JeremyJ said:In reply to iansane (Forum Supporter) :

Tacoma is definitely grittier than Bothell. I can see that. I'm in Kent.

Keep up the good work. You're a hell of a guy for taking on that Audi project. That's a hell of a job.

Haha, it seemed more daunting that it was. It was actually pretty straight forward. It was actually made more difficulte because he bought almost EVERYTHING brand new. All new hoses, bolts, clips, everything. So sometimes it was hard to figured out where new parts went. It did transform the car though. The new turbos and stage3 tune it goes like stink. Faster than the jag I'm sure.

bonylad said:So like um Im putting a small block in a S10?

That's always been a combo I want. An 80s square s10 standard cab short bed with an LS. I rolled around in a 90 2.8/5speed for a year or so and it was fun, but anemic! What year is your s10?

I'm over here falling in love with everything you have. The T5/T5 is so cool. The C50 is a killer pickup. A manual STypeR?! Ooof

young_boomer said:I want to be you when I grow up.

I'm not sure I've grown up yet myself! It's just a 9 year olds brain playing with LEGOs in a 36 year olds body.

I had some spare time before diving into the Jag swap to bust out some maintenance on the silver e30. In the interest of hitting as many birds with as few stones as possible I had a slew of things to do. The car is lowered a decent amount and if any of you know, the e30s have a nonadjustable rear trailing arm suspension. Better than my trans am's stick axle, but not by much. Lowered like it was it, had decently bad camber but much worse toe. I drive it a lot and was eating my 255s regularly. I had previously welded in an adjustment kit that used some e39 bolts and slotted adjusters. It worked, but poorly. The bolts slipped and they were a PAIN to get to. I planned to go back to fixed mounts and use raised subframe bushings hocked by condor speed. Nice delrin pieces. The e30s also also use a 2pc driveshaft. I knew that I was going to switch to a 1pc shaft with slip yoke when I tossed the v8 in. I also knew from an offhanded comment made by vorshlag about their v8e30 that because the diff flange was set so far back into the rear subframe, it was impossible to pull the driveshaft out(and consequently the transmission) with the engine in the car. I wanted serviceability. I decided I was going to cut the subframe and make a removable crossbar. I'm trying to find pictures now but for some reason I only have the ones from when I did this to the volvo30 to fit it's 1pc shaft. So I'll just show those for now.

.jpg?width=1920&height=1080&fit=bounds)

In version2 for the silver car I ditched the nutserts and when with threaded weld inserts and bigger allen head socket style cap screws along with welding a tube into the holes where the screws went.

In doing that I figured I should ditch the stock style dual pump setup (lift pump in the tank and HP pump on the frame) for a single high pressure in tank pump. I had killed the factory pump and all the aftermarket ones I found locally required a funky hodgepodge of fittings to aim the fuel in the correct direction.

It was easiest to drop the tank if the subframe was out of the way. So much room for activities! I also had an issue since I bought the car that I could only ever get 7 gallons in. I even went so far as to run the car out of gas to verify the gauge wasn't berked. It wasn't. From empty to full it read correctly yet only yielded 6, maybe 7 gallons. I never really cared since the car got amazing mileage I still only filled up once a week, max. Well I bought a new tank to go with the new pump to alleviate any issues. Then I pulled the old tank out and found this.

My tank was cut in half. Not only was it cut in half (very well, I might add) The "empty" half had a secret compartment in it only accessible from underneath the car.

Dun dun duuuuun. Immediately I assumed my car was running drugs across the Canadian border when it was new. Maybe mexican border? I have no info on previous owners so no idea. If I didn't have weird luck, I'd have no luck at all.

I don't remember when exactly but at some point I bought an alfa. Because every real car guy has to own an alfa, right?

It doesn't run. It hasn't in at least ten years. When I was a commercial manager at an O'Reilly Auto Parts, one of my accounts that was a body shop and auto repair facility had this sitting on the side of the shop. The owner of the shop said it came in for a paintjob and a bunch of funky custom touches. It had shaved door handles, jaguar tailights/shaved rear bumper/frenched license plate, old mopar bullet marker lights among others. It's a mechanically fuel injected 2.0liter. The points/condenser were toasted so I swapped those with an HEI setup but still couldn't get it to fire on anything but starting fluid. So I grabbed a microsquirt for it and a set of streetbike throttlebodies but haven't had time to make an adapter to the factory intake yet. I didn't realize the new bikes use dual throttle blades and two sets of injectors. I imagine one is cable controlled and one is computer controlled? That's waaaay down the list of things, however.

Every year there's an e30 gathering right down the road from me. People come from all over the country. Something like 200+ e30s. All sorts. Coupes, convertibles, wagons, m3s, all the special versions and models. Well last year there was another lifted e30 there. I wasn't an outlier anymore. I couldn't have that. Well, I think I was just jealous because their car was in much nicer shape and an actual complete car. I guess you could say I wanted to 1up them? How can you do that? You make an e30 based trailer.

.jpg?width=1920&height=1080&fit=bounds)

I started with a crazy rusted shell that someone else had parted out as much as they wanted. I was thinking I could two fold this. I could cut the back end off for a trailer and use the front end as a jig for building a custom long arm setup for the truck instead of having the truck down for a long time. So I got to cutting.

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

Then my ADD stepped in and I started working on something else shiny. Or I had too much beer. I can't remember. Either way it was a few months until I got to the suspension. Since I wanted both the truck and trailer to be fully functional (eventually) I decided a set of airbags would make the trailer tall to fit some A/Ts or M/Ts while still having the carrying capacity for hauling around engines and such. (I had put a 5.3 LS in the back of the truck at one point and it was DRAGGING.

Generic air lift bags and valves. I plan just to mount a big tank on the front rails behind the tongue of the trailer and put the valves/gauge inside the gas door on the "quarterpanel". And obviously fit as big of a tire as I can.

In case you're wondering, I did save the roof section too. If I want to try a shooting brake or something weird later on.

I particularly love your first photo. I worked at the museum in the early 80s, and the pre Olympics highway was my daily commute.

Not gonna lie, I think I am physically sick from seeing such a clean shell get cut in half! What is the story behind that car?

In reply to Mrfurzzy :

This man has not seen real rust if he calls that shell a rusty one. That would be pristine here in PA, let alone OH or upstate NY.

In reply to TurnerX19 :

Exactly! I'm from Wisconsin and people here would list that as rust free. Unless he somehow managed to hide all of the rust holes in the pictures.

Mrfurzzy said:Not gonna lie, I think I am physically sick from seeing such a clean shell get cut in half! What is the story behind that car?

Ha, "Clean" isn't what I would've described this as. Granted, it still drove and stopped but not a lot on this car was structurally intact. I actually regretted using this chassis as I had to reweld both rockers completely to get enough metal to attach the trailer frame rails to. I don't have any experience for what the midwest tolerates in regards to rust but why make more work for myself? They made well over 2 million e30s.

Both strut towers had rusted away from the body. The driver side was the lesser of the two.

That rust dust on the floor was just from the vibration of the sawzall cutting through the floorpan.

.jpg?width=1920&height=1080&fit=bounds)

You can see the holes in the fenderwells below the air spring. Both sides had holes at least this large. And those holes go into the trunk.

I don't have any pictures of it but at some point in this cars life it had a new passenger rear quarter hung and the shop that did the work was crap. They didn't seal the sheetmetal and just seam sealed over lots of the joints so almost all of them rusted out from within. The rear valance on the side I pulled away from the car like a stubborn scab. I felt bad at the beginngin because it seemed like a good looking car but underneath it was a train wreck held together with bondo, seam sealer and luck.

I tried doing two things on Saturday. Attempting to welding the intercooler together for the 90 and getting the pedal assembly out of the jag. My fitment was trash on the intercooler so that took awhile and I only got one side done. The jag has adjustable brake pedal which really made it even more claustrophobic in the footwell. Couple that with the battery being disconnected (so the seat wouldn't move back) and I got very little accomplished. Not even any pictures. I figured I'd bag it and try again on Sunday but I woke up to a horribly tweaked back and sat around swapping between heating pad and ice pack. I'm still sore.

Incidentally, I can't believe thingiverse or the like don't have any files to make tube plugs for pressure testing/backpurging welding stuff! I had to draw some up for the intercooler and they're printing as I'm at work.

But I did see a ton of military rigs on a train when I was leaving work on friday. (I work at the port of seattle).

In reply to iansane (Forum Supporter) :

3d printed tube plugs are a great idea! let me know how they turn out for you! I'd be interested in getting my hands on the files potentially too.

In reply to AWSX1686 (Forum Supporter) :

Speaking as somebody who welds a TON of tubing everyday, the only thing I would worry about is heat. Especially if your weld seam is an inch or so away, like a lot of the joints and stuff I deal with are.

The plugs I use are from TiCon. They're actually quite cheap in some ways - but expensive in others. I realize 300 for the set is pretty steep for a guy out of his garage buying a set of silicon plugs. But I use mine all the damn time and they are worth every penny.

What I would like to see and will probably work on myself - is an elbow cutting jig for making transitions & collectors, etc. THAT is the perfect application for 3d printing. I'll have to fire up fusion360 & my Ender3 and figure something out. lol.

GaryC83 said:In reply to AWSX1686 (Forum Supporter) :

Speaking as somebody who welds a TON of tubing everyday, the only thing I would worry about is heat. Especially if your weld seam is an inch or so away, like a lot of the joints and stuff I deal with are.

The plugs I use are from TiCon. They're actually quite cheap in some ways - but expensive in others. I realize 300 for the set is pretty steep for a guy out of his garage buying a set of silicon plugs. But I use mine all the damn time and they are worth every penny.

What I would like to see and will probably work on myself - is an elbow cutting jig for making transitions & collectors, etc. THAT is the perfect application for 3d printing. I'll have to fire up fusion360 & my Ender3 and figure something out. lol.

I was apprehensive about 3dplugs for back purging exactly for the reason you stated. Heat. That aluminum gets HOT. Especially since I suck at TIG'ing. I haven't tried them for that yet since I also don't have a gas setup for it. But they did work reasonably well for leak testing. I printed a taper and a specific size plug for the intercooler since I was only initially testing one side and I had already chopped off the outlet tube of the opposite side.

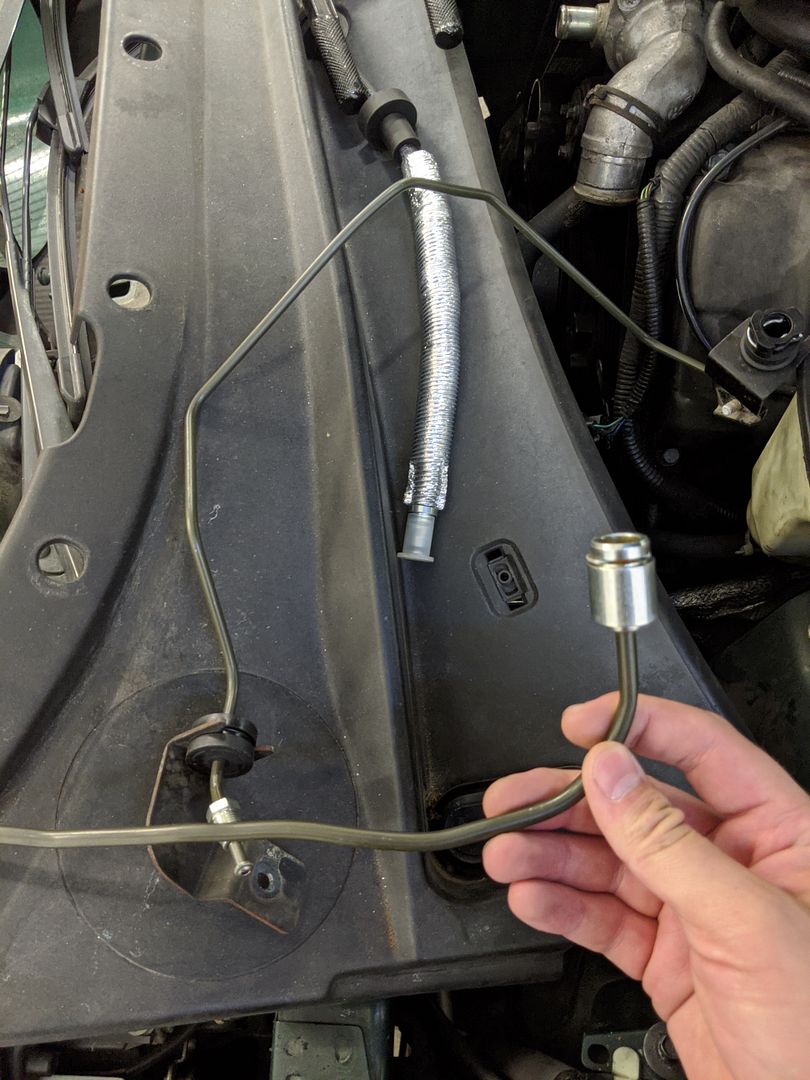

This weekend was kind of all over the place. I finished getting the pedal box/clutch master cylinder into the jag. It uses fairly weird quick disconnect style fittings for the lines. I ordered new ones knowing they wouldn't fit perfect but I could cannibalize them for the fittings. It's like the standard disconnects on GM master cylinders, but backwards. The line has the female and the MC has the male fitting. And they're mostly hardline. Which is nice because I cut the last few inches of either side, bent to point in the direction I needed and I'll have a custom line made when the trans is in and I know how long it'll have to be.

I was also pretty confused on how the pedal return spring works on these. It seems to only "spring back" at the top 1" or so of pedal travel. Anything below that must utilize the hydraulic pressure from the clutch?

Whatever. I hope it works. It'll be a pain to pull back out when the car is back on the ground. I'm still waiting on the new slave cylinder that's coming from across the pond. I have a tracking number but no updates as of yet. Ugh. I'm too impatient. When I got that all bolted down I pivoted to welding.

I welded an elbow to the audi90 intercooler in the hopes of getting a straight shot to the turbo outlet. I realize now (After the turbo and everything is all mounted and torqued down) that I should've welded a 90* on the turbo outlet and then I could've just used a long straight silicone coupler/reduzcer to hit the intercooler. I'm not pulling all that apart now though! Luckily, I found a 2" to 2.5" silicone 90* elbow on amazon that will hopefully work. After a few hours hamfisting my way through TIG'ing (which I've done all of two times in my life so far) I moved on to the trans am.

I found a guy who would make me some customer wheel adapters. I have a set of 4 rear audi r8 19x11 wheels I'm trying to fit.

Audi uses 5x112 and the trans am is 5x120.65. No big deal because I've using a pair of 2" bolt on adapters to run the c6 wheels for a decade or more. However, this guy is deadset on making them hub centric, not lug centric. First off, the trans am uses a cast hub. I don't know how you can make a hub centric adapter fit a cast hub perfectly. Secondly, since it uses a pair of tapered bearings, the hub/spindle stick out a large amount from the wheel mounting flange. So much so they project into the center of the r8 wheel. Which oddly enough uses a smaller hub bore than the trans am. So I'm trying to find a local place that will machine out the center of the r8 wheel so I can fit it over the spindle/hub of the trans am. Then I can commit to a hub bore spec to order from the guy. Since, it seems he won't just run with a lugcentric style. Also, it'd convert from factory m12 lug studs, to the audi m14 lug studs.

Random adapter I picked up but the lug holes are too big. I think these are meant for m14 on both sides.

Old trusty. I've been using this guy for over a decade. I know lug studs/adapters can be a consumable I've just been apprehensive about the quality decline in the last few years.

On the pedal spring return, YES! that is exactly how it is supposed to work. The OEMs funkerdoodled the geometry such that it only applies return pressure at the very top of the pedal stroke, so that when the pedal is down you are only pushing against the hydraulic resistance and not the spring.

In reply to BrianC72gt (Forum Supporter) :

My f250 is similar, except even more weird. The spring on that clutch pedal works like a compound bow almost, once you're past half way, the spring actually helps you push in the clutch. Weird.

AWSX1686 (Forum Supporter) said:In reply to BrianC72gt (Forum Supporter) :

My f250 is similar, except even more weird. The spring on that clutch pedal works like a compound bow almost, once you're past half way, the spring actually helps you push in the clutch. Weird.

I wonder if that's what my '67 Mustang tries to do. If you don't have the clutch adjusted correctly it will actually get over-center and snap the clutch pedal to the floor.

You'll need to log in to post.