BTW, I ordered some acrylic for another project today. Since I know I'll have some leftovers, I asked for cast acrylic. It engraves much better, apparently. The guy immediately asked if I was doing laser work, and given the size of the piece of acrylic assumed it was something commercial so he started pitching for my business :)

I did indeed get the 15W laser unit but somehow I ended up with the Asian power supply. Must acquire a travel adapter before pewpew

Whoopsie!

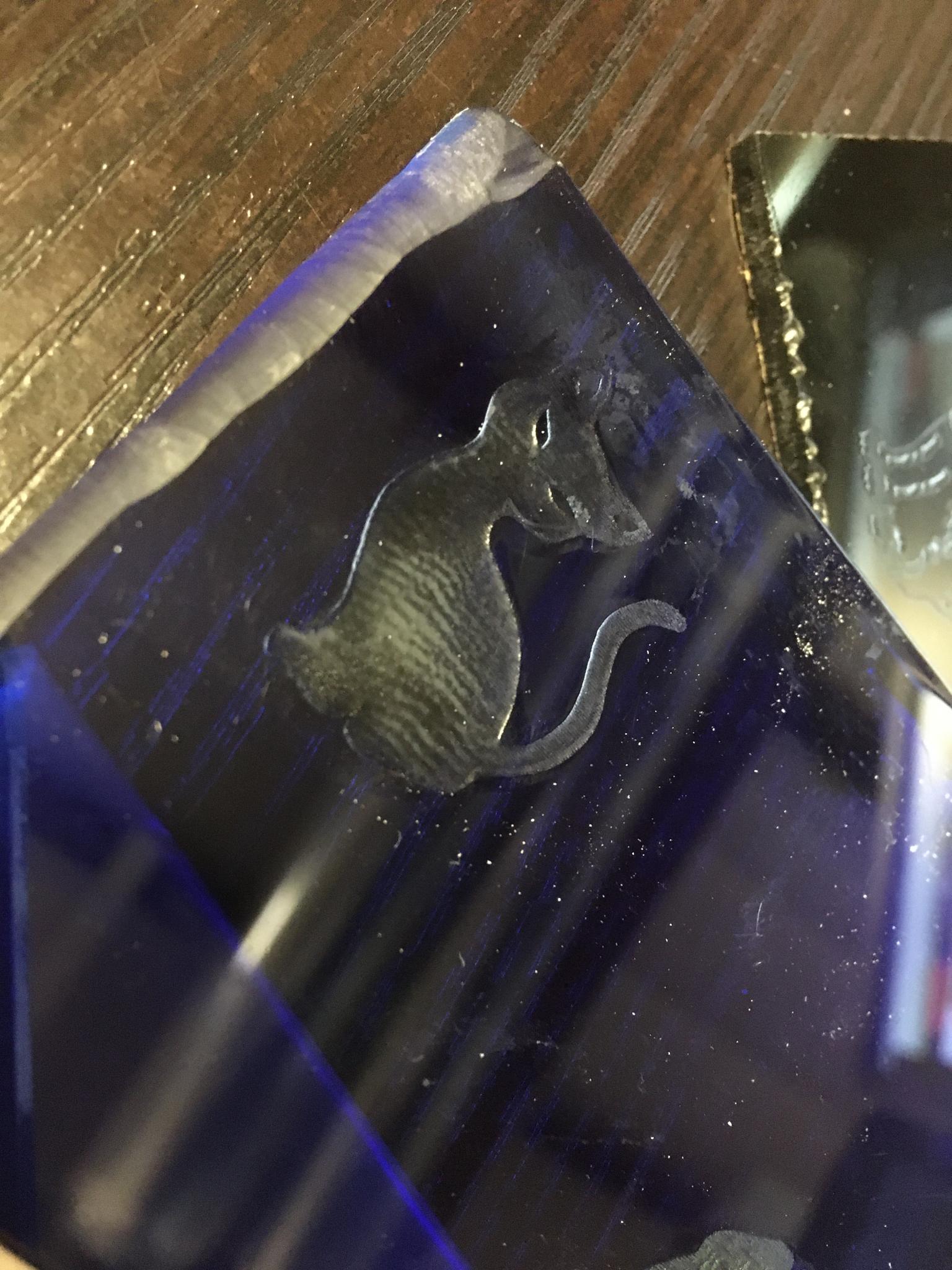

I played a bit more with mine yesterday. I'm getting better at focus. But the big change was acrylic. I had some translucent blue cast acrylic on hand for some other work, and I also grabbed an off-cut of black to play with.

It cuts quite nicely. The middle "science" is the nicest in person. The squares at the right were attempts to see what slower feed rate does as well as multiple passes. Can I cut acrylic? Turns out I may not be able to. It's a bit of a weird material.

The biggest problem comes from the kraft paper curling up and interfering with the laser on big surface area cuts - I had a large design fail on this, which was a little disappointing because it was not a test piece. I think that's also what happened on the rectangle up above, that's actually two squares that were run at different settings. The upper half of the square had two passes, and the remnants of the paper got in the way on the second pass. And yes, you need the paper.

The biggest problem comes from the kraft paper curling up and interfering with the laser on big surface area cuts - I had a large design fail on this, which was a little disappointing because it was not a test piece. I think that's also what happened on the rectangle up above, that's actually two squares that were run at different settings. The upper half of the square had two passes, and the remnants of the paper got in the way on the second pass. And yes, you need the paper.

The translucent blue worked fairly well. As you can see, this particular piece of blue was also being used for other testing like fine-tuning router settings :)

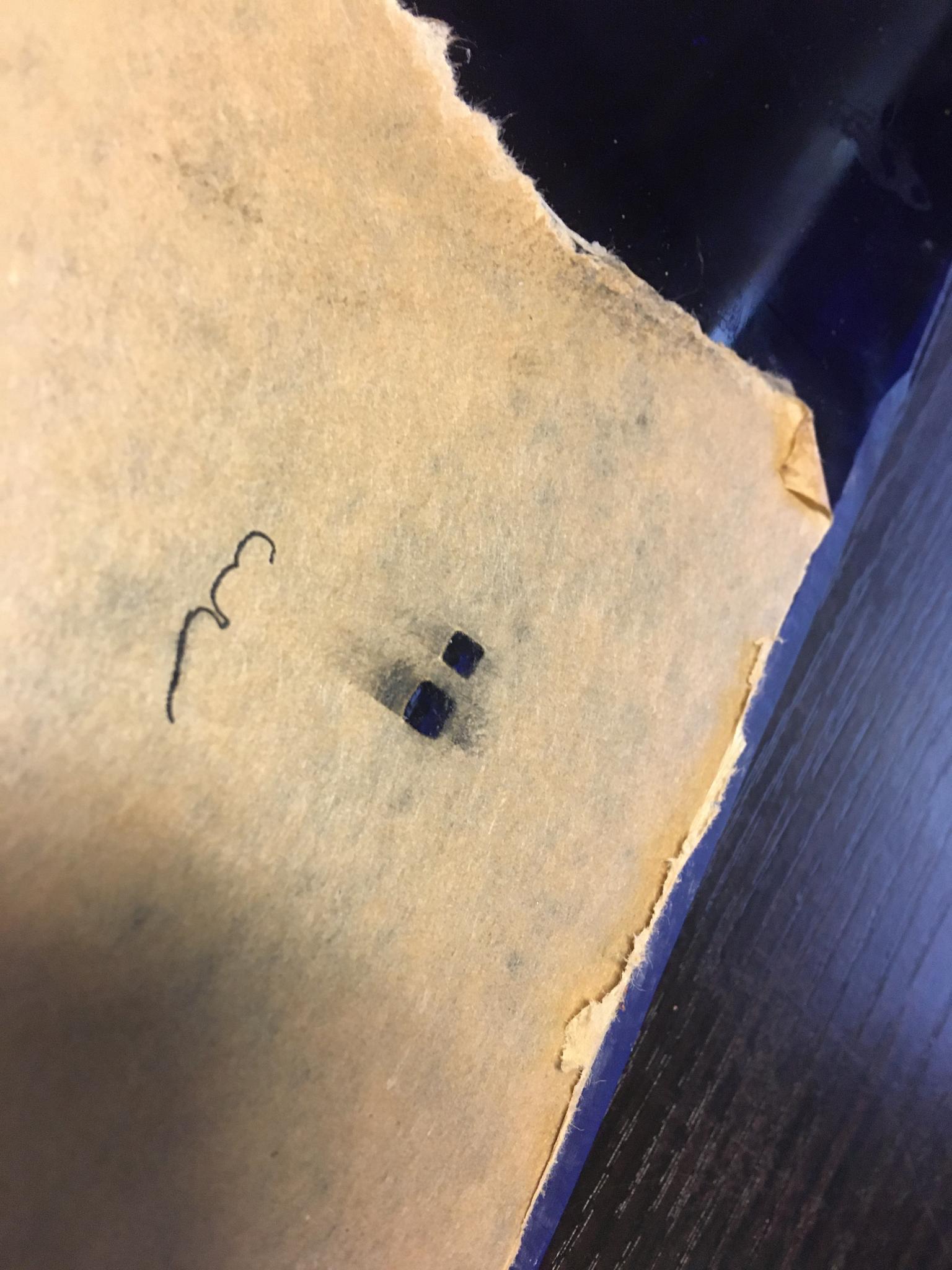

But I did find one odd thing with the blue. It was highly sensitive to focus. If you got it wrong, the laser would pass right through the acrylic and nail the paper on the backside. For example, check these test squares.

Here's the flip side. Note how the two smaller squares went straight through, but the bigger one did not. Same settings, just a different focus setting. Sometimes, the out of focus laser wouldn't even touch the acrylic but would just abuse the paper on each side and also burn on my table surface.

I was able to do a few test burns today. I am having an issue with not being able to do multiple passes. As soon as it finishes the first pass it gives a soft limit error when it should return to the beginning. I have research to do on that.

Laser at full power and set the mm/minute at 250 and I almost made it through spray paint on aluminum in one pass though

Update the firmware before you go too far. Iirc they don't do full power or max speed until you do.

But I'll bet you could etch what you have there. I haven't been able to get clean metal yes, it's always been a bit sooty. What kind of paint? Looks like it worked better than my high temp stuff - which kinda stands to reason when I think about it...

Wurth fast dry flat black. I chose it because it was in the spray station meaning the last guy hadn't put it away and because it said "fast dry"

That was about my level of give a crap.

Updated the firmware and did another burn. Seemed exactly the same and didn't appear to make it through the paint. Then I washed it off in the sink and I'll be darned it made it through on both! What looked like paint was just soot.

Please excuse the photo through a magnifying glass.

After a bit more fine tuning I should be ready. These were done in non vector mode so the vertical lines are decidedly not straight.

Now the hard part of actually doing the graphic design work.

Excellent! Way to hit the ground running. I'm looking forward to learning more about the etching process itself.

I'm using these: https://www.amazon.com/gp/product/B07DCRR8NG/

Update!

I've been dinking around with this, doing things like coasters. I've found that the one thing I really want to do is cut wood to make...stuff. So I spent a bit more time fine-tuning the setup and it's all about the focus. Unfortunately, there is no way to actually measure or quantify the focus, you just have to do it by eyeball. I managed to get it pretty right for my little chunks of wood.

Three passes at 250 mm/sec lets me cut through with a bit of charring. I sanded the top of this lightly.

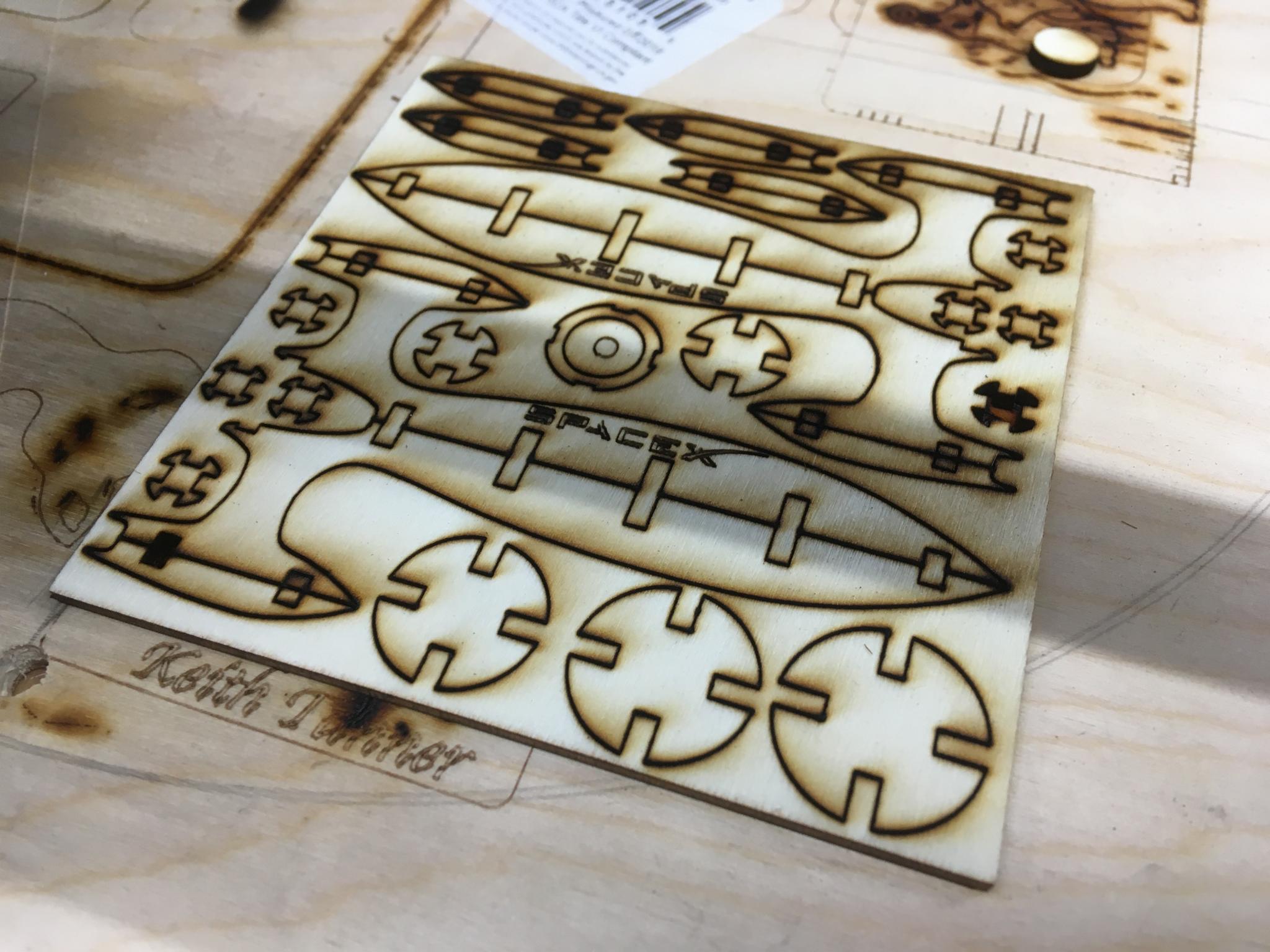

Since I could now cut through without too much trauma, it was time to get ambitious. This is a basic design I downloaded, then reworked to suit my material size and thickness. And added a SpaceX logo :) I screwed up a bit with the design and overlaid a couple of lines, which means they got 6 passes. That doesn't seem to cut any further, but it does mean more scorching. I'm pushing the limits of what this can do.

These chunks of wood are just under 4" across. They cut well, so I've just been playing with them.

The backside.

Because some of the cuts didn't quite get through the backside, I used a knife to finish the job.

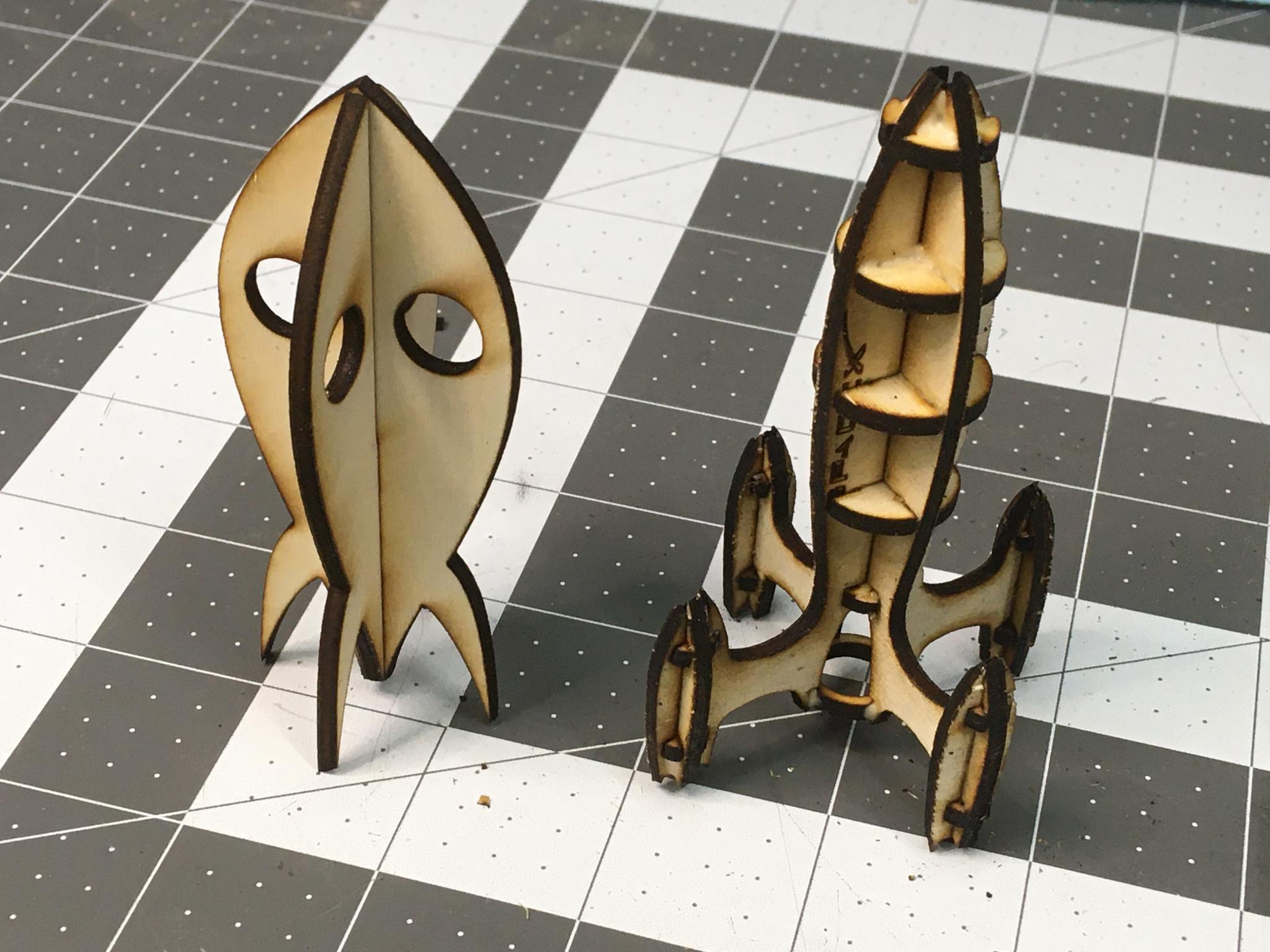

Built alongside a simpler one I did first. The squares on the mat are 1".

I ordered some ferric chloride so I can try proper engraving next, but I've found that it's cutting material that's really interesting. So things are escalating, more to come.

One of the things the lab at USF did for their laser's focus was to cut out a template that let you see how close you were to the laser's optimal focus (72mm)

Theat one then let you set the depth of the material so it could move the bed up and maintain a good cut, but you may be able to set something manual up with yours with enough practice.

The biggest problem with setting the focus is that you can only do it with trial and error. Fine-tuning is done by turning the housing of the lens, but it doesn't move so there's nothing you can measure if you want to duplicate it. I can do gross measurements by loosening a couple of locking screws and moving the whole laser up and down, but it's a bit crude. This thing doesn't have a separate bed at the moment, although I suppose I could build something. Build a bed that sits underneath and has a lab jack or something so I can do fine adjustments to match my pre-set focus. Hmm.

Right now, I store this thing in a small IKEA wooden crate. Makes it really convenient to set up and tear down. Adding a bed would complicate that but I have an idea.

That sounds like a really bad way to design such an important piece of the system. Something to think of if I ever get one, I guess.

Interesting stuff. A decade ago the sign shop I worked in had a laser etcher and a 5'x10' CNC router table. Very different animals. I remember focus being a real issue on the laser. As I remember we bought the laser around 2005 or 6 and it was...$6k? My, how things have changed.

Yeah, this is definitely built down to a price. And some of its characteristics are because it's a diode laser - the fact that it's more of a slit than a point is apparently part of that. You can still buy $6k lasers, but they have an order of magnitude more power and software that's a little better designed. Also safety interlocks so you don't fry yourself.

I think the reason the focus isn't well thought-out is because this thing basically sits on top of whatever it's engraving. It doesn't have a separate bed. So if you set the focus (via trial and error) so that it's perfect for whatever it's sitting on, you just lift the whole thing by the same amount. For example, if I'm engraving 3mm wood, I put the two feet on pieces of 3mm wood as well. That would keep the focus consistent. I don't know how the fine focus mechanism works, someday I'll take this thing apart and look inside.

So things escalated: I upgraded to a K40.

I'll still be using the little one for quick jobs, and it has one big advantage in that there is no maximum size to the material. Want to engrave your coffee table or put a doodle on a pizza paddle? Can't do that with the big boy. So they will coexist, and I suspect I will learn things from the K40 that will apply to this one. My approach towards focus is going to change, for example.

I worked at a laser shop programing and doing art for the companies YAG and CO2 lasers 20 years ago and I am super impressed with how much you can accomplish for how little these days. Our workhorses were FOBA YAG lasers mounted on Bridgeport setups.. One of my great achievements was working on the engraving on the neck of the molds for the Gatorade bottles when they first came out will all of those crazy 3d designs. VERY little of that type of work had even been done with a laser on those types of surfaces before. We also had a pretty trick for the time setup to burn images on clyinders.. like.. hundreds of thousands of duck calls... It was interesting work.

For setting the focus I don't know if I would even waste time with what I hear you talking about. I would find some way to adjust the Z axis Shim stacks would work in a pinch. Or a screw jack to move it up and down smoothly... Then once it is set perfect take some Laser pointers mounted just to each side of the head of the laser and fix them so they point exactly together right at the center of the field of your laser. Then as you move up and down the laser pointers would separate and then come back together when you have the right focal length.

There's no way something like this should be so cheap :)

The plan is to simply set the focus so it's perfect for the surface the laser is resting upon via trial and error. Then, when it comes time to engrave, I'll simply put some extra material under the two feet. Or, if I'm trying to cut and therefore aiming at getting the focus point right in the middle, I be more creative in shimming. I think that's the easiest option. Given how much this struggles to cut as opposed to just doing some surface engraving, I think it'll be dedicated to that task.

You can get rotary attachments for the K40. Perfect for engraving those powdercoated Yeti tumblers. I've also started seeing engraved rolling pins in some of the online shops that are clearly just blank pins that are chucked in the laser cutter when someone orders one.

Friend of mine is now a stay at home mom. Has played with these before, but wants something she can use for a small home business with a minimum of 12"x12" engraving volume.

Any recommendations?

In reply to Keith Tanner :

Stainless etching, paint removal, leather burning, stuff along those lines.

What do you mean by capabilities?

Like the difference between engraving acrylic and cutting it. Speaks to the power level as well as the laser type.

12x12 is a pretty big area. My K40 has 9x12 (ish) after modifications. The cheap one that stars in this thread can only do about 6x6 but you can move it around on the work piece.

Gotcha. I'd imagine she'd want to be able to cut as well as engrave, but I'm not 100%. I'll reach out and check.

I think the area comes from belt and suspenders thinking on her part. I don't know that she wants to do that big a panel regularly, but she did talk about customizing some jackets for her dad's Harley club and came up with those rough measurements.

You'll need to log in to post.