So if I was hypothetically wanting to repower an old GT242 John Deere with something bigger/cooler/more gooder than it's current John Deere K 14hp (Kawasaki) on the cheap. Where would one look? I googled breifly and my first thought of a vertical shaft diesel is apparently a thing that doesn't exist. This isn't a need project, this is purely me wasting more of my time and resources on something stupid if it actually happens.

In reply to Chadeux:

A Husqvarna 450x is where I'd start.

Doesn't satisfy cheap, or repower, or basically anything you asked for. I just hate cutting the grass on my steep ass lawn and I like robots.

The yard mowing duty is covered by 2 reliable mowers usually operated by somebody else. This is purely just a dumb driveway experiment.

One of those 26hp Kohler VTwins tuned to run on E85 with a K04 turbo?

Or just the Vtwin they're pretty easy to get.

Oooo or one of those Ford 1L 3 cyl engines? I have no idea how you'd adapt that though.

IHI makes a really tiny turbo. Probably shouldn't have looked that up again, looks like there's knockoffs out there for pretty cheap. Bad ideas...

Alternatively, we played with come Chinabay knockoffs of a Yanmar diesel on the Formula Hybrid team in college. Side shaft, so IDK how easy that would be to convert. IIRC, they were running somewhere around $400-450, but it's probably been 7 years since I've looked.

The0retical wrote: A Husqvarna 450x is where I'd start. Doesn't satisfy cheap, or repower, or basically anything you asked for. I just hate cutting the grass on my steep ass lawn and I like robots.

Huh.. I was wondering how long it would take to get those things to market. Maybe my next mower won't be a zero turn...

In reply to Furious_E:

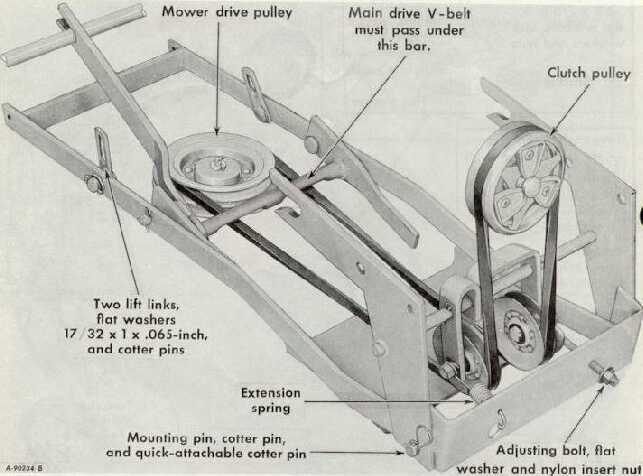

I know old wheel horse mowers used side shaft engines with a not that complicated pulley system to get the power to a transaxle similar to what I have here.

This seems not ideal making belts live very long though.

There's also this arrangement

In reply to Chadeux:

I've become quite familiar with Wheel Horses the past several weeks, more so than I had hoped to be lol.

So that diagram is what you're working with for drive belt routing? Seems that could be adapted to side shaft configuration without too much difficulty, as long as there's clearance to run the belt. I was thinking the pulley on the transaxle (assuming that's #1 above) would be oriented 90 degrees to how it's shown on a vertical shaft engine.

If this is just a goof off job I would probably do a port and polish, find a bigger carb, open up the exhaust, bypass the governor, and look into if lightening the flywheel is possible. A scattershield would be a good idea considering the engine would be between your knees. It would probably be cheaper and easier. And if (when) you grenade it then you could do an engine swap.

In reply to Furious_E:

Both of those are grabs from google. Mine is currently a standard vertical shaft engine to vertical shaft axle. It will more than likely stay that way and I'll just look for a bigger twin cylinder vertical shaft engine.

Not cheap, but this should pep things up a bit. 50% more HP and probably very reliable.

You'll need to log in to post.