I have a bolt that holds the CAS in a Miata valve cover that snapped. I center punched a dimple and drilled a small centering hole. Left hand drill bit, with the drill set to reverse. As soon as I start the bit snapped. And again a second time. So now it's time to summon the hive. Is it me or the tool? Is there a good high quality bit I should try?

You need an easy out.

https://www.irwin.com/tools/screw-bolt-extractors/spiral-flute-screw-extractors-535524-series-set

I have used a left hand drill to remove screws before by drilling with it. It sounds like you are trying to use the drill as an extractor.

In reply to akylekoz :

Easy out is the most miss-named tool ever.

79rex

New Reader

4/8/19 12:10 p.m.

If you are trying a left handed drill bit having a hole in it 1st will make it snap easier.

In reply to akylekoz :

Drilling the pilot for the easy-out with a left hand drill is a pretty accepted method, it's in case the screw catches and turns with the drill bit it'll come out instead of going farther in.

In reply to glueguy :

Are you drilling at low speed? You want to be at low speed going into steel. Using cutting oil? Even wd40 is good enough, but you typically want something. Keep the bit lubed, spray a bit of lube on the tip every 15-30 seconds or as the existing lube evaporates / cooks off. Don't press very hard, especially with the smaller bits. In the end it might be the tool - there are some atomically crappy drill bits out there.

You need a mig welder and a handful of nuts to weld to the borken one.

If you are lucky it will come out on the first one, keep trying.

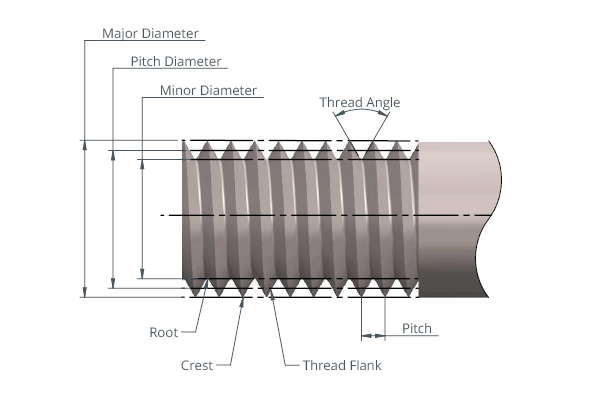

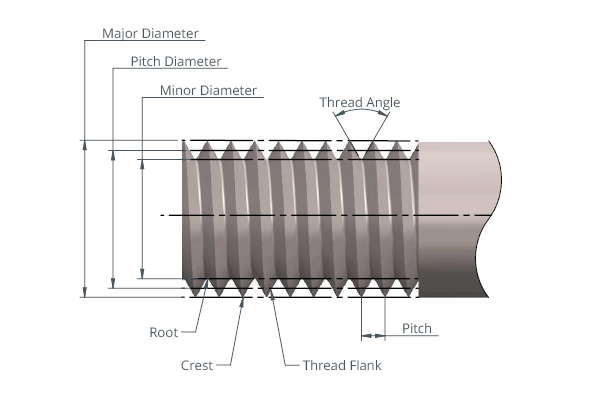

Use a drill (RH) that's close to the minor diameter of the thread, go to the bottom and then use a punch or pointy thing to fold the threads into the new hole.

A good left-hand drill bit will work just like a conventional but with the drill turning in the opposite direction so you're either doing something wrong or the bits are junk. I use whatever McMaster-Carr ships when I order.

I have Snap-On reverse thread bits and EZ Outs and I guard them with my life.

There are cheaper and better ones out there I am sure, but these are mine and thus far they are batting 1000.

But yeah buy reverse thread bits from a known vendor of quality stuff and you will be in the money.

https://www.ebay.com/p/Snap-on-EXDL-10-Cobalt-Drill-Extractor-Set-LT-Hand-Split-Point-Cobalt-Drills/1133049164?iid=264272550835&chn=ps

TurnerX19 said:

In reply to akylekoz :

Easy out is the most miss-named tool ever.

I've called them Hard-Outs for about 50 years...

How big is the pilot hole in reference to the attempted LH bits?

Sounds like the pilot hole is too big and the bits are catching and burying themselves instead of making chips. You don't want to use a pilot hole big enough to see through the flutes.

dculberson said:

In reply to glueguy :

Are you drilling at low speed? You want to be at low speed going into steel. Using cutting oil? Even wd40 is good enough, but you typically want something. Keep the bit lubed, spray a bit of lube on the tip every 15-30 seconds or as the existing lube evaporates / cooks off. Don't press very hard, especially with the smaller bits. In the end it might be the tool - there are some atomically crappy drill bits out there.

Yes to going slow, probably not enough cutting oil. In fact, as soon as the bit would make 2-3 revolutions the tip would snap.

Crackers said:

How big is the pilot hole in reference to the attempted LH bits?

Sounds like the pilot hole is too big and the bits are catching and burying themselves instead of making chips. You don't want to use a pilot hole big enough to see through the flutes.

Pilot hole was small. I was thinking too small diameter and too shallow. I think I just made a "super dimple" instead of drilling a real hole in the center.