So to make a long story shortish we have a 231 oddfire Buick V6 with a factory HEI distributor I more or less (without a lathe at my disposal) ruined during a botched pickup replacement (ejected the upper bushing and then drove it back in too far). Reman oddfire distributors of questionable quality are ~$120+, an all new evenfire 231 HEI of questionable quality is $65 delivered, so I figured "hey, I've got a set of good low wear oddfire distributor guts (pickup, star wheel), so I'll just swap some stuff around and come out ahead with all new electrical stuff" (this car has a sudden intermittent stall issue we were working on). So I did that, and and later learned this is a trick the jeep crowd uses, cleaned all the swarf out it, made sure the star wheel was lined up right after greasing the advance mechanism (I reused the entire oddfire shaft and advance mech), made sure the gear is on with the dimple pointed to the rotor alignment tab, etc. I feel it was a thorough job.

The trouble starts when we go to put it in the car and roughly static time it to get it started, with #1 at 12* BTDC (confirmed TDC mark is correct with screwdriver in plug hole) the distributor was dropped in, engine rocked to get it in all the way over the oil pump drive, distributor turned to line up the star wheel points with the the "fat" points on the pickup (being oddfire it's important this be phased correctly), and having tried every gear tooth on the distributor, twice, can't for the life of me get the rotor to land under the #1 cap contact, at best it seems to land adjacent, at worst in between contacts, even after abandoning the idea that it need to be under a specific post on the cap (which I later came to understand can't be done on an oddfire v6) it wouldn't line up.

The only thing I can find different between the distributor bodies is the cap index tab slot is 90* off, and that may create a problem because this dizzy will only twist like 80* between running the wire harness into the head, a cap hold down boss into the head, or advance can into the radiator hose. Push come to shove I can put the berkeleyer in a (distant) Bridgeport I have occasional access too and add another slot, or just do some careful layout work and use a file, but I'd rather not do that due to time constraints and how this is allegedly supposed to work, and on old Jeep motors designed around a small cap distributor at that. It's possible I managed to get it 180 out rocking it around, but I kinda doubt that, would have confirmed it but we ran out of daylight. The only other possibility is I'm stupid and working on a bad line up procedure.

Thoughts?

you said you found TDC with a screwdriver, are you sure it wasnt at the top of the exhaust stroke? can you verify both valves are shut?

In reply to edizzle89 :

Before pulling the old distributor out I made sure I was on the timing mark and the rotor was under #1, the screwdriver was just confirmation the balancer ring hadn't slipped. The only way it could have ended up 180 out is if I forgot which way I rocked it once and got upside down. Next time I'm out there I'll put the battery in it and feel for compression while cranking, or borrow a bore camera. Engine is too filthy for me to be comfortable popping a valve cover off if it can be avoided.

It sounds like either the pickup coil is out of time with the distributor body or the rotor is out of time with the lobe wheel. Is it possible that you've got the advance mechanism assembled wrong? Did you remove the correct teeth from the lobe wheel? Will the pickup coil go on more than one way?

Pickup only goes one way, the vacuum advance attaches to it.

Advance mech is assembled correctly per this picture, I didn't remove teeth from the lobe wheel, I used the old oddfire 3 point wheel.

not sure if this is what you are describing but the oil pump shaft in the center can be moved/ rotated/ allowing the teeth to engage in an In between sort of spot that may give the Posistion you want. just a touch of rotation, kinda the distance between teeth.

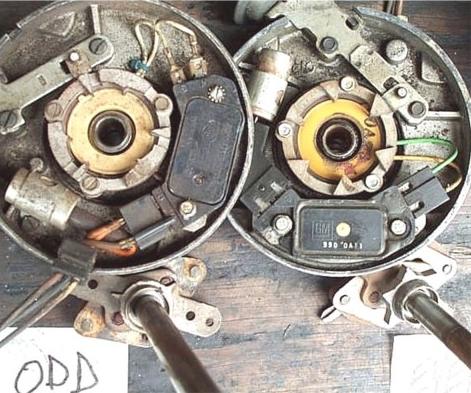

Ok, I think I see where I screwed up. In the usual even to odd conversion you grind 3 lobes off the even fire wheel, but this gives you a different lobe-rotor phasing than a genuine odd fire wheel that I used, 30 degrees of difference by the looks of it, which is about how far out of whack I kept coming up... You can see it in the pic I posted above, none of the points on the even fire assembly are in line with the rotor mounting plate, one is on the oddfire.

So my options are either pull it all apart again and put in the relatively sloppy (not that super tight timing is required for a stock smog motor, but still) chinesium wheel with 3 points ground off, or put a new cap index slot in the body (and by my math that's not super critical, one degree is like 0.020 on the circumference, the hard part will be laying it out).

That sound right?

BrokenYugo said:Ok, I think I see where I screwed up. In the usual even to odd conversion you grind 3 lobes off the even fire wheel, but this gives you a different lobe-rotor phasing than a genuine odd fire wheel that I used, 30 degrees of difference by the looks of it, which is about how far out of whack I kept coming up... You can see it in the pic I posted above, none of the points on the even fire assembly are in line with the rotor mounting plate, one is on the oddfire.

So my options are either pull it all apart again and put in the relatively sloppy (not that super tight timing is required for a stock smog motor, but still) chinesium wheel with 3 points ground off, or put a new cap index slot in the body (and by my math that's not super critical, one degree is like 0.020 on the circumference, the hard part will be laying it out).

That sound right?

That does sound right and yes, it's not super critical. As long as the rotor is more or less under the teminal when it fires it'll be fine.

In reply to APEowner :

Yeah I was reading that Chevy even made some "semi odd" engines where the crank pins were split, but not to full even fire spec, and they used the even fire cap and called it good enough. Rather informative article here http://www.britishv8.org/Articles/Buick-Odd-Fire-V6.htm . On the Chinese even fire body the slot isn't even machined, just a feature in the raw cast aluminum.

For posterity's sake.

Locating and carefully filing in a new cap indexing slot 90* off from the evenfire one, to match the oddfire body, did do the job. I just used calipers, a sharpie, and a sharp knife to make a paper strip 1/4 the circumference of the body, checked my layout work by making another strip off the old body between the cap index slot and the machined in wiring grommet slot, it agreed well. Then filed the slot to match dimensions of the machined in slot in the oddfire body (the new body just had it cast in). This put the rotor partway under the #1 cap terminal, and all the way when I started playing with the advance mechanisms like it would be when actually running. Had the car back on the road in half an hour.

You'll need to log in to post.