Progress has been good for the last couple of days. I wasn't feeling too hot on Monday or Tuesday, but the last couple of days I've been feeling a lot better and things have been moving along much better.

Earlier in the week I was fooling around with the front anti-roll bar. Until this week, I hadn't even tried to see if I could fit a bar in there. This was one of the project aspects that I've just been wingin', as I assumed I could figure something custom out later and the front bar was a pretty low priority. As luck would have it, the stock bar just BARELY fits. I had to relocate my cooling fan, and the lower radiator support will need some new modifications, but otherwise things are pretty close to stock. This was GREAT news, as I could reuse the stock mounts and bar.

Unfortunately, it wasn't quite a slam dunk. The stock end links in the stock attachment point would have to go right through the front axle boot. I tried a few different ways to do an end link before I finally figured out something that fit and I was satisfied with. Here are my three different tries, first on the left, last on the right:

They aren't pretty looking, but I think they'll work fine. I was actually surprised how close the final pair ended up being, considering I was working with a bunch of very rough tools and hunks of scrap metal:

To give you an idea of how tight things are, here are two shots showing the knuckle turned in each direction. In the first one you can see how close the axle boot gets to the end link, and in the second you can see how close the tie rod/knuckle gets to the end link.

Note that I still need to add some type of standoff to keep the end link from rotating. Like I said, not pretty, but it will get the job done. I think this setup is worth the hassle since it allows me to use the stock bar, end link bushings, control arm mounting location, etc.

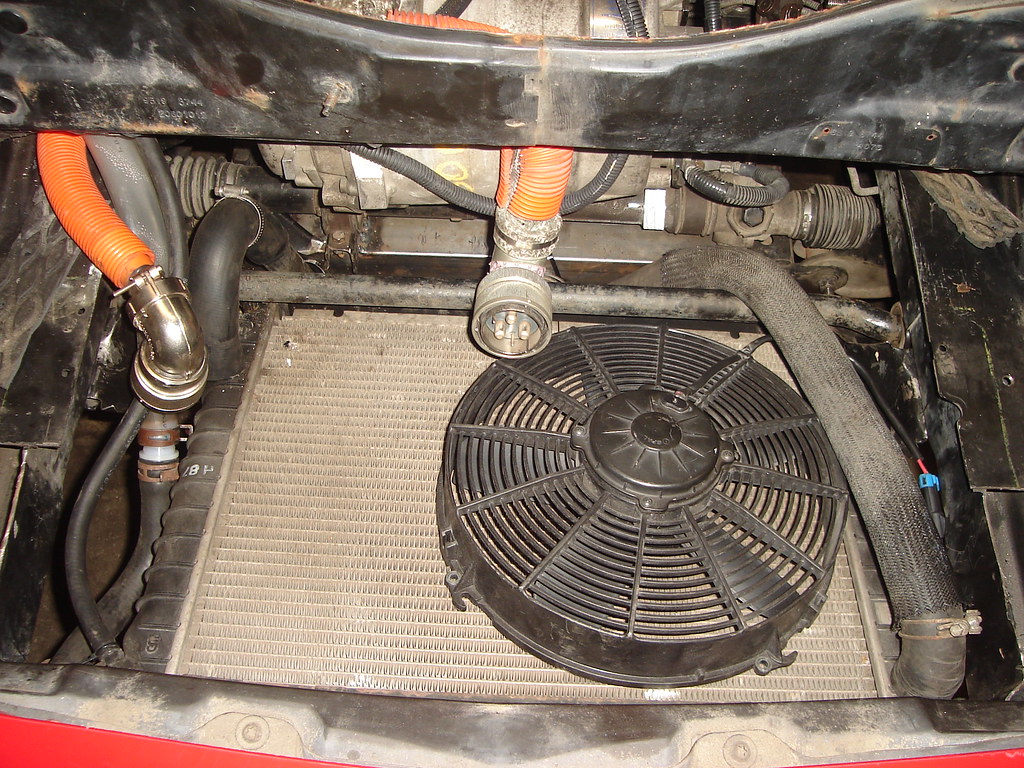

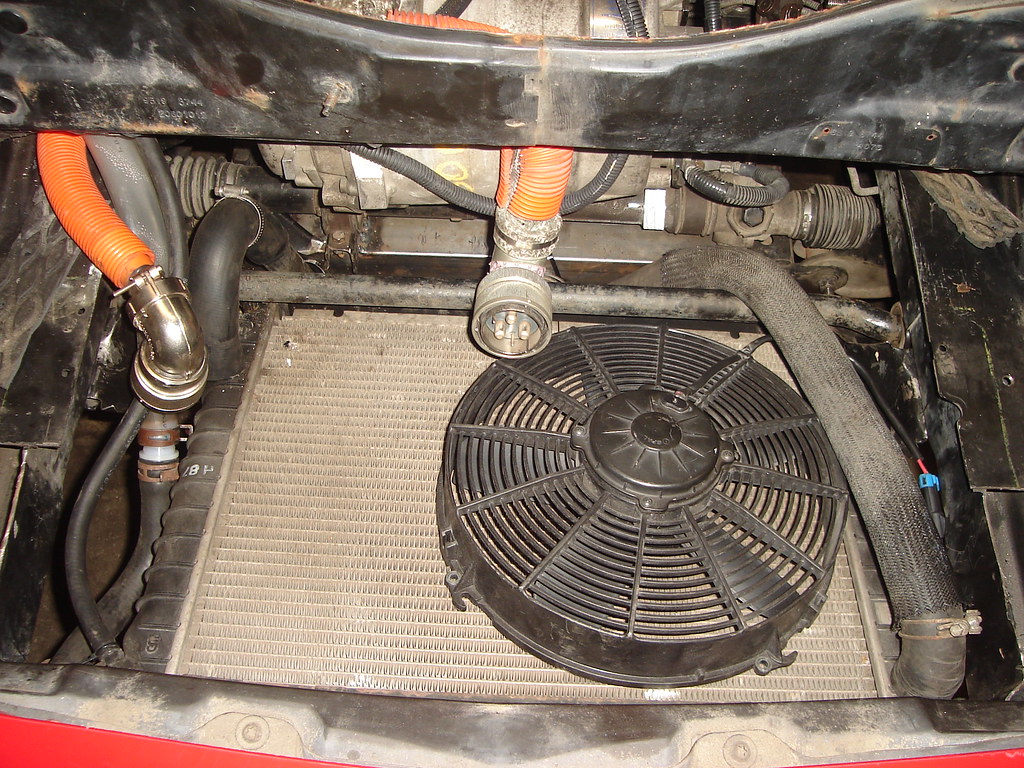

So, with the bar installed, here's a shot showing how tight things are with the cooling package. I thought things were getting pretty close before, but with the bar in there it's REALLY tight.

The radiator is about an inch away and both of the large cooling hoses wrap around the bar and then shoot straight down. The electric fan sits on top of the radiator just forward of the sway bar and when the inverter sits in place it fits about 1/2" above the electric fan. Like I said, tight squeeze!

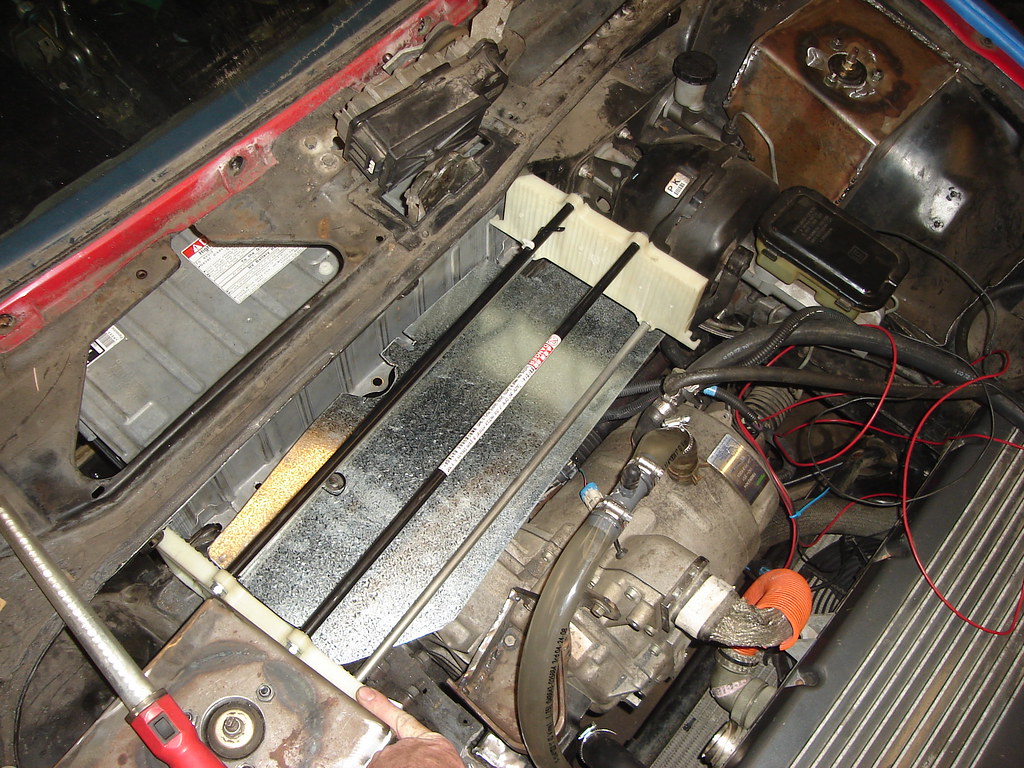

Once the sway bar stuff was finished up, then I moved on to the hood mounts. This is a shot from where the radiator would normally be. You can see the hood on top, and the hinge leads down to some sheet metal that I cut out. I had to cut this out to fit the inverter between the bumper and the motor without modifying the hood.

I seperated the original stud plate that the hood hinge mounted to and trimmed it to be very small. Then, with the hood in place and the hinges bolted to the hood so the pivot would be in the proper spot, I tack welded the stud plate to the chassis. This is where it ended up:

This allows me to use the stock hood, hinges, latch, release, and even have the same adjustability as the stock setup. Tomorrow I'll add some reinforcement to the new stud plate setup and finish weld it, box in the area that I had to cut out for inverter clearance, and reinstall the inverter for a test fit with the new metal in place.

I'm pretty happy with how things are shaping up. I was thinking I should show how some of this stuff goes together because once it's all finally assembled, it will be nearly impossible to see everything that's going on. Of course, in the name of making it look factory, I guess that's a good thing.

Oh yeah, one more thing. I said I would take pictures of the current throttle pedal setup. Here's how it looks currently, it's been really handy having the pedals independent while I do test drives (sorry for the blurry pictures).

Bryce

![]()