Can anyone help me figure out if shortening uca and lca on an amc eagle 1 1/2" each side be doable.I don't mean the actual cut,weld,plate,etc (I can do that) I'm talking about the effect on suspension geometry.Would it be better or the same if I narrowed the cross member 3" instead of each control arm 1 1/2"?Thanks and really appreciate any suspension savvy guys help.

I would trust a shortened cross member verses shortened control arms.

Thanks Appleseed I not worried about shortening the control from a safety point as far as welds are concerned.I need to know if shortening them or narrowing the cross member will have a negative effect on my suspension from a handling standpoint.I hope it has a neutral effect.If it has a positive effect that's a bonus.

Shorter arms would reduce wheel suspension travel an possible increase tire scrub.

Draw it out on a graph paper and compare.

In my opinion, not the best idea.

Narrowing the cross member is the way to reduce the cars track width. But this may still be a problem if one or more suspension links are attached to some other part of the car and not just the cross member. Say on a strut suspension the alignment will go way positive on camber. In the case of say a Miata or similar suspension where all of the links are mounted to the cross member then it has no effect other then a narrower track.

jimbbski The uca are attached to the shock tower like an early mustang and falcon.I had planned on moving the uca mounts to match the narrowed cross member.The cars track width is 60" and I'd like to narrow it to 57".Do you know what effect on handling,etc. this would have?

Question: Why? Just curious as most racers are looking to make it as wide as possible with control arms as long as possible.

turboswede I'm converting a hornet to awd by using all stock parts from an amc eagle.The eagle has a wider track width and uses flares to cover the tires.I do not like flares on a hornet so plan to narrow the eagle front suspension/engine cross member to have the same track width as the hornets rear track width.

singledownloop wrote:

I'm converting a hornet to awd by using all stock parts from an amc eagle.

I like the sound of this.

Will narrowing the crossmember cause any clearance issues with the engine?

stuart in mn the beauty of narrowing the track width is that I don't have to actually narrow the cross member.The lca hang of the bottom of it and there is plenty of room to move the mounting point of the lca in toward the center of the cross member.I have the hornet in the garage and ready.I plan to use 18's on front and back and have it nice and low.There will be no clearance issues.The engine compartment is huge and they were available with a v8.The amc v8's are externally about the same size of a big block mopar 440 engine.This fits between the frame rails easily.

singledownloop wrote:

turboswede I'm converting a hornet to awd by using all stock parts from an amc eagle.The eagle has a wider track width and uses flares to cover the tires.I do not like flares on a hornet so plan to narrow the eagle front suspension/engine cross member to have the same track width as the hornets rear track width.

Projects like this are why I like this forum. Carry on and good luck with it.

I guess my question now is what is the backspacing of the wheels? Could that be changed enough to loose some of that nasty track width? Or at least reduce the amount you have to move it?

I do know something about the AMC's. My sister's first car was a 1970 Gremlin and my father bought a 1976 Hornet to drive to work. I worked on both.

The wheel bolt pattern is the same as Fords so there may be some interchange there to investigate.

jimbbski it's cool you had amc's in the family.I'm a died in the wool rambler and amc guy.The eagle uses positive offset wheels but still needs flares to cover the tires.The eagle track width is actually 4" wider then the hornets.I'm going to narrow the track width 3" with the cross member and 1" with the wheels.

Flares would be the easiest thing to do. They can make anything look better. Just look at the Boxflaresthread.

Flares are not an option in any form at all.The lack of flares is a very major design aspect of this build.I do agree flares look great when done right by someone that wants them.

I'm here for pics of said creation.

Shortening the control arms will increase the amount of toe and camber change the tires sees during use, probably not a good idea.

another thing to think about is if you shorten the control arms then you will have to have shortened cv shafts. it may just be me but i would try to keep the cv's stock length so that if they ever get worn out you can get a new one off the shelf without having to have have another one custom made

edizzle89 I will have to shortened cv shafts to achieve my goals.

mr2peak I plan to follow advice and not shorten the control arms but relocated them.

singledownloop wrote:

edizzle89 I will have to shortened cv shafts to achieve my goals.

mr2peak I plan to follow advice and not shorten the control arms but relocated them.

Given the number of shared parts used in the AMC world, I'd be surprised if the CV joints weren't able to be swapped to a set of shorter shafts. Check with raxles.com (a GRM advertiser and well versed in the world of CV Joints) and see if they can find some shorter shafts. Otherwise you'll need to shorten the shafts, respline and harden them (have two sets made so you can have a spare set in case you bust one).

Don't labor under the misconception that your factory geometry is correct or even "good enough" Most RWD American cars of that era were still based on early 60's designs and had lots of bump steer and gained silly amounts of positive camber under compression. Shortening the upper arm is common to alter camber curves.

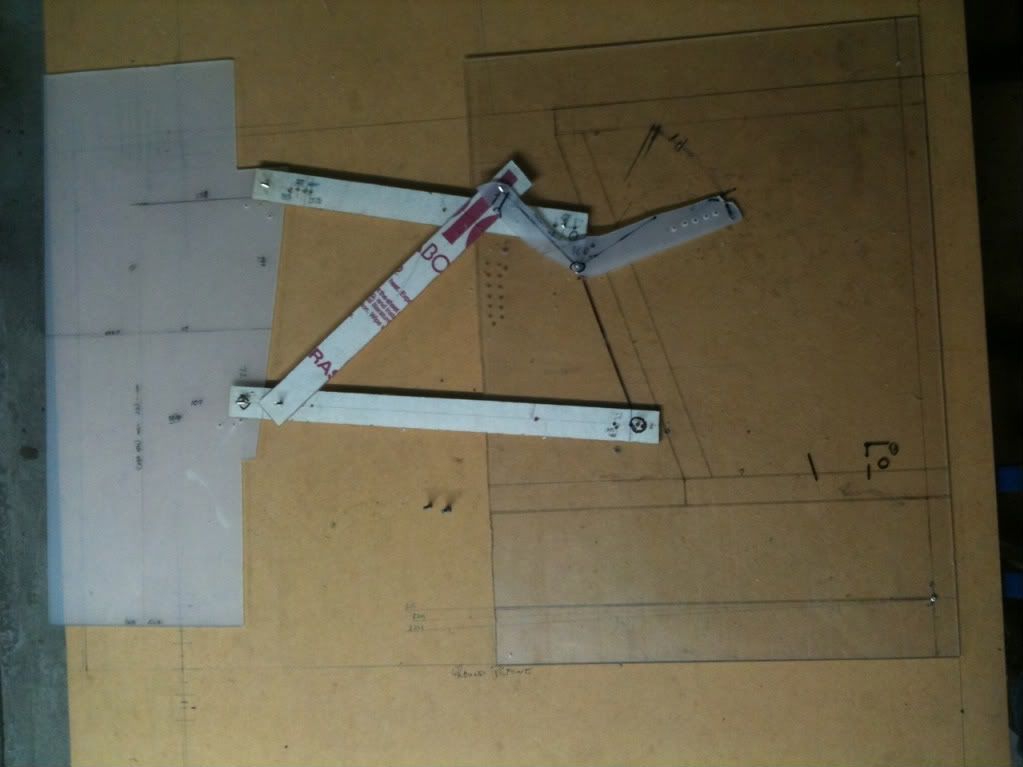

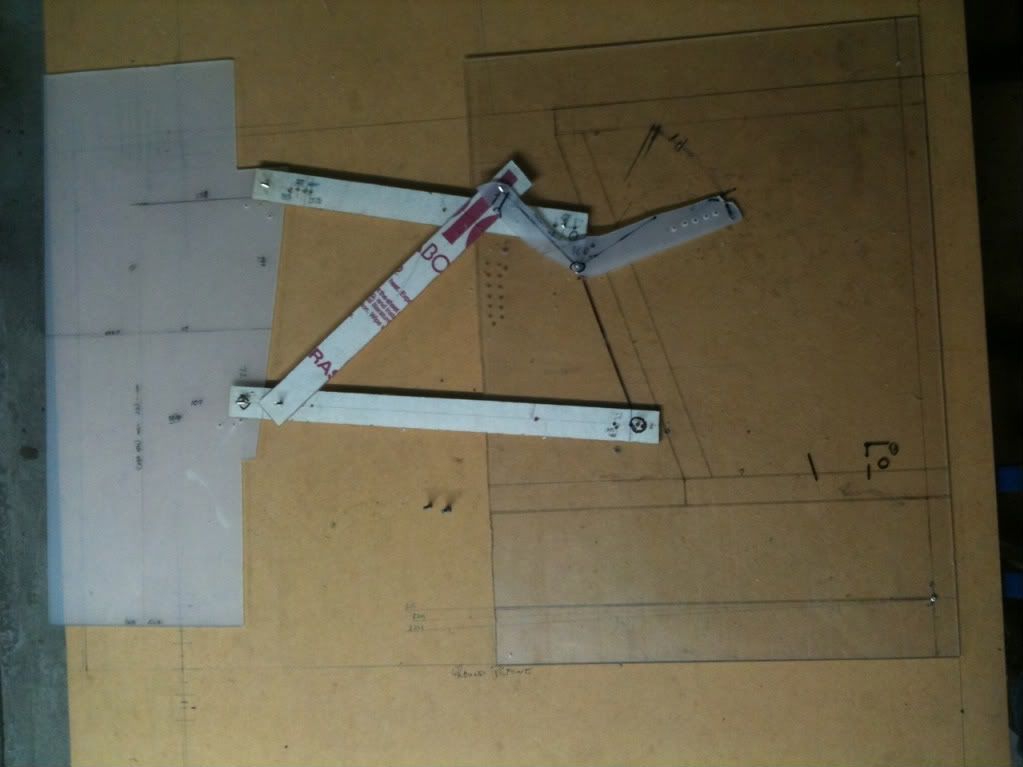

I say arm yourself with various measuring devices, build a string computer and see what happens.

Start by shortening the lower arm to the track width you need and then see what length upper gives the camber curve you require. Play with mounting points to tune the roll centers and you should be in the ballpark, or at least miles better than what AMC let it leave the factory with.

turboswede I know the amc guys use s10 4x4 axles on there lifted eagles because they are a little longer.They are a bolt in so I plan to research gm axles.

Ditchdigger I've never designed a suspension.I don't have an assembled eagle front end or enough parts to mock one up to measure.I've never built or used a string computer.Any chance you want to crunch the numbers

Find a copy of this book if you can.

http://www.amazon.com/Race-Rally-Car-Sourcebook-Competition/dp/1859608469

Local library perhaps? It lays out the string "computer". There are no real numbers, just intersecting lines.

I will try and photograph the necessary pages if I have time.

I know certain highly prepped autocross miata are narrowing the crossmember, and I'm pretty sure they are making the right move, but the amc suspension is probably less than ideal to begin with.

A friend has ran a custom car shop since 1976.He is constantly installing different width aftermarket mustang II crossmembers.The original spindles and control arms are often used.While not amc suspension it's just an example that comes to mind,he builds pre-1960 rods.He put a 2" narrowed mustang II with stock arms and spindles in a 59 rambler american for me years ago.

If anyone can help me figure this out it would be much appreciated.I'd ideally like to narrow the control arms instead of the crossmember.I don't trust myself figure out if it will work or not before modifying parts.

Driven5

HalfDork

12/4/14 11:30 a.m.

I'll second starting with the 'string computer' CAD (Cardboard Aided Design) idea before finalizing any plans. If you're actually concerned about the quality of the suspension geometry, it will be well worth your time to research it further and build a basic understanding for yourself. But it will really help you to have the components on hand before making any final decisions. In addition to the camber gain and roll center height, you'll want to check the scrub radius that your desired wheels will give you with those spindles, as well as watch out for any undesirable bump steer effects.

Here is a good primer.

If you're not overly concerned with the quality of the suspension geometry, just build it and drive it like hot rodders have been doing for decades.