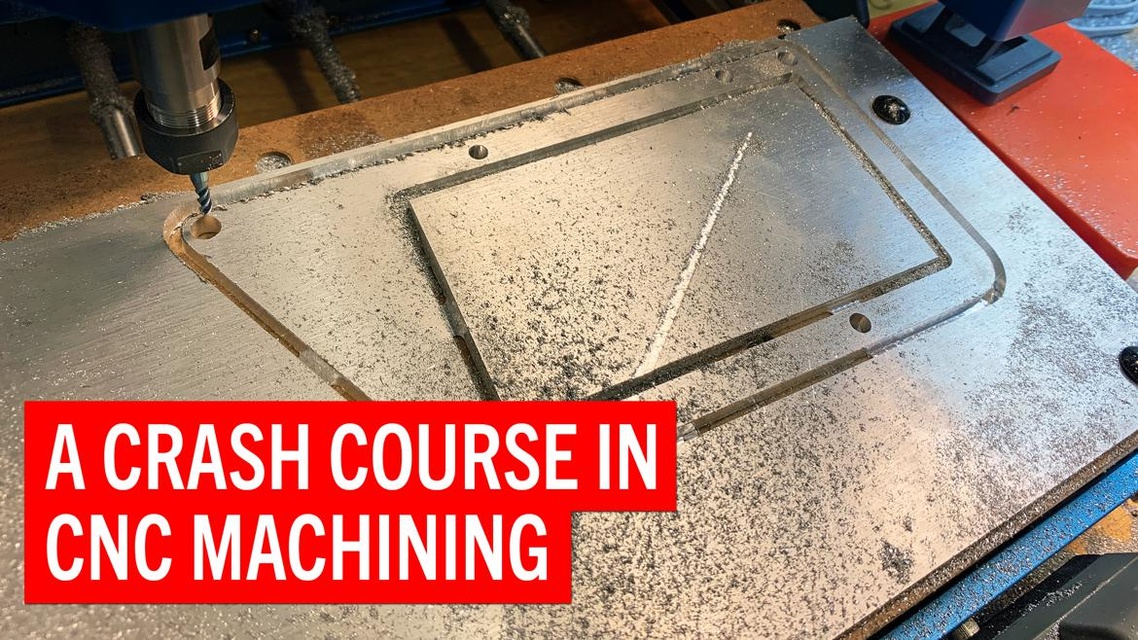

Our series on helping every fabricator build better parts started with the basics: How to draw those parts, design them with a computer, and instruct a sub-$200 3D printer to bring them to life from plastic. Now it’s time to start cutting metal.

Hehe, did I hear someone say CNC crash?

Jokes aside, this is a great article series. I've been drooling at small CNC mills for a couple years.

Some forum members have had good luck with mail order custom machined parts, any chance of an article on those options?

<<We couldn’t find a clear set of rules that categorizes machines as one or the other.>>

I'm reasonably sure that a mill has a stationary cutting head, while the part is mounted to a moving platform,

and a router has a moving cutter head and a stationary platform.

In reply to BimmerMaven :

Depending on the machine the platform or head or both is moving on a CNC mill. The platform might be responsible for certain axis and the head others. Just depends.

I covered that in the first part of the series: https://grassrootsmotorsports.com/articles/technical-drawing-universal-language-making-stuff/

In reply to BimmerMaven :

I don't know if there is a hard and fast rule but I have run both routers and mills, of every imaginable size.

The spindle moves in three of four axis on this monster, but it is definitely a mill.

In a previous job I ran a bellotti 5-axis router. That was cutting composites. fiberglass, graphite and kevlar. If you've ever been on a plane, I probably made part of it.

The main difference as I understood it was the spindle itself. A mill is a torquey machine with soindle speeds up to 5000 rpm. My routers would spin in the neighborhood of 35,000 rpm.

You'll need to log in to post.