4cylndrfury wrote: LOL still not sure about the ITALICS????

You didn't close a bracket up there.

more fun with metal casting in the backyard...Heres a lil contest im involved in on another forum: http://www.backyardmetalcasting.com/forums/viewtopic.php?t=3706&start=130

Heres a teaser of my casting:

Im thinking that if I can get enough things right, my centrifugal supercharger idea may not be so crazy afterall...Im learning a lot about how to make better alloys from scrap aluminum, create more uniform densities, and have castings requiring less finish machining.

Anyway, feel free to register and cast your vote for me at that website linked above when voting starts come the new year...what? We are all competitive, is stuffing the ballot box so wrong?![]() ha ha just kidding...theres a lot of talent Im up against, and I probably dont have a quarter the talent some of the other guys there have. Im just glad to compete, let alone if I place in the comp

ha ha just kidding...theres a lot of talent Im up against, and I probably dont have a quarter the talent some of the other guys there have. Im just glad to compete, let alone if I place in the comp![]() ...that would be crazy! There was even talk of classing some of these guys as they are current/retired professionals working in real foundries. There's tons of win on that website.

...that would be crazy! There was even talk of classing some of these guys as they are current/retired professionals working in real foundries. There's tons of win on that website.![]() class="smiley" alt="" />

class="smiley" alt="" />

more metal casting fun...This time, its an imitation of a professional foundry furnace at about 1/4 scale![]()

Started with an old water expansion tank I found on the side of the road. I cut it open and removed the rubber bladder inside. Now i had a nice empty steel shell...perfect. Next I built legs. Theyre leftovers from a garage door opener kit. I didnt need the track as I only needed to replace a burned up motor. This track was essentially free scrap - score![]()

Next, I cast some ultra high temp refractory (3000° to be exact) as the floor of this beast:

Then I cut up some ceramic board (this is an insulator rated up to 2400°):

I created an inner form buy taking a plastic paint can, cutting off the handle tabs, and adding a few inches of extra height by taping on some heavy cardstock. I also used 2" PVC pipe as my blower tube for the burner to enter the furnace. I used hot glue to seal it all up:

I cast the refractory slurry into the shell. This stuff acts a lot like concrete when mixed with water. The main difference is that this mix bonds on a chemical level, where as normal cement bonds mechanically. Mechanical bonds break down at high temps...bad news for a furnace you hope to be able to melt iron with.![]() . Heres the pic:

. Heres the pic:

TADAAAHHH - here she is after about 30 hours of curing. Once I fire it for the first time, the grey refractory will turn nearly white. There is 0 shrink in this material too, so no dimensional distortion. 7 1/2" bore and 8 1/2 height. I plan to make a lid next that will add another inch or so to the overal height of the crucible that can fit into this furnace.

The best part about this build? IT was all FREEEEEE![]() . I found a boiler installation joint that lets me have their partial/damaged stuff for nothing...not even a song

. I found a boiler installation joint that lets me have their partial/damaged stuff for nothing...not even a song![]() . Basically, all the stuff I have here was either garbage, found on the side of the road, or leftovers from something else. Doesnt get more grassroots than that!

. Basically, all the stuff I have here was either garbage, found on the side of the road, or leftovers from something else. Doesnt get more grassroots than that!

In reply to 4cylndrfury:

I'm getting into this too, I just finished making my furnice using 3000 deg refactory. I'm firing mine with waste oil that I have plenty of and now all my friends are giving me theirs so I'll have the capabilty to do all the way up to steel castings for free.

Chris Rummel

914Driver wrote: I see the Nintendo generation every few months in the new Machinist apprentice classes. A few couldn't figure out how to get a chuck key into a drill press chuck. No mechanical experience. Yes, sad.

Especially since a chuck-key is what Hospital Corpsmen called "Marine-proof." I could go on and on about this...

However, I'll try to remain on-topic. Nice work with the metal-casting by 4cylndrfury! I'd like to try that, just as soon as I get a backyard.

ah man missed this thread, this is pretty cool. In college we turned a pile of bricks into a forge using a squirrel cage fan I had lying around, we melted some aluminum bars and cast corn shaped ingots lol ![]()

so its been a while, but my little foundry is all grown up...sorry for the terrible quality - my phone takes ridiculously low quality video. See more about this HERE

http://www.youtube.com/watch?v=FgkbchUnlK8

Tommy Suddard wrote: No shop in my highschool. The closest thing is a robotics program. They have some tools, but... Here's my favorite scoldings from the past year: "Tommy! You could hurt yourself with that screwdriver. You have to wear safety goggles." "Tommy! You need a fire extinguisher next to that. And gloves!" (watching someone drill a hole in a piece of metal in a vice on a drill press) etc, etc. Of course, we weren't allowed to use any of the tools except the screwdrivers until we were 18. Even vice grips. I had to show a lot of the 18 year olds how to use the tools.

What's funny about that is that some kid in my school stabbed another kid with a screwdriver (in his arm--it wasn't terrible). Both were under 18. I don't think there were any other shop-related injuries that year and our school didn't have silly age rules like yours, Tommy. I was spot-welding in 7th grade! Metal shop was fun.

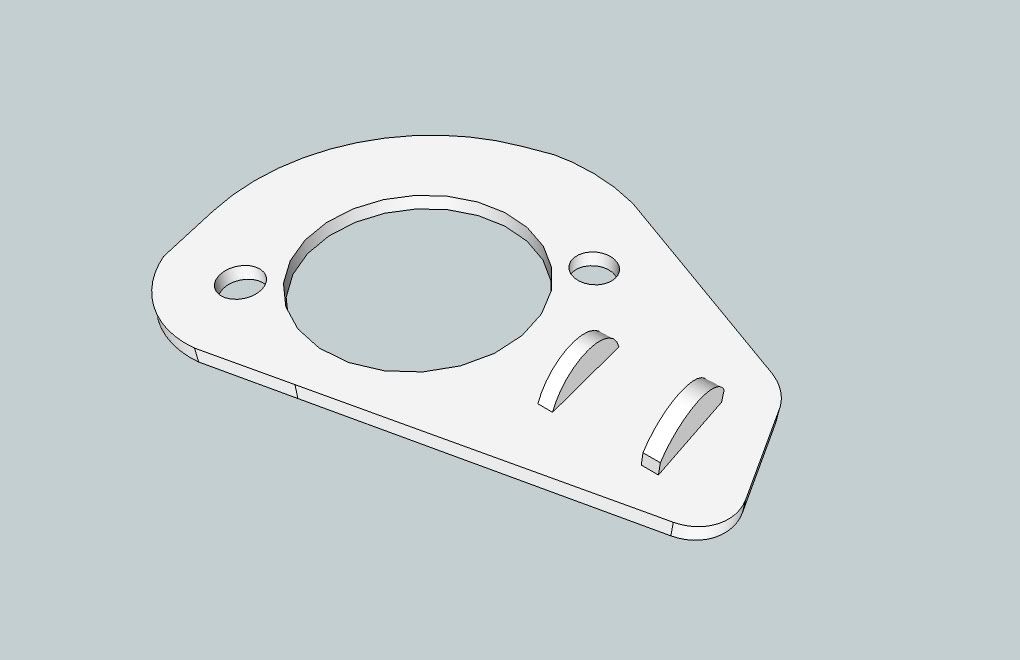

So I am embarking on my first automotive related casting project - I want to make a strut tower bar for the back end of my G20. I made a little sketch in Sketcup :

This is the base plate - as close as I can measure, the 2 strut mounting studs are 88mm apart and the center hole in the strut tower is 65mm. That means the hole in the base plate needs to be approx 68mm for good clearance. the actual bar will be some extrusion that I will pick up at the bigbox/metal surplus - something fairly rigid with a decent cross sectional structure. I will also cast plugs to insert into the extrusion that will bolt in between the plates.

This is barely off the ground yet - i made this little sketch and have started cutting the pattern by hand from the 5mm rigid polystyrene board that made the for sale sign that was in my front yard 2 years ago when we bought our home. i just thought this would be a fun spot to put the casting photos. Once the project is done, I will post a thread with photos of the completed bar...

Dr. Hess wrote: Making boolits yourself is easy, inexpensive and straight forward. You can roll your own for basically free to a penny each (including lube). I've been doing it myself since I was 13. With the price of store-bought boolits and bullets these days, there isn't much other choice.

I have scarfed a neat little cache of lead type and lead ingots from two printing opertions with the intent on using it to make some boolets. All I have to do is get the front-loading fire stick.

You'll need to log in to post.