just need a roller and the widowmaker project is done. . .

I wont waste space with a double post but here is a link for a fender roller made from a vw/audi spare tire jack if anyone else is interested.

DIY fender roller

. . . I more or less followed these dimensions, just changed a few things for ease of fabrication with the limited tools I have.

I wont waste space with a double post but here is a link for a fender roller made from a vw/audi spare tire jack if anyone else is interested.

DIY fender roller

. . . I more or less followed these dimensions, just changed a few things for ease of fabrication with the limited tools I have.

Finally have a complete set of MC pistons after months of waiting. Now the machine shop can bore out that 2.1 and make it a legit 2.2 5cyl. Gonna run those down after cleaning them up this morning, should be assembling the fresh short block in the coming weeks. . . still need to get the head done. . . thinking about going full DIY on it to save money. . . thoughts? experiences? suggestions? powerblock is ![]()

been puttin in work all week. . . seems like I should have more to show for it bieng unemployed.

got the CSV block off plates fab'd up

these showed up in the mail today

and I got the manifold all primed and wrinkled

I also dropped off the throttle linkage and all the visible engine hardware at the plating shop. . . the cost?? an 18 pack. ![]()

Ok so I've got some decisions to make. . . mostly with my injector choice. I've got a set of vw injectors (2.0 ABA) for free but they are some of the lowest flowrates I have ever seen. pretty sure they won't cut it. Another problem is space. Once you squeeze in the injector bushing, injector, fuel rail and throttle body, things get awfully tight up by cylinder # 1 as you can see here

I'm lucky that my car came with the ugly duckling KH engine, as it has the best intake option for an EFI setup, plus it's the only 10vt that came with a round single plate throttle body. I'm not sure if its the single barrell or a change in the manifold that gives it more room, but i have read it's the only 10vt manifold that does not require a spacer to fit a fuel rail. . . i'll take it as a win.

I'm lucky that my car came with the ugly duckling KH engine, as it has the best intake option for an EFI setup, plus it's the only 10vt that came with a round single plate throttle body. I'm not sure if its the single barrell or a change in the manifold that gives it more room, but i have read it's the only 10vt manifold that does not require a spacer to fit a fuel rail. . . i'll take it as a win.

Back to the subject, As you can see in the pic there is no room to spare. I plan on milling down that fuel rail as much as possible but I still will need the shortest injector I can find. Been looking at these but I just don't think I need a 60lb 630cc sprayer. . Not to mention they are a little steep for my gr price range.

Does anyone know of a nice low profile injector like this with a little less flow and a smaller price tag?? that would be perfect for this application. If not I may just have to bite the bullet, buy the siemens and run as an exhibition when I blow the $2013 budget cap ![]()

To be honest, if you get the Siemens Deka, you will be set up for big power later, but those things idle rediculously well for their flow rate. They are really really nice to tune with.

Forgot to add, they are a little cheaper on that seller's website too, and I think they will ship them in flow-matched sets. Plus there is a lot of info on the injector spec sheets.

http://www.siemensdeka.com/index.php?main_page=product_info&cPath=1&products_id=12&zenid=molnf7l767f3anlmh337d83816

thats very good news about the idle. . . I was kinda curious how accurate the ms rating was for such a large injector but it sounds like you have dealt with them before. Also, I just found this ultra cheap source for them this morning so I think i'm about to pull the trigger. sounds like they will be a worthwhile investment. plus I already bought the bushings and ev1 connectors so I might as well ![]()

With the 5 cylinder you will get pretty far with lower flowing injectors. Lets say 350cc to 550 CC for 240 to 300 hp

I totally agree, but I could not find anything lower than 630cc in that short body, dual o-ring style so I ordered them. ![]() Who knows, maybe someday i'll try ethanol and will actually need those monsters. I also went to the parts store and got stuff to lap the valves today. Tried to pick up the bottom end this morning but the door was locked, pretty sure i could see an I-5 wrapped in plastic near the front door

Who knows, maybe someday i'll try ethanol and will actually need those monsters. I also went to the parts store and got stuff to lap the valves today. Tried to pick up the bottom end this morning but the door was locked, pretty sure i could see an I-5 wrapped in plastic near the front door ![]()

busy busy. Made vw tool # 5411/2036 equivalent using a napa valve spring compressor and some 1" square tubing

Ported the head out on tuesday, most of the work was put into opening up the exhaust to match a 2.0 ABA gasket.

then i spent a little time cleaning up the casting burs in the intake ports.

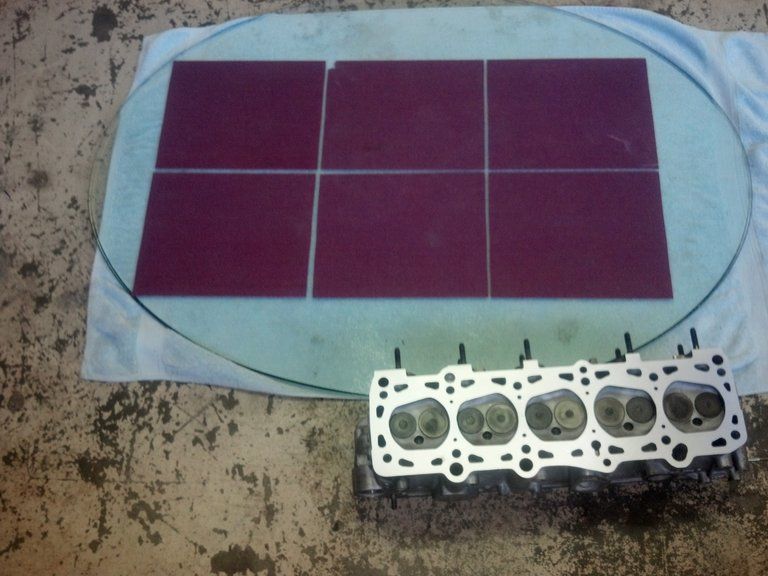

once i felt good about how they looked and felt, I went ahead and measured each valve for stretch (all good) and lapped in all 10. Re-installed them and set up my new, high tech milling machine

I sure am glad this head is in such great shape considering it's turbo upbringing. re-surfacing a head this way is an incredible workout, but it's also just as effective as the glorified belt sander most shops use when milling is not necessary. It's all about how you use this "tool" I like to keep changing direction, and orientation every 10-20 strokes, giving it a nice crosshatch pattern while keeping the head nice and flat. no downward pressure is needed, the head is heavy enough to do the job of Z feeding into the sandpaper, besides, you will get plenty of work just keeping it moving back and fourth in x and y

I sure am glad this head is in such great shape considering it's turbo upbringing. re-surfacing a head this way is an incredible workout, but it's also just as effective as the glorified belt sander most shops use when milling is not necessary. It's all about how you use this "tool" I like to keep changing direction, and orientation every 10-20 strokes, giving it a nice crosshatch pattern while keeping the head nice and flat. no downward pressure is needed, the head is heavy enough to do the job of Z feeding into the sandpaper, besides, you will get plenty of work just keeping it moving back and fourth in x and y ![]() don't forget to blow off that paper regularly.

don't forget to blow off that paper regularly.

If I had a warped head I would just spring for a machine shop to do the work but this one is in such good shape I am lucky enough to have the option of doing it myself. even the valves hardly needed lapping.

Once I finished the 100 grit stage I decided I would do the manifolds gasket surface also. . . should have left it alone. Got alll but 4 studs out with a triple jamnut but four of them required a welded nut. Two of those still broke and I spent the rest of the night drilling and grinding them out. Tired now. gonna get helicoils tomorrow, need sleep ![]()

I'm deffinetly anxious to see how it runs as well. A little bit of bad news, went by the machine shop again the other day and a note on the door read:

Colsed

sorry

broken knee

so I have no idea if my block is even finished yet, better give him a call (if i can even get ahold of him on his shop #) that did not stop me from finishing the top end however. Got all the studs out, helicoils installed in the two really stubborn ones as you can see in this photo representation of

Easy. . . . . . Medium. . . . Hard. .FUUUUUUUUUUUUUUUUUUUUUUU

Easy. . . . . . Medium. . . . Hard. .FUUUUUUUUUUUUUUUUUUUUUUU

After that I worked on my fuel rail mounting/injector o-ring seating. I picked two places on the head, inline with the fuel rail that had alot of meat, grabbed the trusty die grinder and a big file, then made two flat mounting points parallel with the injector angle, then drilled and tapped them for an 8mm bolt or stud, whatever I decide to use. Now all i will need is a couple custom brackets that drop off of the fuel rail. I don't know if it has been done like this before but I'm fairly proud of my idea over others I have seen online. Here you can see the two allen heads sticking up at an angle on each end.

Also removed the vacuum port for the air shrouded CIS injectors and tapped it for a plug. you can also see my EFI injector bushings showed up the other day.

Also removed the vacuum port for the air shrouded CIS injectors and tapped it for a plug. you can also see my EFI injector bushings showed up the other day.

Only an idiot such as myself would do all this fab work after lapping valves and starting the head re-surface. . . lesson learned. After that was all squared away I re-finished the head on 3 sides (didn't wanna mess with all the top studs after the fiasco earlier) first with 100, then 180, and finished with 220 grit. I am pretty happy with how it turned out, tucked it away before even taking a photo in an attempt to keep those surfaces clean and straight.

Only an idiot such as myself would do all this fab work after lapping valves and starting the head re-surface. . . lesson learned. After that was all squared away I re-finished the head on 3 sides (didn't wanna mess with all the top studs after the fiasco earlier) first with 100, then 180, and finished with 220 grit. I am pretty happy with how it turned out, tucked it away before even taking a photo in an attempt to keep those surfaces clean and straight.

Alot of parts showed up this week, enough to warrent this photo

I call it "mandatory turbo parts" you know. . the kind of thing wife's and gf's just dont seem to get.

I call it "mandatory turbo parts" you know. . the kind of thing wife's and gf's just dont seem to get. ![]()

Got the exhaust manifold port matched to the head today. It's true what I have read in the past, this thing has a serious choke hold on each port, tapering down almost an 8th of an inch at the flange. Hard to see untill you start opening them up but once you get rid of that entrance ring they have quite a bit more cross section. It's still hard to see in this pic but i'll post it anyway

I'm gonna give that ultra high temp VHT header paint a whirl on the manifold and the down pipe.

Getting very close on my 10vt swap checklist, the plan is to have everything ready to go before I pull the JT engine keeping downtime to a minimum. I don't need to loose motivation or momentum on this project, Wuste is right around the corner ![]()

got the timing covers wrinkled. Downpipe, manifold and wastegate are all cleaned and painted. the wg is my favorite so far ![]()

incase no one is watching, underhood detailing is one of my highest set goals right now.. . . like. . higher than job hunting. . . does that make me some sort of car bum??

incase no one is watching, underhood detailing is one of my highest set goals right now.. . . like. . higher than job hunting. . . does that make me some sort of car bum?? ![]() I do feel extremely fortunate that I can do this financially right now. . . livin the dream but i'll be waking up, snapping out of it before long. . . back to the daily grind where you give all the overtime they ask of you only to be let go 8 years later without so much as a reason why. damn i sound depressing right now. lol

I do feel extremely fortunate that I can do this financially right now. . . livin the dream but i'll be waking up, snapping out of it before long. . . back to the daily grind where you give all the overtime they ask of you only to be let go 8 years later without so much as a reason why. damn i sound depressing right now. lol

the last few engine bits are spending the night in the parts washer. now if i could just get my block and reciprocating assembly's back I`d have one clean complete long block in a day ![]()

I discovered 2 things about my fender roller yesterday. The gummy longboard wheel i got is too soft, and the base plate for the sliding roller assembly was too thin.

Boxed in the base plate with some channel i had. Dont you love it when the only piece you have is the perfect width??

I finally painted it today also. glad i tested it first since i had to re-enforce it a little. . . hopefully it will all hold up once I get a hard roller.

I'd love to rent that roller from you big fella!! I plan on running 225/45-16's on 16x8 wheels on the 4000q of "dilapidation"!! I might try to fit 245's at some point!!

In reply to noddaz:

yeah i'm working on getting some nylon or maybe UHMW drop so I can turn a custom roller for it. as you pointed out on the last page, It probly won't work with the stock flare, even if I "make" them fit I don't think I will be happy with it. I plan on asking a local yard if they will loan me a power outlet so I can cut some fat mk1 flares off of either a rabbit or caddy. . . then i will like the fitment and be proud of it. . . lots of work ahead of me but I wouldnt have it any other way ![]()

In reply to type85:

you bet! maybe we could work out a trade with some extra suspension bits you might have laying around. . . ![]()

"Powered by Max" sells replacement wheels for their fender roller(I have one) and they are wicked.

I'm liking this thread!

those rollers look like solid steel! nice tool tho. I should have put more adjustment in my design like some of the high dollar ones available but I think it will work out once I get a roller thats a little more substantial and a little less bubblicious ![]()

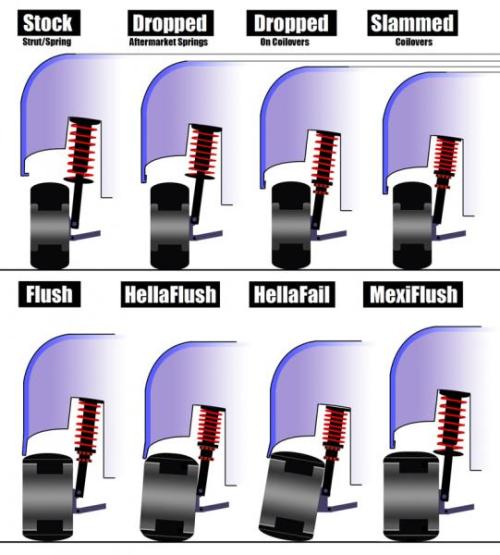

Roll or weld in. . . . either way I need to come up with the solution quick. My friend and I organized a new gtg/cruise this spring in ouray, colorado thats finally picking up interest. I will be riding on these wheels by april 27th one way or another. . . only question is, what level of street cred will I be awarded for my efforts?? lol. see figure A:

*disclaimer: I couldn't care less about the "stance" scene. . . I just like wide, fat lip wheels. always have. so long as they fit and look right on the car.

In reply to 2K4Kcsq:

Speaking for my people, the last one isnt even close. Looking out the window at my tio's pickup I can say for certain that the centerline of the tire must be at, or past, the lip of the fender.

Ojala wrote: In reply to 2K4Kcsq: Speaking for my people, the last one isnt even close. Looking out the window at my tio's pickup I can say for certain that the centerline of the tire must be at, or past, the lip of the fender.

Now that is funny.

meanwhile in colorado. . . this happened:

should have the fronts done today.

should have the fronts done today.

It takes some balls to cut up a near perfect & rust free B2 body. But the fit with the new wheels keeps me looking forward, not back. separating the men from the boys on this one.

You'll need to log in to post.