JoeyM

Mod Squad

10/14/13 11:36 a.m.

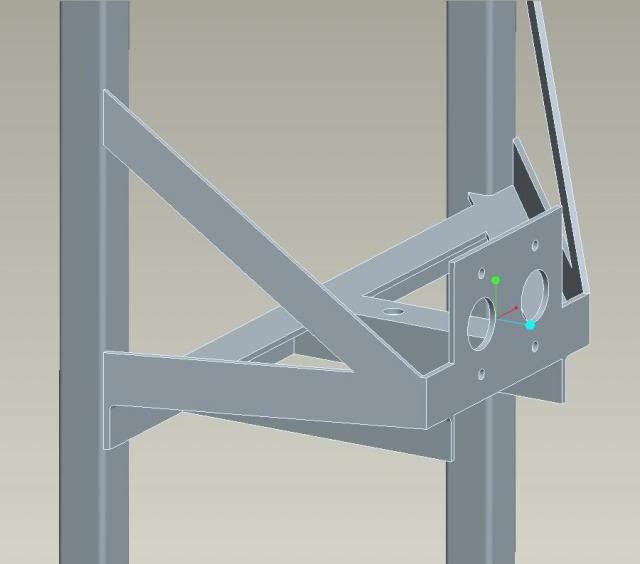

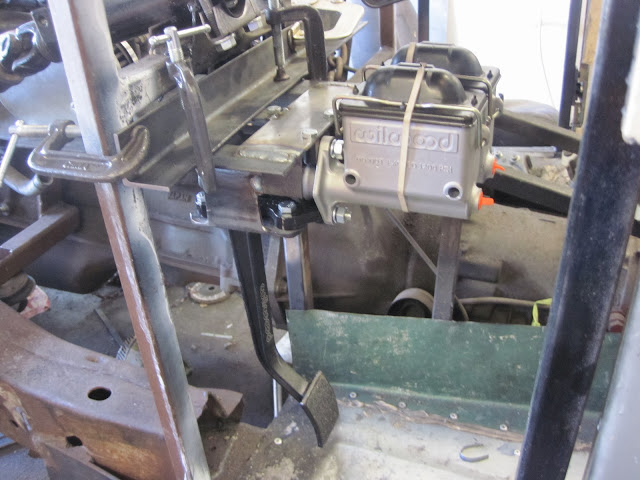

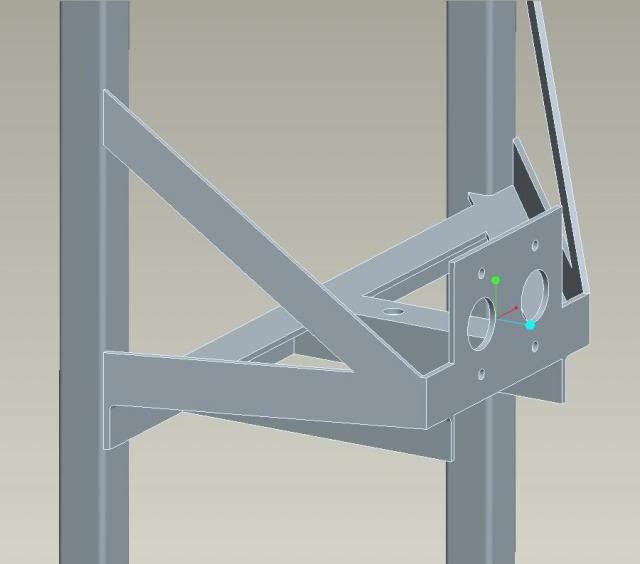

OK, those of you who have been watching my build thread know that I recently purchased this reverse swing pedal assembly.

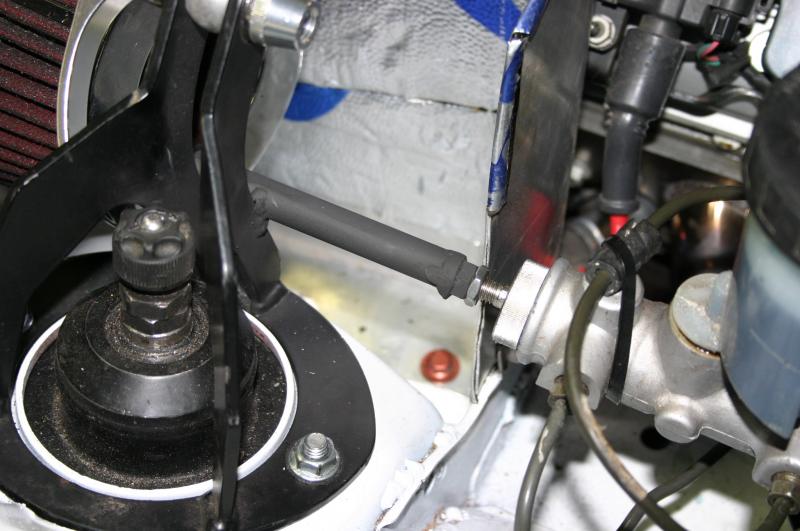

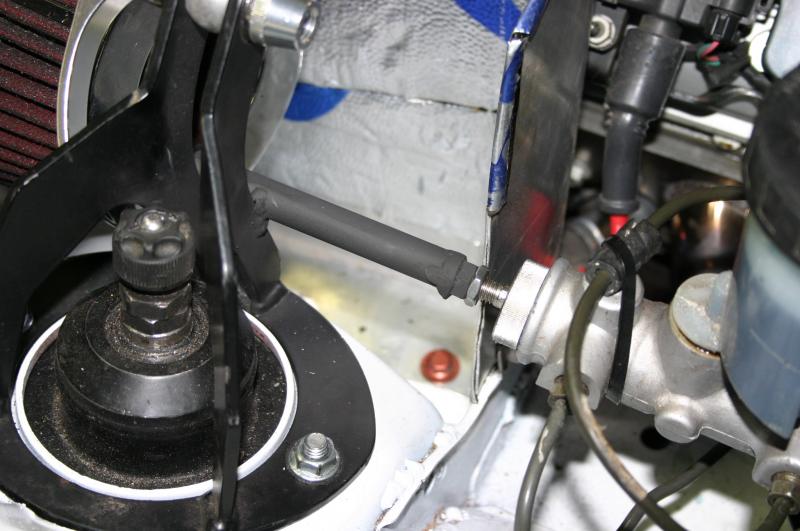

The photo above is the assembly being test-mounted to approximately the appropriate spot in the chassis. The location is OK (great, actually) but those master cylinders hanging out the back will have a lot of mass. I want to have a way to support them at the back. Low and behold, there are holes cast through the metal master cylinders at the front and back. (See photo above.)

Can I safely run a threaded rod through those holes and use it to support the master cylinders? Are those holes designed for such a thing? Will it weaken the master cylinders to have the walls of those holes vibrate against the rod?

I think you could. I don't think you need to. The mc should be designed to support itself. Unless Wildwood Tells you to support it I wouldn't worry about it. I would redesign the mount though.. I know that's temporary do you know what you have planed for the Mount?

I'm pretty sure nocones is right, and the forces involved in using the brakes are going to dwarf the forces involved in supporting the MC itself.

tuna55

PowerDork

10/14/13 11:47 a.m.

nocones wrote:

I think you could. I don't think you need to. The mc should be designed to support itself. Unless Wildwood Tells you to support it I wouldn't worry about it. I would redesign the mount though.. I know that's temporary do you know what you have planed for the Mount?

This. I've never seen a master cylinder supported any other way, although I have not seen anything.

JoeyM

Mod Squad

10/14/13 1:17 p.m.

nocones wrote:

I think you could. I don't think you need to. The mc should be designed to support itself. Unless Wildwood Tells you to support it I wouldn't worry about it. I would redesign the mount though.. I know that's temporary do you know what you have planed for the Mount?

My plan was:

1) weld one piece of angle iron (the upper) to the chassis.

2) drill through the flats of both pieces where they touch, holding them together with a 5/16" bolt on each side.

That should anchor the front, but I don't feel like it is adequate. I want to anchor the back of the assembly, too. (i.e. two points of attachment to the chassis at the front, two at the back.)

The pedal mount I pulled off the 910 was only bolted to the firewall, but this was done with four bolts. I feel like I need to anchor the back, too. If I don't do it via the holes in the MC, I could weld verticals at the back of the mount to tie the whole thing to the dash.

JoeyM

Mod Squad

10/14/13 5:12 p.m.

OK, stopped by the speed shop on the way home. (Yes, an old fashioned one, with their own machine shop next door.) They said the holes in the master cylinder castings are there so the MC can be bolted to the chassis if you prefer the below-the-floor mounting option. (i.e. they are plenty strong enough to run a rod through and use it as part of a mounting bracket.)

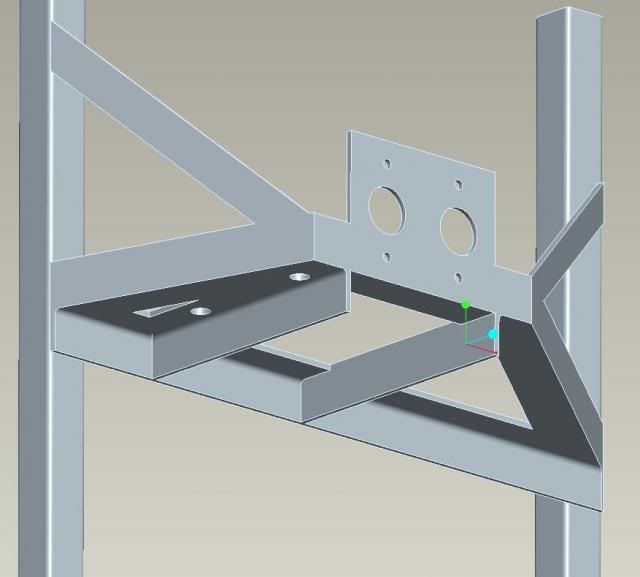

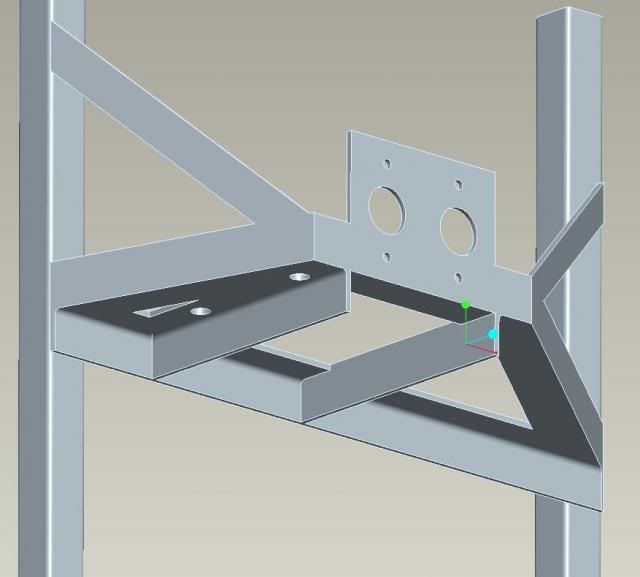

Joey I put some thought into mounting your MC setup and I would build something like this.

I would construct it out of 1x1x1/8" angle for the most part. The main cross beam could be larger. I would weld in a washer under the 4 pedal mounting bolts to reinforce that area. It's possible this is what you were describing but I just took 10 minutes and threw this together to illustrate how I would complete it.

JoeyM

Mod Squad

10/16/13 10:15 a.m.

Wow, thanks! You put a lot of work into that. I really appreciate it.

It would not be difficult to turn what I have already into something like that, and those diagonals solve what I was freaking out about (i.e. supporting the back.) When I get back into the garage I will take some more photos to make it clear what I have already[*] and we can talk about how to modify it into what you've drawn.

--

* - the plate with the holes is a really good idea. I never would have thought of it, since the MCs mount to a similar surface in the pedal assembly. I can definitely see how the plate would create a tighter connection between the bracket, pedal assembly, and MCs.

Nice solution. I like the diagonal drop bars.

About the amount of force involved in braking- I've got the stock Miata master cylinder mount plus a reinforcing brace on the backside tied into a shock tower brace.

When we were bleeding the brakes the other day, I looked up to check the fluid level and saw the entire shock tower brace flexing back and forth as Brandon checked pedal firmness. He wasn't trying to push the pedal through the firewall or anything, merely giving it a shove. It was pretty eye-opening. Needless to say, I've reinforced it since.

I think it would also be a good idea to think about your degrees of freedom allowed in the system. If you contrain the MC in too rigid a structure it may not be able to flex/grow/shrink with changing pressures and temps. While small those stresses could generate a stress concentration in some corner and cause you problems. The mount Cones engineered/designed would be a good way to go if it also doesn't interfere with your other controls (Steering column/wheel!)

Trust that Wilwood has designed a product to be supported in either way but double confirm with them that the unit can be constrained at ALL mounting points rather than just one or the other.

JoeyM

Mod Squad

10/17/13 11:56 a.m.

Advan046 wrote:

Trust that Wilwood has designed a product to be supported in either way but double confirm with them that the unit can be constrained at ALL mounting points rather than just one or the other.

Good point. They easily could have designed it for an either/or mounting scenario, planning for some movement to occur.