I usually get the premade hose in my hands, then use that fitting to find the right pieces.

What I was thinking that but I think the easiest thing to do is get a 6an fitting that fits the rack then just get a 6an to 6an high pressure hose but I need to know what threads are in the stock rack..

Also Duster I need to come grab that carb from you some time. Hopefully this thing will be ready to start up soon.

I made my own PS line with parts from ANPlumping.com Here is what I ordered:

139106 2 Earls Hose Size: -6 AN Thread: -6 -- 130006 2 Earls Hose Size: -6 -- 871606 2 XRP Metric Thread: 16mm X 1.50 AN Thread: -6

I used the Mazda banjo fitting on the rack side and attached the 16mm x 1.5 to -6 adapter on it and the Ford PS pump. Works great so far.

Got a few things done and have more questions!

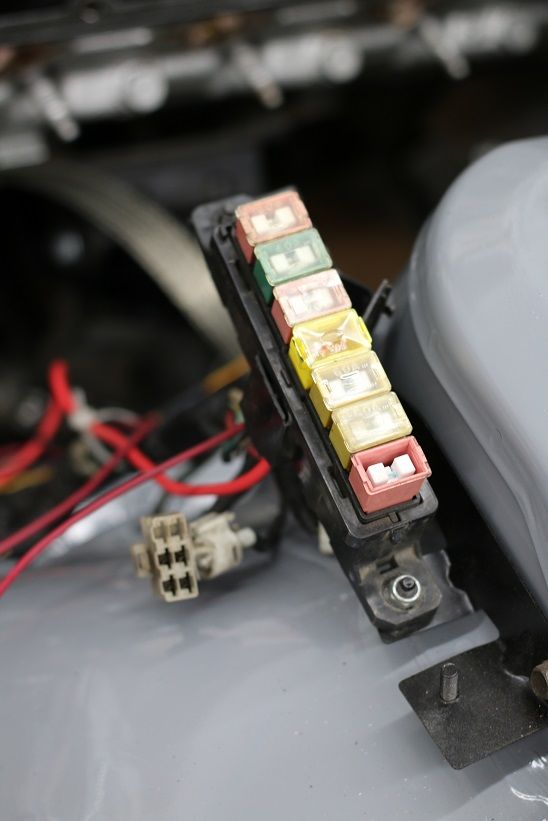

When I got the car it had been slightly rewired and the main wire going from the battery to the main fuse under the hood had been reworked. Now I am reworking on top of that... So here is my question. The main fuse, one side runs to the battery and one side runs to..... I have no idea. I have the front side (side facing the fron of the car, notice the fuse box sits infront of the drivers side strut tower that you can see in the pic) I have wirred to the battery for the main 12v. Does the other side go to ground? Can't seem to find it online...

Also looked at my spair steering rack and it has the fitting with the bango bolts so SCORE!!

Power goes into fuse block, through fuse, and out to whatever needs power, like an electric choke, and then that choke is grounded.

Hopefully that helps.

Wanna come down and get that carb soon?

There is a slightly smaller gauge wire that goes from teh alternator post to that main fuse. The smaller wire attaches by bolting onto the "back" of the fuse block. The battery cable bolts onto the "front" of the fuse block. Therefore, your battery is protected if anything goes poof. The fuse box you have there has a buss that goes from the front side of the fuse box to power everything else. If you connect the battery to the wrong side it will not be protected by the fuses.

I will take some pics and email them if you need it.

Rob R.

Ok that's starting to make more since. I will run a wire from my alternator to side one of the 80A main fuse and side 2 will go to the battery. Right now I have the alternator running to the wire between the battery and the fuse block which does not protect the battery from some kind of failure in the charging system.

Sounds Like I will be running some new wires but that means I will be able to power this bad boy up soon!

Also I was wanting to see where I need to wire in the green wire coming off my alternator...

This is the best pic I can find on how its wired. The white wire runs in a loop and mine is already run in a loop when I got it so it may be factory like that. The two black wires and the yellow run to side one of the main fuse but where does green wire go? I don't think I need to wire my charging gauge back up I think it should still work within the stock Mazda wiring. So do I just hook all 4 wires to the fuse block? Just seems to easy that way...

One of the wires in teh stock mazda harness is the wire that goes to the gauge on the dash. I believe you need that line hooked up or the system MAY not charge.

I will try to figure out which one it is in teh stock system.

Connector X-04 (FE-02) (same connector as oil pressure) Black w/ white stripe... there are 2 of these wires, which are 12v+ when the ignition is on. A good source for power for your V-8's ignition system.

That is what I pulled from granny speed on that, and I pulled this from granny "how to guide" as well.

Alternator Wiring...Mazda routed the alternator wires differently depending on model... ...Non turbo models...If you are using the RX-7 alternator, the small "T" shaped connector A-12(EM-36) that plugs into the alternator does not need to be changed, but these wires were routed thru the emissions harness (located on the passenger side) and will need to be separated from it and salvaged if the emissions harness is removed.

I have looked through the "Harness and Identifying Connectors & Wires" and "A-12(EM-36)" does not show up. And to make it all a bit harder my harness has been gone through... So I will need to look at what I have from the stock leads going to the alternator and back track from there. I think that the harness that I had taken apart had one large wire going to the alternator and two small wires doing something... Will have to wait till next week to take a look what I have and what I need.

Sorry for the lack of updates! I have been taking a bit of a brake from the car, I can get burned out working on it ever spare second that I have. I did free up some funds! I sold the explorer oil pan as well as the GT40 intake. Just to help but the last few parts.

Also been thinking about buying a foxbody H pipe to save myself a lot of exhoust work. I think it will work with my headers and It would give me a good start on the system. Here is a guy that built a H pipe for his 302/RX He built his first then later got his hands on a stock mustang unit and he shows that they are very similar.

JTNWEvo wrote: I have found says you need about 1.25 inches of travel to fully disengage the clutch on a 302/T-5. It is hard to measure but I am getting at least 1 inch of travel right now.

Seems like I am having some issues like you were having. I picked up a new master cylinder and installed it last night. No pic because I was covered in DOT3... I used a vacuum bleeder and pulled some fluid down to the slave and got it moving right off the bat confirming that my old one was bad. Then got it to bleed and had clean fluid coming out with no bubbles. Surprisingly it was moving the clutch fork about a inch. Iv been slowly been bleeding it and small bubbles keep coming up from the master cylinder. The bracket is flexing which is eating up some of the force that the slave cylinder is putting out so I need to build a brace for it.

My real concern is how easy it is to move... The pedal feels like a miata's, very light. It does move the fork and starts to disengage the clutch I don't this it is fully but I thought with a stage 2 mustang clutch it would be heavy as crap! I know my 4.6 mustang with a stock clutch was one of the heaver clutches that I have used but this seems to not even be in the same playing field! I guess I need to bleed it more and weld up a bracket to keep it from flexing which will help pedal feel but I don't think it will that much.

The center force stuff always has had a light pedal. One of their selling points actually. So don't be overly concerned.

That makes me feel a little bit better, it still needs to be bleed again. I also thought about a way to check and see its working(fulling disengaging the clutch) I should be able to put it into gear and push the clutch, then spin the output shaft and if it spins then its free and I will be able to drive the car!

Got a start on the power steering hook up. Iv got a 6an fittings and line from work. I have a 6an adapter on the power steering pump already so I will just need to order the 6mm X 1.50 AN Thread: -6 to go from the rack to 6an. Then I will work on the return side of things and figure out a way to block off the low pressure side.

Well its safe to say im on the last 10% because nothing is working!

Well I did got some things done. Found a turbo 2 being parted out and I grabbed the seats which are smaller and much better fitting and don't have any rips. As well I grabbed some trim pieces that were in better shape then mine.

Stock seats.

Now to the other parts, JTNWEvo most of this is going to need your help!

Don't know which adapter goes from the rack to the 6an fitting. You list a lot of fitting so I got a bit confused and the fitting are $12 each so id like to get the right one the first time. Also does it need to be the kind with the o ring like this?

Also need help on my clutch set up as well. Just wanting to see if you used the stock master cylinder or a wilwood unit? I looked on there site and can't find a master that big! Also what slave did you use? Im using a toyta slave its a 3/4" bore and with the stock 5/8" master cylinder I get about 1" of moment and I need about 1/2"s out of it!

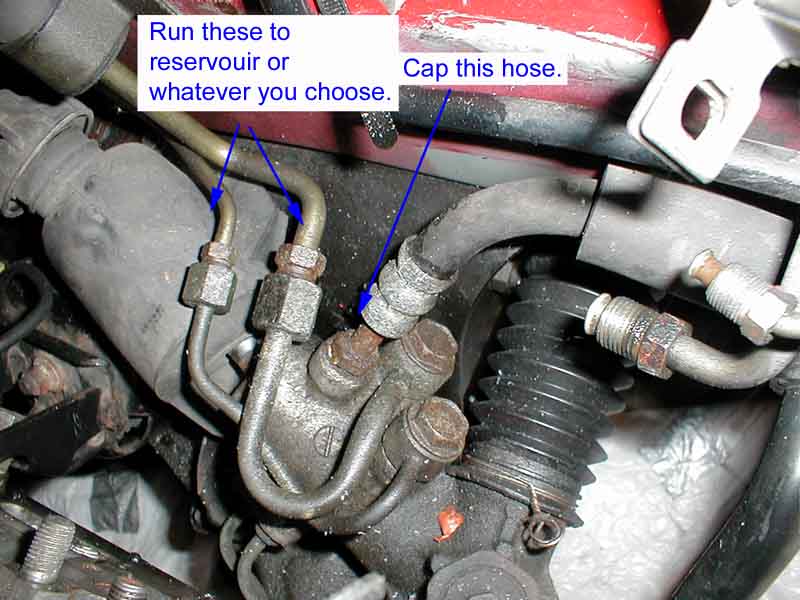

Do you have the stock banjo bolt fitting for the power steering rack? If so, I screwed a -6an fitting into it and one went into the stock Ford PS pump. If you don't have the banjo fitting I'm not sure what you need. The best pic of the power steering banjo fitting I could find is here: http://www.rx7turbo.com/projectcosmo/psrack.jpg The -6an adapter would screw into the end of the U-shaped hardline coming off of the rack. On anplumbing.com the metric to -6an adapter is part # 871606. The other fitting that I mentioned before attaches to the ends of the -6an line itself.

I used the 1" Wilwood Master and Wilwood pull-type slave that Grannys site recommended. The summit part # for the master is WIL-260-3378 and the slave is WIL-260-1333.

Grate! Huge thanks man! Thought I knew what I was doing coming into this swap but I now know I have no idea haha! I have the guys at work checking on the master cylinder(should get a grate price through work) and I will order that fitting here in a little. I do have the hard line that connects to the rack with the banjo fittings so it looks like the large line is the high pressure line and the small line is a return line?

Also in other news I did run a new wire from the alternator to the fuse block. Once I figured out how the thing worked it was easy to get it going. The only wiring i have left is the distributor and the green wire coming off the alternator. I know how im going to wire the distributor but don't know what im doing with the alternator yet.

There is a good picture in this post of what each hose does: http://www.norotors.com/index.php?topic=14389.msg195163#msg195163

I have the 3 port rack so I just capped off the port for the electronic controller.

I have the 3 port as well. For some reason the photos won't pull up for me on the link. But I did find this pic that is very "Getto" but shows me witch of the ports needs to be plugged.

Yep that one worked, and I didn't know that it was a electrically controlled power steering I thought that one side was for low rpm and one was for high. Must have read some wrong info online. Do you know how much pressure the return line is under? I would amuse little to none. I was going to just use rubber line and hose clamps.

Well wilwood 1" master cylinder is ordered as well as the fitting to get the rack hooked up.

More wiring done last night, the distributor is wired up and I had to run new wires to the horns because the got moved with the new rad. I need to go get a battery the one that came with the car can't hold a charge. Any idea what battery I should use? Cheap and light are key! I figure I don't need all of the power of a stock mustang or explorer battery since the most draw would be headlights and heater. I have no AC not much of a sound system.

You'll need to log in to post.