Could I theoretically get something like this and pull out the ball?

Obviously with everything measaured out first

I use Summits online catalog to find what I need, then order the part number from my local parts store.

Try these Dorman numbers: http://www.summitracing.com/int/parts/rnb-41034/overview/ http://www.summitracing.com/int/parts/rnb-41031/overview/ http://www.summitracing.com/int/parts/rnb-41030/overview/ http://www.summitracing.com/int/parts/rnb-41033/overview/

Failing that, Mr.Gasket has a kit with ballstuds, cables, rods and brackets. http://www.summitracing.com/int/parts/mrg-3831g/overview/

If they don't have what you need, check out the PDF catalog here: http://www.restorationstuff.com/catalog.html I buy from Restoration Supply all the time at work and their stuff is good quality and ships fast.

Hope that helps.

Shawn

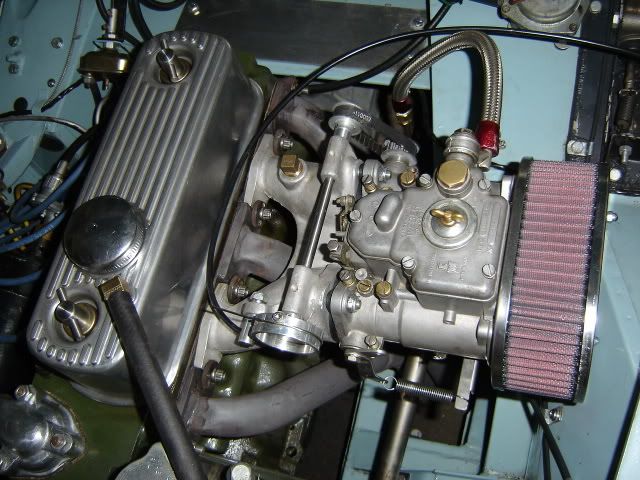

I dislike the monkey-motion of bellcranks and try to avoid them if at all possible. In an effort to get as linear as possible relationship between pedal and throttle plates, I made this linkage for the DCOE in my Sprite using a turned aluminum pulley, a bicycle brake cable, and some pulleys and toothed belt I had laying around.

I have built lots of throttle linkages using many different styles of actuation, mostly due to what was on hand, secondly due to it's application. There are lots of ways to do it effectively and well.

The feel to a driver is an important consideration. Butterfly throttles have a very non-linear airflow to degrees of opening ratio. Butterfly throttles have the most inrush from from the first part of throttle opening and then the flow increase declines as the butterfly is rotated farther.

Taking this into consideration I have worked with lever angles and lengths to make this more linear. A rotating lever has it's maximum linear pull at 90° to the direction of pull. One can arrange the levers so the advantage increases as the lever swings and the throttle is opened very slowly at first and rotation speeds up the farther the throttle depressed.

Using cables you can also accomplish this with an elliptic shaped pulley, you will find these on many modern car applications. This flattens out the airflow curve at the pedal, eliminating the big initial surge by reducing the linear travel to rotational travel ratio in the early degrees of opening.

This imparts a smoother throttle (less jerkyness) and improves a drivers ability to facilitate right footed traction control.

Cool_Hand_Luke wrote: Could I theoretically get something like this and pull out the ball? Obviously with everything measaured out first

Puling the ball out of that will destroy it. There are plenty of other options. You can also buy rod ends with left handed threads so you can do a turnbuckle for synchronization. You can get ball and socket fittings with quick disconnects and positive locking (think Morse cables).

bentwrench wrote:Cool_Hand_Luke wrote: Could I theoretically get something like this and pull out the ball? Obviously with everything measaured out firstPuling the ball out of that will destroy it. There are plenty of other options. You can also buy rod ends with left handed threads so you can do a turnbuckle for synchronization. You can get ball and socket fittings with quick disconnects and positive locking (think Morse cables).

Where can I find those quick disconnnect ball and socket fittings though?

bentwrench wrote: jegs.com

Thanks! Boy they're not cheap though

Here is the McMaster Carr Link this will be an industrial use type joint with quick disconnect.

You'll need to log in to post.