the main rails).

I started getting the corner braces made.

The are .25" Plate, plasma cut out, then bent into 90° corners with 2" .120w Angle iron mitered in. Just need to get them welded up.

Got 75% of the passenger side LCA built. I have the coil over mounts cut out, but need to get them bent and welded in.

This thread makes me happy. I have kicked around the idea of making my own frame for my '79 C10. Following.

I saw you are using LS7 lifters in a SBC? I know the lifter bore is the same but what is keeping the lifters located? In a LS you use the plastic trays or go to a lifter with the dogbone.

As a fellow gmt400 owner I'll be watching, looks like you have some fab skills!

But why convert to short bed? I love my long truck.

In reply to 1SlowVW :

Mainly weight and handling. The engine is going to be set back almost 7" from the factory location and main components will be moved to the bed for the sole purpose of moving the weight bias rear ward. Shortening the wheel base is the easiest way to get more rear end weight bias. I'll be slightly shorter than the factory RCBS wheelbase. Ill be at 116.75", factory is 117.5". Tighter bed gap, Front wheels 1/4" back, rear wheels 1/4" forward.

In reply to loudandproud :

So call me crazy, why not mount the engine in the front of the bed/under the back of the cab with a rearward facing dog house.

I'm only asking because I've thought about it. May not be enough room with a trans and a short bed. My fab skills aren't there yet...but looking at your stuff it would seem possible.

Awesome.

How come you're moving the front wheels rearward as well? I'm used to 4x4 guys moving them forwards for tire clearance with the cab and approach angles.

1SlowVW said:In reply to loudandproud :

So call me crazy, why not mount the engine in the front of the bed/under the back of the cab with a rearward facing dog house.

I'm only asking because I've thought about it. May not be enough room with a trans and a short bed. My fab skills aren't there yet...but looking at your stuff it would seem possible.

I looked at multiple options. I was seriously entertaining the Dobbertin Performance corvette setups, but if you do the measurements, it doesnt work in a RCSB well at all.

I did consider a corvette trans, rear, suspension and torque tube setup but decided against it because of where am trying to work to power wise long term.

Run_Away said:Awesome.

How come you're moving the front wheels rearward as well? I'm used to 4x4 guys moving them forwards for tire clearance with the cab and approach angles.

I'm moving the front back 1/4" and the rear forward simply to soak up the shorter wheelbase without looking weird in the fender wells. It will not result in a significant difference.

Tonight I started laying out the cage in CAD. I went out to the truck and started to take some measurements. It's the rough layout only right now. The main purpose was to see where the cage falls in relation to the cab mounts and the outriggers on the chassis.

I'm currently in a holding pattern until my frame rails are delivered.

I ordered then from Boling Bros in CA. They should be here in a week and a half. The rails will be very similar to the rails in their IG post below:

I also 3D printed some balljoint plumb bob holders to get a real exact measurement on the ball joint relationships to each when the crossmember is dead square.

Its tighter than 1/16" total spread. I'll call that good.

You'll need to log in to post.