So in electrics, a transformer can be used to change from high current / low voltage to low current / high voltage.

In mechanics, gearing can be used to go from high torque / low rpm to low torque / high rpm.

In fluids, (BLANK) can be used to go from high vacuum pressure / low CFM to low vacuum pressure / high CFM.

Why do I care?

I'm trying to make a shop vac double as a shop dust collection system. Need more CFM, need less suction.

Trying to make your own one of these?

I would search here!

As I understand it, Shop Vacs are setup for low flow high vacuum tasks... like pumping water or sucking up large wads of paper that might clog the tube.

While shop ventilation systems are high flow low vacuum tasks since all they are moving is air with some particulate mixed in. They must move a lot because they have to clean out the entire volume of the shop in something like 6 minutes.

The cyclone style dust separators are amazing. I've made one before and it's shocking how well they work. But they just collect dust. They don't increase the flow in the system.

This is what I am trying to address. It may be impossible.

They will pull the same vacuum regardless of the length of pipe as long as you don't increase the diameter or number of openings. To build a really fast and dirty cyclone just save your old shop vac and put it inline before the one doing the work without plugging it in. Most of the dirt/sawdust will stop there and save on filters.

Download this Duct Sizer program and play around with it. If you really want to get into designing it then buy a pitot tube and make yourself a manometer with some plastic tubing and cardboard. Do some test to find out what you really need/want.

The word you are looking for is nozzle...

Convergent or divergent. (at least thats the way my fluid mechanics book stated it)

If you are talking a steady state, a larger opening leading to the pump will do it. Question is if it is moving enough volume to meet your goals.

You want a certian amount of mass flow, you just have a pump with the power that can pull a vaccum.

The question is if your pump (shopvac) can move the mass (air) at the rate you need for it to be effective.

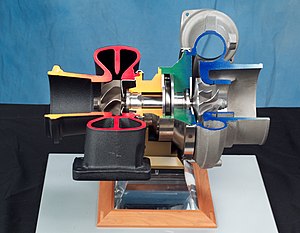

I think what I need is one of these

the ratio between the pitch on each turbine should change the flow / pressure characteristics of the "source" i suppose you could call it. right?

It would also have the added benefit of isolating the motor from any explosive fumes or dust. There would be a loss in efficiency, however. One could bypass the filter in the shop vac to (perhaps) make up for this change in efficiency.

Give us more information about the ductwork layout, and the shop vac or fan. I've been doing HVAC design for 6 years now and I've never needed a turbocharger for anything other than IC engines. ![]()

They make explosion proof motors, too.

If you find a fan that does 300 cfm at a static pressure of 0.5 inch of water column, it will have more static pressure availble with less cfm (until it becomes unstable), and less pressure available with more cfm. It's depended on the system (ductwork). Look up a fan curve. http://www.solutionsforair.com/dayton_content/pdfs/FanCurves.pdf

You're gonna need a fan with the proper horsepower and CFM rating.

To go back to your original example, you can change voltages with a transformer, but you are still limited to what you can output based on what you have for an input. Same story for gear reduction. You can slow down output RPM and increase output torque, but you are still limited based on the input power available. Since there is no device out there that makes "free power", you are still constrained by the inputs.

Sure, given an infinite amount of gear reduction, you could move a complete freight train with the motor out of your wife's vibrator, but it would be infinitely slow as well.

With vacuum/airflow, you can decrease flow/increase vacuum or decrease vacuum/increase flow to a point with the nozzle and piping, but your system is still limited based on the input power available.

You'll need to log in to post.