Stampie said:Forgive my lack of terminology but how much of porting is just smoothing the rough casting versus hogging it out?

Btw this is probably my favorite thread here. I always get excited when it pops up to the top.

It all depends.......

For example... on a largeport 4AG head, the port itself is too large, so I tend to clean up the port casting... but when it comes to the valve seat, and bowl... there is a whole lot more work then just removing the casting marks.....

another good example of this is my current project. A Toyota 1G-GTE head. For those not in the know... Toyota's 1G is a 2 liter inline 6 cylinder. - bore 75mm(inder 3"), stroke 75mm. This particular head, 1G-GTE is a head used with the turbocharged version of the engine.

The ports themselves are nearly the same size as a 4AG port, but the intake valves are even smaller (4AG=30.5mm, 1GG=28mm). So very little was done on the ports themselves, but work inside the bowls, as well as shortening the valve guides goes a long way to improving flow, and boosting port velocity.

more to come........ ![]()

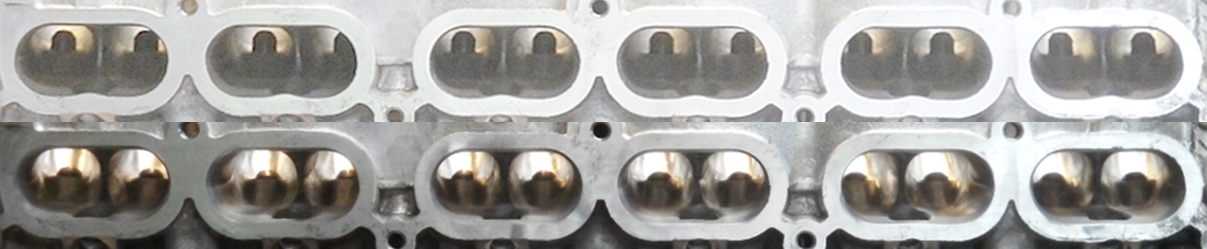

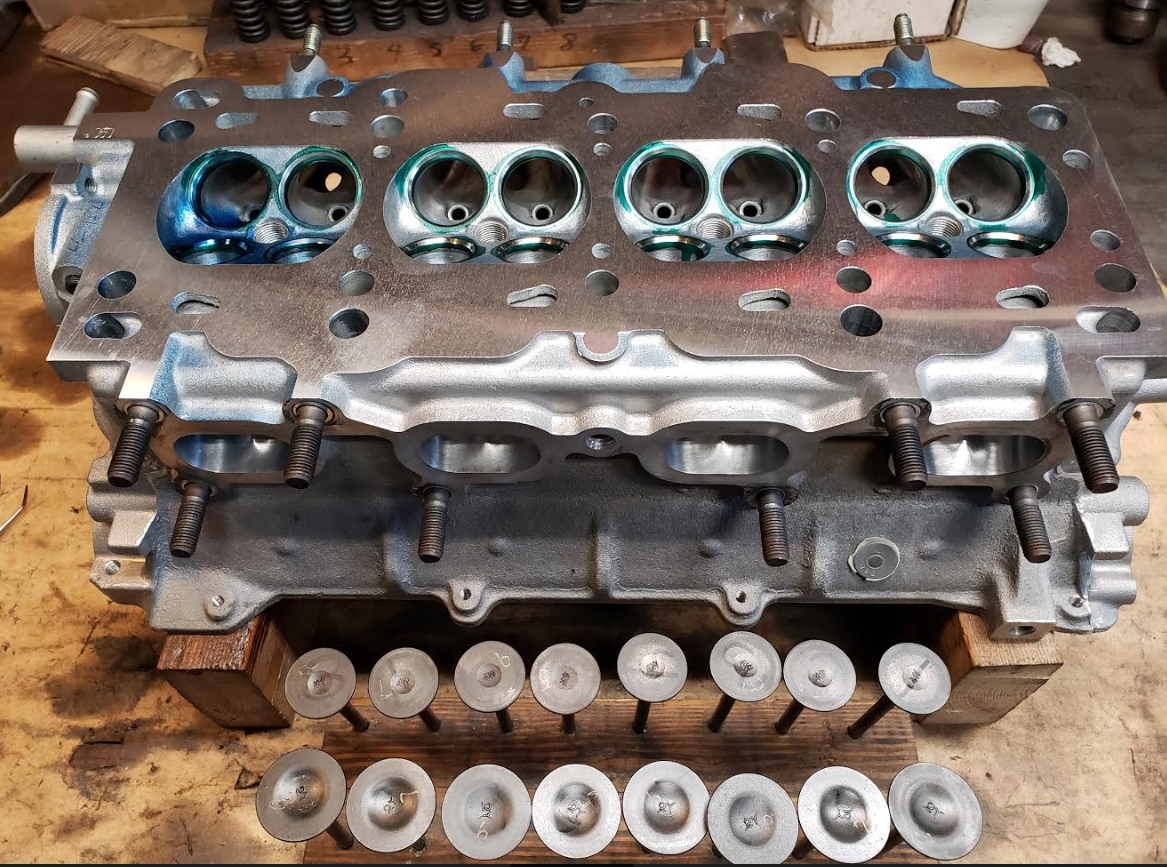

Touching up a BP4W....

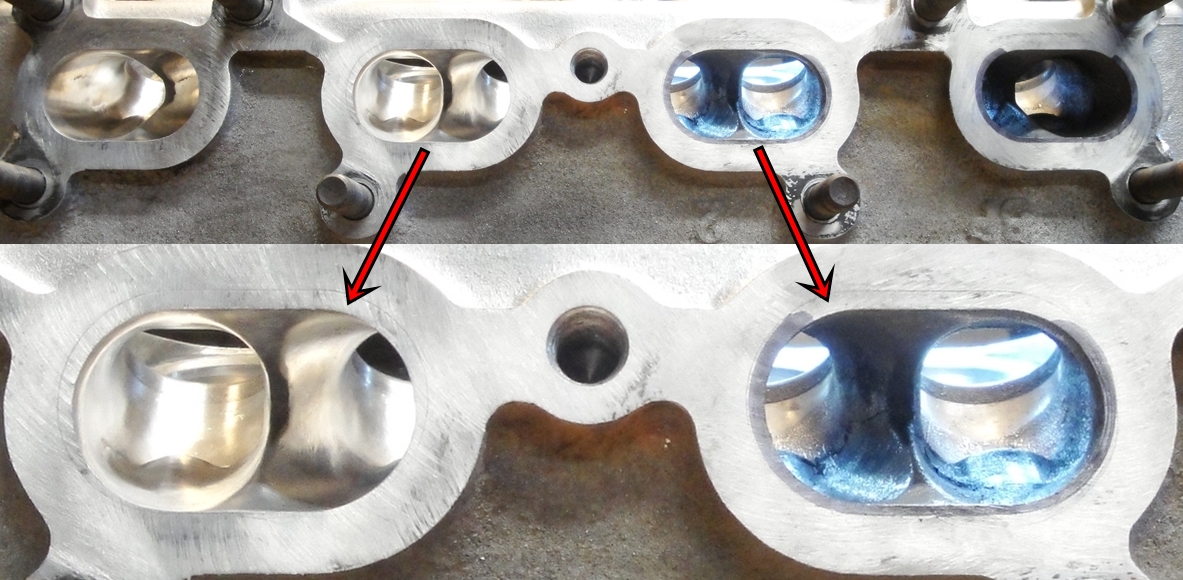

7 of 8 intake bowls worked.... can you find the unfinished one?

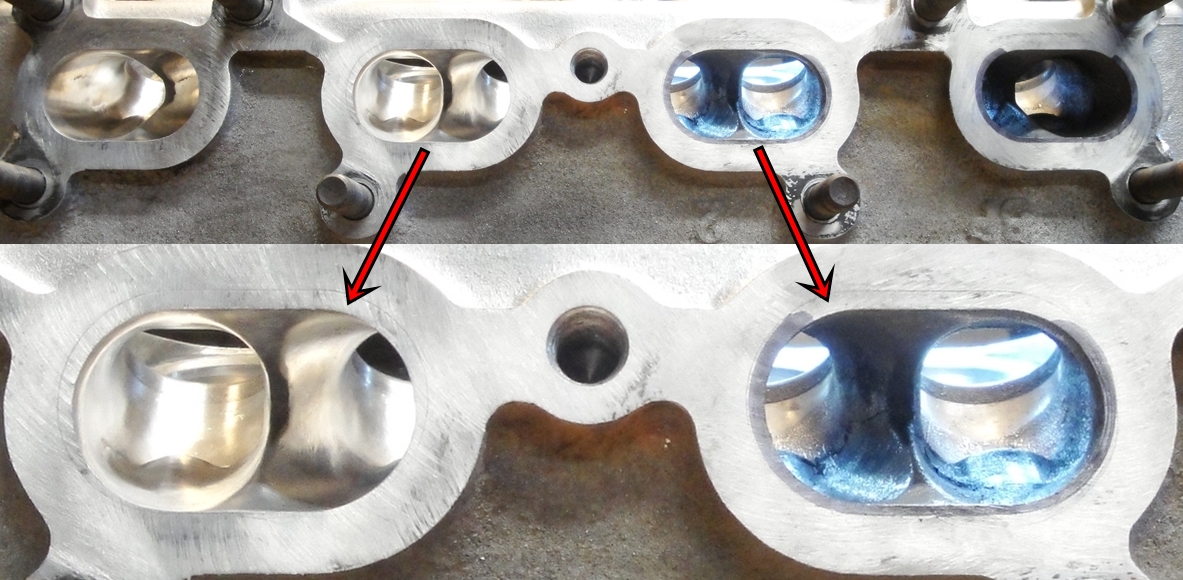

working the exhaust side too...

and a little before/after on that port.....

more to come........ ![]()

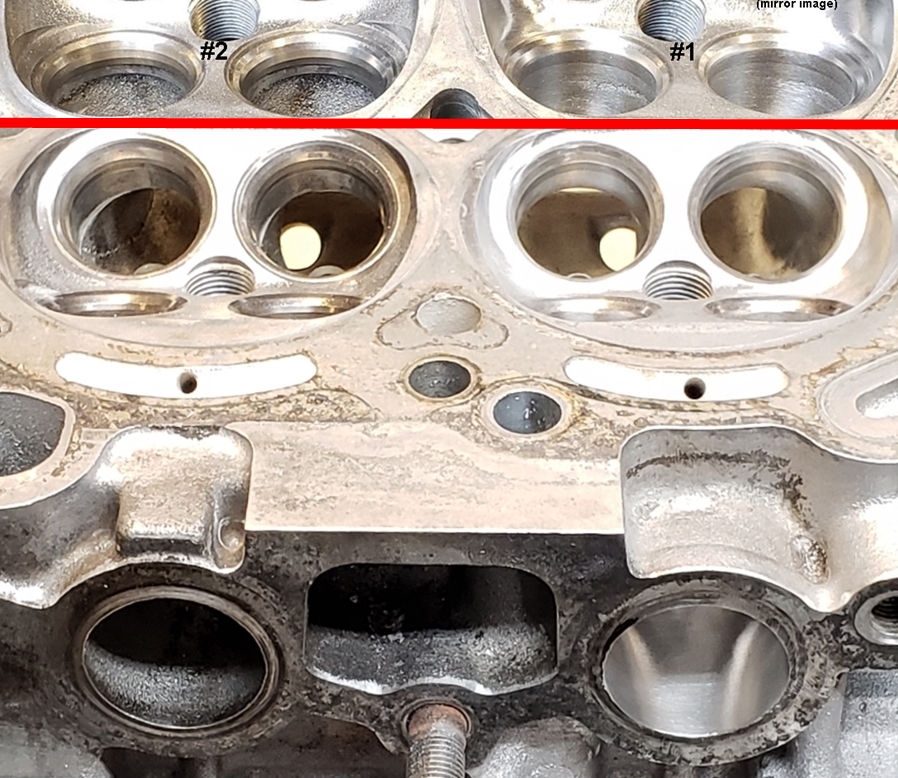

Sometimes you need more than a Dremel... sometimes you need to know to stop..........

While flaws remain, they will have less affect then making this bigger (slowing down bowl velocity)

This is a pretty crappy casting......

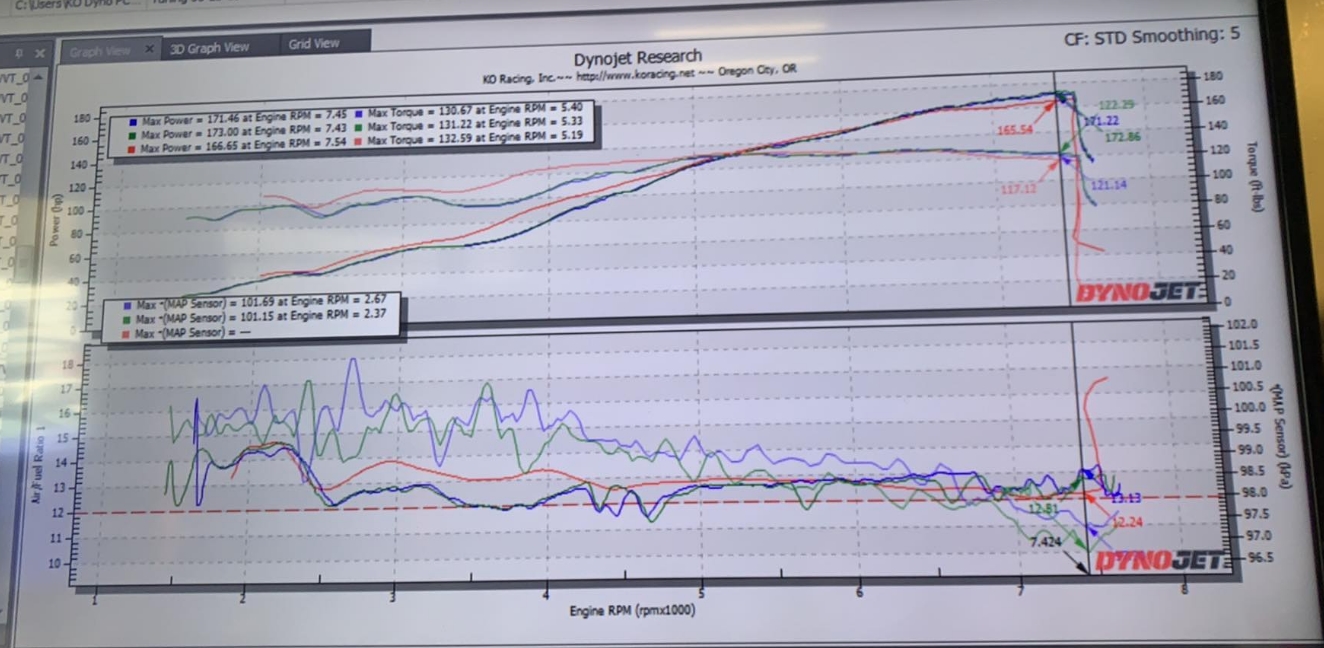

So... back in December I built OST-061, my second Miata head, a non-VVT 1.8

Well.... I got the results.... 172whp ![]() (#s in red are OST-038 the first Miata head I did - it is a VVT head)

(#s in red are OST-038 the first Miata head I did - it is a VVT head)

Whenever you bump this thread, it makes me wonder what you could accomplish with a VWAG 8-valve head, or a Volvo DOHC head. The Volvo's an interesting one because it looks like there is no SSR at all, just straight port to the seat. The seats also overhang a bit, which I'm told helps re-atomize any liquid fuel stuck to the walls.

In reply to oldeskewltoy :

I proved that to myself. I had 5 MGTD heads plus I had access to three others.

one of the three actually had the divider between ports removed and some clever work done dealing with the head stud that goes through that divider. ( removed and replaced with a countersunk Allen head )

Nice big open port I was convinced would make the most power.

Flow bench said so. On the dyno it made 3 horsepower over stock all at near redline. Less power once it was 500 rpm below redline.

Of the three I had ported my best made 9 horsepower more and at least stock power through the curve.

I had one head done by a professional. It didn't look as good as mine. I thought he was too conservative. Mine flowed better too.

But on the dyno he made 11 horsepower more and no place on the power curve did mine beat his. In fact he was typically 3-5 horsepower more.

Those numbers don't sound impressive but we are talking about a 54 horsepower engine I vintage raced.

The one and only time I beat the pro was on my Jaguar V12's He spent more than 100 hours getting everything to flow even and what he felt should work.

I spent 6 hours with a vertical mill and hand blended the intersecting cuts. ( it helps they were round ports ) the result At 7500 I had 54 more horsepower

and a nice Flatish line. From 3500-7500

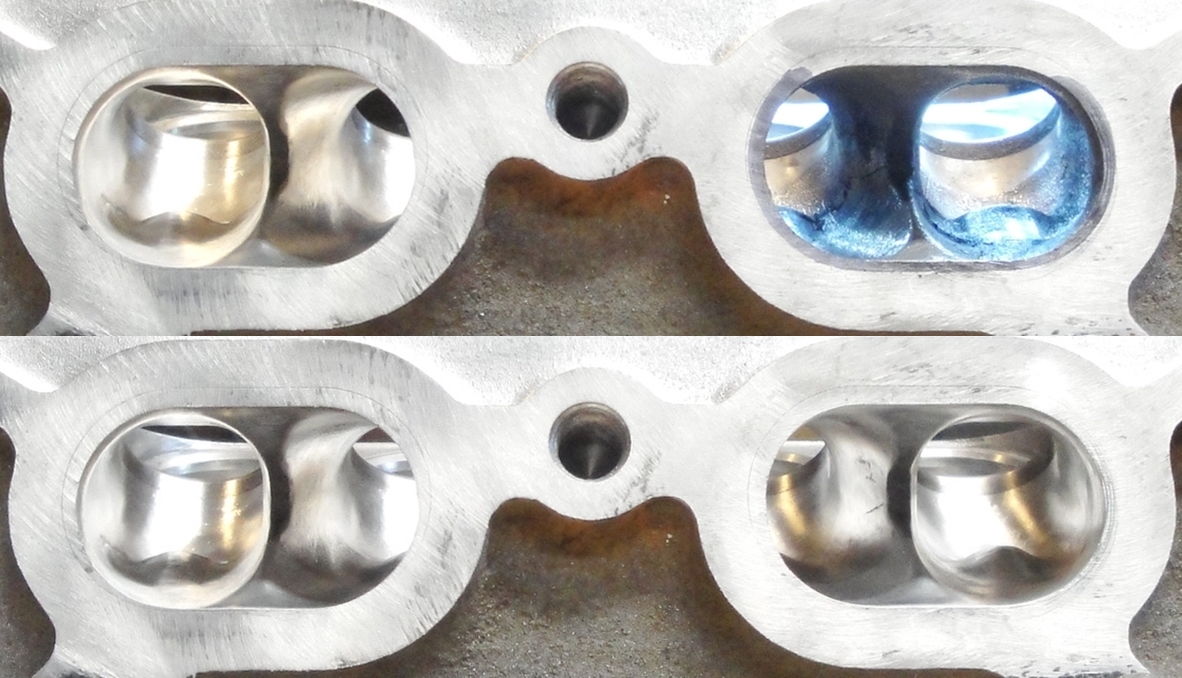

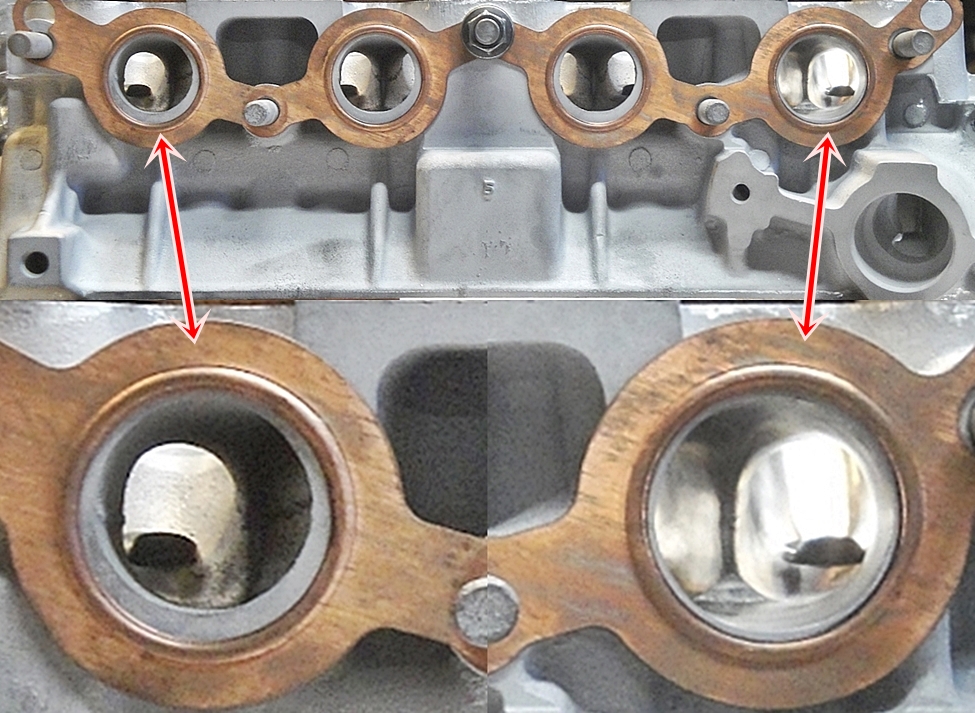

I'll play - here's some work I've been up to on my slant six. This is my first time porting a cylinder head. Before:

Both ports have a noticeable mismatch where the cores for the intake port meet the pattern that formed the combustion chamber.

Bowl work completed.

Next step, I'm going to try a gasket match on both the head and intake manifold. The exhaust manifold didn't look like it needed this work.

oldeskewltoy said:Touching up a BP4W....

7 of 8 intake bowls worked.... can you find the unfinished one?

working the exhaust side too...

and a little before/after on that port.....

more to come........

You polish everything to a mirror finish. I wonder what the contribution of that final step is to the dyno. If you were to say, just do the rough blending and shaping, would that alone increase dyno numbers markedly over stock? Just wondering where we start getting into diminishing returns.

A 401 CJ said:oldeskewltoy said:Touching up a BP4W....

7 of 8 intake bowls worked.... can you find the unfinished one?

working the exhaust side too...

and a little before/after on that port.....

more to come........

You polish everything to a mirror finish. I wonder what the contribution of that final step is to the dyno. If you were to say, just do the rough blending and shaping, would that alone increase dyno numbers markedly over stock? Just wondering where we start getting into diminishing returns.

intake side usually gets down to a 220 finish*, while the exhaust side does get polished. From my experience a polished surface (exhaust) has less chance to build up as the particulate coming from the exhaust has nothing to latch on too.

+ - a LOT depends on where the fuel is added

But you are correct... I've often wondered att what point the returns are no longer needed (flow POV). Yes, I could experiment... putting the head on the bench after each procedure, just have no one willing to pay to know exactly where that occurs.

Some recent exhaust port work

oldeskewltoy said:In reply to MadScientistMatt :

upper left in 1st photo. Pro-Sil 1025

Thanks! Wish I'd thought of getting a jar before I started porting!

You'll need to log in to post.