Hi

I'm using Alfa Romeo 159, it's relatively heavy car. Front Wheel Drive and Front has double wishbone suspension.

As you can see, it is cold formed forged aluminum, and it is very tough. But bushings and rod end is pain in the ass. Every time there is a problem, we need to buy whole assembly. And it costs too much. Rod End has life time of 15.000km :(

I have a CNC, and I can make it from billet aluminum with replaceable bushings and with motor sports ball joints. But I don't know if it will have good life . I saw some aftermarket billet arms. If they can make it. I can make it too. Can you give me hints. Or direct me, suggest me a material. Or I can go welding tubes ?

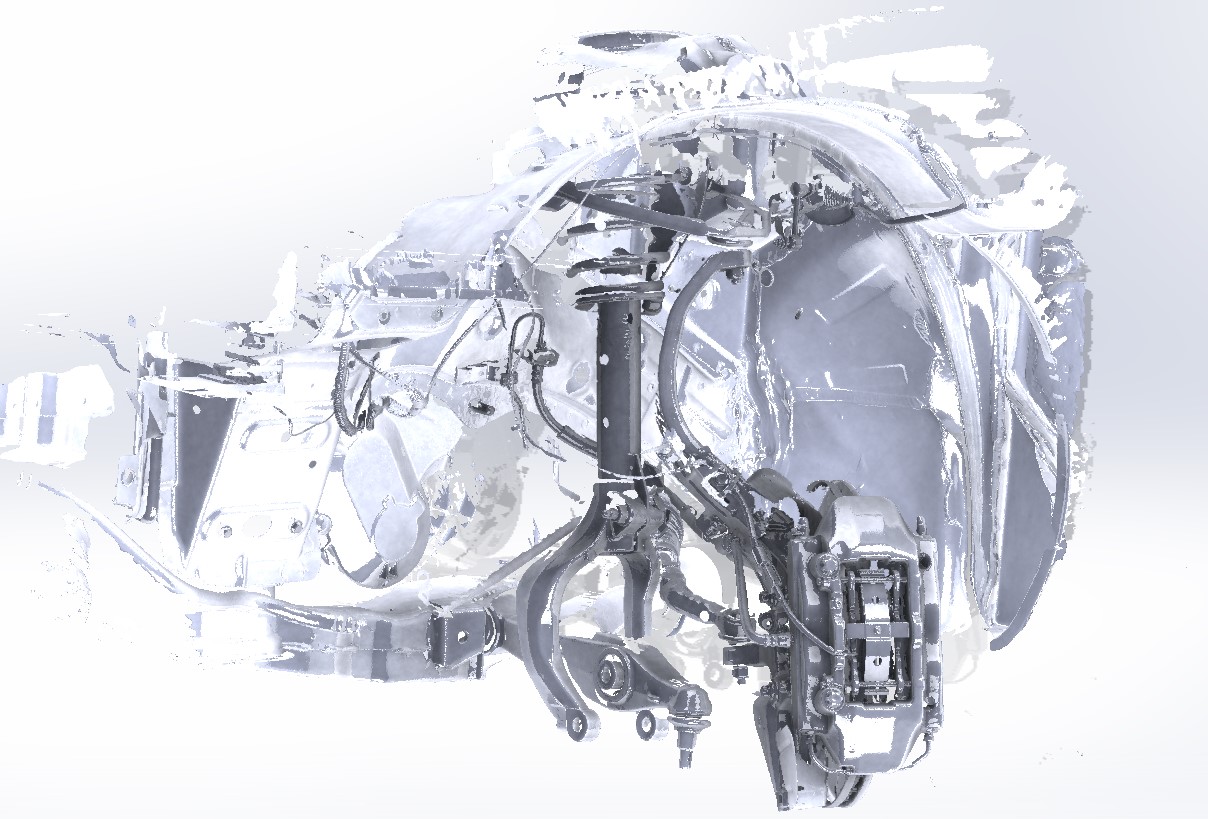

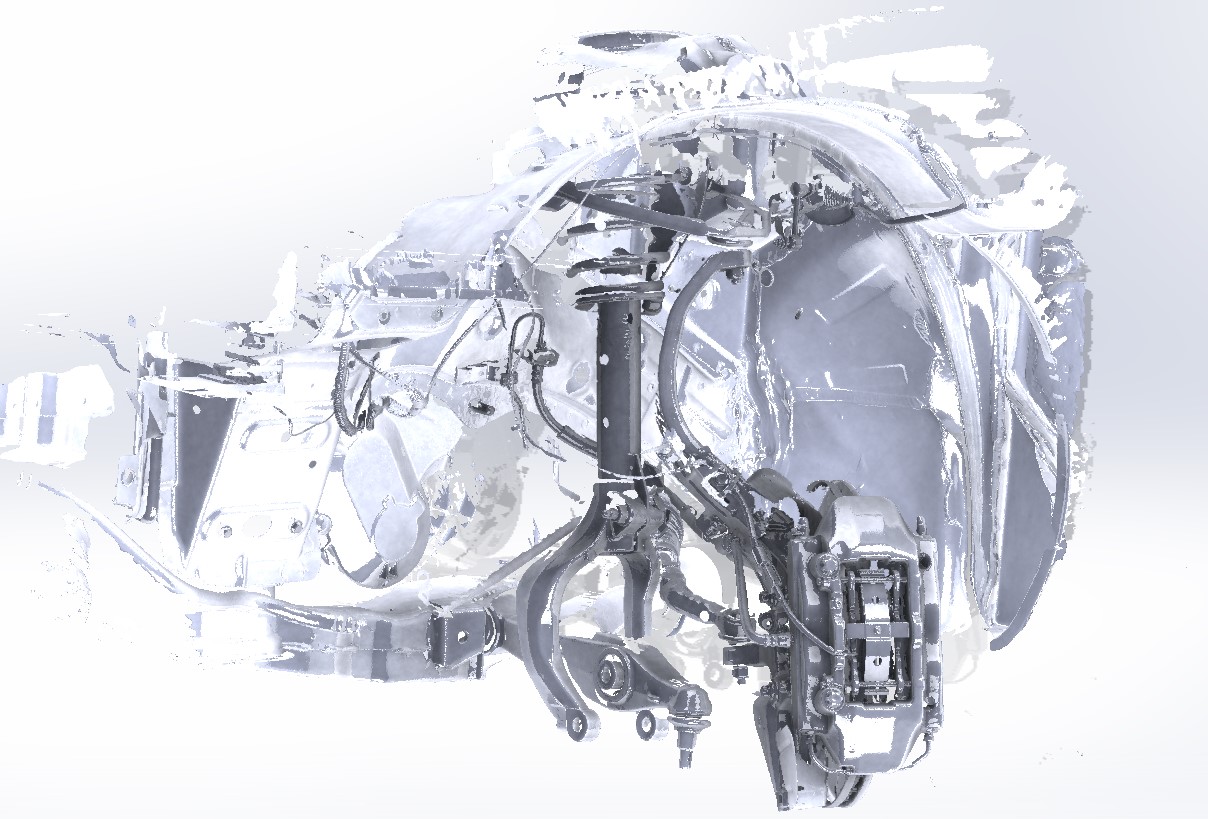

Mean while escaping from Covid19 I did some progress in Suspension geometry and design.

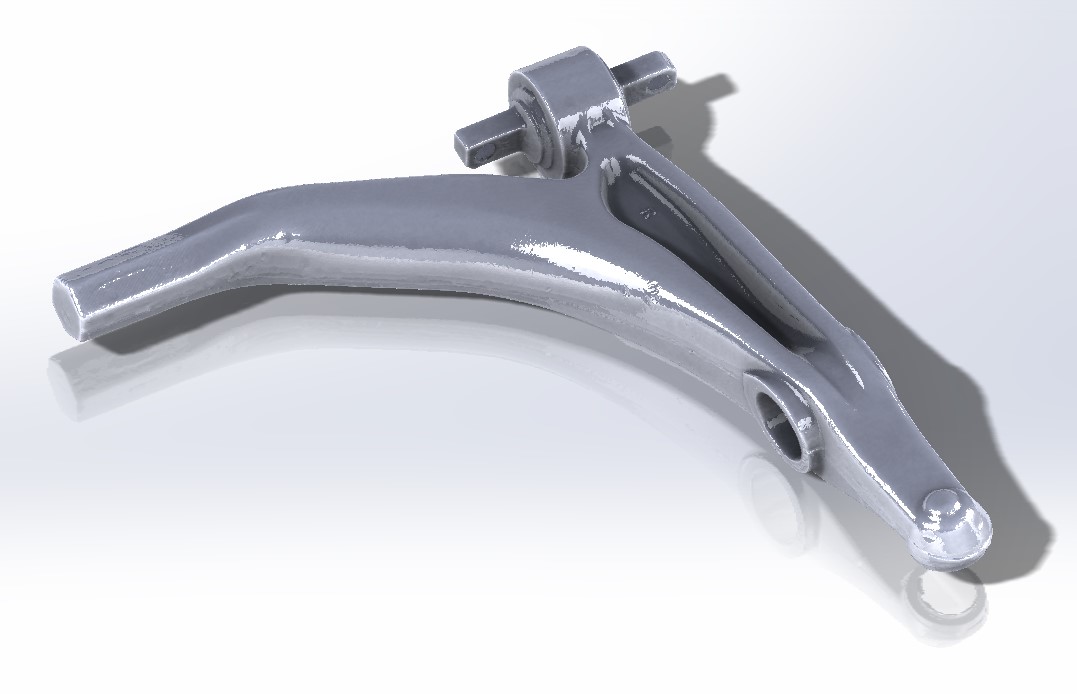

3D Scan of Upper Arm

3D Scan of Lower Arm

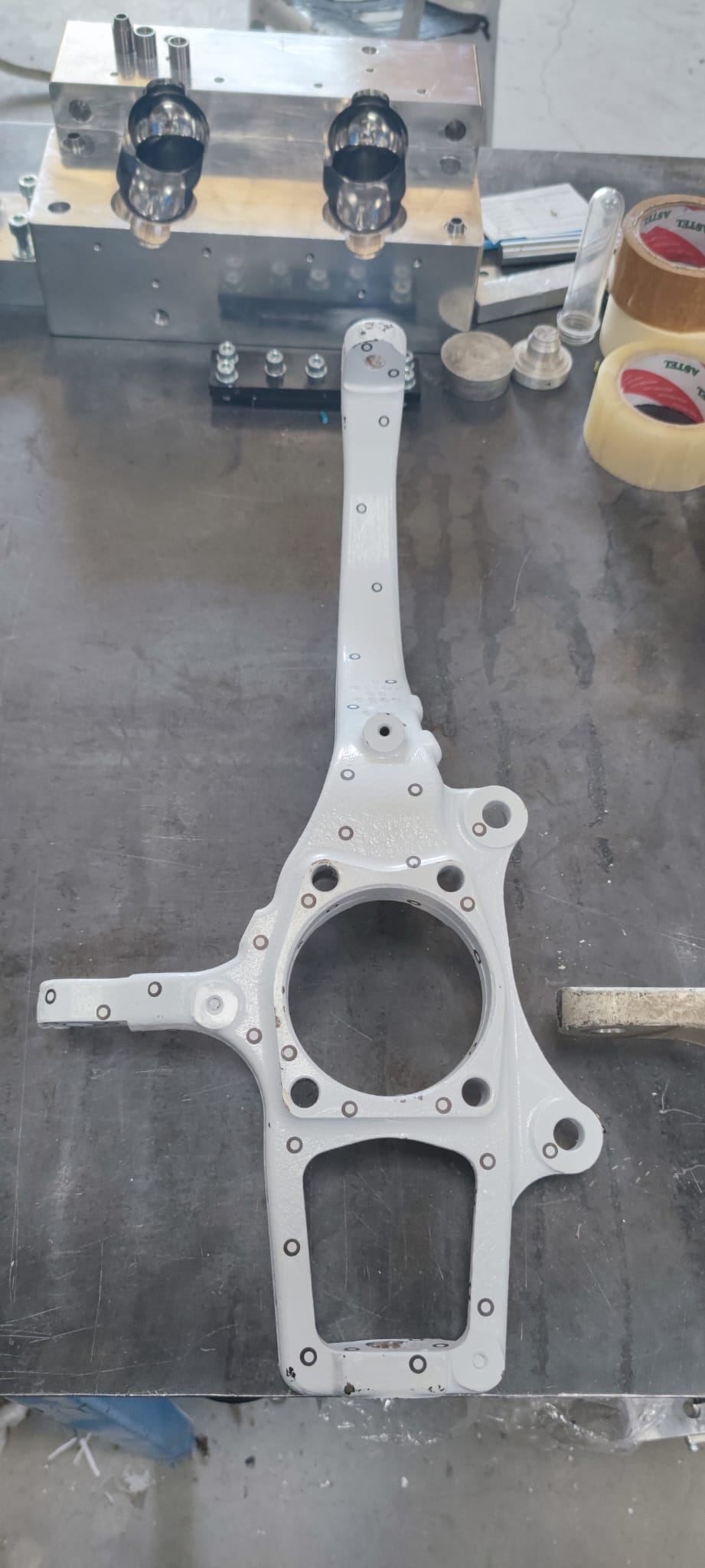

3D Scan of Knuckle

3D Scan of Wheel Arch

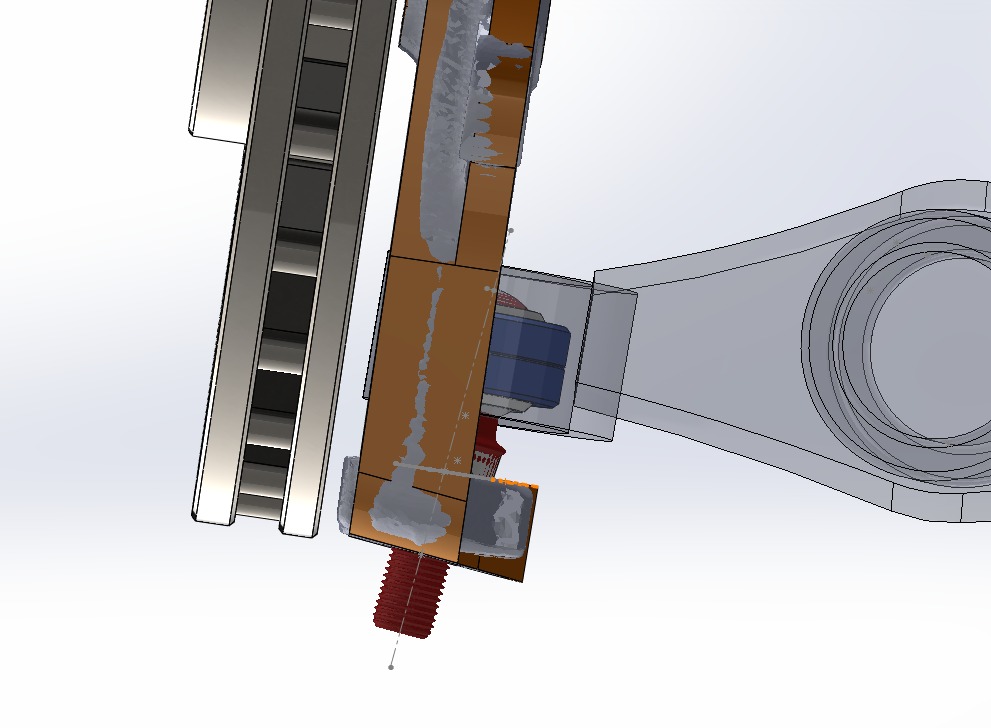

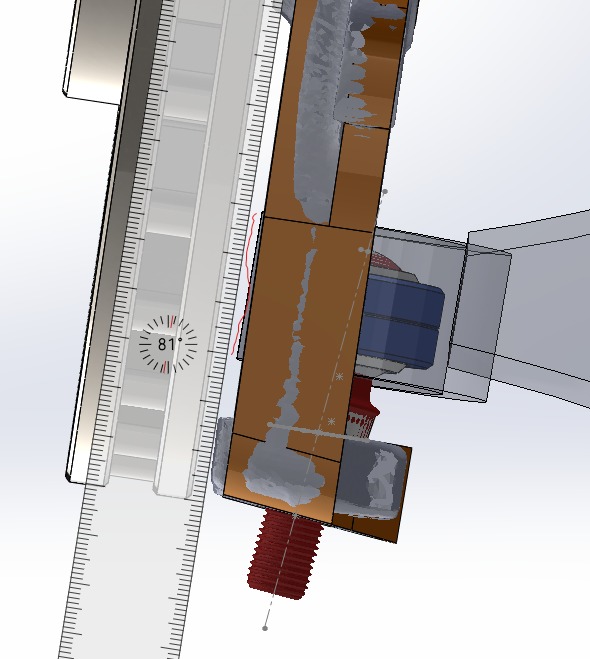

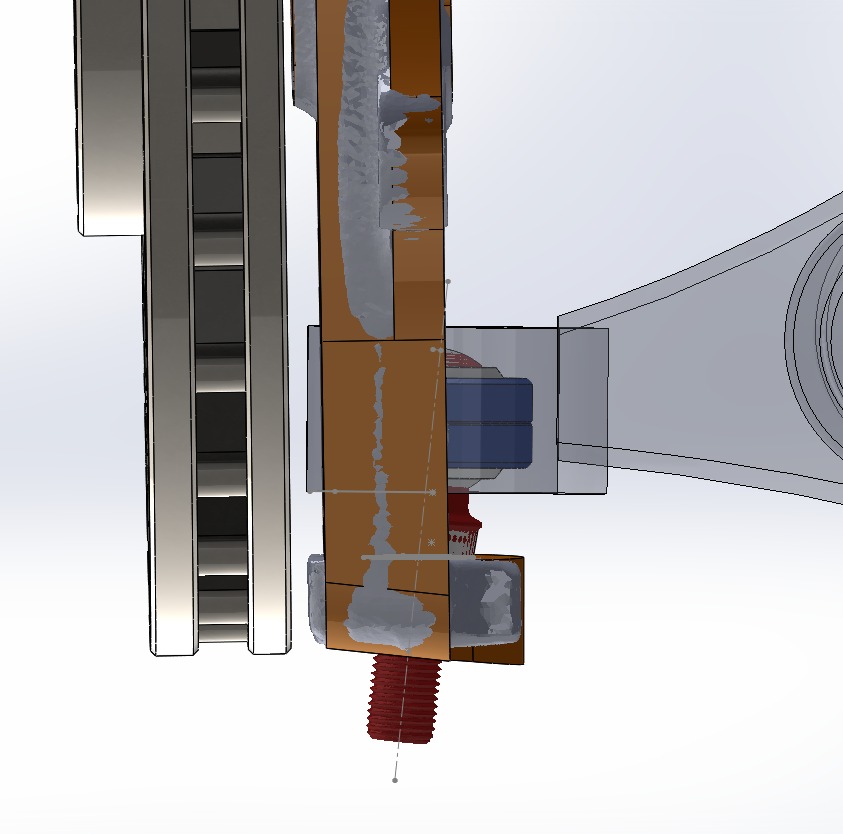

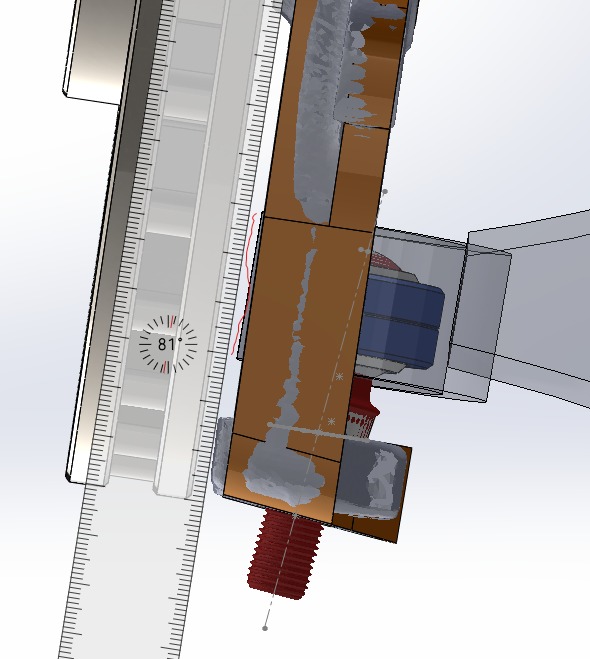

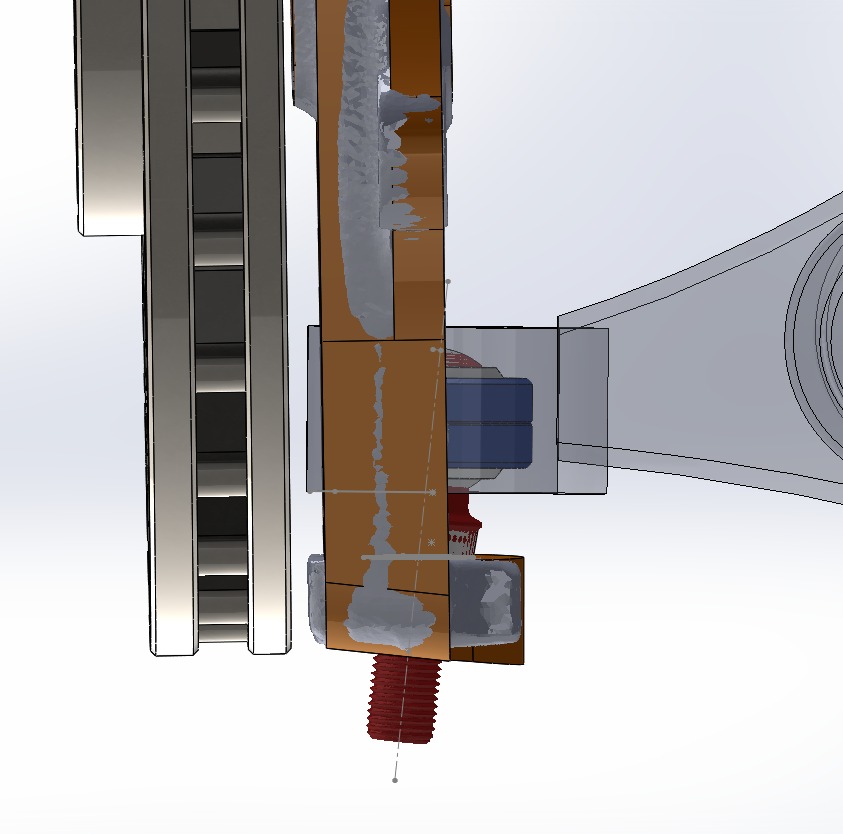

Dirty Work of Solidworks Assembly

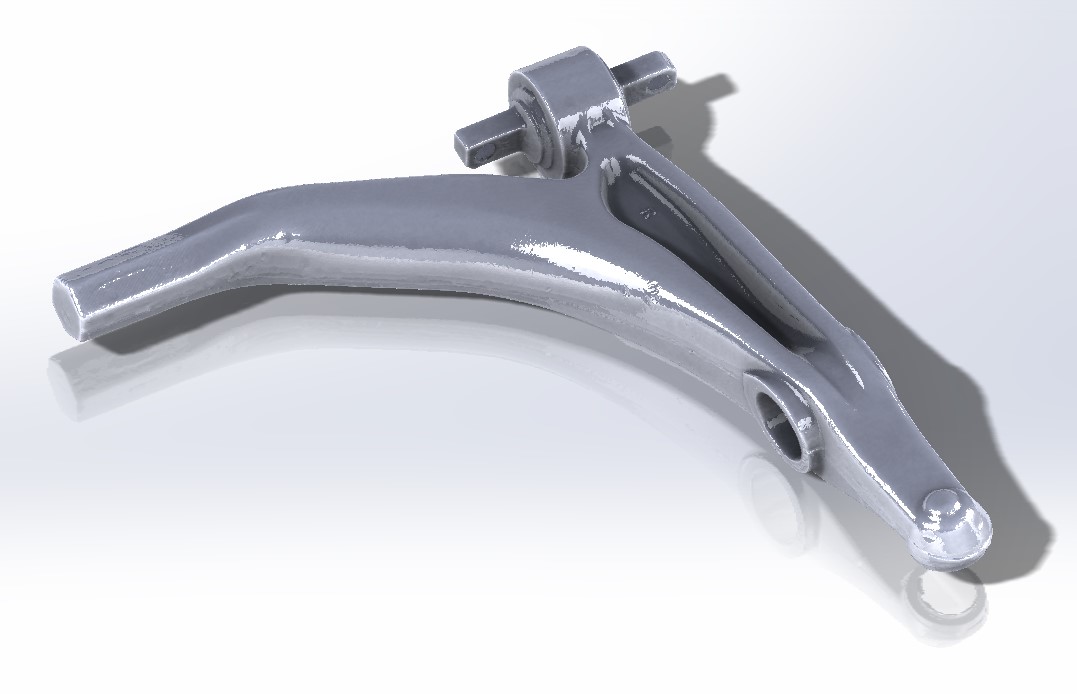

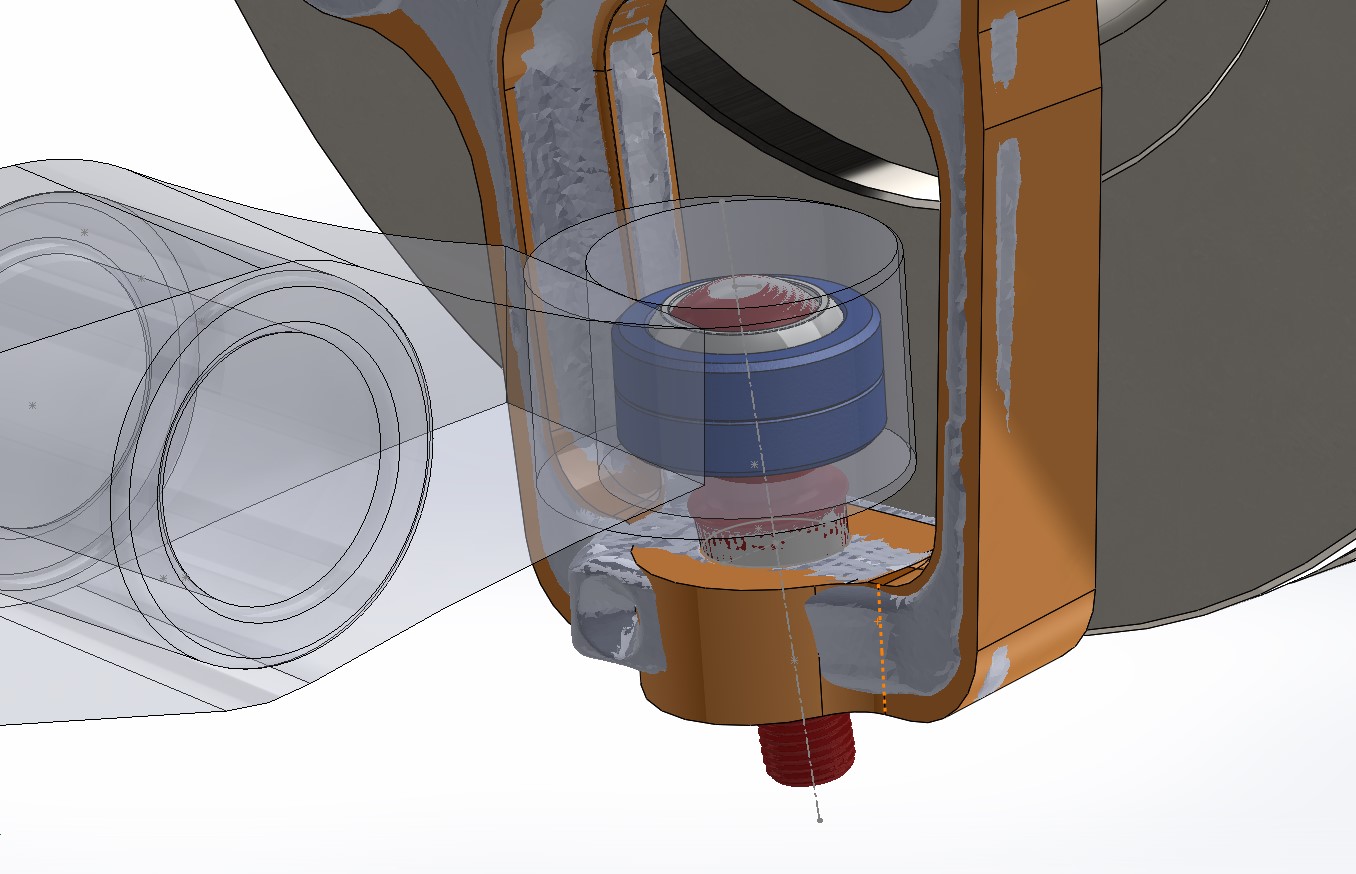

I've finished the Upper Arm CAD model. And I'm very pleased with that. I'll use FK ball joints in front and at chassis I'll use Original Design + PowerFlex Bushings.

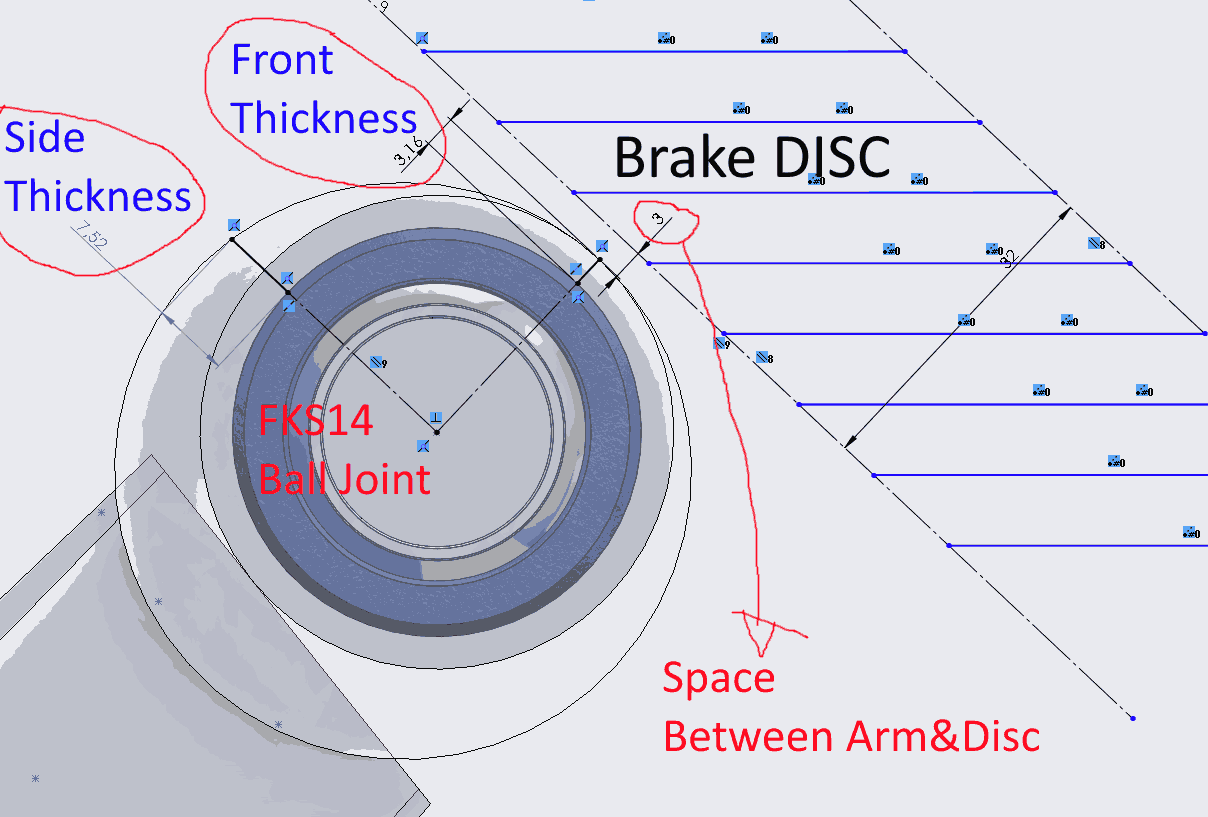

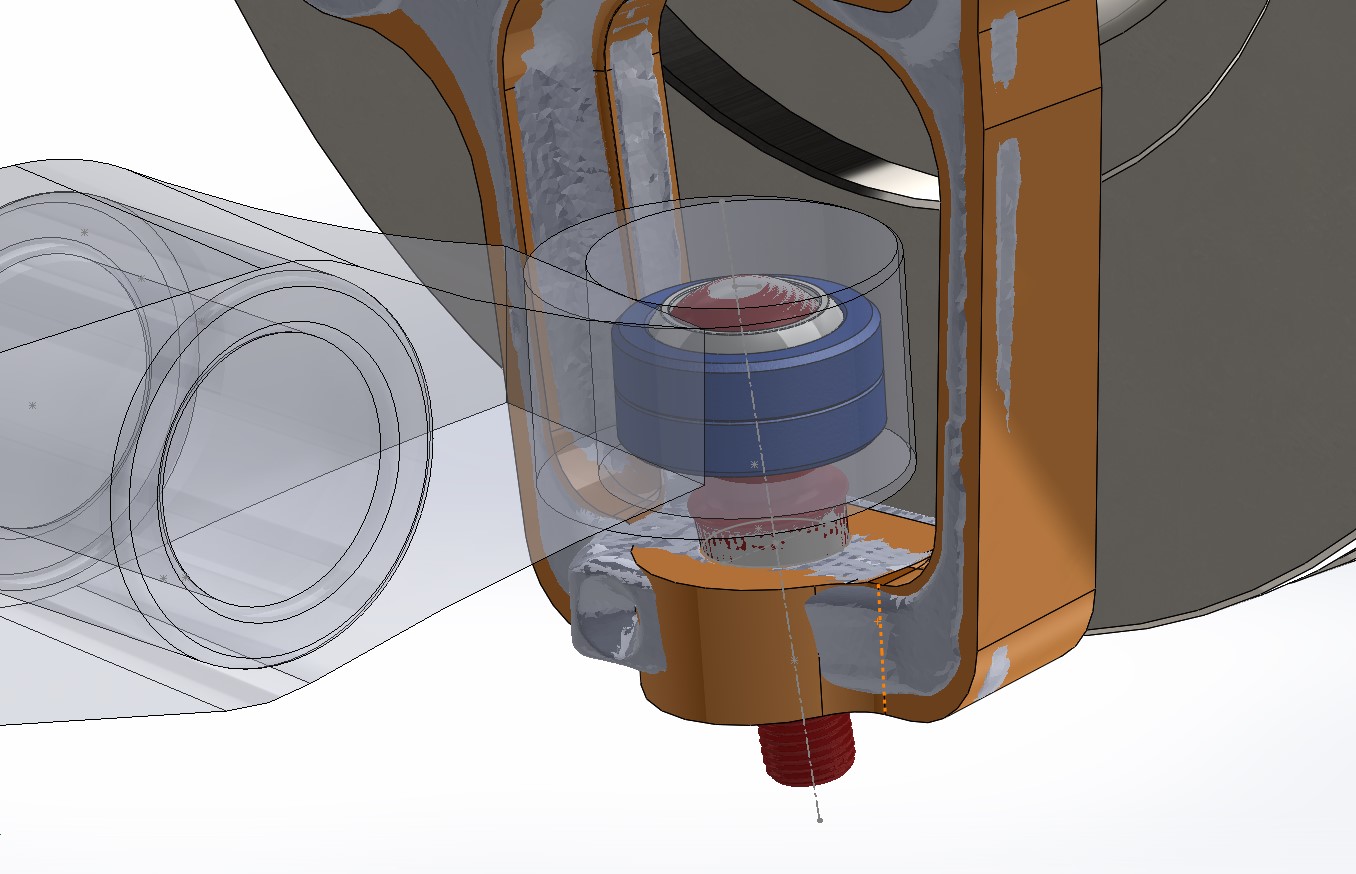

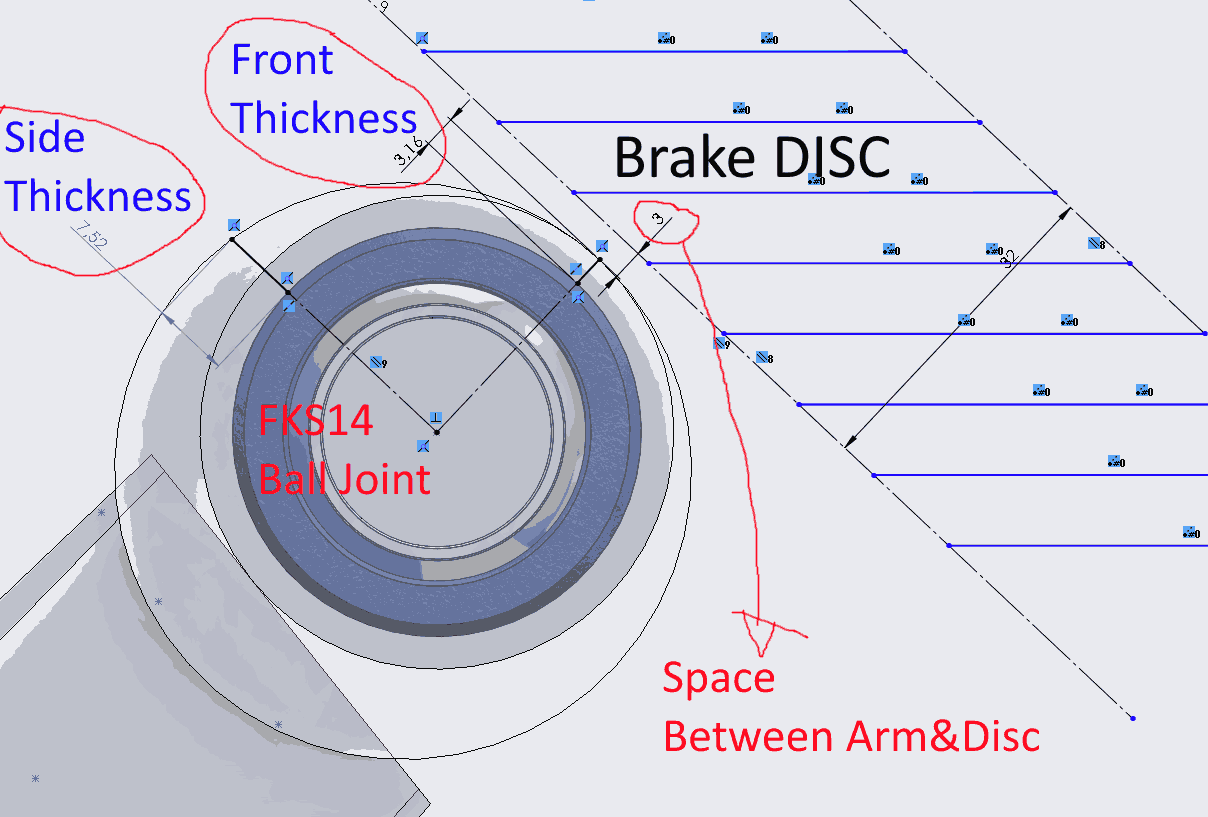

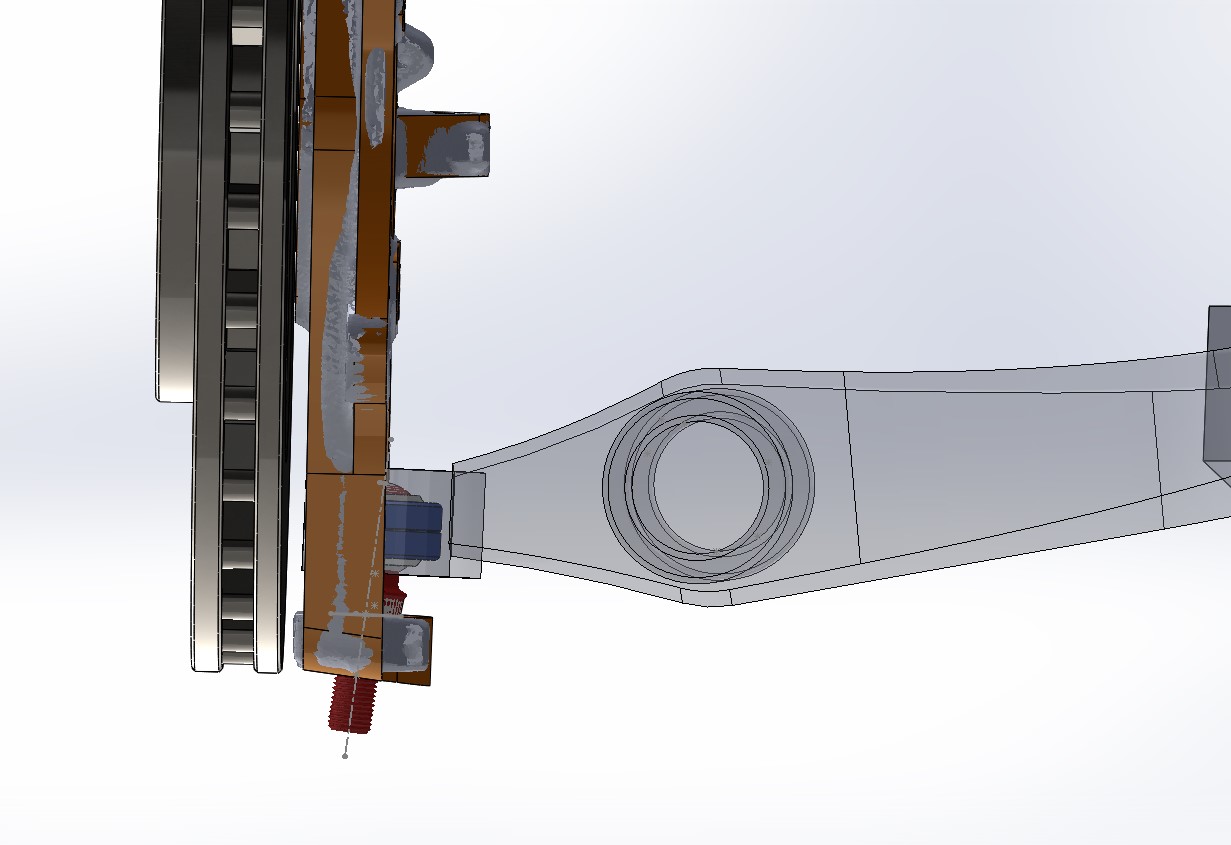

The Problem that I have is the lower arm ball joint area. I want to use bigger diameter eye for Ball joint. "30mm Stock" vs FKS14 "Ball diameter is 33.32mm"

The Problem is the thickness of the material left outside of the arm aluminum.

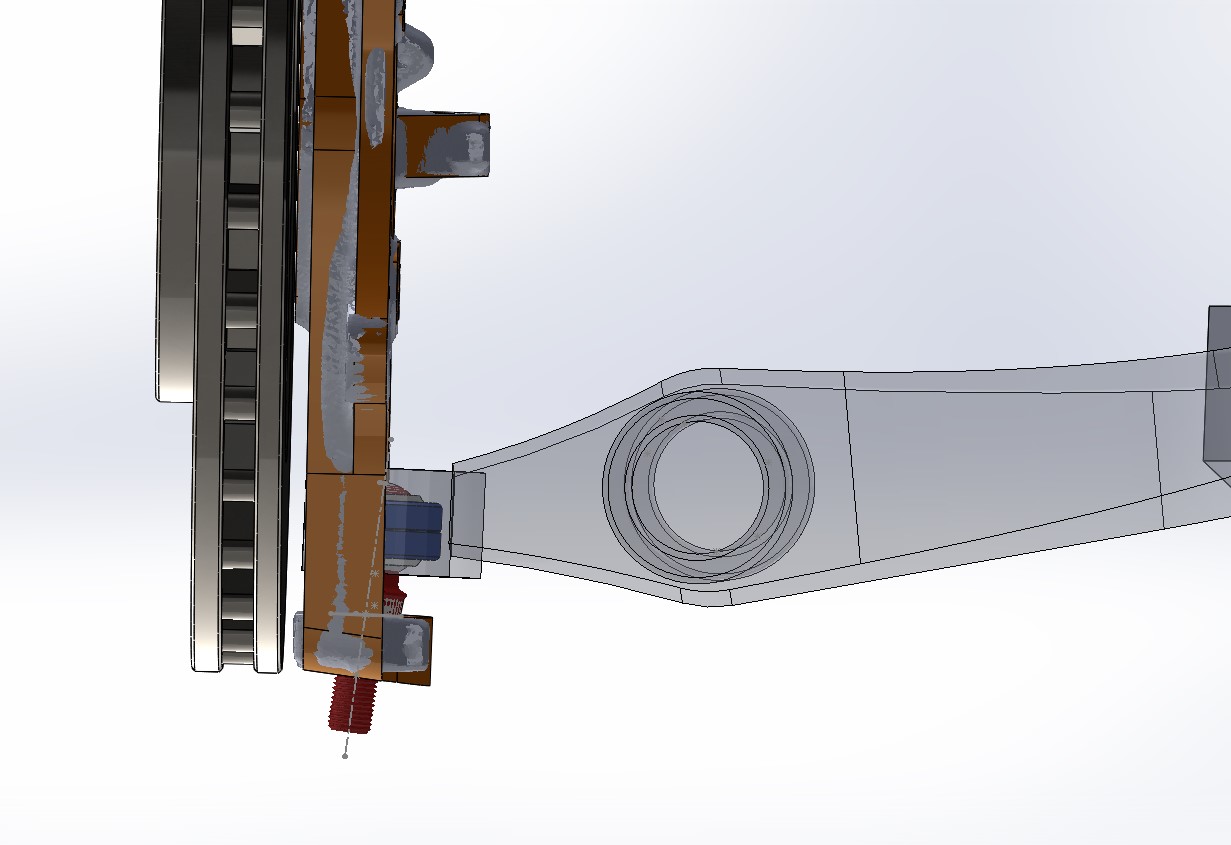

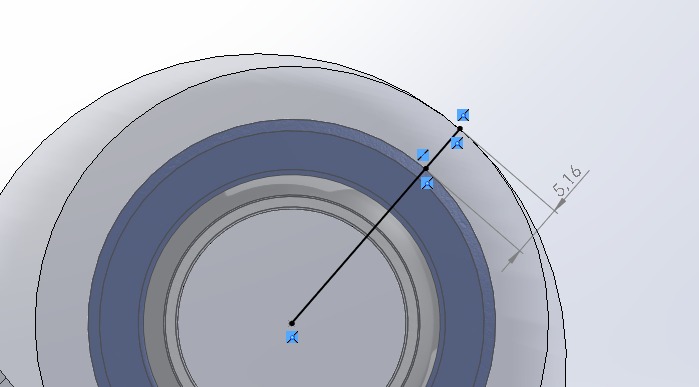

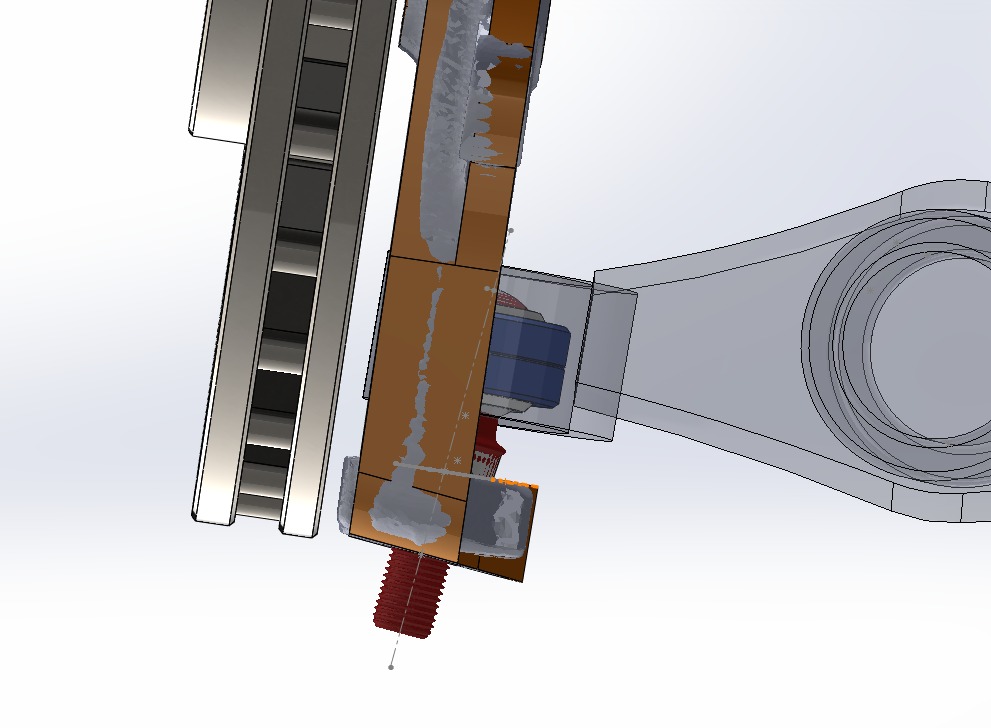

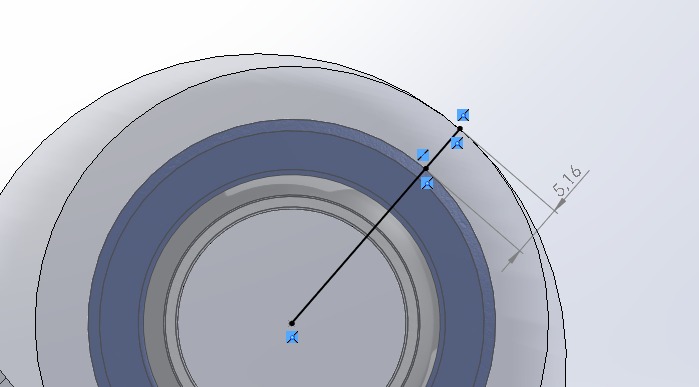

Original Aluminum diameter is 46mm Circle. If I use like that All the thickness around Ball Joint is 3.16mm. But I did a trick and add material only to the side of the ARM. It does not touch the Knuckle. But I could not add more material to the front of the arm. Can you give me some review about it. I could make it steel. But it would make it very heavy. Can you guide me a little bit.

I'm sorry for my English. Maybe I use some words differently.

PS: My main goal is the make a stronger ball joint. And replaceable one if possible. Original ARM is about 3.5kg every time the ball joint fails. I have to put the arm to the junk yard.

Mr_Asa

PowerDork

3/30/22 4:35 p.m.

Welcome to the forum! You have an ambitious project, I look forward to seeing it progress.

I want to add more pictures...

It opens another can of worms, but what about using a different brake rotor that has less offset?

In reply to bgkast :

It is almost impossible for me to do it. I have to buy new calipers new disc + I don't know what else. I've thought that before. When my 330mm Front Disc are bad for me. I'll go 356mm Disc + 6 POT Caliper + 18" Wheel all around. It Means I have to work more to earn money :D

Also With this knuckle I cannot offset my Caliper easily.

When you look at the picture above. You may see that original ball joint have room to touch the disc.

I know that I missed the articulation of the arm. But When you cancel the sheet metal. Or When I open a window to it. I could easily increase the thickness of the outside material by 2mm. from 3.16mm 5.16mm

Hello again. I'm sorry I was absent for a time. I had to work my ass off in my daily job. And I'm swapping the gearbox on the car from M32 to F40. Lots of problem came within swap. Now I'm waiting parts from Europe to finalize the swap. Anyway another subject.

Here is some news. I've checked the some dimensions on the car. And I found that I have 2 more millimeters between disc and the arm. So It means now I have more material to cover the ball joint. It's a good new.

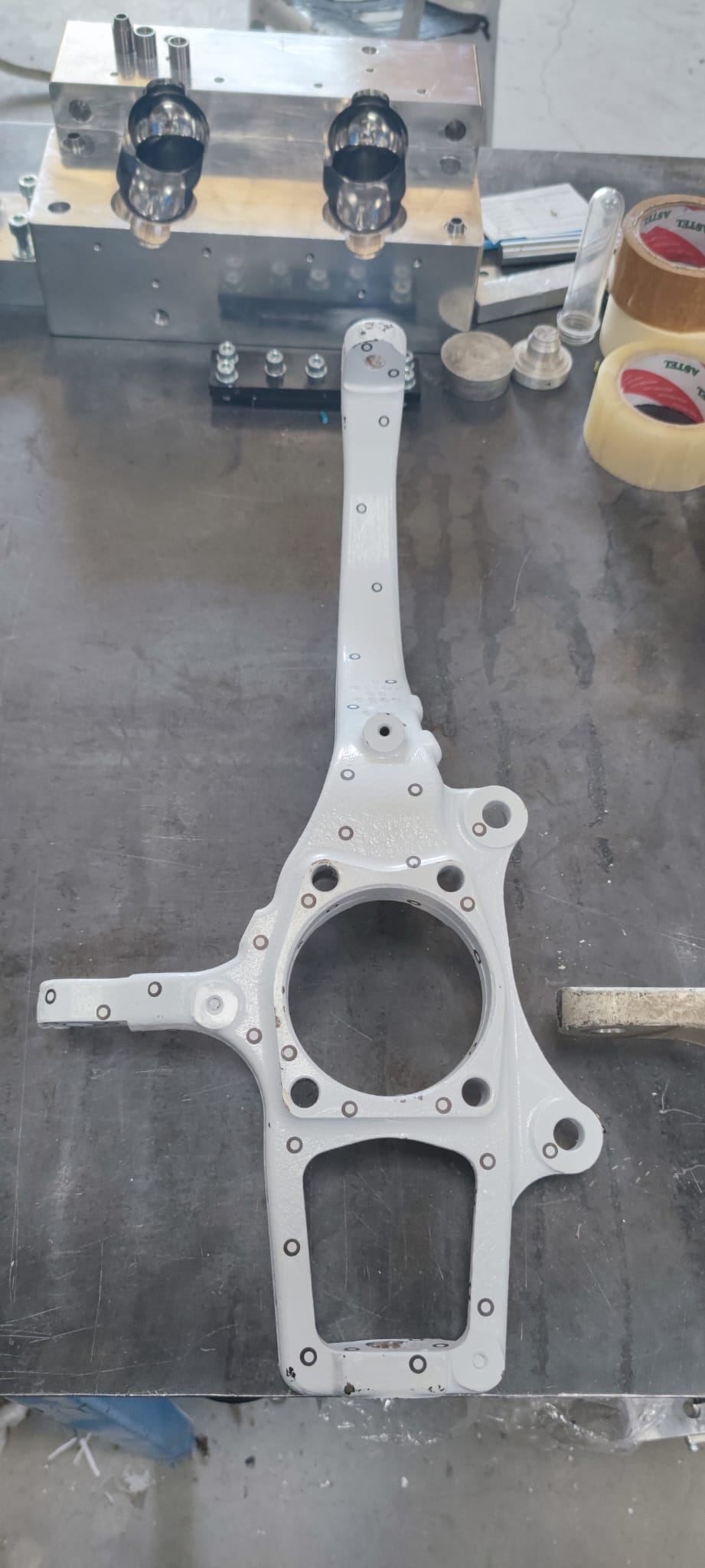

Also I've bought Aluminum Knuckles from a younger car. Before the Alfa Romeo 159 out of production, Engineers put the car on diet and lost 80kg total. And knuckles are on of the part that we can bolt-on swap to our Steel Knuckles.

Steel -

Alu -

Weight of Alu -

Weight of Steel -

Together -

Together -

As you can see. Alu seems to have more material than steel. Bulky design, but less weight.

I wish I could find what material they are using in "forged aluminum arms" I've talked lots of guys in the market. They say our 7075 or 6061 has no strength.

Forged Alu is the key. They say if you go billet, you have to add material to compensate the strength. I've asked some data. I know they tested those materials for life expectancy, but I could not find any good data.

Some said go to China market and bought untouched forget material. And put it on CNC. That would be better. And I think its not. I saw lots of Billet arms on the WEB. And they are using them even on Off-road. I don't know how many years can you use your Billet Arm. But I'm curious.

I have two new CNCs and German cutters. I don't I'll have any problems on that side. I wish only I could trust the materials. Even I have the Factory designs of the arms. But I could not find the Design Calculation Forces to check and redesign the billet arm.

I am not sure where you are located, but you could send the factory aluminum arm to have non-destructive testing to check the properties.

Then you can see whether 7075 would work. If you use 7075, you would probably need to have it anodized as it will corrode otherwise. Coat it fast once out of the machine with wd-40 or something until it gets anodized.

7075 aluminum is pretty strong. I've made valve train components that get subjected upwards of 10k rpms with no issue.

In reply to emre2blue :

I can't help with your questions, but I want to say that you seem to have a good set of capabilities and knowledge.

In reply to Slippery :

I can make it happen actually. I think at least 100km away there is a government lab to help industries materials and calibrations I'll check if they would help. And for the coating you are right. I'll make it too.

Testing will help with the chemistry, but not with the heat treatment and forging. The same chemistry can provide different mechanical properties for different heat treatment and the forging process changes this as well.

With your space constraints, I suggest using steel. Even if you have just a steel cup for the ball joint and bolt that to the rest of the control arm.