Starting off with a warning. This steering wheel is for off-road use only. Any pictures or accounts are for information only. If you chose to try something similar all liability is your own.

That said. I've decided to try to build a steering wheel. I have an old Nardi wood rim wheel that I've been using for my mockups that is ~14-15" OD. It's much to big. I nearly pulled the trigger on either a Kart wheel or a 10x9 Dshaped wheel but reviews of those wheels for regular cars are not favorable (too small and awkward). I owned a MKV GTI which has probably the best steering wheel I've ever used so I looked to it for my shape inspiration. The Nardi wheel provided my design inspiration.

The Nardi is basically a pice of aluminum with pieces of wood glued to the front and back of it. It has no fasteners/plugs and relys on glue to hold everything together. Mine has been through alot as it is at least 30 years old and has been completely submerged in a flood with very little ill effect. I would love to continue to use it but it's just to big and not very "sporty" feeling.

I like everyone like nice things and want the feel of a $300 aftermarket sport steering wheel but I'm decidedly low cost on this sort of thing. This post will take you through day 1 of this build. I am not done so you will be following along, however it is my intention to work on this until it is finished so it won't be but a week or so.

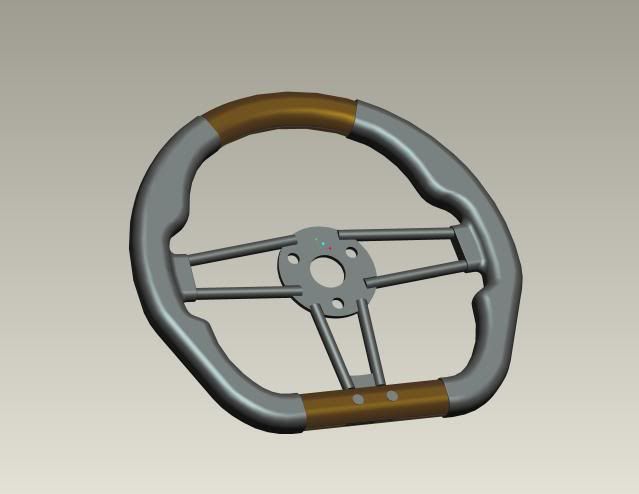

Step 1 was the concept.

I origionally had it designed to use a flat sheet of aluminum as the hub. I then costed that out and found that that sheet of aluminum would be ~$30 from Mcmaster and decided I would just weld up the hub.

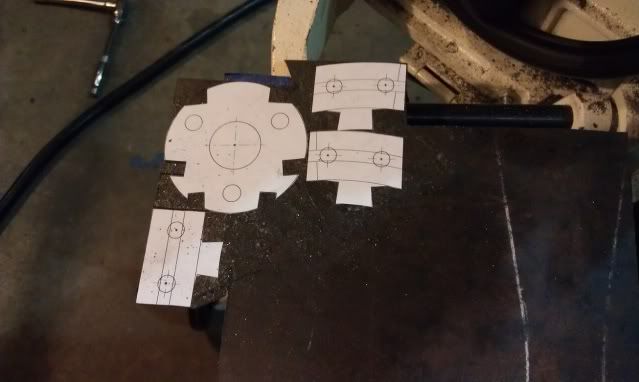

I built the hub up out of 5/16" rod and .125" steel plate. Total cost ~$6 as I had to buy the rod at Tractor supply. I am going to finish weld both sides but welded on 1 side the 3 prongs are in the right spot and flat.

I then Glued the templates for the wood forms which will be glued together clamping the hub in the middle. I will use hardwood dowels ($1) to go through the two pieces of wood ($Scrap from flooring project) and the holes in the 3 tabs creating hopefully a solid stiff sandwich.

I cut out 1 template thus far leaving 1/6" or so for finish sanding. This should allow me to glue the two together and still have enough space to sand to my final desired shape.

And here is the mockup. the gap between the botom bumps and the hub is a little small but I will enlarge is slightly when I get to the profile sanding phase.

Next steps are cut out the other template. Relieve the wood for the metal thickness (1/6" per side so the metal is centered between the wood). Glue/Clamp it together with dowels inserted. Assess overall strength to determine if I want to move forward. Then sand/file/plane down the shape I want on all of the parts. Once that is done I will varnish/seal it and decide if I want to try to leather wrap it or leave it wood.

If I leather wrap it it will be with leather from an old jacket for max cost effectiveness.

So there you go. This will either be a display of how to succesfully build a nice steerign wheel or it will serve as a leason to others of something they should not attempt. I'm hoping this goes over ok and people don't pile on me for how bad of an Idea this is. Realize that I'm building a CAR from scratch. I have fabricated things on this vehicle that a much more life threatening than a steering wheel.

Thanks for looking,

Daniel

jonnyd330 wrote: Looks cool you should wrap that thing in alcantara

I've thought about it. I'll probalby go looking for fabric/old coats/bad bolstered racing seats to steal material from. New alcantara would be out of budget.. Although hilarious.. Hey I covered my $15 home made steering wheel in $75 worth of Alcantara!

Daily Update

I cut out the other half and clamped 1 half to the hub. I used a 5/16 drill bit on high speed to drill the holes to match the hub. I then clamped the two halfs together and drill through the holes in 1 half into the other. After that was complete I put hardwood furniture dowels in to hole it aligned. I was then ready to sand down the profile I had printed.

As you can see I used the Harbor Freight 20 Piece Sanding Drum $7.99. I use very light pressure and High speed. I also highly recomend the Sanding Belt Cleaner $6.99 as this works REALY good at cleaning the drums and can be used to clean files and all sorts of stuff.

This shows how I milled reliefs for the hub metal, I don't own a router otherwise this would have been easy. I chucked up a center bitless hole saw and slowly fed the part in whith the drill running. I went slow in about 6 passes. Worked great.

And here is the Mockup with the hub in place. Fits up good, the hub is flat and spins centered.

Show with my Hand for scale.

I am happy with progress thus far. Next is glue/clamp it together and then start shapping it to my final desired shape.

I also painted the Hub in preparation for gluing together.

Dont' want to be a downer, but dont' most steering wheels have some sort of metal center running through the whole perimeter of the wheel itself? Maybe a sheet of steel like you made the center hub out of and attach the spokes and everything to that then apply the wood? Looks like you've already got the wood glued and everything, so I may be too late...

Conquest351 wrote: Dont' want to be a downer.......

No worries. I've thought about this. And my conclusion was I'm not sure its necessary. Some wheels are not full circles and open on the top. My nardi has a approx. .2 x .5" band of aluminum running around it. The other wheels I have dismantled some have rods some have sheet. Some Karts, lawnmowers and off highway equipment have plastic injection molded wheels. The glued wood should have more than enough strength for normal use. The steel reinforcement I suspect has more to do with keeping the wheel from cracking during accidents when people impact them. I'm really only concerned that someone will push the car from the top of the wheel causing damage. Loading during use should be low as the car has harnesses that will be used 100% of the time and the steeringwheel will be removed for driver egress.

That said if it feels even remotely flimsy or ever makes any cracking sounds I will try again with reinforcement or call up Momo. Or if anyone knows of any regulations requireing metal reinforcement in the wheel by sanctioning bodies I can add some. I may fiberglass/carbon wrap it then it should have no problem.

I will trust this wheel more than an EBay Chinese knockoff for sure though.

Looks good, got any ideas for a center cap?

Also I hope the wood you're using is stiff. From a safety standpoint I agree the metal core isn't really necessary, but you know this may end up feeling like a floppy gag wheel as found on many '50s/'60s sports cars...

I did some checking. This type of wheel will not be legal for SCCA road racing (NASA looks like they don't care). For Autox it is legal. As near as I can tell it doesn't matter if I do the metal core or not SCCA just blanketly says no wood rimmed wheels.

GameBoy, It is quite stiff. I can't deflect the halfs of the wheel by hand. If when completed and mounted it is not stiff or feels sub-par I won't use it.

I will probably be following this up with creation of a Road course" legal wheel that will cost me more (.190 aluminum sheet core throughout the wheel, stiff foam for shape and then Carbon/Fiberglass over the foam). This one will be my Street/autox wheel that I won't care if it gets wet, droped, dinged or scratched. Or it may go in the trash and you can all say I told you so ![]() I'm ok with failure I will have learned alot either way. I hope people get the feeling that this is an Idea being explored and not me trying to say "this is how to make a wheel!". This is simply how I am trying to make a wheel. If this is the most dangerous thing on the car I will be a Happy happy man as I've done other stuff that has much higher potential for danger than a wood rimmed steering wheel.

I'm ok with failure I will have learned alot either way. I hope people get the feeling that this is an Idea being explored and not me trying to say "this is how to make a wheel!". This is simply how I am trying to make a wheel. If this is the most dangerous thing on the car I will be a Happy happy man as I've done other stuff that has much higher potential for danger than a wood rimmed steering wheel.

And just FYI I do appreciate the concern/interest. I hope you don't feel I am flipantly blowing off your concerns. It makes me critically think/examine what I'm doing to make sure I feel it will work as I think it will. Example when I embarked I was unaware that SCCA bans "wood rimmed" wheels for W2W. It won't affect me at this time but I only looked into it because of people bringing things up.

I think it's cool, I like how you're basically sharing your experiment with us. Might encourage us to do the same or show us why we shouldn't.

Is that 2 layers of 3/4" plywood? That would be really stiff, normal steering loads won't cause much if any deflection. A typical 50's/60's steering wheel was a 1/2" piece of plastic with maybe a metal band through the middle. Those were flexy!

And just like that it is pretty well done.

Today over my lunch hour I came home to glue and clamp the wheel together. I put a mess of glue on and even more clamps.

This evening after everyone was in bed I snuck out and started shapping. I used my drill press to hold the sanding drums swung the table out of the way and started sanding. I got the shape very close to what I wanted with 150 grit drums. I used the 2" 1" and .5" diameter drums to get the detail I wanted.

I then did some block sanding and some hand sanding to get the wood ready for stain. Wood finishing isn't my strongest activity but I threw some red mahogany on the wheel and will do a though polurethane job on it once it dries.

At this point really this project is done. The wheel took about 6 hours of spare time to build. It cost about $10. It's fairly light, stiff and is exactly the size/shape I wanted.

Can't wait to get it out in the sun and use it. I will update this if I decide to make any changes or attempt to wrap part of it.

Thanks for following along.

Daniel

Nice job. What are you going to use it on? I just looked back to the first post and didn't see that you told us.

It does look good. I'm interested because I want to do something for my Valiant, and have been looking at related projects online.

If I were you, I wouldn't want those metal bars between my fingers. If anything caused the steering wheel to jerk suddenly, you might be out a finger.

scardeal wrote: If I were you, I wouldn't want those metal bars between my fingers. If anything caused the steering wheel to jerk suddenly, you might be out a finger.

Decent point. I will have to think about covering them or otherwise filling them in to keep the digits out of them..

They are wide enough that getting your figers in/out should be fairly easy. I've seen a lot of Hot rod type aftermarket wheels that have large openings that are similar, and even some OEM ones (Current Honda civic and I'm sure others) that have finger trapping openings.

My next one will have solid Aluminum spokes and SCCA W2W legal construction materials. Which apparently include anything you can possibly make it out of that is not wood.

A steering wheel does very little if the cars on jackstands, unfinished ![]()

![]()

Also, if youd like, I am capable of casting custom parts from aluminum. If you want some bits fabbed up, perhaps we should chat. I work for cheap (free) - so long as I have the rights to the finished patterns...

4cylndrfury wrote: Also, if youd like, I am capable of casting custom parts from aluminum. If you want some bits fabbed up, perhaps we should chat. I work for cheap (free) - so long as I have the rights to the finished patterns...

...filed away for future reference...

I took a cheap 10" deep dish steering wheel like ~This~, that someone gave me, and shortened the inner spokes, "flattened" it and welded it back together.

Then flipped it over and mounted it in my ~Red Rat~ (built entirely from cast-off bit and pieces).

The stock setup in this car would have a huge, in-you-face steering wheel. This little wheel makes things much nicer and does not require excess effort (my race-Spridget also has a 10" wheel).

You'll need to log in to post.