Teammate and buddy Dan has been putting together awesome in-car vids from the BMW for this race. Sadly, no Opile in-car this time despite the fact that Alex is a cinematographer! I guess work is work and play is play ;-)

My Sunday morning stint, doing slow laps in the beginning as my brain warms up to the idea of POWER

You can see me pass my wife in the Opile several times in this video.

Here's Dan (Gielamonster from Evil Engineering as I think he's known here) doing some proper work behind the wheel.

Green flag is at 14:57 with a prompt pass of Nate in the Opile.

I didn't look for pictures of your car, but most of the gill coupes came with the 1.1L "sport" transmission. There's not much difference internally, but the sport trans has a shifter extension on the top that moves where the lever comes out up an back by about a foot. Correspondingly the floor is shaped differently to cover that, which gives you a little more room for a transmission but it is tall, skinny room. The only two transmissions I have found that might fit without major tunnel work are the Samurai 5-speed and the Chevette sport 4-speed. Since the sammy trans comes bolted to a g13, that might go well with a Suzuki swap, though in that car the Metro/Sprint 3-cylinder might be a better fit, and turbocharged would be plenty of power.

The Chevette 1.6 wouldn't be a terrible swap either, if you can find one. There are some other Chevette parts that can be used on the Opel too, with a little tweaking.

oldopelguy said:I didn't look for pictures of your car, but most of the gill coupes came with the 1.1L "sport" transmission. There's not much difference internally, but the sport trans has a shifter extension on the top that moves where the lever comes out up an back by about a foot. Correspondingly the floor is shaped differently to cover that, which gives you a little more room for a transmission but it is tall, skinny room. The only two transmissions I have found that might fit without major tunnel work are the Samurai 5-speed and the Chevette sport 4-speed. Since the sammy trans comes bolted to a g13, that might go well with a Suzuki swap, though in that car the Metro/Sprint 3-cylinder might be a better fit, and turbocharged would be plenty of power.

The Chevette 1.6 wouldn't be a terrible swap either, if you can find one. There are some other Chevette parts that can be used on the Opel too, with a little tweaking.

Thanks again for the great detailed feedback. I'll pass this along to Alex. For now though, we are good to go - he rebuilt the 1.1L with a big twist. I'll get to that writeup as soon as I can.

Since this has spilled over to a new page, it may be worth mentioning that my wordy Buttonwillow 2019 race report starts about 1/3 of the way down pg. 2.

There's some good stuff coming about the engine that you guys will probably get excited about.

Here's the 2nd part of my BMW stint. My wife Michele makes her first appearance in the Opile at around 7:50 - I gave her plenty of space this time in Cotton Corners...

oldopelguy said:I didn't look for pictures of your car, but most of the gill coupes came with the 1.1L "sport" transmission. There's not much difference internally, but the sport trans has a shifter extension on the top that moves where the lever comes out up an back by about a foot. Correspondingly the floor is shaped differently to cover that, which gives you a little more room for a transmission but it is tall, skinny room. The only two transmissions I have found that might fit without major tunnel work are the Samurai 5-speed and the Chevette sport 4-speed. Since the sammy trans comes bolted to a g13, that might go well with a Suzuki swap, though in that car the Metro/Sprint 3-cylinder might be a better fit, and turbocharged would be plenty of power.

The Chevette 1.6 wouldn't be a terrible swap either, if you can find one. There are some other Chevette parts that can be used on the Opel too, with a little tweaking.

If you're anywhere near Omaha Nebraska, there's an '84 Diesel Chevette that has wound up in the Upullit South yards. They've only taken the manual trans, and the engine is complete.

Big news on the Opile lately is what Alex is calling “giving it a Brazilian.” On the bottom end. I’ll explain.

After the Buttonwillow race had ended and the car wheezed its way off the track and onto the trailer, it was plainly evident that the bottom end needed lots of attention. The head, valvetrain, induction, and exhaust were all addressed earlier so we felt good there – but with massive oil leaks, low compression, loss of oil pressure, and general malaise we all agreed the bottom end was done.

The guy from whom we bought the two red Kadetts in the Phoenix area coincidentally sent me a text around this time, saying he’d be in So-Cal soon and could bring this zero-mile rebuilt 1.1L bottom end with him. A low, low price of $125 sealed the deal – mystery engine with one photo…sure! It visibly had pistons, rods, a crank, and a cam but we didn’t know much more than that.

When we got the engine back to the shop it was obvious that it had been rebuilt and not used, but stored away for a long, long time. Lots of dust and surface rust. It would’ve been great to do a simple swap without tearing this down but that wasn’t in the cards. After a quick disassembly we could see that it had new rings, new rod bearings, main bearings, etc... all crusty but clearly never used.

Since we were into a teardown anyway, Alex started digging around on the internet for parts to try an idea he’d been kicking around for a while – modern pistons and rods. Using one assembly from the rebuilt bottom end he measured from the big end centerline of the rod to the crown of the piston, and worked some magic to discover newer options with around that same dimension. The modern Mini 1.6L floated to the top as the best candidate. $100 later and Alex had a full set of 4 pistons and rods in hand from ebay. These were from a 2003 base-model (for the US) Cooper.

The 1.6L Mini engine was known as the Tritec, and it has a bit of a fascinating history. It was a joint effort between Rover and Chrysler. Mini and the rest of the Rover stable were bought by BMW who built the first new-generation R53 cars but apparently Rover in Gaydon was still semi-autonomous and needed an engine development partner to get the new project going. Chrysler was it. So the 1.6 was designed in Auburn Hills, in collaboration with Rover engineers. Apparently it shares some design aspects with the 1.8 / 2.0 / 2.4L Neon engines although I don’t know if they share any hard parts. Tritec manufacturing happened at a bespoke factory in Brazil, and then the engines were shipped to the UK for assembly into the new BMW-Mini R53. Anyway…

The naturally aspirated Tritec 1.6 is a little tractor of an undersquare engine with a 77.0mm bore and 85.8mm stroke. The Opel pushrod 1.1L on the other hand is quite sportily oversquare with a 75.0mm bore and baby 61.0mm stroke. Alex’s idea was to use just the pistons, rings, and rods from the Tritec but to keep the Opel crank and stay close to the stock Opel stroke, only modifying stroke for deck height if necessary. So the modified Opel engine would end up around 77.0mm bore x 61.0mm stroke. Henceforth this would be known as “giving it a Brazilian.” Engine displacement goes up to 1,136cc from the original 1,078 – which is nice, but the displacement bump was never really the point. The big gains here are the ~2 lb. reduction in reciprocating mass, shorter piston skirts, much longer rods, and modern rings which are much thinner and have to both A) seal better and B) reduce friction losses compared to the old clunkers. The big end rod bearings are a bit smaller as well giving reduced bearing speed which is another nice bonus.

So the plan was to use the “fresh” old rebuilt engine as the basis, but first Alex decided to tear down the race car’s current engine anyway, to diagnose its issues before moving on. We pulled it a few weeks after the race and found some very unhappy rod bearings, a broken piston ring, and not much else to speak of. I think the bearing damage was 100% attributable to running with no oil pressure for a few minutes elapsed time, which in turn was caused by massive hemorrhaging leaks at the front main seal. The engine ran fine and felt fine really even with this bearing damage; it was just down on power a bit. After tearing down the race engine Alex decided it was best to just rebuild this one with the new mods since it needed lots of help anyway. So the newly acquired rebuilt stocker went back on the shelf for another time. It did give up its cam however, which was a fresh mystery re-grind with about .75mm more lift vs. the bumpiest stock Opel "SR" cam that we have.

Alex took the race car’s crank and block to his friendly local old guy machine shop and had the bore opened up and the rod journals on the crank ground down to the Mini diameter. I believe the diameter reduction was about 0.75mm. From there, the whole rotating assembly was balanced by Revco in Long Beach. This included the crank, flywheel, clutch, and front pulley. Ebay was tapped again for new Mini rings, and Rock Auto for new Mini rod bearings. The mains and cam bearings were new as well, from Opel GT Source.

Before putting this all back together the head was milled again, so it’s now 1.5mm shorter than stock and therefore static compression has been raised to a dizzying 9.7:1. Still pretty mild but a big improvement. The piston crowns are essentially flush with the block deck. Alex did some cam degreeing, careful checking of the piston to valve clearances with a dial indicator, and bearing clearance checks with plastigage. He found a modern front main seal that was the right size to press into the front cover and slip over the front crank pulley, so he machined the old spiral groove off the pulley and pulled out the old felt seal. The only real disparity in the new setup is something we knew about - the Mini rods are something like 1.0mm narrower than the old Opel rods, at the big ends. So the side clearances to the crank are about 0.5mm bigger than with the stock Opel rods. We debated back and forth about addressing this, and the consensus was "run it - it'll be fine." It shouldn't depend on oil pressure to steer the rods between those surfaces anyway.

The block got a fresh coat of gloss black and the valve cover got some wrinkle. We then found ourselves at the “assemble and pray” stage, and dropped it back into the car.

It works! This thing fired up almost instantly and sounded so much better right off the bat. It has a really "zingy" character now that it never even dreamed of before. After one or two test drives it was clear that the power kept on building past the old 6,000 rpm redline so Alex upped it to 7,250. This is metered by the Pertronix Ignitor III module in the distributor.

Some initial feedback from Alex:

It's such a big change I can't describe it all but suffice it to say it's WAY faster. I can't get the temp over 170. I think the new thermostat I put in is too cold. I'll put the old one back in. The engine is the real deal my friend. It cray. I'm guessing it'sa bout as fast as a stock NA Miata. With new 7250 redline it's geared to go over 120. That's ridiculous. Next big move will be to get the Rallye diff. Lower gear will make it even better.

After this he did some further tuning, rebuilt the carbs, and replaced the 3rd gear synchro in the trans, which was a bit crunchy in the last race. I've driven it after all this work and it's like a switch has been flipped. This is a different car. Still not intimidating or uncontrollable, but definitely fun, sporty, and quick. It revs freely and feels like a vintage racer should feel (in my mind anyway). Dynamic compression testing gives us 200psi now pretty consistently across all cylinders – before the rebuild & mods it was at 155, for reference. The increased connecting rod to crank side clearance doesn't seem to be a problem at all. It's not making any clackity-clack noises and no discernible issues have shown themselves.

Now my only problem is: it would be rude and silly not to do a Brazilian to my red street car, using the new/old rebuilt shortblock as a basis. So stay tuned for that. Isky is local and they have an Opel 1.1L cam profile, so I'll take the old race car cam to them for some work, and get the block and crank back to Alex's favorite old timey machine shop. I'll document all the mods closely as I'm doing them now that the trail has been blazed, and will post it all up here.

Here are the pics from the teardown of the original engine. Look at those bearings! I guess the oil pressure gauge was on to something when it said "zero." The broken rings were a bonus.

I love it when new tech can be adapted to old engines and parts. What's your butt-dyno saying she's up to, power wise?

GIRTHQUAKE said:I love it when new tech can be adapted to old engines and parts. What's your butt-dyno saying she's up to, power wise?

There's more to come too - it's been fun for Alex and rewarding too, and I'm itching to do more on the red car. We will both keep going and I'll keep updating the thread. After driving it I'd say the new engine feels like somewhere around 90hp at least. This is a very lightweight car, maybe 1600 lb, so my butt-dyno may need recalibration. But it definitely feels about as lively as an NA Miata now when you wind it out. I have a '93 NA trackday car so we could stage a drag race to find out. I think the Opel will make it back on the dyno soon too.

AngryCorvair said:This is fantastic. I friggin’ Love it!

Thanks man! More to come. I'm working on a short video with the new engine.

Here's my latest silly video. You can hear how zingy this thing revs now. It doesn't convey how much faster the car is!

Using Bike carbs. What jetting/needle changes, etc did you need to do to adapt them? I have a couple projects that might find the carbs usable

In reply to Duder :

I love that you guys dubbed the engine mods "a Brazilian". It makes perfect sense, as you're simply getting rid of all the stuff in the way of the real fun...

twentyover said:Using Bike carbs. What jetting/needle changes, etc did you need to do to adapt them? I have a couple projects that might find the carbs usable

Definitely lots of tuning required - I will have to ask Alex exactly what jetting he ended up at. It changed quite a bit with the new bottom end and higher compression. I think the key was that he started with twin carbs from 1.0L v-twin bike engine and adapted them to a 1.1L 4-cylinder with only two (siamesed) intake ports. So each carb was already pretty close to what 1/2 of the Opel engine needed in size range.

Recon1342 said:In reply to Duder :

I love that you guys dubbed the engine mods "a Brazilian". It makes perfect sense, as you're simply getting rid of all the stuff in the way of the real fun...

Never thought of it that way, but I think this one's probably a lot less painful, and not really all that much more expensive. The whole new bottom end was less than $500 for new parts, used Mini parts, and labor - not counting the Opel block, crank, and cam which we already had.

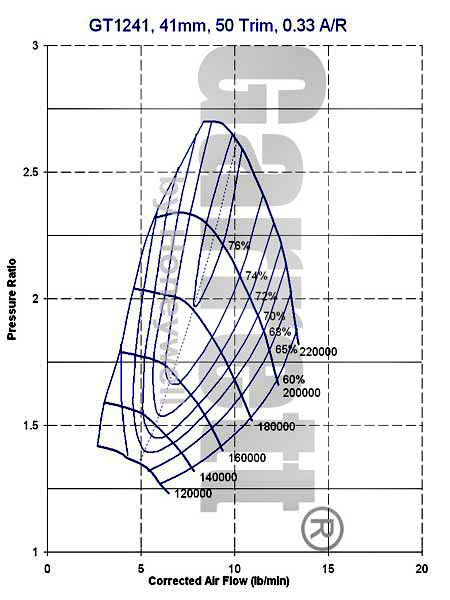

I'm going to start using this thread to document my turbo engine build as I go. I'll be using the recently acquired shortblock, a ported head, another set of Mini 1.6L Tritec pistons & rods, a Megasquirt II, and a GT12 turbocharger.

First thing that came to mind is pistons & rods. Alex has 3 spares, so I need to order one more.

Next is cams. Here are the two cams that came with the 1.1L:

SR cam:

Lift: 10.3mm (0.406 in)

Intake: 316deg. duration. 112deg. atdc lobe center.

Exhaust: 280deg. duration. 230deg atdc lobe center.

76deg. overlap.

Lame Cam:

Lift: 9.2mm (0.362 in)

Intake: 312deg. duration. 114deg. atdc lobe center.

Exhaust: 298deg. duration. 239deg atdc lobe center.

84deg. overlap.

I think the lame cam was installed in both the base engine and the S engine. The SR engine is the Rallye version with dual carbs, etc.

Next step on cams is I need to call Isky and see what grinds they have on file. We have some spare used cam cores I can take over there (they're local). The previous owner of the race car at one point got a $250 quote from them for a cam grind.

So here's the basic plan, in bullet point list form, because I love me some lists.

Here's Step 1:

Oh man, this really is getting interesting now. I was considering buying a 1950 buick with the Fireball I8 a little while ago and I was also wanting to turbocharge it, though my reasoning was to get around the inherent inefficiencies of the flatheads (and get more power, natch).

I love how the battery is nearly as big as the whole engine. Have you thought of a smaller replacement? What are Lemon's rules on batteries that AREN'T lead-acids, cause I think a charge controller and some salvaged 18650 Lithiums from old power tools and laptops could fire that motor off without much fuss and save several pounds. Just a thought.

Since you're having the crank ground anyway, would it be worth a few extra bucks to have the rod journals offset ground for a little stroke increase? I mean, everybody likes a little stroke increase.

GIRTHQUAKE said:Oh man, this really is getting interesting now. I was considering buying a 1950 buick with the Fireball I8 a little while ago and I was also wanting to turbocharge it, though my reasoning was to get around the inherent inefficiencies of the flatheads (and get more power, natch).

I love how the battery is nearly as big as the whole engine. Have you thought of a smaller replacement? What are Lemon's rules on batteries that AREN'T lead-acids, cause I think a charge controller and some salvaged 18650 Lithiums from old power tools and laptops could fire that motor off without much fuss and save several pounds. Just a thought.

Do it! I've secretly wanted to do a turbo build on a Ford Flathead V8 for decades now, but never pulled the trigger. While it's true that the turbo will help overcome its inherent inefficiencies, it's also true that anything you would do for an NA build still helps the engine breathe easier, except maybe for the exact values of cam overlap or compression ratio. But anything you can do to improve VE (porting, bigger valves, better manifolds) will reduce demand on the turbo, thereby reducing boost and pumping losses, making the whole system more efficient.

The red car is my street car and will run an Odyssey PC680 AGM battery in the standard location there on the firewall. The Lemons car is the greyish one, and it's got the battery on the passenger floorboard in the cabin. I think it's also a big standard lead acid but I don't remember. Good to have extra capacity there in case of a charging issue on the track, and the weight is down low and much closer to centered in the car. Lemons rules allow AGM; not sure about Lithium.

AngryCorvair said:Since you're having the crank ground anyway, would it be worth a few extra bucks to have the rod journals offset ground for a little stroke increase? I mean, everybody likes a little stroke increase.

Alex and I talked about that before he got his crank ground, and I think the issue was deck height difference. With the stock stroke but a slight reduction in journal diameter, the piston crown height vs. block deck height ended up perfect. I think the piston would've been proud of the head gasket with any increase in stroke. Will confirm!

In reply to Duder :

Yeah, I only ask on the battery because LeMons now has the electric car class and that Jet Electra 007, so clearly they've prepared for some kind lithium fire if an EV shows. To be fair... you'd fight it with foam instead of water, which the fire service does routinely anyway now due to all the other componds and plastics used in current cars.

I would have pulled the trigger but someone else got it- it's cool tho, I found some local Hundson collectors I'm giving the eye towards, and a Hornet is quicker anyway ![]() . I DO know that you have to be careful about the exhaust valves in flatheads and upgrade them if possible, they like to get burned and the old materials can't hold up to the heat. Funny enough, the biggest problem is typically reducing weight- Fireball I8s it turns out, have MASSIVE rods and tons of reciprocating mass, to the point where they're actually what limits them to 4,000RPM.

. I DO know that you have to be careful about the exhaust valves in flatheads and upgrade them if possible, they like to get burned and the old materials can't hold up to the heat. Funny enough, the biggest problem is typically reducing weight- Fireball I8s it turns out, have MASSIVE rods and tons of reciprocating mass, to the point where they're actually what limits them to 4,000RPM.

In reply to Duder :

Brilliant! I forgot that increasing stroke would raise the piston at the top of its travel. No doubt you guys have it under control.

You'll need to log in to post.