Nick_Comstock wrote: I haven't read everything here so forgive me if it's been mentioned but do you have a flow bench?

Top of second page.....

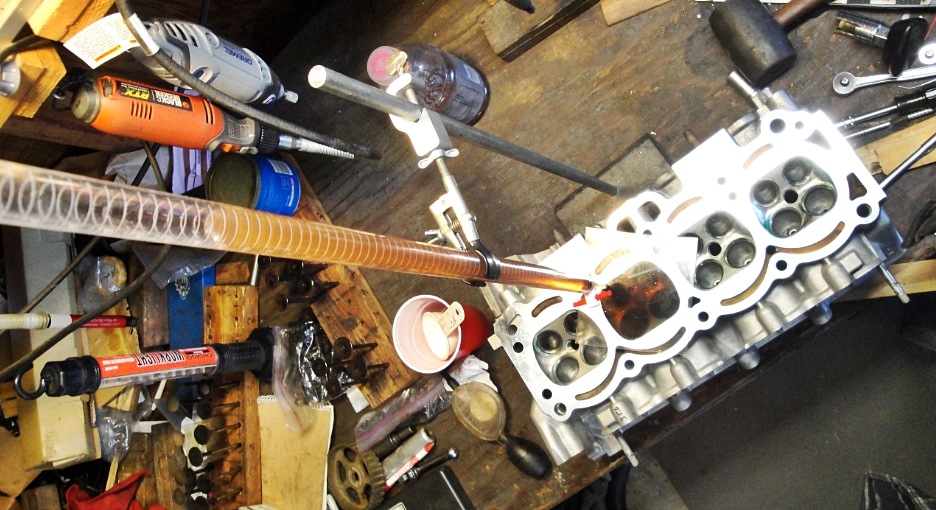

oldeskewltoy wrote: A discussion on porting generally leads to a discussion on testing the porting - the before, and after effects. A great tool for testing port work is a flowbench.I used a kit found on the net for my bench (I do NOT recommend the model I have because the interface is NOT user friendly... and the manual was NOT written in a logical, methodical fashion) I then built my bench so it could be portable (if you've seen my work space you'd understand) I can now do flowbench testing on... 82mm bore, 84mm bore, and now.......

86mm bores

The 82mm adapter I got initially for testing Toyota 4AG/AF heads, and Honda B series heads...

the 84mm adapter was made for testing Toyota's 7MG head... The 86mm adapter allows for testing MANY new engines - Subaru/Toyota FA20/4-UGSE, Mazda/Ford F2T, Toyota 1J/2J, Nissan SR20, Nissan RB25/26, Toyota 3SG... to name just a few... A flowbench is just a tool... a special tool, I'll grant you, but like any other special tool (torque wrench, electrical meter, English Wheel) it requires a knowledgeable user, to get the most from the tools use.

I would love to try my hand at porting. I like the idea of taking what is already there and making it better rather than just throwing parts at it. But, I am afraid of making it worse than it was. I just can't see doing anything other than cleaning up the casting without a flowbench so I can actually see what is being affected. Thanks for showing your work, it is inspiring.

Nick_Comstock wrote: But, I am afraid of making it worse than it was. I just can't see doing anything other than cleaning up the casting without a flowbench so I can actually see what is being affected.

There are a few things you can do without a flowbench...

Get those chambers cleaned up, raise the chambers resistance to detonation by removing the chamber flaws.

Also with a burette you can measure the chambers in order to equalize chamber volume

Who wants to gut/mild port a lower intake for a Honda for me?

Wanting to go from this:

http://s1310.photobucket.com/user/AccordCD7/media/photo5_zps38b7f58a.jpg.html

To as close to this as possible. Already cleaned up/matched the ports at the head with a dremel and started grinding away in the plenum. This one doesn't look that great, but gives an idea.

beans wrote: Who wants to gut/mild port a lower intake for a Honda for me? Wanting to go from this: http://s1310.photobucket.com/user/AccordCD7/media/photo5_zps38b7f58a.jpg.html To as close to this as possible. Already cleaned up/matched the ports at the head with a dremel and started grinding away in the plenum. This one doesn't look that great, but gives an idea.

Is there any empirical evidence showing opening that plenum that much offers an improvement?

Just as a POV...

from another forum said: Then you port match the head

Port Matching - 90%+ of the car performance world do NOT understand what "port matching" is.... To make this as simple as possible.... "port matching" is using a flowbench to check that your port flows match. Let me repeat that... and for you to let it sink in... "port matching" is using a flowbench to check that your port flows match.

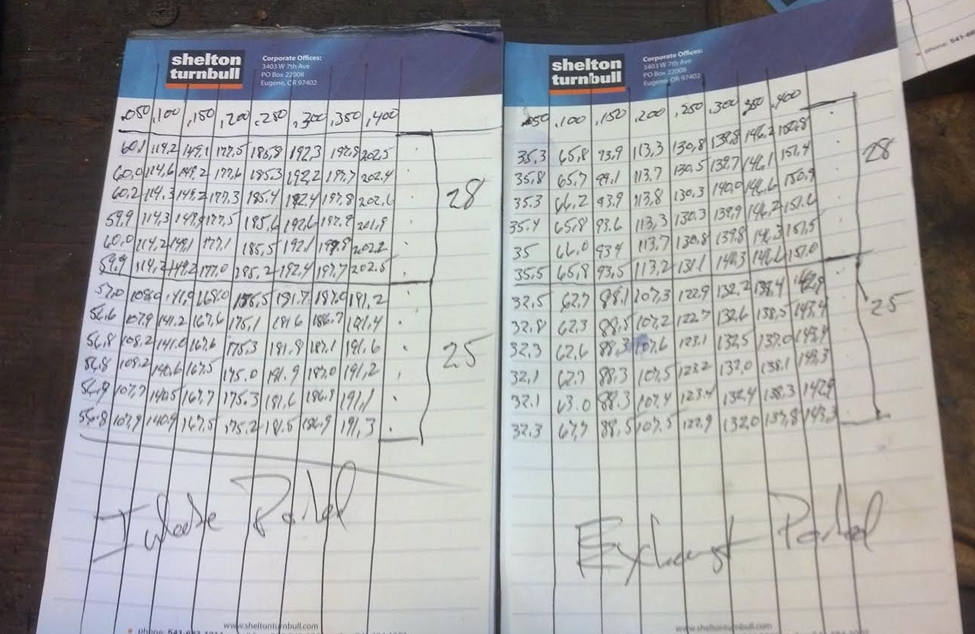

THIS is "port matching" I have the 4 exhaust ports flowing VERY similar volumes at similar lift points around similar valves... and with all of that, there is less than a 1% difference across the board.

.

.

.

Gasket matching is another story...... On the exhaust side... the gasket is what we'll change to fit what "we" want.....

In reply to oldeskewltoy:

Big improvement in top end power with little to no loss in torque, when tuning is applied. Cuts the runners down about 3", much larger plenum volume. Velocity is already pretty high, the factory manifold starts to create vacuum around 5500rpm, fuel cut is about 6400.

hmmmmmmm, NOT KNOWING Honda....

the two manifolds are not the same...

this is definitely a 4 port intake

The large one you show...

I believe began life as an 8 port intake....

Yeah, just using it as an example. All the pictures of a ported F23 manifold like I want aren't hosted anymore or something.

beans wrote: Yeah, just using it as an example. All the pictures of a ported F23 manifold like I want aren't hosted anymore or something.

flap wheel[s] should handle most of it.......

I wouldn't cut anything down until I'd have both parts of the manifold to check.... not sure about other porting specialists... but I couldn't give you an estimate until I figured out how long it would take.......

I would love to have you run through a spare F23A1 head and intake manifold for next year. Shoot me a quote when you get a chance. No rush, I wouldn't even make a move on something until after the challenge, so it'd be around January before I could get something together.

beans wrote: I would love to have you run through a spare F23A1 head and intake manifold for next year. Shoot me a quote when you get a chance. No rush, I wouldn't even make a move on something until after the challenge, so it'd be around January before I could get something together.

send me an email when you are ready.... (click on my logo to get to the contact page)

typically... a 4 cyl, 4 valve head costs between $600 and $800 for port work - this does NOT include ANY rebuilding costs. The intake manifold shouldn't run over $250

Nick_Comstock wrote: I haven't read everything here so forgive me if it's been mentioned but do you have a flow bench?

What I've been doing this week........

What kind of typical gains(HP or in flow on the bench) have you seen/expect from a small(1.4-1.6l) DOHC 4 valve per cyl head?

I'm not sure anybody had gone all out on a 1.5l Mazda2 engine yet. I'm curious how well(or not)it would respond to some porting and bigger valves/cams. (Prepared class)

If you're familiar with the limited rules of Street Prepared, only porting 1in into the head, I'm assuming the gains are very little if any?

flatlander937 wrote: What kind of typical gains(HP or in flow on the bench) have you seen/expect from a small(1.4-1.6l) DOHC 4 valve per cyl head? I'm not sure anybody had gone all out on a 1.5l Mazda2 engine yet. I'm curious how well(or not)it would respond to some porting and bigger valves/cams. (Prepared class) If you're familiar with the limited rules of Street Prepared, only porting 1in into the head, I'm assuming the gains are very little if any?

I typically advertise my port work adds 3hp to 10hp on a 4AGE depending on original casting quality.

BUT.... typically more than just a head goes into one of the engines I've built heads for, often times there are cams, more compression, and more attention to assembly specifications - such as gasket thicknesses to improve/optimize "squish". So far as I know none of my clients has only had the head done, so I don't have a hard hp number to offer.

The only hard numbers I have are from my flowbench. Using that as the scale, I've managed to improve flow on 3 types of 4AGE heads (smallport, largeport, and now Blacktop 20V), I've also managed to improve flow in an SR20DE head.

As to working a 1.5 L Mazda 2 head, a full inspection would be necessary. Ideally you have a few spare heads so they could be cut up to show available room for O/S valves and porting.

Street Prepared is very limiting... a good 3 angle on a carefully researched* original casting is your best bet.

You'll need to log in to post.