759NRNG said:Man I wish I was 900mi closer .......I'd dump a bunch of my '91 rear susp metal in yur driveway an haul A$$.....Merry St.Patty's Day !!!!

B. Cahill

If you two can figure out what needs to go north, and it can wait until June, I might be able to make that happen. Maybe.

I did that exact drive once to pick up a puppy for my mom. I'm well aware of how out of the way it is. I do dumb things all the time. It's fine.

Dbd13, I have the stock rear leaf springs(1/2ton) for your enjoyment.....plus assorted leaves from a set of dearched (lowered5") springs......

In reply to 759NRNG :

I appreciate the offer. However between the two sets of half-ton leaves that I have and the set of three quarter tons I think I'm good on leaf springs for now.

mazdeuce - Seth said:759NRNG said:Man I wish I was 900mi closer .......I'd dump a bunch of my '91 rear susp metal in yur driveway an haul A$$.....Merry St.Patty's Day !!!!

B. Cahill

If you two can figure out what needs to go north, and it can wait until June, I might be able to make that happen. Maybe.

Dusterbd13's not that far from my in-laws... and I'm sure I'll have to go down there after OneLap sometime... although I dunno if the civic/sonata will have room for the described bits

I love this place.

Due to weather, bed srop off is cancelled for tonight. Were waiting for the weather to break. Which means that the chassis and brake work is on hold.

So, tonight is rebuild the drivers side door guts/retint the purple window/sound deaden/insulate. Maybe even diagnose the dome light lack of operation.

In reply to Bob the REAL oil guy. :

I can take measurements of the 4 laying around on my floor if that helps.

Dusterbd13 said:I love this place.

Due to weather, bed srop off is cancelled for tonight. Were waiting for the weather to break. Which means that the chassis and brake work is on hold.

So, tonight is rebuild the drivers side door guts/retint the purple window/sound deaden/insulate. Maybe even diagnose the dome light lack of operation.

Ok, so I'm jumping in late and out of context... but.... I know that the dome light has an override button next to the headlight switch.

Have you tried pushing that?

In reply to a_florida_man :

Yup. Even hit it with contact cleaner.

I determined tonight that the dome light (at the bulb) has power. The bulb is not blown. Therefore its a ground issue. My bet is that both jamb switches are dead. However, i quit rather early as the girls were at a girlscout meeting and my head was killing me.

Sat on tbe couch and listened to the rain instead. Tomorrow is a different day.

Budget first:

previously was 700.07

new money:

billet grille: ebay 31.46

clear headlights/turn signals/corners: ebay 49.59

firestone sport rite bags: amazon 280.80

105 amp alternator: amazon 57.50

fuel pump and sending unit: amazon 36.98

5 gallon air tank: free

most of a DJM flip kit with shock extenders, notches, new front rotors, and unknown drop front coils: helped a friend

DJM LCAs, 2 inch drop: 150 from Patrick

rear 8600GVWR wheel cylinders, amazon: 17.66

front 8600 GVWR front calipers, advance: 20.99 ea

front wheel seals: advance 8.25

led 3rd brake light: ebay 23.99

sold 2500 leaves: 50

sold bedrails: 40

sold GMC grille: 30

new total: 1278.61

“Half measures availed us nothing. We stood at the turning point. We asked His protection and care with complete abandon.” Alcoholics Anonymous page 59

this is a very fitting quote, as in the case of almost every drivabeater there has been that point. I truly believe I am at it now. We started pulling the truck apart for paint, and I have started hunting down every evil and sin that is hiding in it. There's more than I expected, to be honest.

Lets start with chronological order, if possible,

first, my third brake light was cracked, with bad gaskets and burned out bulbs. It was within a few dollars to change the whole thing to an ebay special LED unit. Worked perfectly after clipping the yellow wire, which is apparently pretty common on them. Little strange looking to my eye, so I plan to use some VHT red taillight tint to turn the whole thing red. Maybe. Haven't really gotten that far yet.

20180309_080506 by Michael Crawford, on Flickr

20180309_080506 by Michael Crawford, on Flickr

I also was told by my body man to bring the bumpers and tailgate over for him to work on and use as test pieces for setting spray patterns/mix ratios/etc. Tailgate was pretty mangled, so hes getting that straightened out as well. Only a couple other dents and dings, and a few extra holes to fill otherwise. Pretty simple paint and body job in his opinion. After we pulled parts, we threw a few hundred rounds down range. It was a good night.

20180307_180505 by Michael Crawford, on Flickr

20180307_180505 by Michael Crawford, on Flickr

next, the LCAs came in. same day as the tonneau cover. So I mocked up the tonneau to decide what to do about the bedliner and rails. I have decided that I am keeping the bedliner, but am modifying it to make it fit flush instead of going over the rails. The tailgate piece will still wrap over, but will be done in black. The tonneau is very cheaply made, but that's to be expected when its only a third of the price of others. The hardware they sent doesn't come close to working to mount it to the truck, and im ok with that. There's some solutions going around my brain, but nothing certain yet.

20180308_142032 by Michael Crawford, on Flickr

20180308_142032 by Michael Crawford, on Flickr

20180319_203128 by Michael Crawford, on Flickr

20180319_203128 by Michael Crawford, on Flickr

20180308_144734 by Michael Crawford, on Flickr

20180308_144734 by Michael Crawford, on Flickr

I went ahead and pulled the diamond plate. Figured it was time to rip the band aid off and see what was under it. I was very pleasantly surprised. Not even a spec of surface rust. Just fantastic!

20180311_171102 by Michael Crawford, on Flickr

20180311_171102 by Michael Crawford, on Flickr

somewhere in there I started working on getting the frame clean enough to paint, in addition to being clean enough that it didn't drop crap all over me and the floor when I go to redo the suspension. I also had an offer from a friend I couldn't refuse: due to a hernia, he couldn't do the heavy lifting on lowering his GMT400 6/8. he offered me a smorgasbord of used stock and drop parts in exchange for helping him. So I removed the bed, notched the frame, replaced the rear axle/springs, did 2 inch shackles and a flip. Up front spindles, drop arms, and coilovers. Freaking thing is LOW. Which makes me want to make mine lower. And reminded me how nice it is to work on these things without sheetmetal in the way. No pictures of his truck because I suck. But here's pictures of the parts he gave me.

20180319_203137 by Michael Crawford, on Flickr

20180319_203137 by Michael Crawford, on Flickr

in addition, eBay was running a one day 20% off sale. So I went ahead and got the front lights and billet grilles, as I mangled the free billet when trying to cut and shape it, and one of my headlights is cracked.

20180319_203145 by Michael Crawford, on Flickr

20180319_203145 by Michael Crawford, on Flickr

20180319_203151 by Michael Crawford, on Flickr

20180319_203151 by Michael Crawford, on Flickr

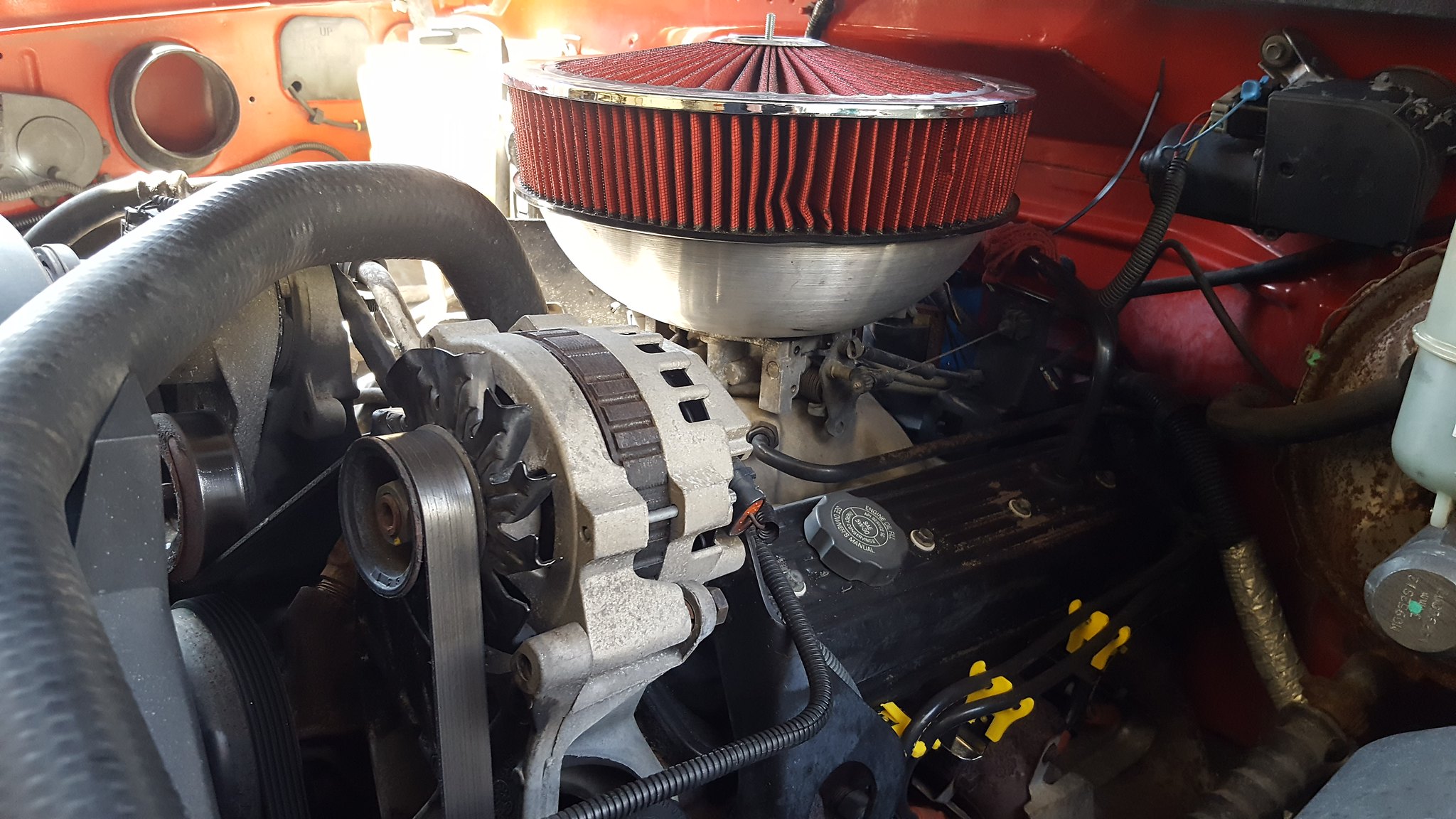

I also installed my “salad bowl” (an aluminum wok lid from habitat) and air cleaner. These were leftovers from the elky, as they didn't clear the hood or look right. Picked me up 1.5 mpg average over 600 miles. Ill call that a win. I do have to get the crankcase breather hooked in though. Right now its a filter into the valve cover, but id rather it be in the air cleaner assembly.

20180308_135358 by Michael Crawford, on Flickr

20180308_135358 by Michael Crawford, on Flickr

20180315_120900 by Michael Crawford, on Flickr

20180315_120900 by Michael Crawford, on Flickr

also, I developed a squeak from one of the accessories last week. Last night upon return home, the squeak stopped. Spit the bearing out of the back of the alternator and cracked the case. In the driveway. Backing up to the shop. Couldn't have happened at a better time or place.

20180319_191908 by Michael Crawford, on Flickr

20180319_191908 by Michael Crawford, on Flickr

so this all brings us up to the reason for the quote: we pulled the bed last night, shedding light on a multitude of sins. First, we shall show pictures of bed just pulled, then discuss the issues I have fond and my plans to fix them.

20180319_190451 by Michael Crawford, on Flickr

20180319_190451 by Michael Crawford, on Flickr

sin number 1, and my biggest concern, is the notches. Im not sure that they are in the right place. The bumpstop pad on the drivers side of the axle was cut off due to contact before my purchase. They are only held in with half the fasteners, and really ugly welds. Mu first step is to pull the bolts from the shackles, pull the shocks, and drop the frame as far down the axle as I can. See what hits and what doesn't. If it clears, I will grind welds down, clean everything, and burn it in with a good 220v welder. In addition, box the back side of the frame for strength. If it doesn't, I will cut them out, fit the DJM notches I was given, and follow the same weld/box plan. In addition, the brake line bracket is not actually doing anything but adding extra strain to the hardline by being cantilevered out into space and haphazardly zip tied. This will be firmly bolted to the frame or boxing plate, and shortened as necessary.

20180320_182734 by Michael Crawford, on Flickr

20180320_182734 by Michael Crawford, on Flickr

20180320_182802 by Michael Crawford, on Flickr

20180320_182802 by Michael Crawford, on Flickr

next, the axle is crooked in the frame by roughly a half inch. Unknown why at this point. Axle may be bent, but more likely is that its a flip kit issue. The bottom plates are pretty bad, and the saddles to the axle tubes don't actually fit the axle. This will all be addressed after I figure out what I want to do, and how best to accomplish it. I will set pinion angle at the same time, however its pretty close right now as there is no vibration.

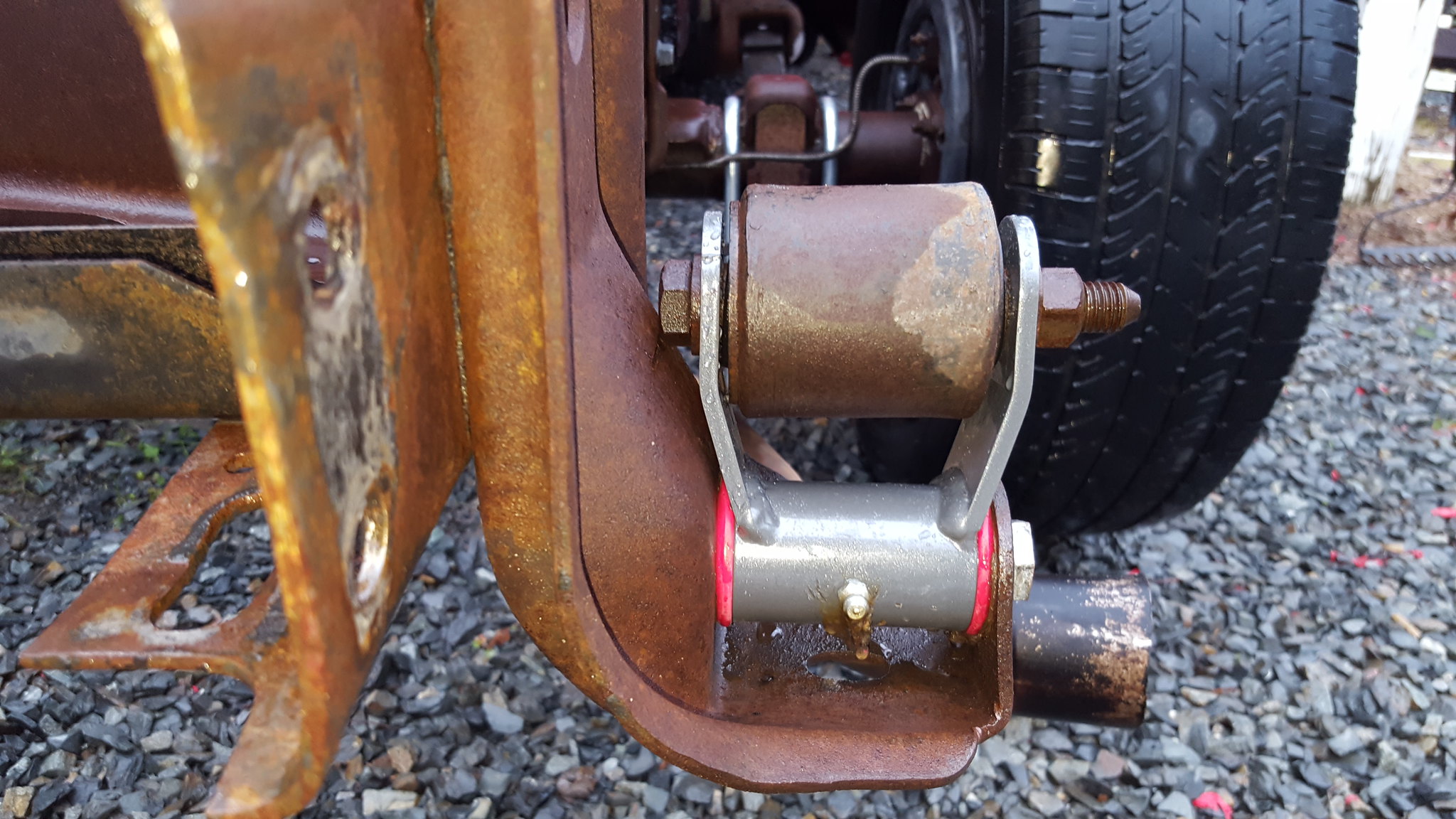

Next on the list of sins to fix is shocks and shackles. These two items are the biggest contributors to the poor ride quality in my mind. The unknown brand (included with the flip kit per Jeremy) shocks are at a truly horrible angle due to no extenders. I have a pair of bilsteins off a suburban (don't remember why or when I bought them, but do remember where) and the free DJM extenders for that issue. The shackles are lift shackles that Jeremy put in to cure the pumpkin hitting the bed support and level the truck some. I got the stock ones from my buddy's truck, and will use them. Biggest issue with the lift shackle is that they are in a severe bind due to hardware. The head of the upper bolt has dug into the hangar bracket, making the rear spring rate near infinite. Also, neither of the front leaf spring bolts have nuts on them any more. That cant be good.

20180320_182750 by Michael Crawford, on Flickr

20180320_182750 by Michael Crawford, on Flickr

lastly is springs themselves. I want to go slightly softer in the rear, and have scrapped the plan of the 2500HD springs I had bought. Instead, I bought the firestone load bags, and plan to pull the overload leaf (currently an active leaf in the pack, adding a metric E36 M3ton of spring rate) as it will no longer be the main source of weight capacity. I will check the bushings and spring pads and re-grease while its all apart. In addition, I may decide to go with onboard air for this, and filling tires at the autocross, side of the road, etc. haven't made up my mind yet. But I have a large amount of parts for onboard air already on hand....

also, I have picked up everything to go through the brakes while its apart, just to be anal retentive. Going with the 2500hd stuff, as the internet tells me that that's the sweet spot for brakes with these. Well see.

Lastly, in preparation for the rabbit hole that I am heading down, I spent some more quality time with the pressure washer.

20180320_182742 by Michael Crawford, on Flickr

20180320_182742 by Michael Crawford, on Flickr

20180320_182133 by Michael Crawford, on Flickr

20180320_182133 by Michael Crawford, on Flickr

20180320_182128 by Michael Crawford, on Flickr

20180320_182128 by Michael Crawford, on Flickr

tomorrow it gets real.

Have a good evening y'all, and tell your family you love them.

That was a hell of a post! ![]()

Like I said before I am glad this truck is getting a new lease on life and properly sorted. It definitely went to the right home for that.

As you know, I can appreciate an ambitious project... full speed ahead my friend.

It will be over before you know it.

Give the challenge car a little love too...

Hoping to finally get back on the challenge car this weekend. Except for the frame, the list on this thing is pretty quick and easy. Just nuts and bolts. (Famous last words).

Thanksfor the encouragement y'all.

I was pretty worried about what was under that bed liner. Blows me away that everything was fine. And thanks for power washing the motor, that was bothering me.

You'll need to log in to post.