There comes a time in every fabricator’s life when they realize there’s an asymptote in the home garage. No matter how skilled you are with a grinder, how straight your hacksaw cuts, or how steady you can hold that hand drill, there’s an invisible line of quality and accuracy that you can approach–but never cross–at home.

We’re talking about those brackets on your race car that are clearly handmade, or the fabricated parts with more right angles and grinder marks than every other component on your BMW combined.

These flaws add character to any build, and they’re a badge of honor for many enthusiasts. But they’re also proof of your limitations, signs that there’s a whole new world just over the horizon.

We’re talking, of course, about the world of machining, where tolerances are measured in the tenths of a thousandth of an inch, and the possibilities are seemingly endless.

Most enthusiasts have limited experience in this brave new world. Maybe you’ve splurged for a few shiny billet parts or driven over to your local machinist and asked for help. But these methods are often wildly expensive, and you’ll find most machine shops don’t really want to make a single part for your race car; they’d rather make 1000 parts for your business.

But we’re not going to go to trade school, quit our day job, or pay the price of a decent house to learn this skill and acquire the equipment to practice it. Over the next few issues, we’ll explain how we learned to make consistent, accurate, complex race car parts in our home garage–all on a budget with far fewer zeros than you’d expect.

We’re not experts and probably never will be. We’re still new at this. We’re probably doing some of this wrong. Real engineers and machinists will probably write us letters with advice we should have heeded before we started. None of that’s going to stop us, though. Let’s go.

Drafting: Not Just for NASCAR and Horses

Every new skill has a language and rituals. Machining is no different. Before we bought a mill or turned on a lathe, we needed to change our workflow. Welcome to the world of drafting, also called technical drawing. This process is the bedrock of making stuff with accuracy.

We’ll pause briefly here and apologize for our language: Much of what we’ll be talking about in this series isn’t technically machining. We’re using that term, long the holy grail for us and other racers, as shorthand for the idea of planning parts down to the smallest detail, then building them to those plans accurately.

It’s the difference between taking five shots at that new alternator mount with a few hunks of steel plate and a grinder versus measuring, planning and then machining that alternator mount to fit correctly the first time. The benefits are obvious: You’ll build faster, throw less material in the scrap bin, and get a nicer finished product.

So, technical drawing or drafting: Wikipedia describes it as “the act and discipline of composing drawings that visually communicate how something functions or is constructed.” And, well, yeah, that pretty much covers it.

In this day and age, you don’t even need to pick up a pencil. Autodesk’s Fusion 360, a free program, brings computer-aided design to the masses. How do two parts interact? The program can show you.

You’ve probably already done some drafting, even if you didn’t know it. Ever needed to make a tab, then drew a square and a circle on a piece of scrap cardboard with the diameter labeled so you wouldn’t forget which size drill bit to grab? Congratulations, you can add “technical drawing” to your resumé.

Why is this important? Because there’s a line to recognize here: Not all machinists are engineers, and not all engineers are machinists. In fact, most are only one or the other. They don’t communicate with each other in English (an exceedingly rare skill for engineers). Nor do they use hand signals, Morse code or interpretive dance.

The only language engineers and machinists share, and the one you’ll need to learn, is the technical drawing. These are how the engineers explain to the machinists what they need to make, and how the machinists explain to the engineers that they’ve designed something impossible to build without breaking the laws of physics.

If you’re going to build race car parts in your garage, you’ll need to become both an engineer and a machinist, so let’s start at the beginning.

Engineering: Good in Metal, Great on Paper

If you can make a bracket, you’re already an engineer–just on a smaller scale than the ones at SpaceX. Engineering basically means using science to design stuff.

If you’re like us, though, you didn’t sit down with a piece of paper and a pen to figure out exactly what size and shape your bracket should be in advance. You just went to work, using more art than science and letting the piece of scrap metal you grabbed dictate the bracket’s final form.

There’s nothing wrong with that. But we encountered a huge paradigm shift as soon as we started thinking about the drawing instead of just the finished part.

Rather than just start building, take a few extra minutes to sketch out the bracket’s shape on a piece of paper. Next, add the dimensions of each line, including the location and size of any holes you’ll need to drill. Yay, you’ve just finished your first real technical drawing.

By creating a technical drawing and translating your bracket into the universal language of making stuff, you’ve unlocked a whole new world. Now, it doesn’t have to be you who makes that bracket. Your buddy could make it for you. Or the local machine shop. Or you in five years when you break the first one in a tire wall and can’t remember what it looked like.

Technical drawings and engineering are inextricably linked, and we’ve found they force you to solve problems, like an interference or an unsupported axis, on paper instead of after making a part. Conversely, drawings can also help you fill in the blanks by letting you math your way to required dimensions instead of just guessing when you’re standing in front of the bandsaw.

Parametric Design and You

Before we go any further, there’s one more concept to understand: parametric design. Wikipedia has an elevator speech for this, too: “Parametric design is a paradigm in design where the relationship between elements is used to manipulate and inform the design of complex geometries and structures.” We did warn you that engineers don’t do well with English….

Here’s our attempt at an explanation: Parametric design is the idea that a design is actually just a collection of lines and constraints, and they combine to make complicated parts.

Take a square as a simplified example: A normal drawing would express “There’s a square.” A parametric drawing, though, would say “There are four lines, each of equal length, with coincident points at each end and a 90-degree angle at one corner.” Add a dimension to one of those lines–say 2 inches–and because the design is constrained into a square, the other lines must be 2 inches long, too.

Take this a step further and change the square into a cube. Again, a normal drawing would just express “There’s a cube.”

Our parametric drawing, though, creates that cube by saying the square we’ve already constrained is extruded into a solid object with an equal height to the length of the lines in the square. Except, darn, we’ve accidentally drawn our square too small. What happens when we go back and change that 2-inch line to a 3-inch line? Magically, the cube now measures 3 inches on all sides. Our parametric constraints have dictated each element’s relationship to the one that came before it, rather than an absolute shape, meaning our design is easy to modify and to add increasing levels of complication on top of.

Parametric design is the standard for most CAD programs, and though it can be intimidating at first, you’ll soon come to love it.

CAD: Time to Let It Out of the Bag

Drafting that parametric design with a paper and pencil is a pain, right? We attempted it approximately twice before using up the eraser and spilling coffee all over our technical drawing. There has to be a better way and, surprise, it’s computers.

Computer-aided design software is more accessible than it’s ever been, and there’s no reason not to use it. There’s probably a high school drafting teacher somewhere who will cancel their subscription when they read this, but we’ll say it anyway: Move to CAD as soon as you possibly can and never look back.

Don’t believe us? How’s this for an anecdote: We downloaded Autodesk Fusion 360 onto our 8-year-old computer, binge-watched some YouTube tutorials, and had an understanding of how to draw simple parts after one evening.

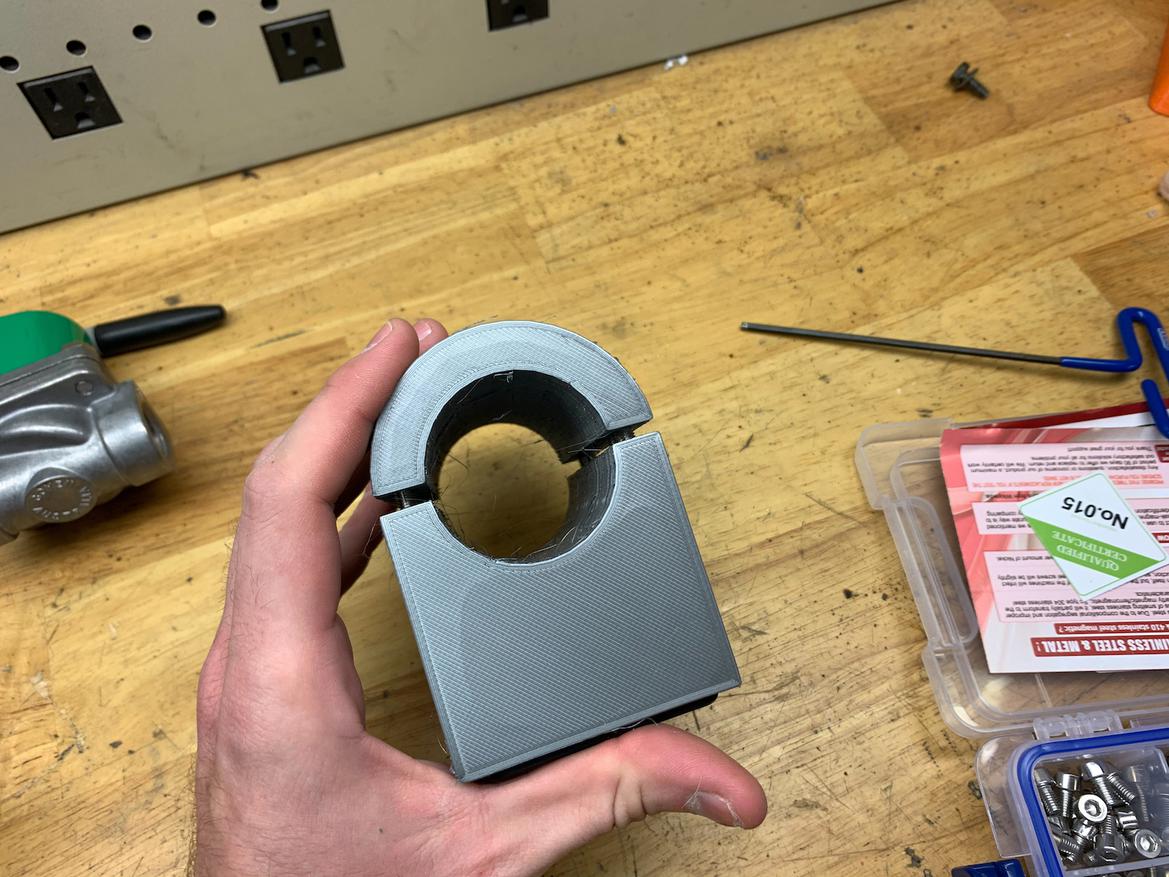

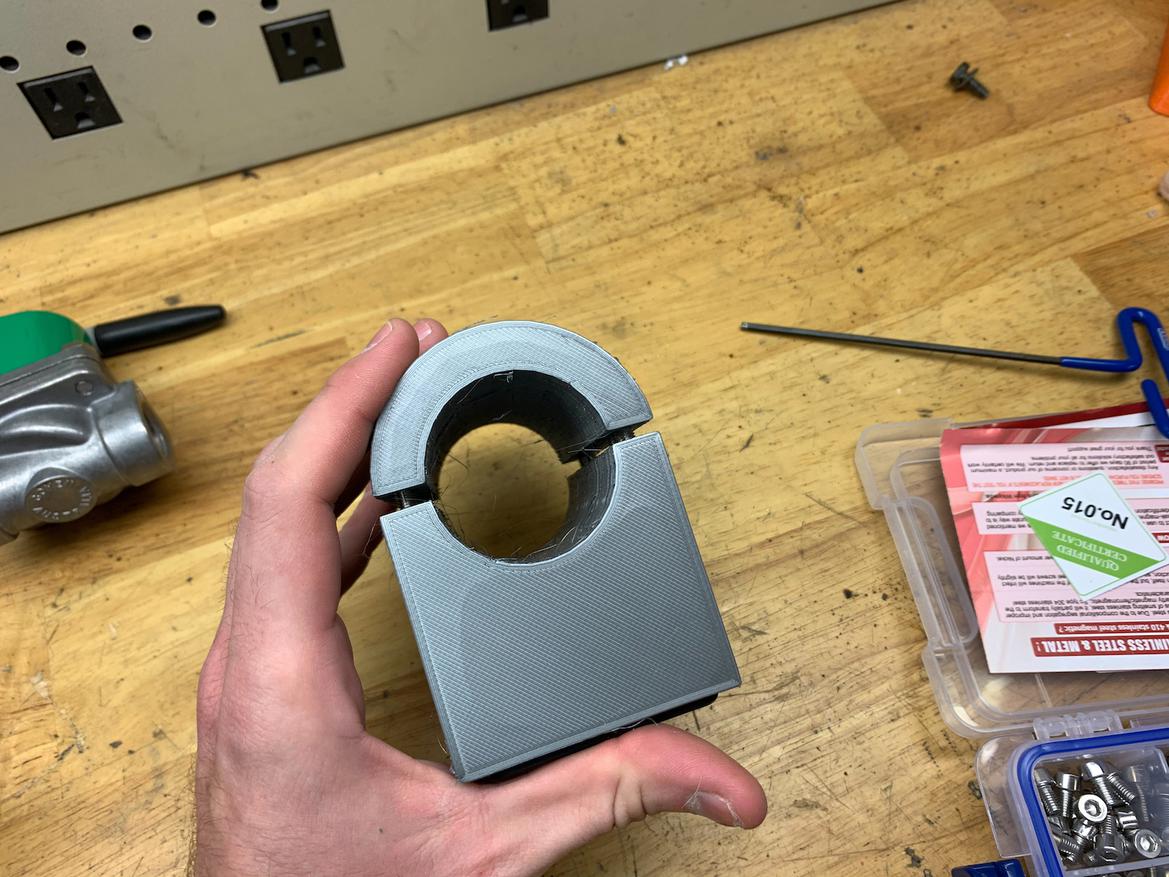

We used Fusion 360 to design this mount for a fire suppression system’s control box. It will mount to our 350Z’s roll cage, and why zip-tie the unit in place when a more elegant solution is possible? After inputting the basic parameters, we worked on the actual design–no prototypes, no wasted material.

After a few months, we can draw more complicated parts than we can figure out how to make on a three-axis mill. Yeah, the days of needing a computer science degree to use CAD are over. Fusion 360 is free for hobbyists and has every feature you’d ever want in a home garage, but there are several great alternatives, too.

Just do what we did and figure out what your friends are using, then download that software. No friends? Don’t worry: The internet is full of tutorials, and they’ll do a far better job explaining the details than we could.

Engineering on the Computer vs. the Workbench

Now that you understand what drafting is, why it’s important, how parametric design works, and how to make a parametric drawing, it’s time to get fancy. You’ve probably barely progressed beyond the ability to draw cubes and cylinders on the computer, but that doesn’t mean you can’t start engineering in a virtual environment.

We spent evening after evening just playing around on the computer, realizing that what used to be engineering brick walls–like exactly how to connect two parts to each other–are actually just opportunities.

Rather than draw the complicated bracket, we found ourselves drawing both parts it needed to bolt together, drawing the metal stock we’d be building the bracket from, then smashing them together in the virtual world to let the computer figure out where we’d need to clearance things and where we were missing material.

It’s a tough concept to explain in a paragraph, but engineering in a CAD drawing is like having X-ray vision, superhuman calculator abilities and a photographic memory all at once, and we’ll never go back to staring at dirty parts on the bench again. The best teacher here seems to be practice, and every dead end can be solved by Googling the name of your CAD software followed by the effect you’re trying to achieve.

And if you make a mistake? You’ve wasted nothing but time, and it’s easy to scroll backward in the timeline and make another attempt at it.

From Your Laptop to Real Life

Now that you’re engineering on the computer, you’re probably looking at images of beautiful three-dimensional parts that are so close yet so far. You can spin them around on screen with your mouse, and even bolt them together with the same keyboard you use for Facebook rants.

But you can’t touch them. Sadly, there’s no Control-P for physical parts. (Well, there sort of is, but we’ll cover that in the next installment of this series.)

Remember Wikipedia’s drafting definition from the beginning of this story? It’s time to create a piece of paper that shows a machinist how to make what you’ve just engineered on your PC.

Fortunately, this is pretty easy. Most CAD programs can generate these drawings almost automatically, and after some tinkering you’ll be able to print a few different views of your part with the necessary dimensions labeled.

It’s exceedingly important to put your required tolerances on the drawing, too: Can something be a few thousands off and still function? Okay, in which direction? Bigger? Smaller? Neither? The subject of tolerances is beyond the scope of this article, but no reputable machinist will make something for you without knowing the margin of error they have to work with.

Way to go: You’ve engineered a part, designed it on a computer, and created visual instructions so somebody can make it for you. Now you just need to find that somebody.

Welcome to the future: We 3D-printed our mount right in our own shop. We’ll detail that process in the next installment.

Good news: That somebody could be you. Drawings will help you make more precise parts, even if your tools haven’t changed. But if you’ve designed something that’s beyond your abilities to produce, a drawing will save you time and money at your local machine shop. Plus, it will transform you from an annoying amateur into another professional they’re happy to deal with. Okay, they’ll still be disappointed you don’t want to have 1000 of your parts made, but the odds of being told no decrease when you walk in the door with a drawing.

Even better, you can upload a 3D CAD model of your part to a mail-order online machine shop. That means you can design a part and have it shipped to your door without leaving your desk. One warning, though: Even online shops can charge a pretty penny for machining short-run parts.

What if you don’t want to pay somebody else to make your parts and would rather do it yourself? It’s time to start buying some equipment–which we’ll cover in the next installment.