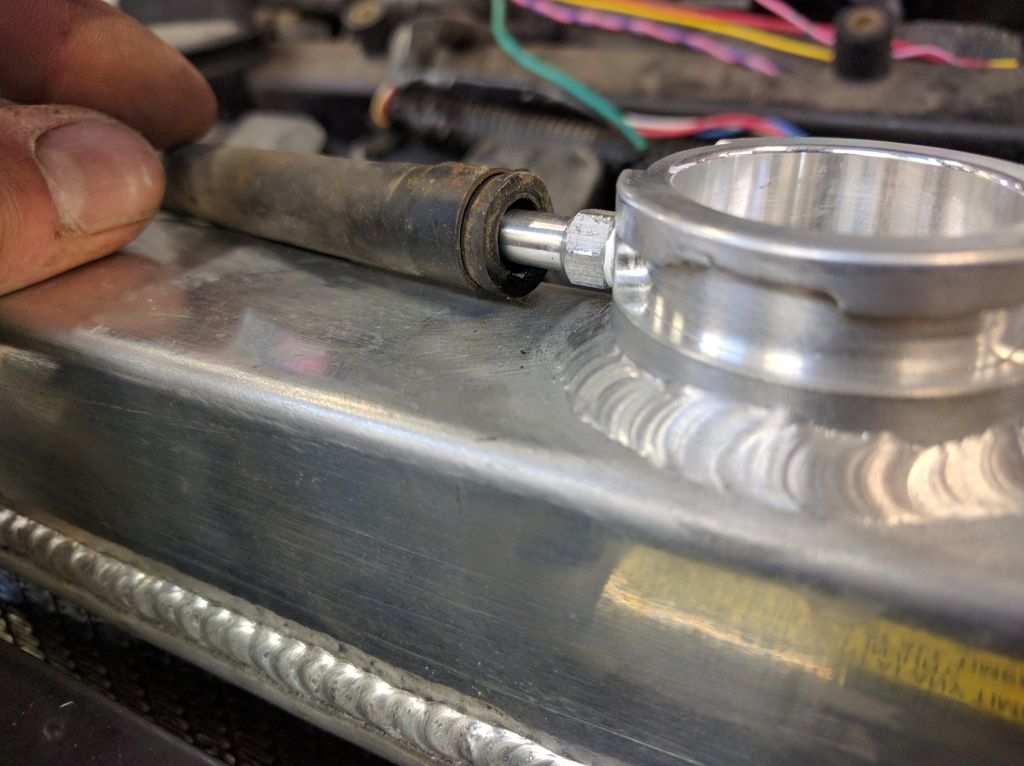

That was my first thought, but the aluminum neck is only about 2mm thick. I considered maybe asking the fab shop if they could just eliminate the little riser/neck and weld the cap flange directly to the top of the rad but figured buying a new filler that will work would be cheaper than having them spend extra time fiddling around trying to save what's there. Wish I knew how to weld.

Edit: here's a pic of the neck. Was trying to see how much clearance I have under the hood.

Put a blob of soft clay on top of the cap and then slowly close the hood. Open the hood to see how much the clay flattened out...

So the new filler neck and cap showed up, it's pretty slick.

I pulled the radiator and dropped it off a couple days ago, should have it back at the beginning of next week.

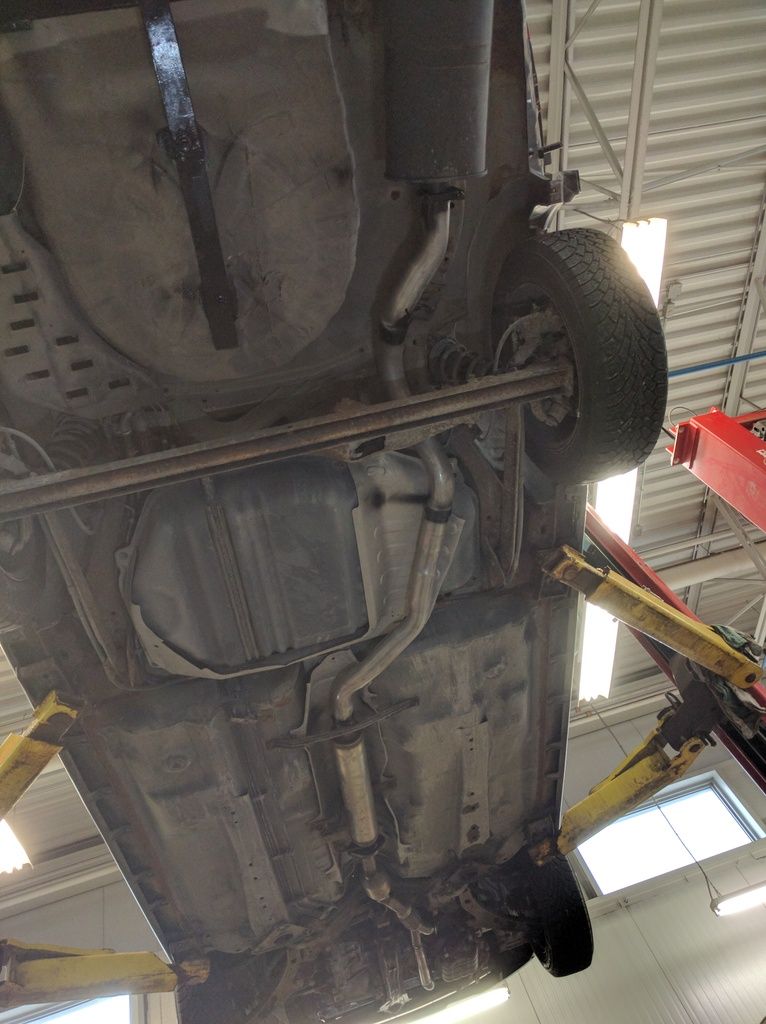

With the radiator out I had room to check out my exhaust leak.

The welds on the #2 runner don't allow the nut to bottom out against the flange.

The welds on the #2 runner don't allow the nut to bottom out against the flange.

Ground down the flange on the nut to let it seal properly. Can't tell if it's 100% gone or now, but it's definitely much much better.

Rigged up an intake.

Just some straight 3" piping, a 60 deg bend, a filter, a cut up stock MAF housing, and some couplers.

Just some straight 3" piping, a 60 deg bend, a filter, a cut up stock MAF housing, and some couplers.

I've also started on getting the power steering working.

Left is the OEM Altima pump, right is a 2001 Maxima pump. They're pretty much the same, except the Altima pump is aluminum and the Maxima is steel. The Maxima has fittings that fit much better in my chassis, but the Sentra high pressure line has this funny straight bit that interferes with the oil supply fitting on the pump. The plan now is to swap the Maxima supply fitting onto the Altima pump, and flip the Altima high pressure feed upside down to get the locating tab for the high pressure line in a better spot.

Left is the OEM Altima pump, right is a 2001 Maxima pump. They're pretty much the same, except the Altima pump is aluminum and the Maxima is steel. The Maxima has fittings that fit much better in my chassis, but the Sentra high pressure line has this funny straight bit that interferes with the oil supply fitting on the pump. The plan now is to swap the Maxima supply fitting onto the Altima pump, and flip the Altima high pressure feed upside down to get the locating tab for the high pressure line in a better spot.

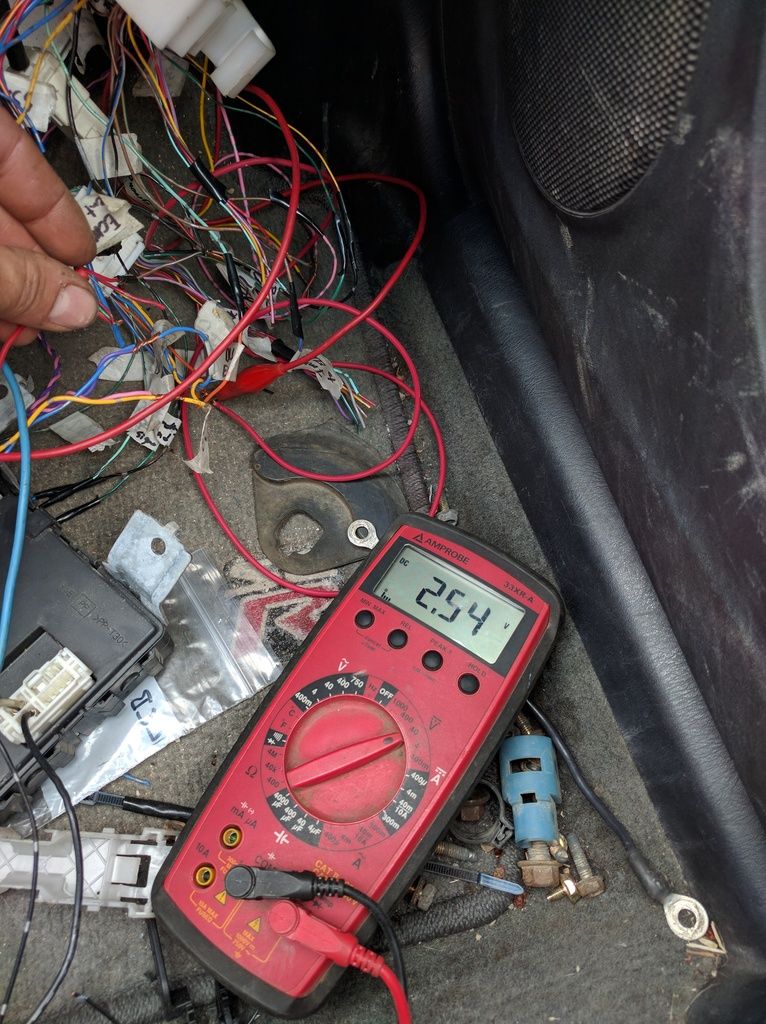

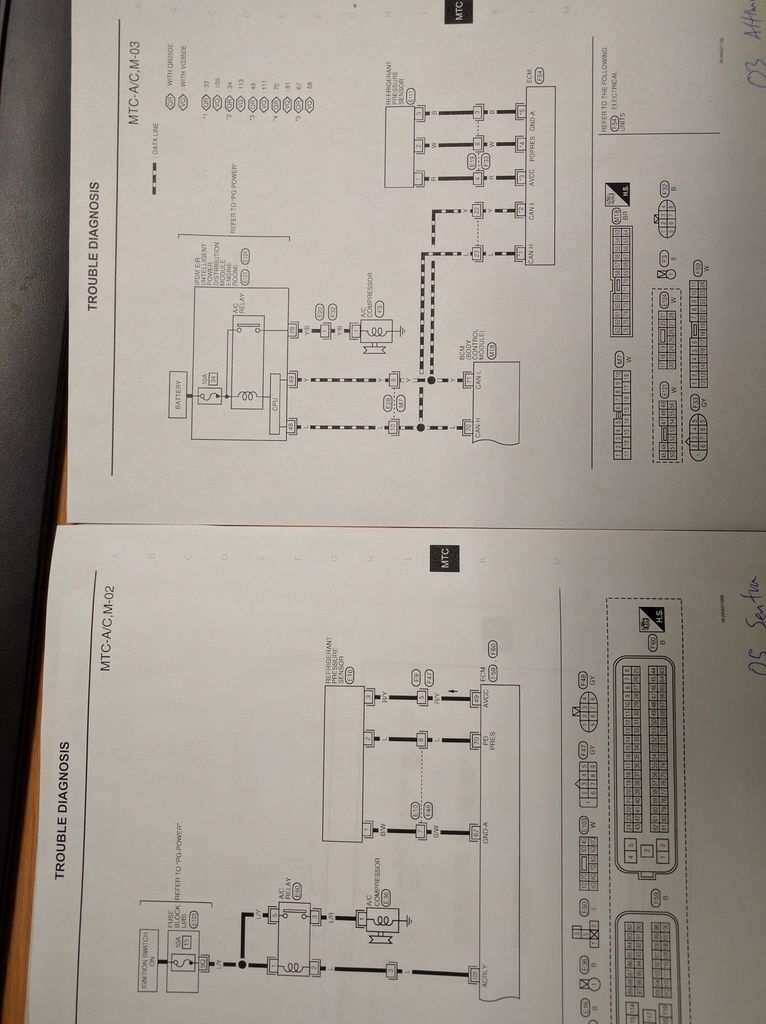

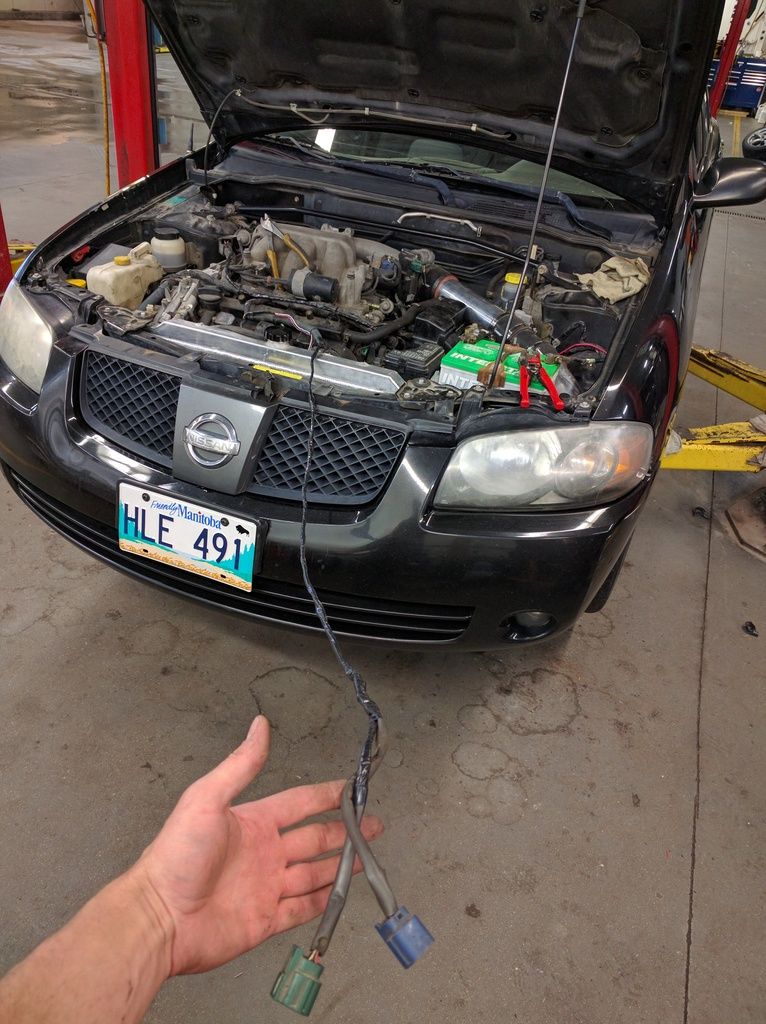

So while the rad was out, I started working on one of the issues I need fixed before I start driving it, namely a parasitic drain.

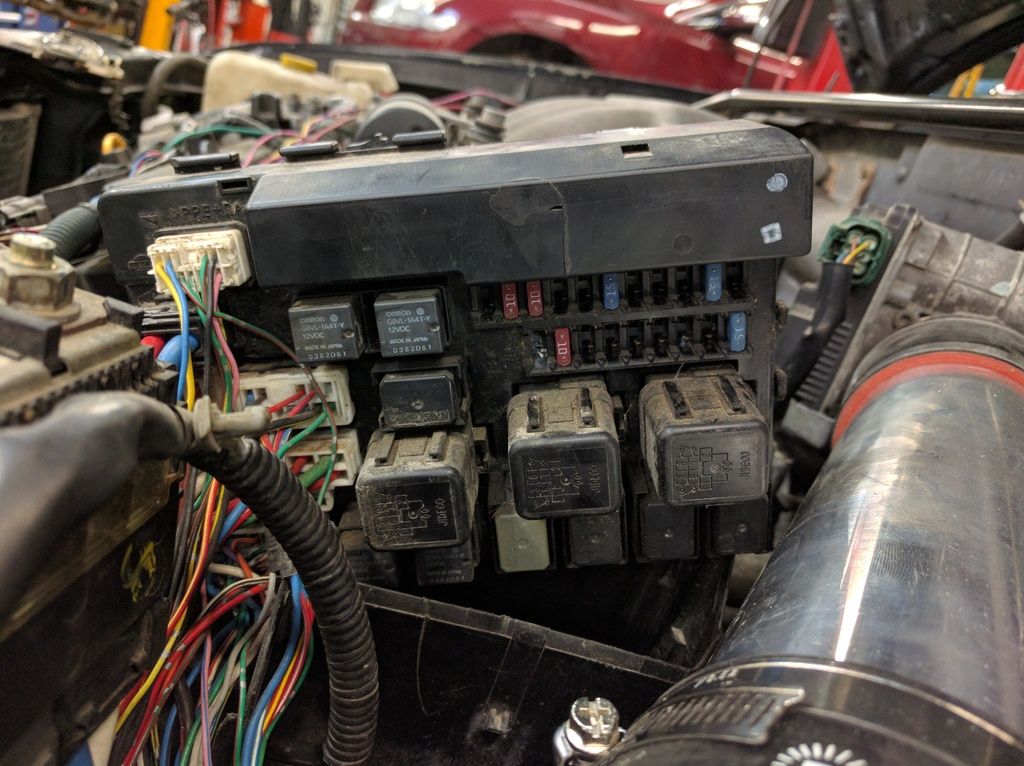

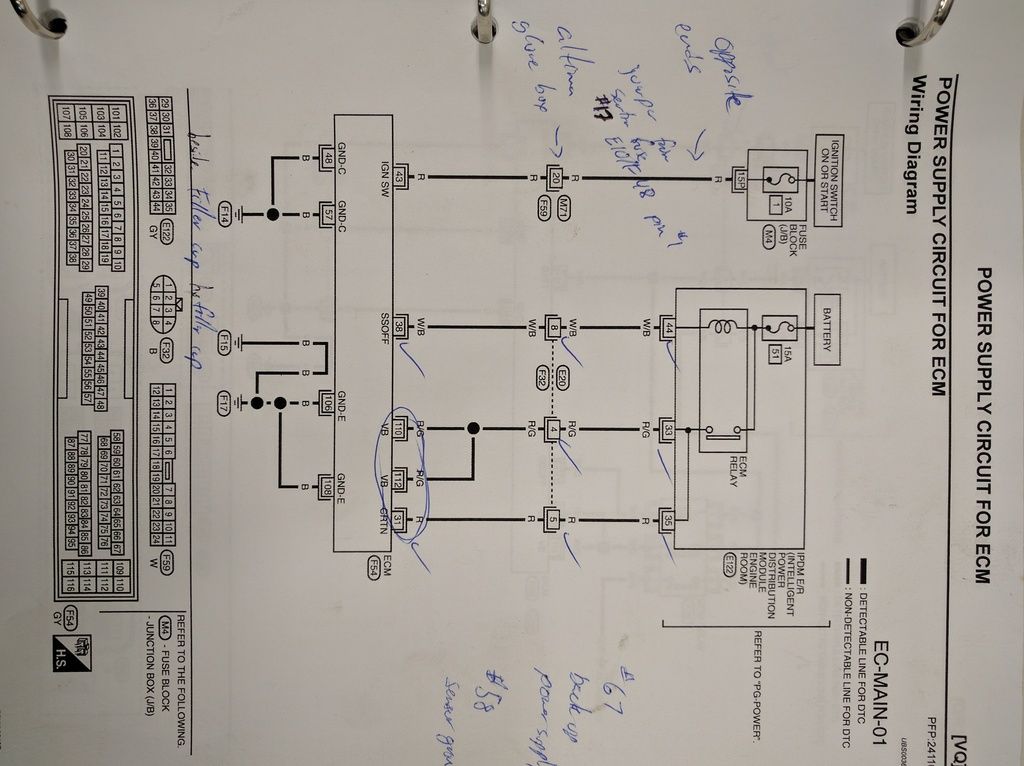

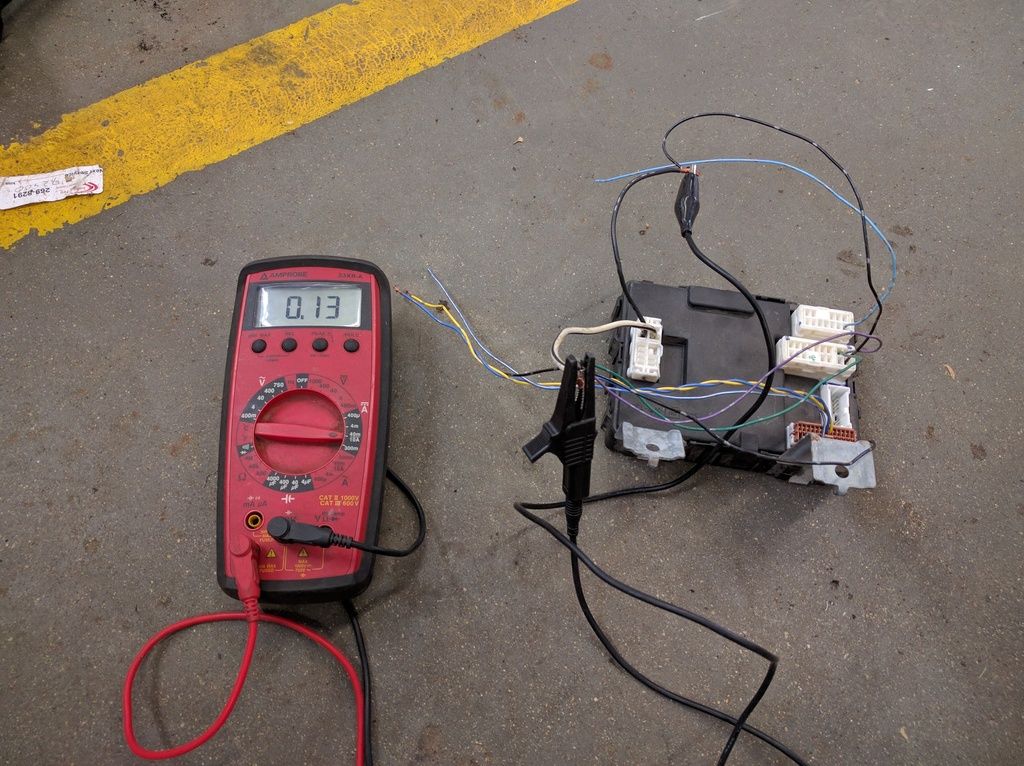

The battery had a 400 mA draw with the ignition off. Enough to kill the battery in a couple days. The draw dropped to under 100 mA when unplugged the main power cable to the retrofitted Altima IPDM, so I started by removing all fuses for unused circuits. I'm not using the IPDM for much, just engine running functions. All the body and lighting functions are still stock Sentra.

I found pulling fuse #51 (the 15A in the bottom right) eliminated the draw. Fuse #51 feeds the ECM relay, and sure enough I found the ECM relay is being stuck on.

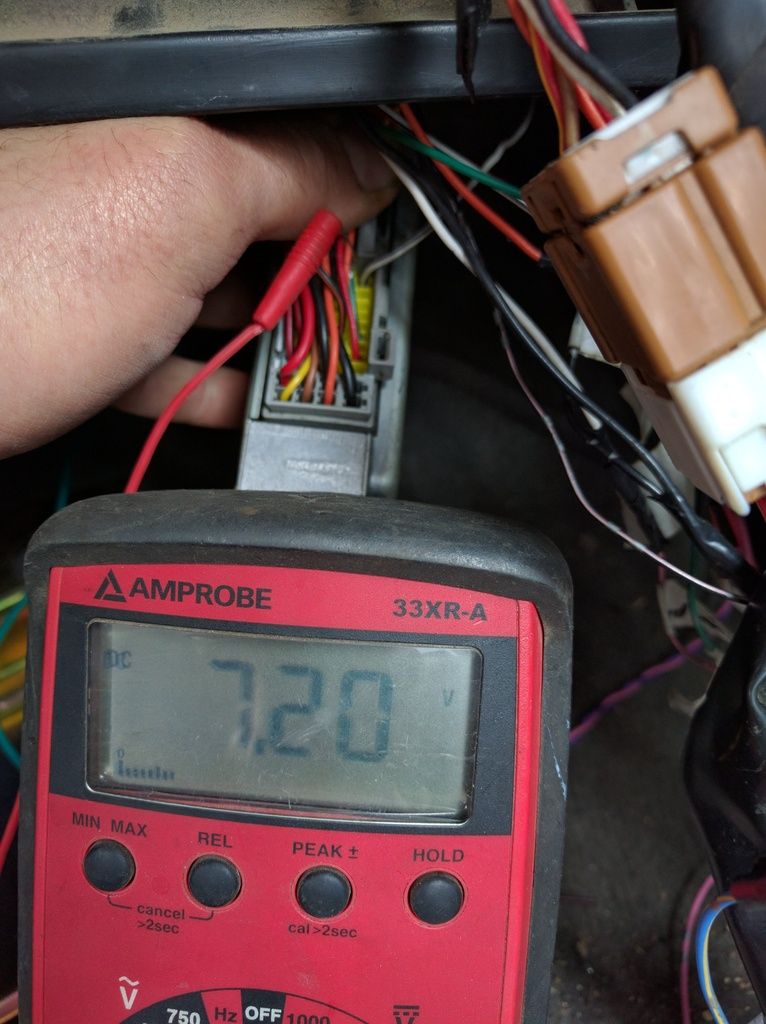

Backprobing at the ECM shows 7.2V, the remaining 5V from battery voltage being consumed by the low side relay. Now the weird part is this circuit it pretty much all factory. I only made one splice, and it was to shorten the wires between the IPDM and connector E20/F32. The ECM is supposed to take away ground from the relay and shut itself off when it no longer sees battery voltage on pin 43, but it's not. It's not a shorted wire either as the remaining 7.2V is still available at the ECM. I've double and triple checked all wires in that circuit, double checked the ECM pinouts for any sort of input it might be missing (and found one, but no change once corrected), and also got my shop foreman to take a look at it. Everything is pointing to bad ECM. I'm not going to buy another ECM (not like I'd be able to find another 02-03 V6 5 speed ECM easily) so I'll probably remove the white/black wire from ECM pin 38 and use a relay to control ground to it when the IGN is on.

The radiator is all done now too, just have to install it.

Just beautiful....wish I could weld like that.

Next Tuesday I'll be installing the rad, putting a relay in to fix the draw, and connecting the valve cover breather to the intake. With the breather open like it is now (see prior post with intake picture), the PCV system is essentially an un-metered intake leak. Connecting it back up before the throttle plate but after the MAF will fix that, and hopefully help it run a bit smoother at idle.

Connected the valve cover breather to the intake piping so I wasn't getting un-metered air in.

The factory intake elbow has a nice little bit of pipe, and a co-worker donated a nice grommet from his junk drawer.

Drill a hole in the pipe, trim down the grommet and pipe, lube it all up to slip together

Finished!

The hose wants to twist the fitting sideways, so I zip tied it to a better angle. Ghetto, but should work. Not sure how long I can expect this to hold together, I expect the rubber to rot out or the pipe to cut into it after a while even though I sanded it down as smooth as I could. Anyone have a better solution? Rather not have to pay someone to TIG a fitting on.

Stuck a couple 12" slim fans on before plunking the rad back in.

Tight....I may have to wrap the header or put some sort of reflective tape over the fan motor. If it burns out I have another fan that matches the drivers side one I can mount as a pusher.

With the radiator back in, time to make a better lower rad hose. Don't trust my plastic irrigation fitting to hold up long term. Got a bit of metal pipe from a wrecked engine, cut out a straight section. I had nothing to flare the ends, but I spotted a junk steering shaft with seized U-joints that worked perfectly.

Fugly, but should work. Nothing touches.

Added a 3rd clamp for more clamping, plus should it ever move and touch the alternator it won't wear though the hose.

And of course, nothing is ever easy. sigh

Went junkyard shopping, found an 02 Spec V.

It has ABS, I was really excited about that as I need a LR wheel speed sensor. Sadly, the bolt snapped flush on removal so I couldn't twist the sensor out of the knuckle. When I tried to push it out from the front I broke it. :( :(

The car also has a trailer hitch which I'm excited about too, but I couldn't get it off as the carriage bolts going through the trunk floor were just spinning. I'm planning on going back armed with tools to convince it off.

The car also has a trailer hitch which I'm excited about too, but I couldn't get it off as the carriage bolts going through the trunk floor were just spinning. I'm planning on going back armed with tools to convince it off.

Long time no update! I've been driving it over 2 weeks now! Let me play catch up on the work.

Fixed the different sized coolant overflow by cramming a bit of vacuum line over the nipple, essentially making a rubber bushing. Works!

Another junkyard trip yielded another IPDM to try.

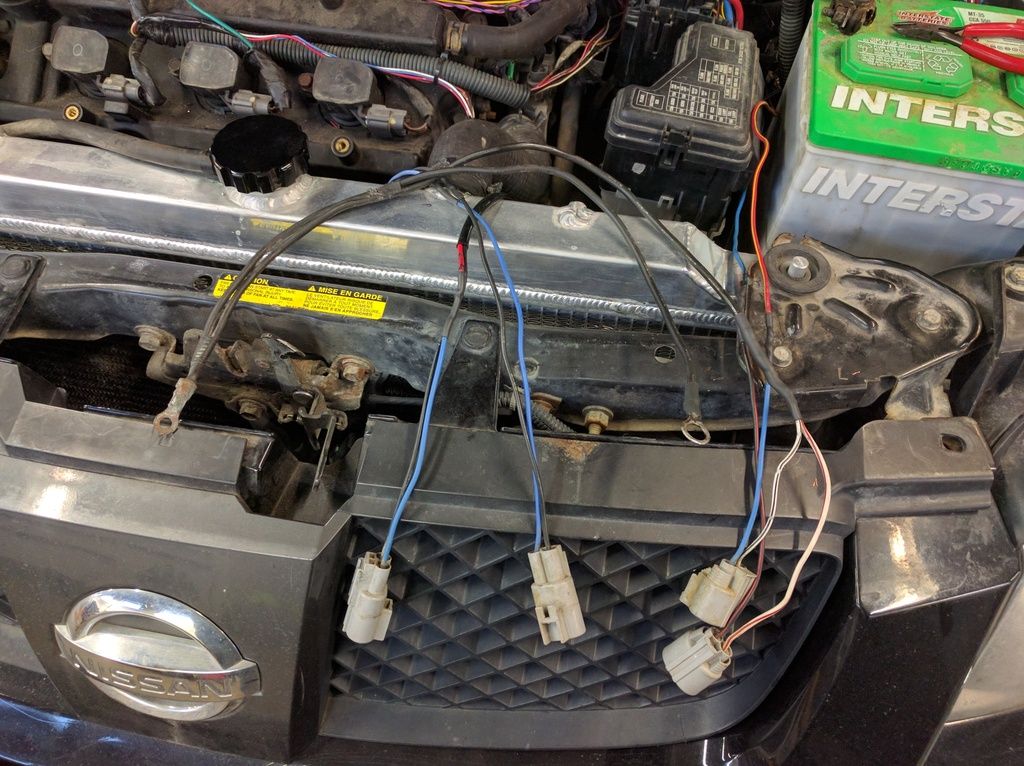

Success! The problem wasn't any of my wiring, but the IPDM itself. Guess the hit it took in the accident was too much. Now have proper voltages on the CAN lines

Success! The problem wasn't any of my wiring, but the IPDM itself. Guess the hit it took in the accident was too much. Now have proper voltages on the CAN lines

and full cooling fan control.

Had to cut the power wires from the Sentra to feed the IPDM, wasn't too happy about that. So far I've managed to make the entire wiring harness pretty much plug and play. Theoretically I could drop a stock QR25 back into the Sentra very easily.

and full cooling fan control.

Had to cut the power wires from the Sentra to feed the IPDM, wasn't too happy about that. So far I've managed to make the entire wiring harness pretty much plug and play. Theoretically I could drop a stock QR25 back into the Sentra very easily.

Robbed the cooling fan connectors from an Avalon at the wreckers.

Robbed the cooling fan connectors from an Avalon at the wreckers.

The fans are wired so the passenger side fan comes on when the factory fans would be on the low speed setting, and the drivers side fan kicks on for the high speed setting.

The fans are wired so the passenger side fan comes on when the factory fans would be on the low speed setting, and the drivers side fan kicks on for the high speed setting.

Power steering pump is in, and VERY tight. The Altima pump with the high pressure extension flipped and low side fitting from a 99-03 Maxima was the ticket. As a bonus, the low pressure hose from the same Maxima is a perfect fit. Zero trimming.

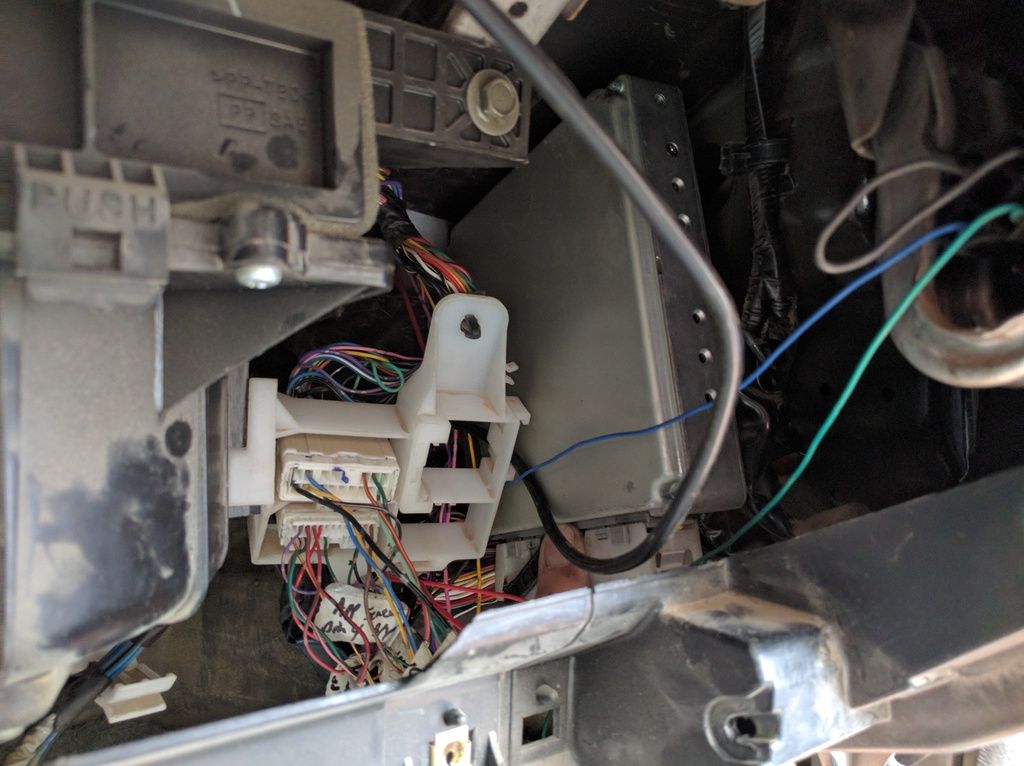

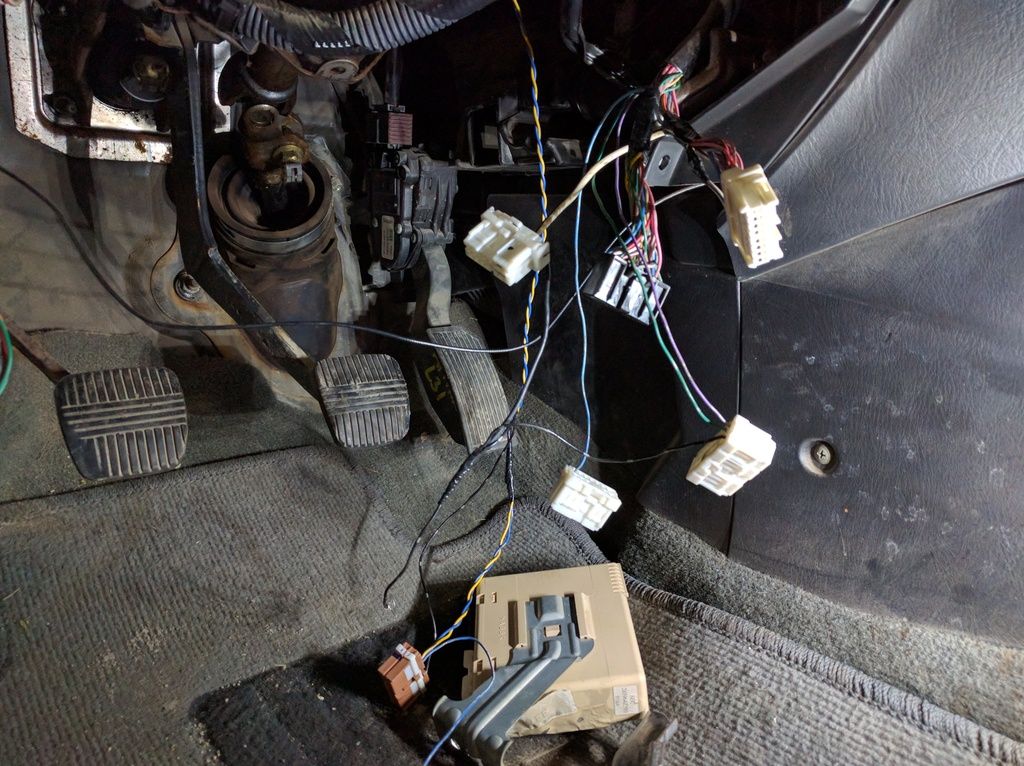

Made a block off plate for where the stock ECM went.

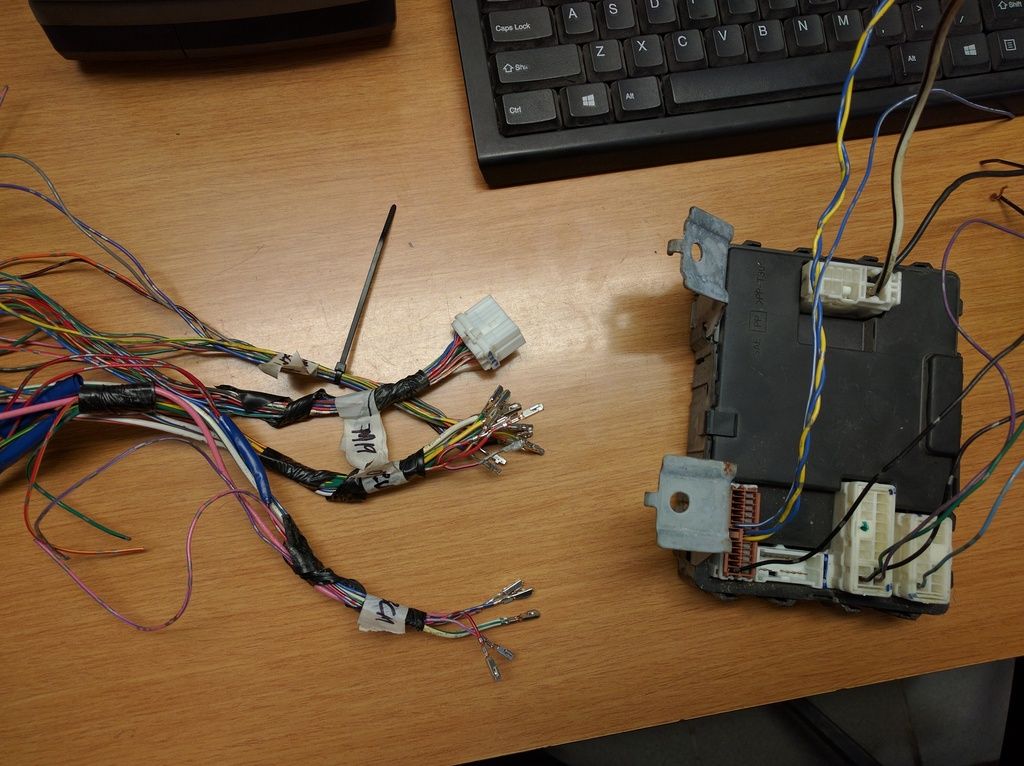

Started to tuck the wiring back under the dash. ECM lives behind the glove box now. It's been cleaned up more since these pics were taken.

Eliminated all the extra wires everywhere. Lots of de-pinning, I've got big bundles all marked. I've had to add several pins back already for stuff I missed...

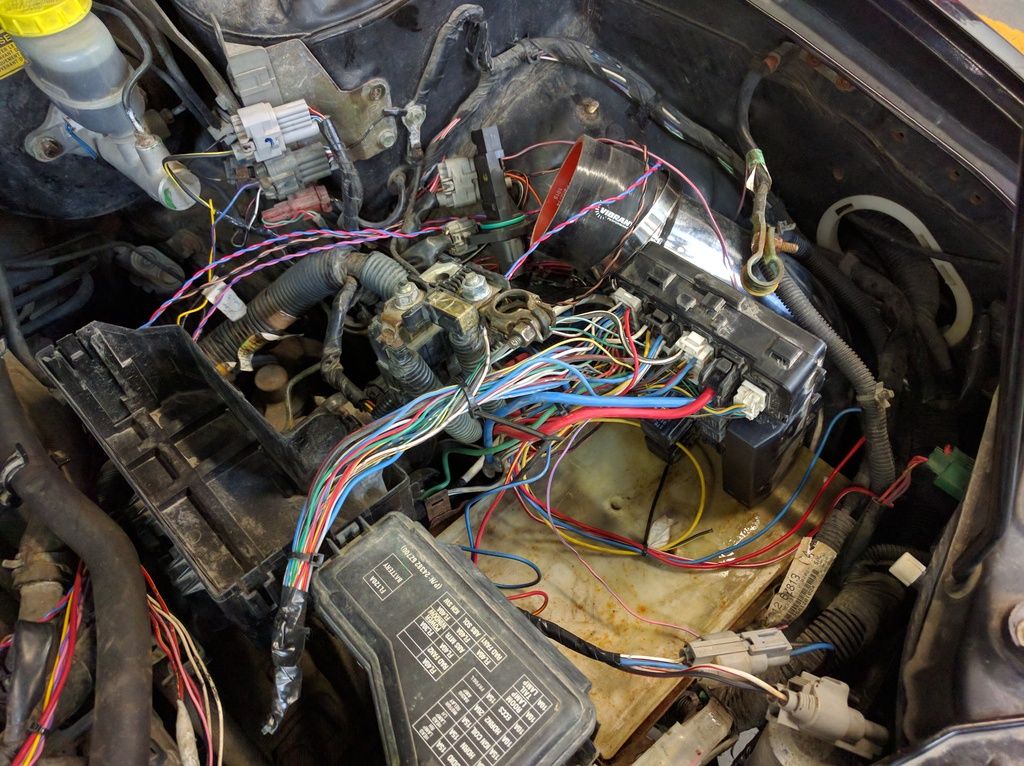

Here's what the underhood looks like now.

Speedometer was reading quite high. Swapped out the speed sensor for the one from the Sentra 6 speed. The gears have a different tooth count and the diameter is larger on the Sentra sensor (pink one) but I looked up the part number of the drive gear that goes on the diff and it's the same part number for both vehicles so it should work (and has for the past two weeks).

Thinking ahead, I've come to the conclusion that I need to add the Altima BCM into the system if I want to ever have air conditioning. The Altima heater controls send a signal to the BCM when the fan switch and a/c request is on, and the BCM relays this to the IPDM and ECM over CAN. The IPDM is what energizes the compressor clutch, and the ECM decides when to engage the compressor. The A/C pressure switch is wired directly to the ECM.

So I've prepped the BCM for install, eliminated all the wires I won't need.

It's basically just getting power, ground, CAN, A/C request, and I left the drivers front door input so I can use the auto-active self diagnosis feature Nissan put in there.

I'm 99% sure if you didn't want A/C and ran a stand-alone fan controller you could do this swap with just the 02-03 Altima ECM. If you want factory style fan control, you need the IPDM. If you want A/C, you need the BCM. The system isn't advanced enough to set U1000 can comm codes in my experience, so it should be possible to do this codeless.

I managed to wrestle the hitch off that junkyard Sentra all by myself. It was pretty silly. I'll let the pictures do the explaining.

Slip joint pliers on the spinning plate, with vicegrips to keep tension on it. The slip joint pliers are up against the spare tire tie down so it can't spin.

Bag of tools to keep it from slipping off.

Ta-da! my contraption held while I unbolted the nut from below. I'm sure many of you think my Sentra is a crusty rust bucket, and it is, but up where I live there's worse Sentras....

So I got my $25 hitch, but the receiver was rusted in place. It took a torch and air hammer to get it all apart.

Halfways grinding off all the rust

Rattle can'd with rust paint.

And a few more little things. Found out last weekend I had zero dash lights. Fixed that today, it was just bulbs.

Of course I managed to break the cover while cleaning it out. Grrr..... Oh! If anyone has a left rear wheel speed sensor they want to sell me, let me know. Still no luck liberating one from the junkyard without destroying it. They're like $100 on RockAuto still too...

And the overhead console hung down a little and rattled. Found where the retaining clip slots into the console is cracked.

Some superglue liberally applied and no more rattles!

Some superglue liberally applied and no more rattles!

Really enjoying the 4 doors. I've only ever really owned coupes, with the exception of a short stint in a Pathfinder and my first civic (hatch).

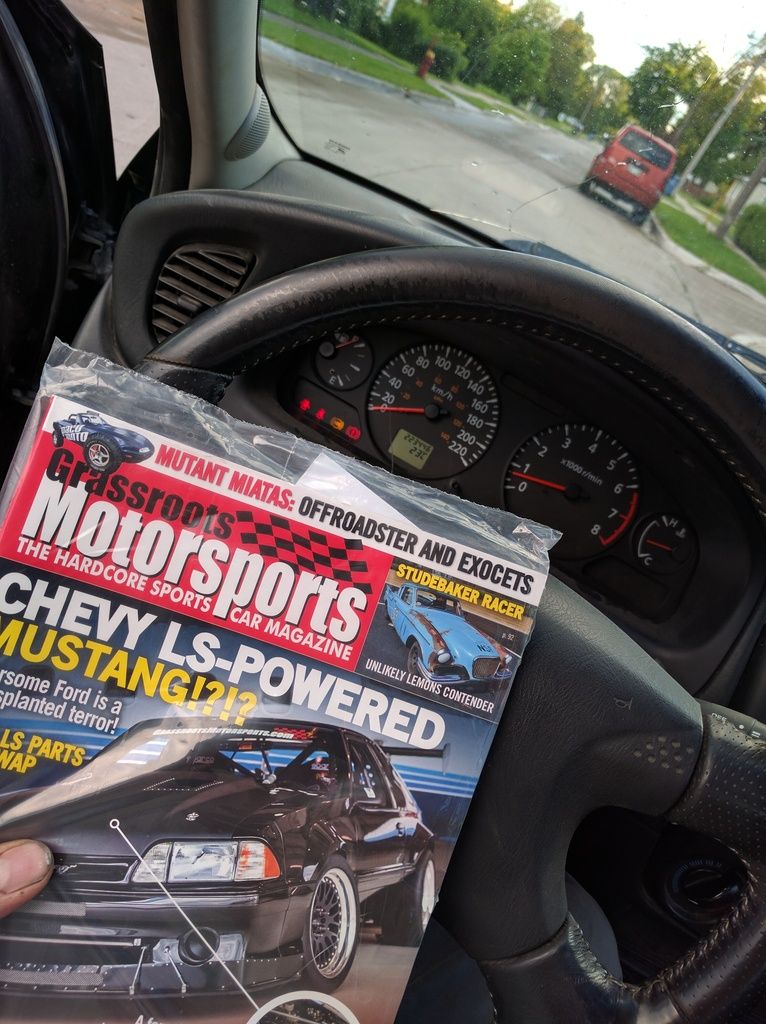

Picked up the mail with the car today and found this waiting for me! Now I know what everyone has been talking about...

Still have to:

-swap over summer wheels and tires (stock 17s with old RT615 Azenis)

-extended wiring for secondary O2 and loom

-solder in resistors to make the Sentra cruise control buttons act like an Altima

-wire in and install the stupid "vacuum cut valve bypass valve" for the last of the codes to go away

-mount and wire in BCM

-re-install A/C lines

-clean interior

-replace burnt bulbs in the climate control

-now that I've run a tank of gas through it, bump base timing 2 deg

1 month since an update!

It's been a reliable and very entertaining daily driver.

Installed the hitch.

Welded the carriage bolts in place and painted.

Installed in bumper rebar after some minor rust removal and paint. If I had more time I would have liked to reinforce some of the rebar, but it will do for my use.

Hitch on

Sealed up

Hit all the welds on the exhaust with high temp paint to slow rust

Muffler strap was rusty.

Now it's not

Clearance to the muffler is tight, but I can report no contact.

Extended the secondary O2 sensor wiring to reach their new location.

Made some holes in the heatsheild to allow the wiring through.

And installed. Two less codes!

Swapped to the summer wheels and tires. It seems 8 24x24 paving stones is probably too much...

So I got a trailer!

Put it to work gather parts for my truck project

Finished cleaning up the wiring under the dash. Also replaced the takata air bag inflator under recall.

Figured out how much current the BCM will be drawing when hooked up to run the A/C. Pretty much none, I feel comfortable adding it to the car's Smart Entrance Control Unit (older "dumber" version BCM) power circuit in parallel.

Revised to-do list

-solder in resistors to make the Sentra cruise control buttons act like an Altima

-install the "vacuum cut valve bypass valve" for the last of the codes to go away - have ran wire from glove box to evap cannister behind drivers rear wheel, need to plumb in the valve

-mount and wire in BCM

-re-install A/C lines

-clean interior

-replace burnt bulbs in the climate control

-swap in Sentra 6 speed gearset and final drive with LSD

-heated seats before the snow flies

-remote start before the snow flies

-helmholtz resonator into the exhaust to reduce drone on the highway? Doing this after the 6 speed sway as I've calculated the extra gear will drop my cruising rpms a bit

Can you PM me? I have a question about my se-r and don't want to crap up your build thread, which is awesome

My buddy has a v6 altima, i can only imagine how much quicker the light little sentra is with the same engine

Great job! Way to much work for me. Makes a SAAB t5 conversion look like child's play.

It does remind me of how much fun Manual gearbox Maxima's are though.

What was the last year. An MT was available in a Maxima?

Message sent, Pat.

Andy, 2006 was the last year you could get a stick shift (or conventional auto) Maxima. The 2007 facelift was CVT only. The altima was available with the vq35 and 6 speed up until 2012 though, at least in coupe format. I think the sedan V6/6 speed was killed in 2010. I'd like to swap one of those newer VQs one day, they have a bunch of nice upgrades. Would require a hacked ecu at least though, unless I wanted to transplant the BCM, ABS module, cluster and more.

In reply to Run_Away:

It looks like the 4th gen Max is a lot lighter than 5th and up. Does the 3.5 VQ swap in easily?

I haven't looked into it, but I'd assume so since they're both VQ engines.

I think lots of maxima guys run the 3.0 timing components on the VQ35 (deleting the variable valve timing on the intake cam) and keep the stock ECU. I'd wire up a 3.5 ECU though to get the full power increase, shouldn't be that difficult or expensive.

That's just me though, I prefer wiring over scraping silicone off timing covers any day of the week.

There are certain ways to get a vq35 into a 4th gen Maxima that would be considered pretty easy, but not all of them get you a 'full' 250+hp vq35. I think it's still one of the easiest and fastest naturally-aspirated FWD builds you can do if you're averaging out the ease with the quickness of the end result.

Love this build, though. Definitely a little more unique!

More towing! Dropped a cab off at the blasters.

Stuck and LED panel in the trunk. Waiting on a larger panel to arrive in the mail for the dome light.

Checked the oil. Looks like this engine burns a little bit...

I'm going to switch to synthetic soon. There's a dyno day at a local speed shop on the 27th and I'm thinking of seeing what it makes.

I'm going to switch to synthetic soon. There's a dyno day at a local speed shop on the 27th and I'm thinking of seeing what it makes.

I went junkyarding yesterday and found several awesome scores. One was another 03 Altima with a V6 and 5 speed manual. I was so excited when I spotted the clutch master cylinder. Went to grab the ECM but someone had already removed it. They stashed it under the drivers seat though, so it's mine!

That should help figuring out why the shelf shut off relay isn't working correctly on mine. Also found a nice low mileage 01 Sentra with the SR20. Grabbed some clips for the side skirts off it, and a left rear wheel speed sensor! I can finally get rid of the light. The speed sensor is $70 plus shipping on Rock Auto. I ended up destroying the last two speed sensors I tried to remove at the junkyard, they're always seized. Hard to find too, only Sentras with rear disk and ABS option, so only a few Spec V models had them plus these early SR20 cars I guess. Got the ECM and the wheel speed sensor both for $35!

It also had a steering wheel in much better shape than mine I couldn't get because I didn't have a T30 security torx with me. I'd also like to get the instrument cluster, as it's much prettier. My current one is pictured on the bottom:

Don't want to swap entire clusters as they're wired completely different. The early clusters don't have CAN lines that mine has, so I'd have to wire up the tach and even then it would read off since it's meant for a 4cyl not 6cyl.

Don't want to swap entire clusters as they're wired completely different. The early clusters don't have CAN lines that mine has, so I'd have to wire up the tach and even then it would read off since it's meant for a 4cyl not 6cyl.

Swapping faces would be difficult too as the screen under the speedo are different shapes.

Been enjoying your build, keep up the good work! I like how you're mixing and matching all the Nissan parts to get the final result, and that you aren't afraid to dig into the wiring and get it all working the way it should.

I feel like Blipshift's new shirt would be a perfect fit (except for it being a B13 instead of a B15)

Love this thread/build so much! I have a real soft spot for Nissans. I really wanted to swap a VQ/6sp into my P11 Infiniti...but I was afraid of the wiring piece. Probably wouldnt have been as tough as I was lead to believe after all!

That's a fantastic shirt! I have a very large collection of Blipshift shirts to the point where I unsubscribed to their emails as I spent way too much with them. Ends up being like $33 a shirt when shipped to Canada....

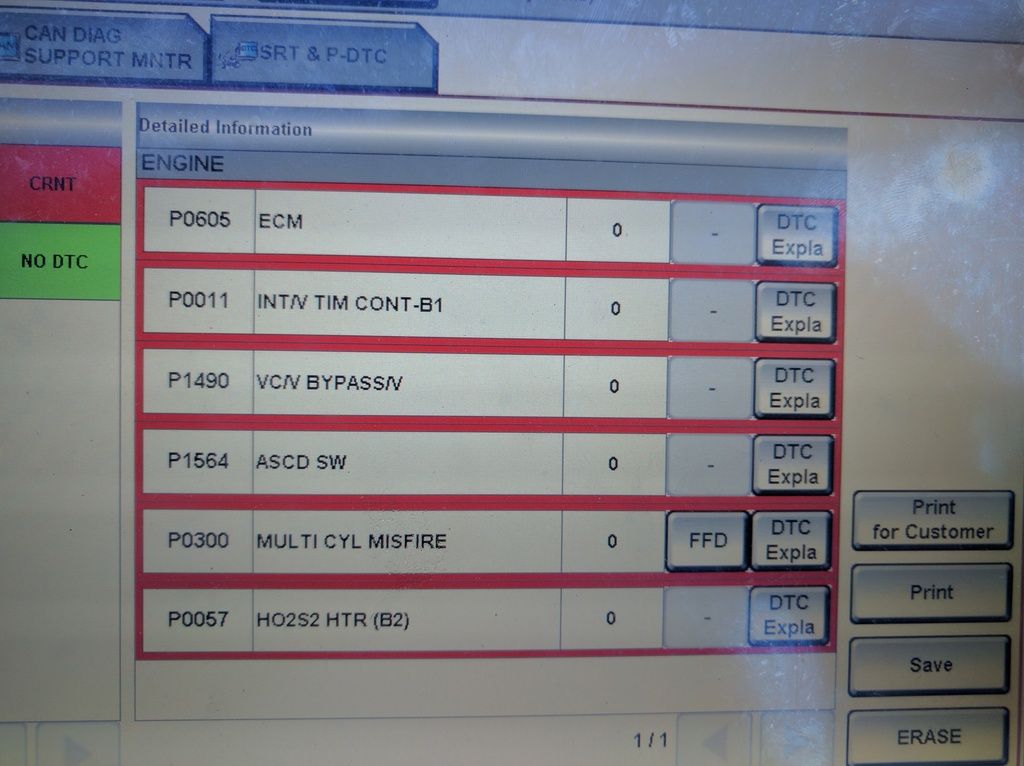

So the car began running like a bag of E36 M3 one evening on the way home. Here's my codes list

Turns out the rear bank (bank 1) IVT solenoid was getting stuck at full advance, so the car was idling with the intake cam 40 deg advanced. Wierd. I had the exact same issue on the front bank on my first real drive of the car to the exhaust shop, now the rear.

I didn't have a spare to swap on so I took the one on the car all apart, blew it out and ran a bunch of brake kleen through it while activating it with some jumper wires and a battery.

<img src="

It's behaved so far since the cleaning.

I also swapped out the ECM with the one I scored at the wreckers, and it fixed the self shut off relay issue. Bad ECM, not my wiring! That also means no more code P0605 as seen above.

I checked the replacement left rear wheel speed sensor I was so happy to score, only to find it was bad too. WHO SENDS A CAR TO THE JUNKYARD WITH BROKEN PARTS (&#@#@&%@& ![]()

![]()

![]()

So instead I wired up the BCM

Went back to the junkyard and grabbed the steering wheel off that one Sentra, only to find it's not quite the same as my Spec V wheel. Torn if I want the nicer condition wheel or the slightly nicer shaped wheel. Got the cluster with the nice white faces too, and grabbed a bunch of evap tubes and hoses so I can fix that P1490 Vacuum cut valve bypass valve code.

Looked for a bank 2 secondary o2 sensor, but no luck. I did find this nice OEM Nissan hitch that's much nicer than mine, but don't feel like doing it all over again for a slightly cleaner look.

One modification that is supposed to gain some power is removing the VIAS (variable intake air system). Basically it's a butterfly valve that makes the intake runners longer at low rpm and shorter at high rpm. I grabbed a spare valve to make my own delete plate. Not sure I want to sacrifice the low end torque for a bit of high end power, but it was free....

Start by cutting the butterfly valve off

Grind it all off, tap the hole where the shaft went

Thread a bolt in with teflon tape and grind off the excess

I haven't installed it yet, but I did visit the dyno yesterday.

You'll need to log in to post.