Is there room for a turbo? Or is it just a better idea to get a full swap in there?

I think that i remember that you are trying for 300hp. I dont know if a rotary can get there though.

In reply to Dusterbd13:

A rotary will do it with no problem but it may end up with a turbo 4 cylinder. That's going to take some research.

Rather than stirring up trouble on another thread, I went outside and worked on the beast today.

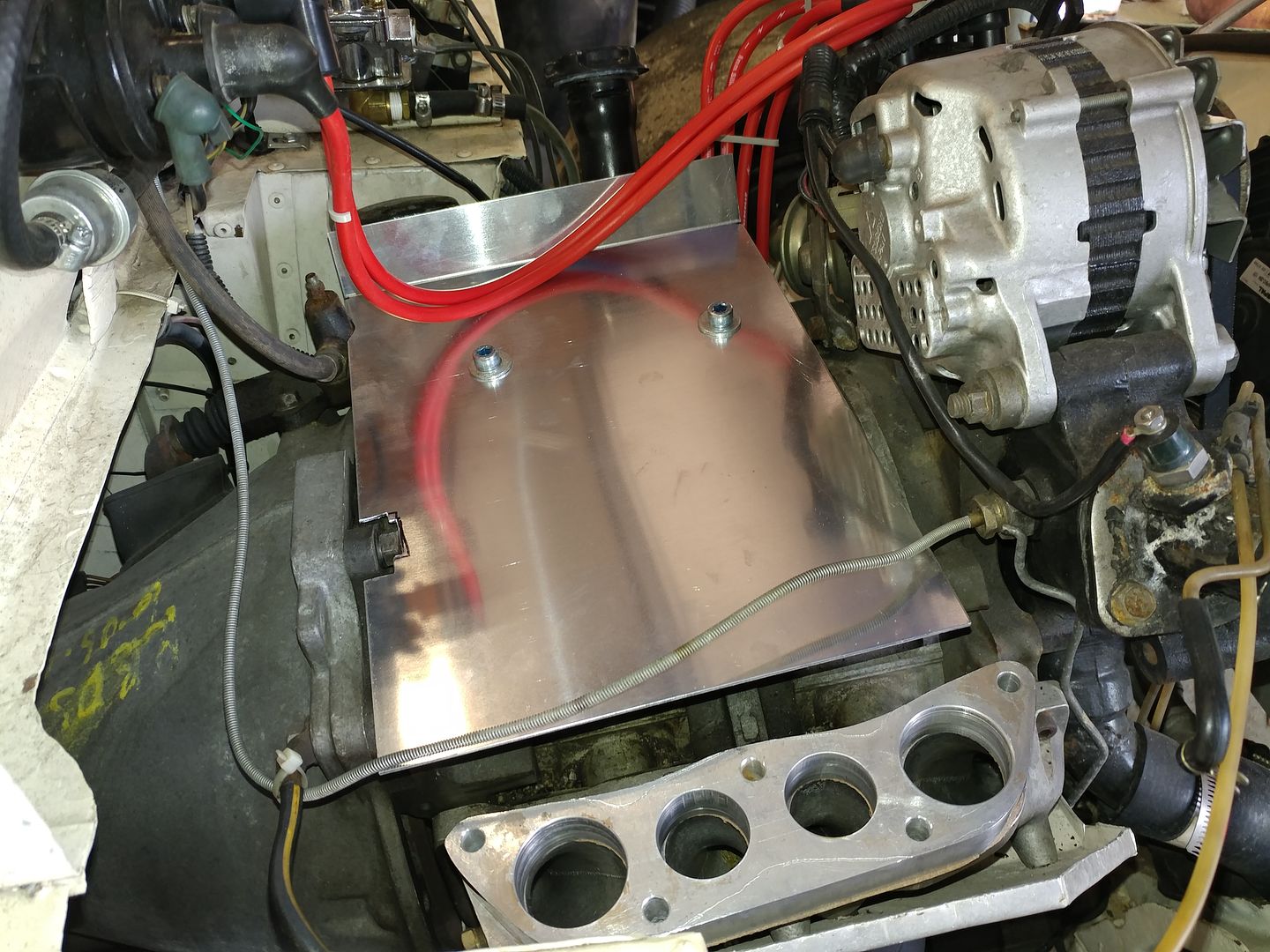

Starting with the heat shield under the carburetor. I'm trying to eliminate the fuel boiling when it's shut down hot. SOP now is, kill fuel, run till starving, kill ignition. It works, but I wanted to keep the carburetor cooler than that.

I had plans for this really cool aluminum box, that I was going to make with that fancy sheet metal machine. It was going to be ducted for cold air, are really spectacular looking. Then I tried building it and realized I have nowhere near the skill to pull that off. So I built this. It is simple and within my skill set. The box will be a future project using this as the base.

I also reinstalled the carburetor for the last time. New gaskets were cut and new hardware was sourced to replace rusted old junk. It's the first time I've ever seen blue zinc plating.

Next up was more heat control. I have literally ended up with 2nd degree burns from the transmission tunnel on a hot day. I had a used thermal blanket that a friend gave me on the interior, but it only helped so much.

This is the problem. The bazillion degree rotary exhaust, runs down the side of the transmission and under the tunnel to the back of the car.

Yay for transmission access.

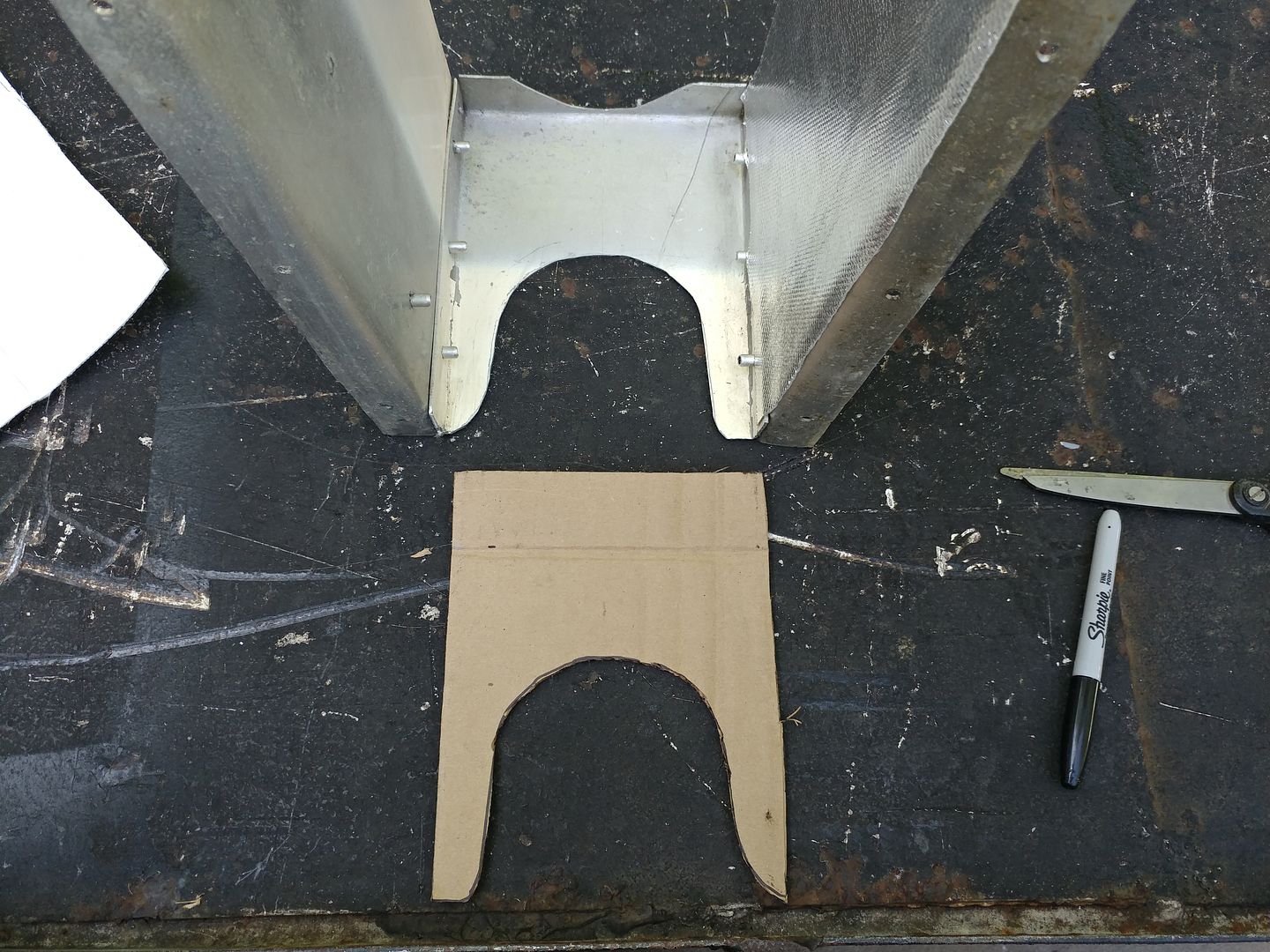

First order of business was some heat-shielding.

The mounting studs are 1/4 - 20 screws welded to the exhaust tube. The sheet metal is spaced off the tube with a nut, and then another nut to hold it in place.

Next up was a aluminium, fiberglass, adhesive backed, insulation. It's not very thick, but it should reflect most of the radiant heat and provide some thermal barrier. I hope.

The entire transmission tunnel is getting treated with the insulation.

A little cardboard helps with cutting odd shapes.

I also installed some heat shielding under the transmission and driveshaft to keep some of the heat out of the tunnel. No pictures of that. I forgot to take them.

I noticed a new-ish heat shield product in a magazine I get: form-a-shield

Not cheap, but I'm considering it for making heat barriers in my Spitfire and GT6.

In reply to Ian F:

Thanks, saved.

That's some good looking stuff. The exhaust is going to be moving in the future and I'll be needing some additional insulation. I'll also be needing some for the firewall on SanFord.

So, today I buttoned up the transmission tunnel. Not much to see.

I also reassembled everything under the hood and dash. Then I pushed it out of the shop and fired it up. It proceeded to dump fuel everywhere. Apparently the accelerator pump diaphragm decided to take a dump. Off comes the carburetor, a quick change of the accelerator pump and all the rest of the gaskets on the bottom of the carburetor. Reassemble, and fire it up again. It seems to be running fine, but I won't know for sure until I get it back on course.

This also happened.

I'm not sure I like it, but it will run at least one autocross like this. Looks kind of sad at the moment.

The new front end will be picked up next week and things will be changing.

Ian F wrote: I noticed a new-ish heat shield product in a magazine I get: form-a-shield Not cheap, but I'm considering it for making heat barriers in my Spitfire and GT6.

This does not make sense?

In order for a reflective surface to work, it needs an air gap and it must face the radiant heat source. The application as shown reminds me of putting Dynamat all over the inside surfaces of a car; total waste of time an money as far as heat reduction is concerned.

This stuff would work great if it was used to line the underside of the tunnel. However, at that point I worry about water in the fiber insulation.

In reply to NOHOME:

Agreed. How they show it on a turbo and manifold doesn't make sense, but that's not how I plan to use it. I plan to line the inside of the transmission tunnel and if space allows, make a second one that has a gap between the firewall and engine. This is mainly for the GT6 for now as Doc Brown did a pretty good job with sealing the Spitfire and interior heat is somwwhat tolerable in that car. Better than my GT6 or the ex's Spit - which felt like there was a flame-thrower on your right foot.

What I'd really like to figure out how to use this to make an OEM style heat shield that provides a gap between the body and the shield, but without contacting the drivetrain. This product looks promising, but I'm not sure how well it can be permanently formed into complex shapes.

Coming along really well. Have you considered ceramic-coating the exhaust? It can be done cheap if you find the right guy and are willing to wait to get in on a job that is already happening.

1200 miles later, we have a new 30# hood. Very nasty, very shop worn, but for $150 I thought it was a pretty good deal.

This thing is ridiculously thin. It's by far the worst thing I have ever tried to strap down to a trailer.

It was flexing so bad over every bump, I was afraid it would crack worse than it already is. So, I stopped by Lowes and spent $10 on 5 bags of mulch. Flexing problem solved.

It's going to take a good bit of work to get this thing cleaned up, repaired and painted. This is after a quick bath.

Oh, and the fat girl P71, returned 22mpg. Better than I expected.

One more thing.

The internet says the factory hood weighs 110 pounds without the lights. So lights included is 125 pounds. Add another 15+ pounds for the hinge and latch parts.

I think I can shed close to 110 pounds by switching to a fiberglass hood. ![]()

Now to find a trunk lid.

More to come.

Today it hit the course to see how the past months modifications went.

The googly eyes were a roaring success. Everyone that saw them loved them. I'm hoping someone shot some pictures of it on course.

Carburetor modifications were a 100% success. All stumble in all turns is gone. It pulls better at every RPM. I was amazed at how well it ran. Like a totally different, new, and better car. This issue has been stressing me a little, because it's so hard to test except at events. I was super happy about this, I was almost dancing a jig at the finish of the first run.

The heat shielding and insulation was also a 100% success. The transmission tunnel was running hot enough to cause burns, now it's hot, but not uncomfortably so. I have some thoughts about additional driver comfort, those will be happening sooner rather than later.

The windshield removal and weight reduction was a 95% success. Visibility is amazing, but I think I have removed enough weight of the front of the car to cause the car to push. That may make changing the bonnet and losing another 100# off the nose a bad idea. I need to start losing weight at the rear of the car as well. I have graciously agreed to store the clubs Longacre scales for the foreseeable future, so it will be getting some corner and front to rear weighting.

I shot a little video today and I'll try to get it up tomorrow.

Congrats, I had mine out today for the first time since all the mods, too. Don't worry about losing weight equally front and rear on the car. You can restore balance with sway bar, spring rate or roll center adjustment. With less weight on the front, you just need to soften the front roll stiffness or raise rear roll center. A poll on the D/Emod discussion group revealed that the vast majority of D/EMod drivers consider high rear weight percentage as an advantage, and it's even written into the EM rules (cars with more than 51% rear weight bias get penalty weight).

In reply to MrJoshua:

F1 is now 45/55.

the 911 has evolved to 42/58 The 458, 650S, MP4-12C Printer Fax Scanner, are that too.

So between 45/55 to 42/58 is probably optimal

You'll need to log in to post.