loosecannon wrote:fasted58 wrote: In reply to loosecannon: muriatic acid woulda cleaned the rust offa that in less than half an hourI used muriatic acid to etch a concrete floor and it's too evil for what I need. The vapors that come off of muriatic will knock you on your bum and will eat away the metal containers I soak my parts in, too.

Been there, done that, and fully agree.

Now that the headers are flipped around, they dump out right where the frame was. I cut the section out on each side and welded in a new piece at a new angle so the exhaust will clear. Here is the section I had to cut out of the drivers side:

And after the new piece is welded in. I have to do some final welding up on it.

I learned from the V12 that motor mounts sticking into the engine bay make it difficult to remove the engine, so for these ones I ran 2" tubing from the stock mounting holes on the block out to the frame and made them bolt-on.

There is no cushion between the engine and frame, it's essentially solid mounts.

4cylndrfury wrote: Looking good! Whats your new timeline? Is there a light at the end of the tunnel?

As soon as I put a goal of running it at this years Nationals, costs ballooned. I have hopes of it being ready for next season but business is going to have to pick up for me to afford some of the parts I need.

The switch from carbs to EFI required a complete change of the fuel system. I needed to remove the old fuel line, pump and filter and add a new fuel pump, feed line, filter and return line. The new fuel pump:

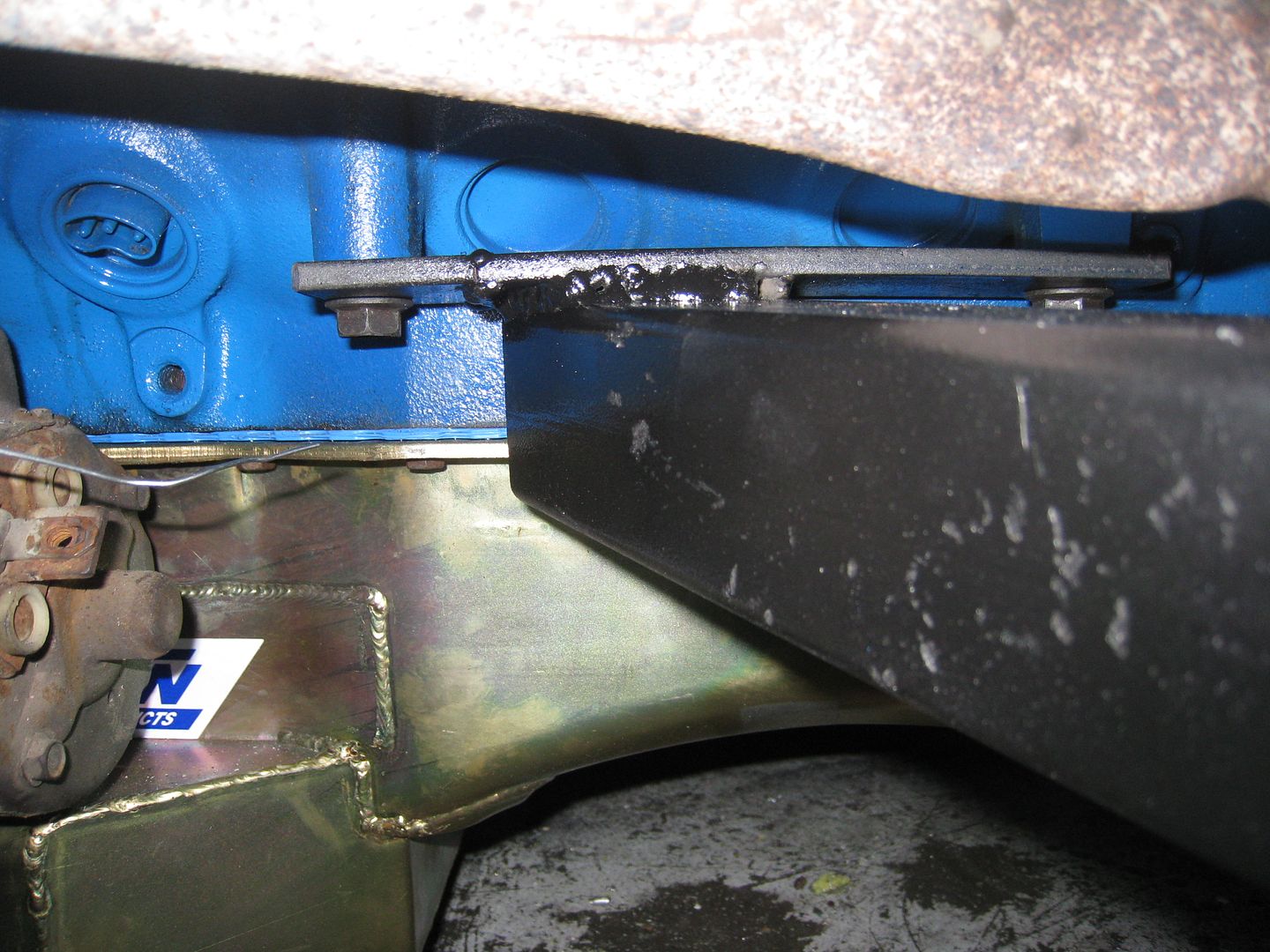

Fuel filter bolted to the frame rail. I hope it's not going to get too warm from the side pipes.

Fuel filter bolted to the frame rail. I hope it's not going to get too warm from the side pipes.

The fuel lines run inside the frame rail until just behind the battery where they pop out and go to the fuel rail on the engine:

The fuel lines run inside the frame rail until just behind the battery where they pop out and go to the fuel rail on the engine:

A piece of sheet metal between your fuel filter and the side pipes with an air gap will act as a heat shield for your fuel system. My dad just fabbed some up on our Challenge car and they seem to do the trick.

hrdlydangerous wrote: A piece of sheet metal between your fuel filter and the side pipes with an air gap will act as a heat shield for your fuel system. My dad just fabbed some up on our Challenge car and they seem to do the trick.

yeh, I think something like that will work fine but I'm not adding an ounce unless I have to.

I used doubled over brake metal (gutter flashing, buy it in rolls at Home Depot) with a gap between them to shield the brake lines on the lemons car. Bent the ends on the metal brake, riveted them together so there was about 1/8" between the sheets. Worked great and weighed almost nothing. It's aluminum so use aluminum or stainless rivets. Probably add grams if that. Even adding a few inches of length to reroute the lines would be more weight. Skipping the second helping at dinner the night before would save more weight. ;-)

Update: Took the Painless wiring harness I bought on E-Bay and began installing it. Everything was going swimmingly until I couldn't find a plug for the ECU. Further investigation revealed that the wiring harness was for a MAP(manifold absolute pressure) engine and I had purchased all the sensors for a MAF (mass airflow)engine. MAF is better so I put the MAP harness back on E-Bay where amazingly it sold within 12 hours and now I have to purchase a harness for a MAF engine.

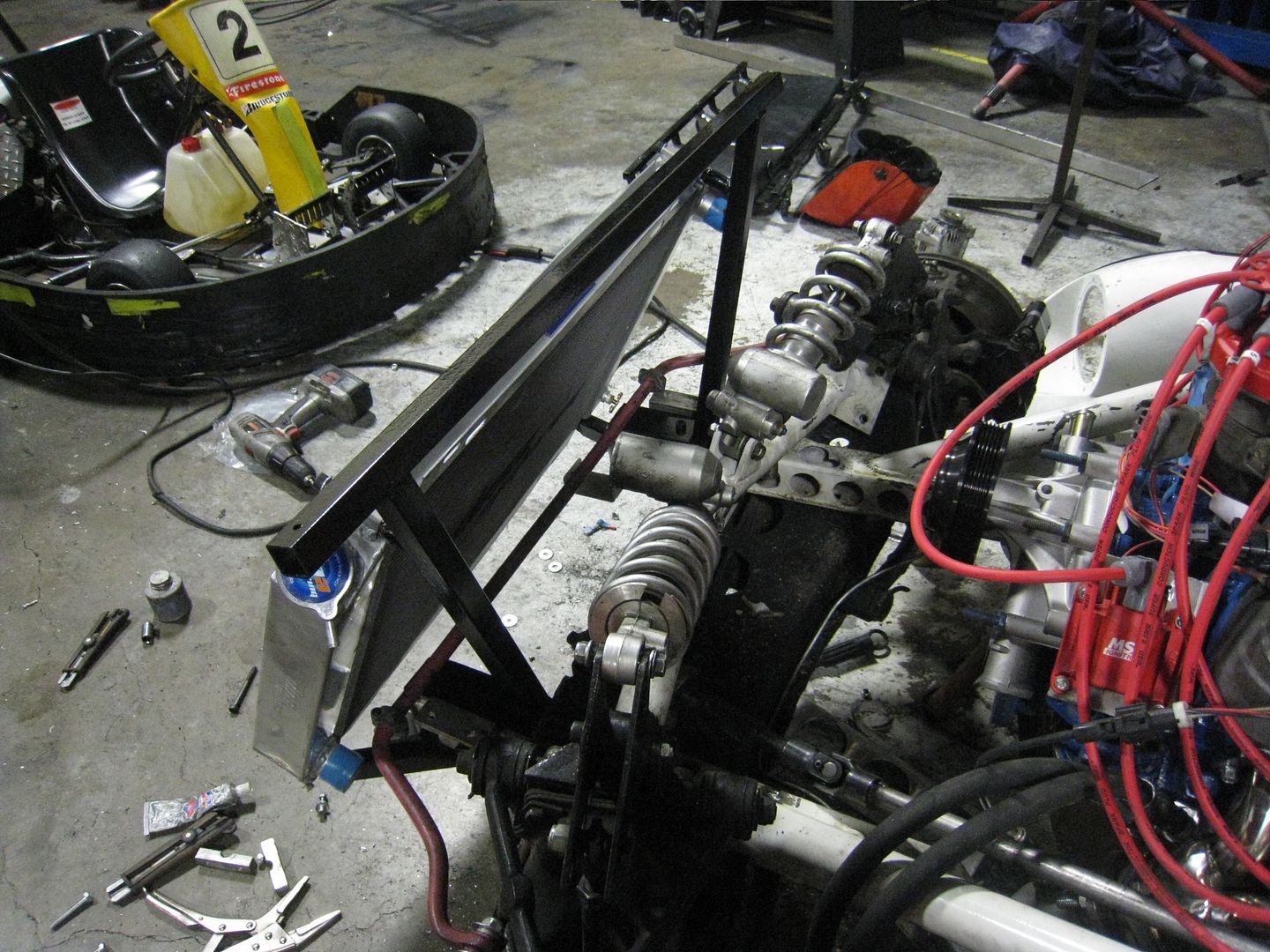

I haven't stopped work on the car, I just haven't completed any tasks. I have been working on a few things, here's some pics:

In this picture of the car in action at an autocross, you can see a lot of daylight between the floor and ground. This was a mistake, I built the floor higher than the MGB floor when I didn't need to. So the next picture shows the whole floor cut out, to be remade entirely out of aluminum and a few inches lower.

In this picture of the car in action at an autocross, you can see a lot of daylight between the floor and ground. This was a mistake, I built the floor higher than the MGB floor when I didn't need to. So the next picture shows the whole floor cut out, to be remade entirely out of aluminum and a few inches lower.

And the upper intake is bolted on. I also began installation of the Painless wiring harness.

And the upper intake is bolted on. I also began installation of the Painless wiring harness.

I am also attempting to build fender flares out of aluminum. I think they will look pretty good when all done.

I am also attempting to build fender flares out of aluminum. I think they will look pretty good when all done.

loosecannon wrote: I am also attempting to build fender flares out of aluminum. I think they will look BITCHIN, AND WAAAAY COOLER THAN YOUR CAR when all done.

FTFY...love the flares ![]()

Thanks guys, In the end I really do want an awesome race car. A problem I have run into is that I enjoyed building it so much, I may have to sell it once it's done to finance my next build. My wife is already suggesting race car builds, so far she has come up with Subaru STi powered Porsche (914,356 or 550 replica), Honda powered classic Mini, Formula Ford turned into BMod auto-x car and now suddenly she's hot for Ariel Atoms.

loosecannon wrote: Thanks guys, In the end I really do want an awesome race car. A problem I have run into is that I enjoyed building it so much, I may have to sell it once it's done to finance my next build. My wife is already suggesting race car builds, so far she has come up with Subaru STi powered Porsche (914,356 or 550 replica), Honda powered classic Mini, Formula Ford turned into BMod auto-x car and now suddenly she's hot for Ariel Atoms.

You shouldn't post things like this here. You're gonna have a bunch of guys trying to steal your wife away from you.

Did I mention that she's this years SCCA BM-L Champion?

hrdlydangerous wrote:loosecannon wrote: Thanks guys, In the end I really do want an awesome race car. A problem I have run into is that I enjoyed building it so much, I may have to sell it once it's done to finance my next build. My wife is already suggesting race car builds, so far she has come up with Subaru STi powered Porsche (914,356 or 550 replica), Honda powered classic Mini, Formula Ford turned into BMod auto-x car and now suddenly she's hot for Ariel Atoms.You shouldn't post things like this here. You're gonna have a bunch of guys trying to steal your wife away from you.

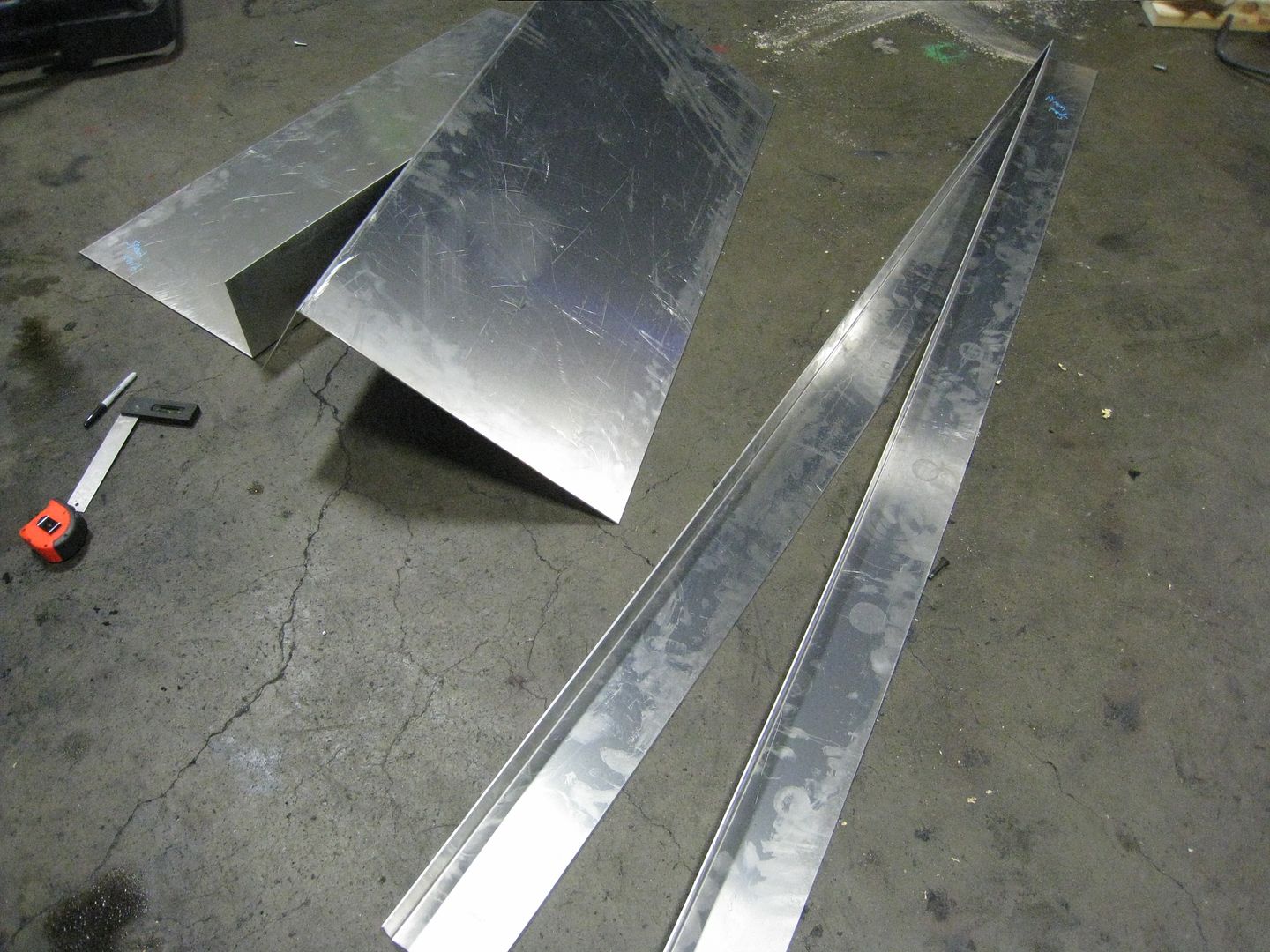

The construction of the new lowered floor began with the drivers side. I ordered some 1/8" aluminum sheet from Tailor Made and had them bend it for me.

The raw materials.

The raw materials.

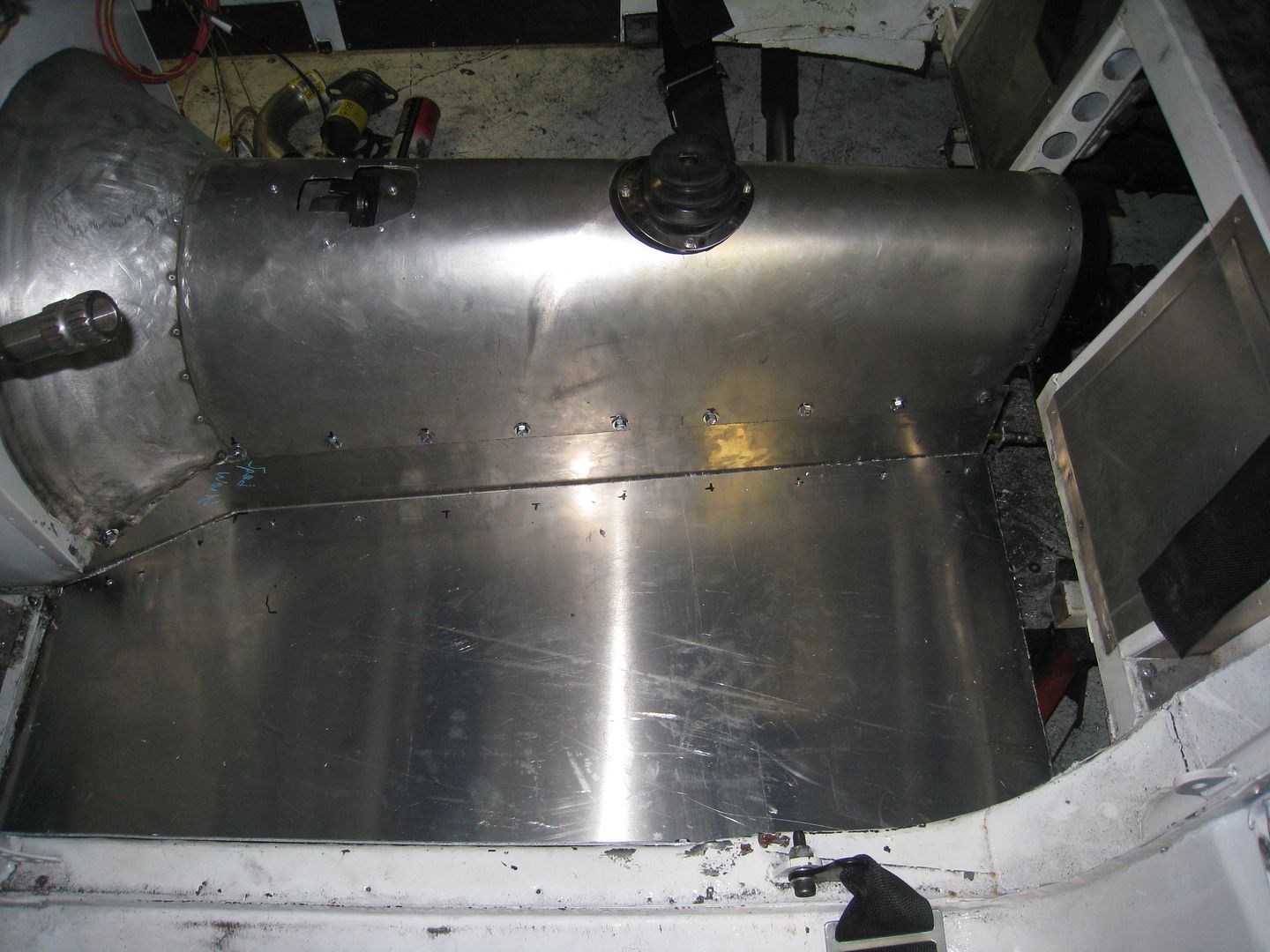

After a lot of fitting, trimming, cutting and re-fitting I was able to use threaded rivets to hold the floor to the frame rails.

After a lot of fitting, trimming, cutting and re-fitting I was able to use threaded rivets to hold the floor to the frame rails.

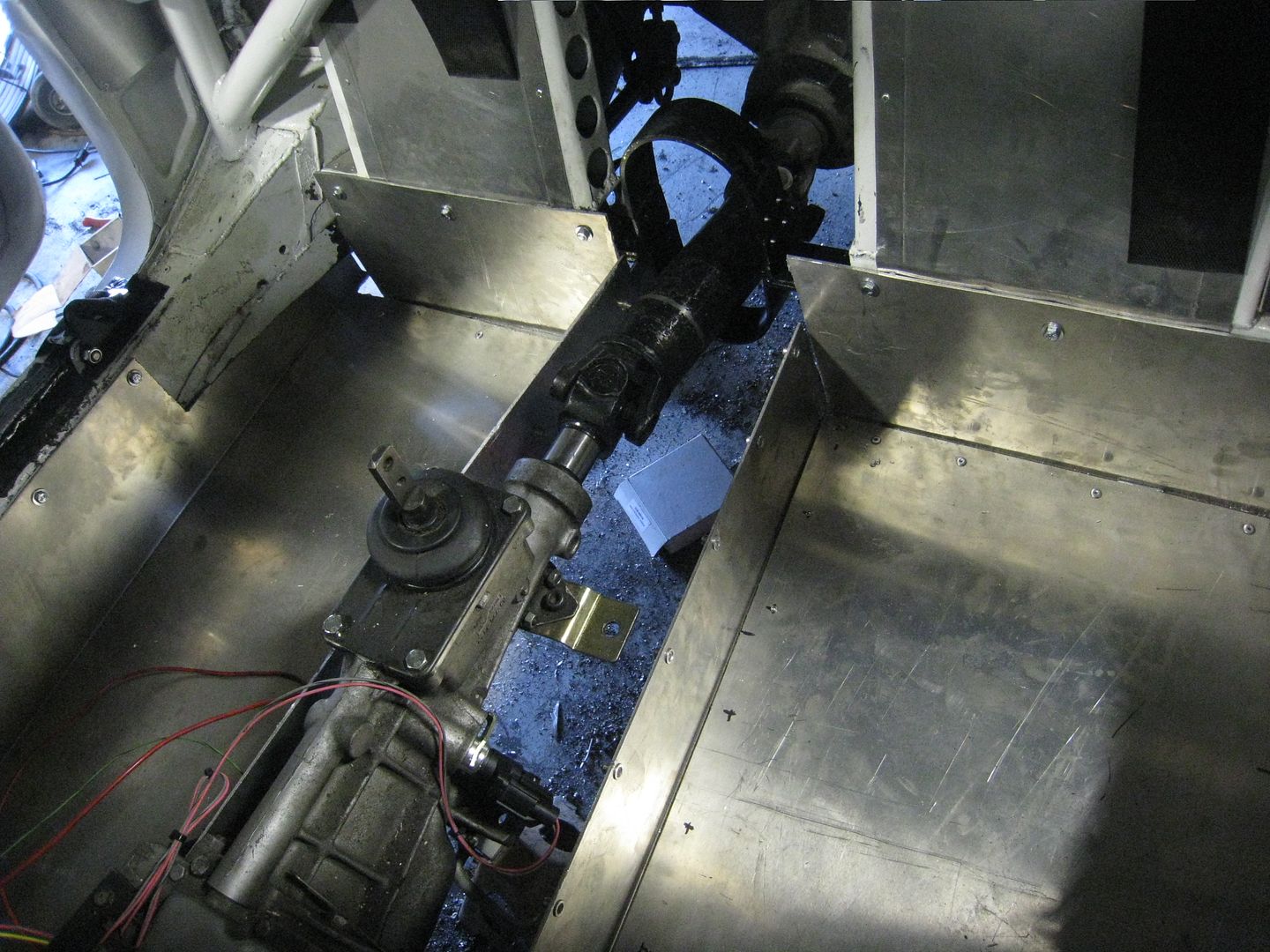

And bolt the tunnel to the floor. I still have to fill in the gap at the back of the floor then onto the passenger side.

And bolt the tunnel to the floor. I still have to fill in the gap at the back of the floor then onto the passenger side.

Awesome work.... Might want to find a used box upper, would hurt the low end a tad, but they are much shorter and smaller than a standard EFI intake ,and bolt to the stock lower. A 94-95 Cobra upper would also give you a little more clearance.

hrdlydangerous wrote: You shouldn't post things like this here. You're gonna have a bunch of guys trying to steal your wife away from you.

Quoted because it was exactly what I said out loud.

And also, by "the next build" you mean this car with a newer Aston Martin V12 in it, right? Well, on second thought, the computer programming degree required for that would probably make it impossible for anyone but some nerd who programs for Microsoft, huh?

loosecannon wrote: Thanks guys, In the end I really do want an awesome race car. A problem I have run into is that I enjoyed building it so much, I may have to sell it once it's done to finance my next build. My wife is already suggesting race car builds, so far she has come up with Subaru STi powered Porsche (914,356 or 550 replica), Honda powered classic Mini, Formula Ford turned into BMod auto-x car and now suddenly she's hot for Ariel Atoms.

Dibs! (On the car, not the wife)

I got everything hooked up on the 5.0 V8 and here is the video of the very first time I pushed the start button: http://www.youtube.com/watch?v=Lp54ywG-RlA

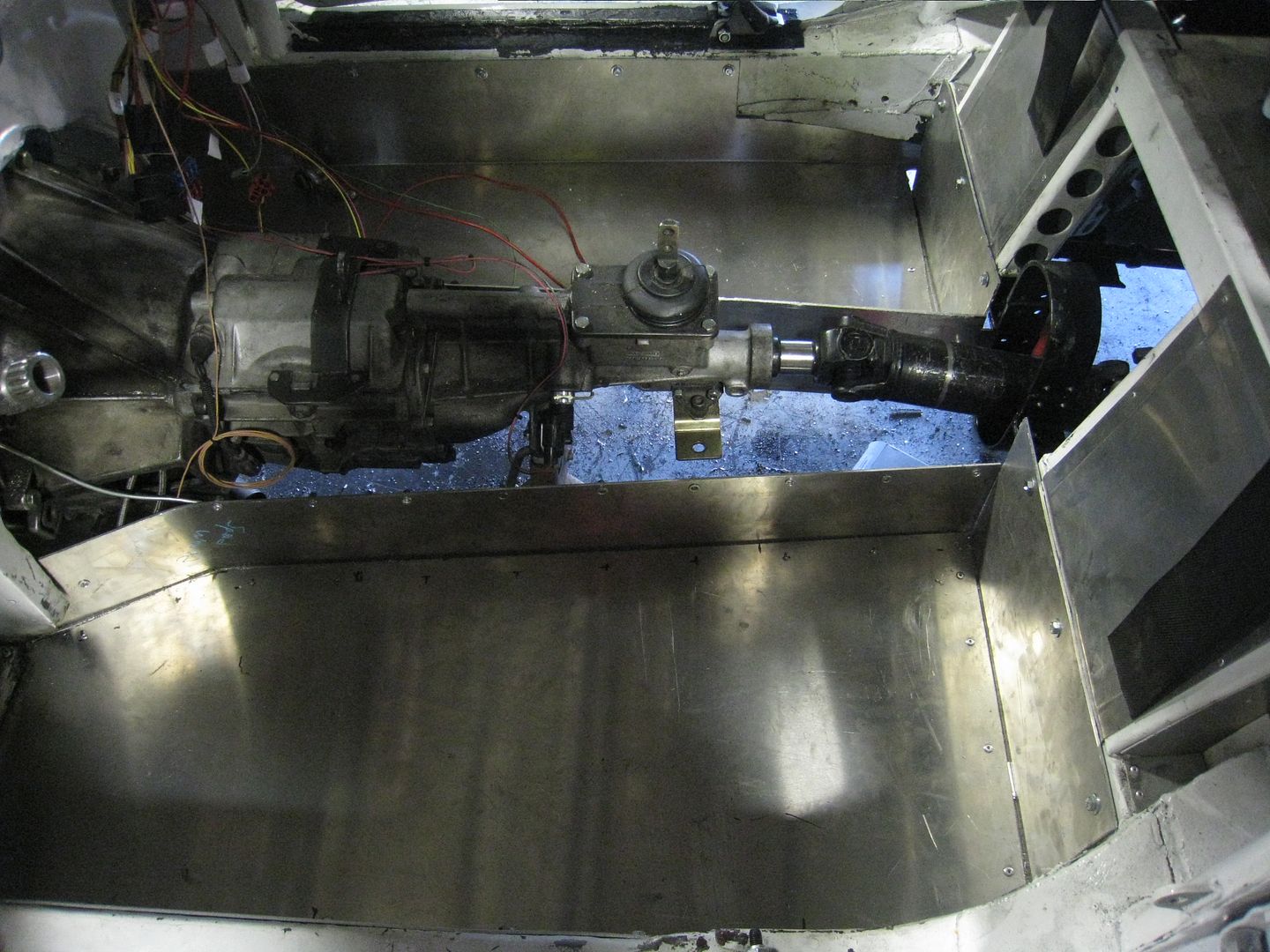

I worked on the passenger side floor and finished up the drivers side floor this week. For now everything is just riveted together but I will be seem welding the whole thing soon. Here it is without the tunnel bolted on.

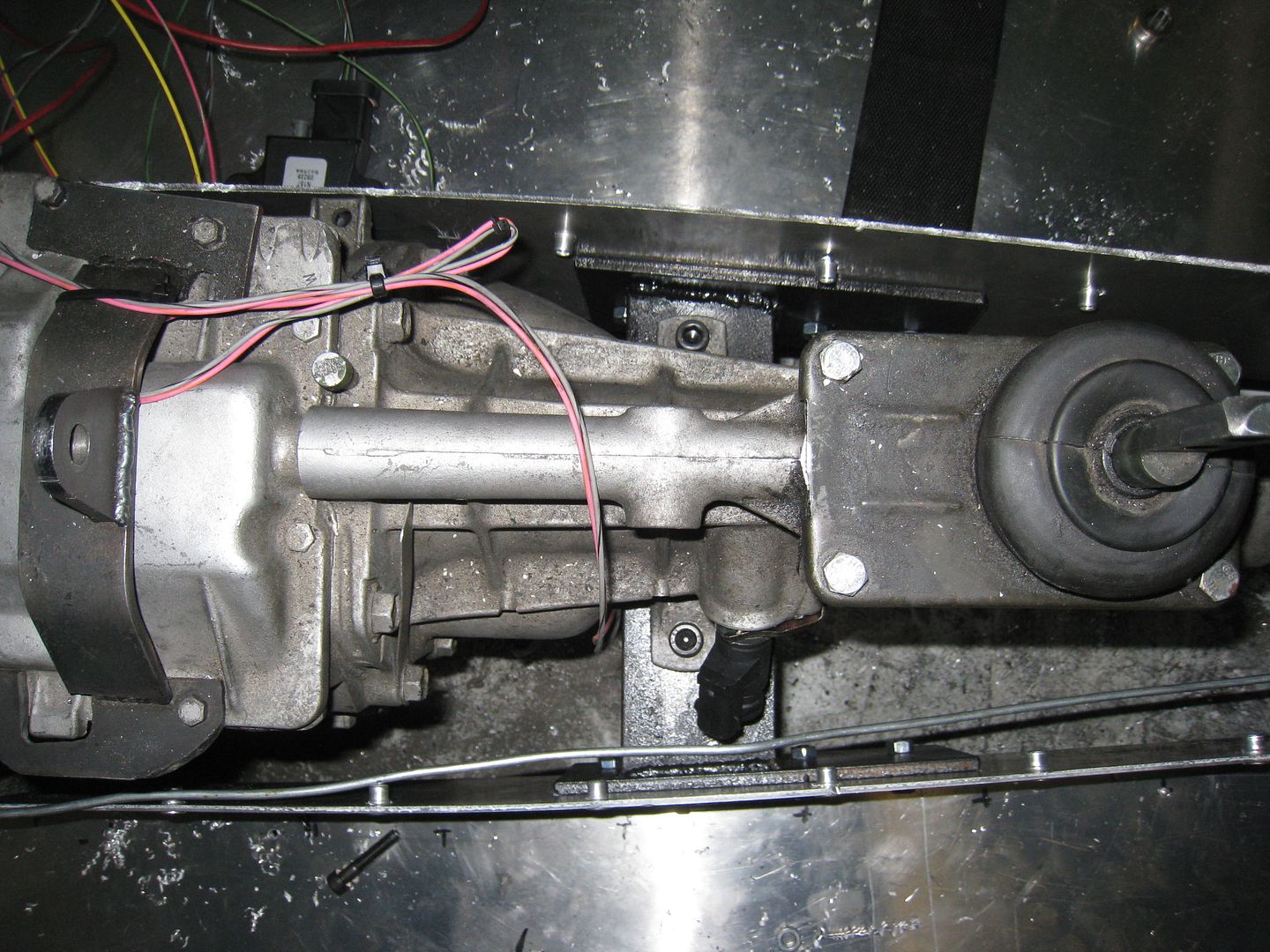

I needed a new rear transmission mount and the floor feels so strong that I decided to build a steel mount that bolts between the driver and passenger side floors. This is the reason I have decided to weld the floors and add some gussets. When I first bolted the bracket in and let down the bottle jack holding up the tranny, it didn't budge, so I take that as a good sign that the floor can handle the weight. I will still be keeping a close eye on it.

oh my, that hing soudns wonderful...not sure how I missed the youtube post, but Im sure glad you did!

Is there a way to include a failsafe so that if the floor does give should you get bumped on the track, the trans isnt liberated in spectacular fashion? Wouldnt have to be fully structural, just the transmissional equivalent of a chain between your trailer and your hitch? are the bellhousing/motor joint + motor mounts strong enough to keep the trans in the car at speed? Just thinking aloud. Looks great as usual!

4cylndrfury wrote: oh my, that hing soudns wonderful...not sure how I missed the youtube post, but Im sure glad you did! Is there a way to include a failsafe so that if the floor does give should you get bumped on the track, the trans isnt liberated in spectacular fashion? Wouldnt have to be fully structural, just the transmissional equivalent of a chain between your trailer and your hitch? are the bellhousing/motor joint + motor mounts strong enough to keep the trans in the car at speed? Just thinking aloud. Looks great as usual!

Funny you should suggest that, I was thinking of putting an aircraft cable between the trans and the driveshaft loop just in case of floor failure. Also, you haven't heard anything yet, it turns out that I had the firing order set to a non HO 5.0, which was wrong. Now that I have it correct, the car really howls-I have to get a video of it to post here.

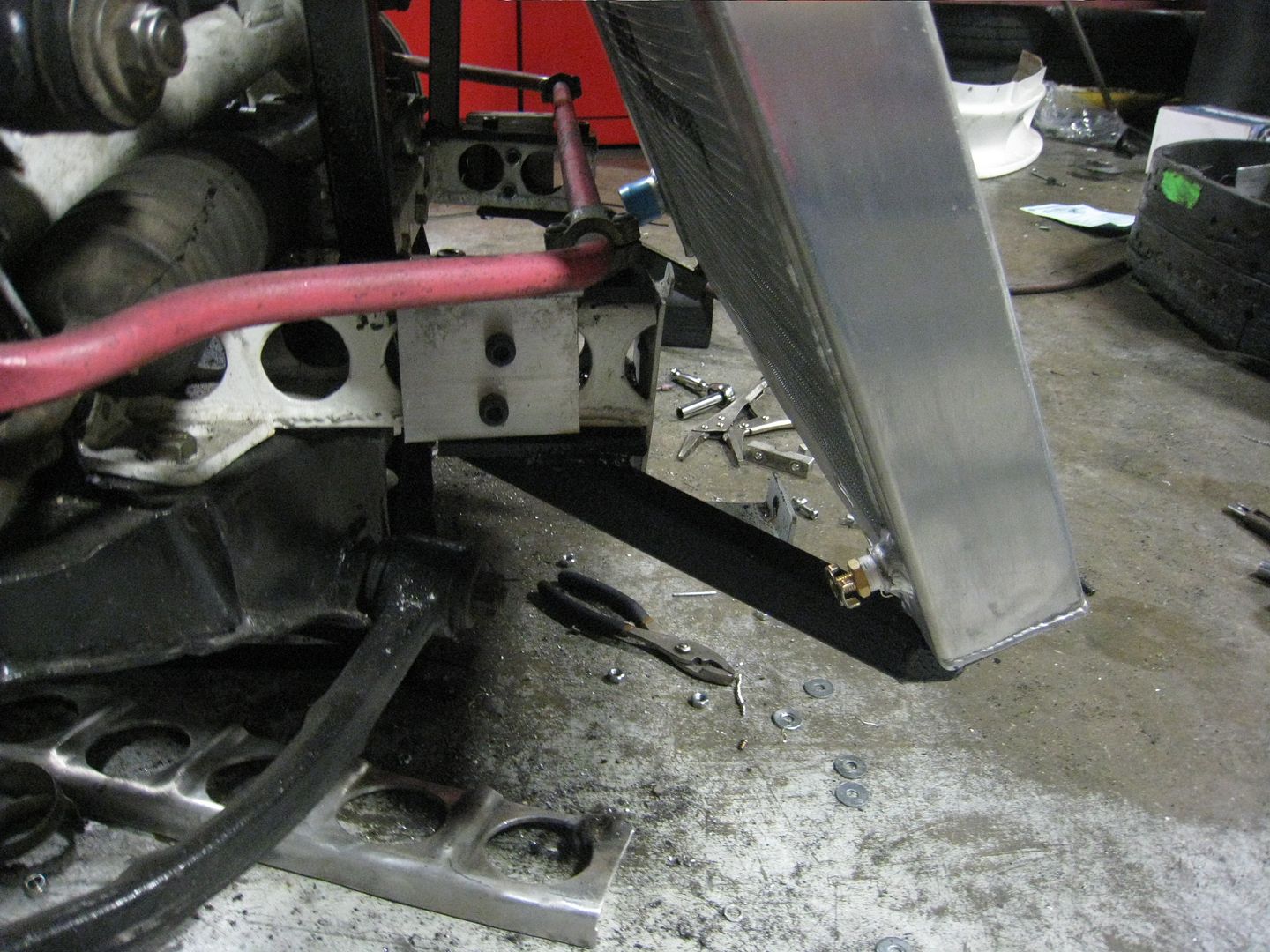

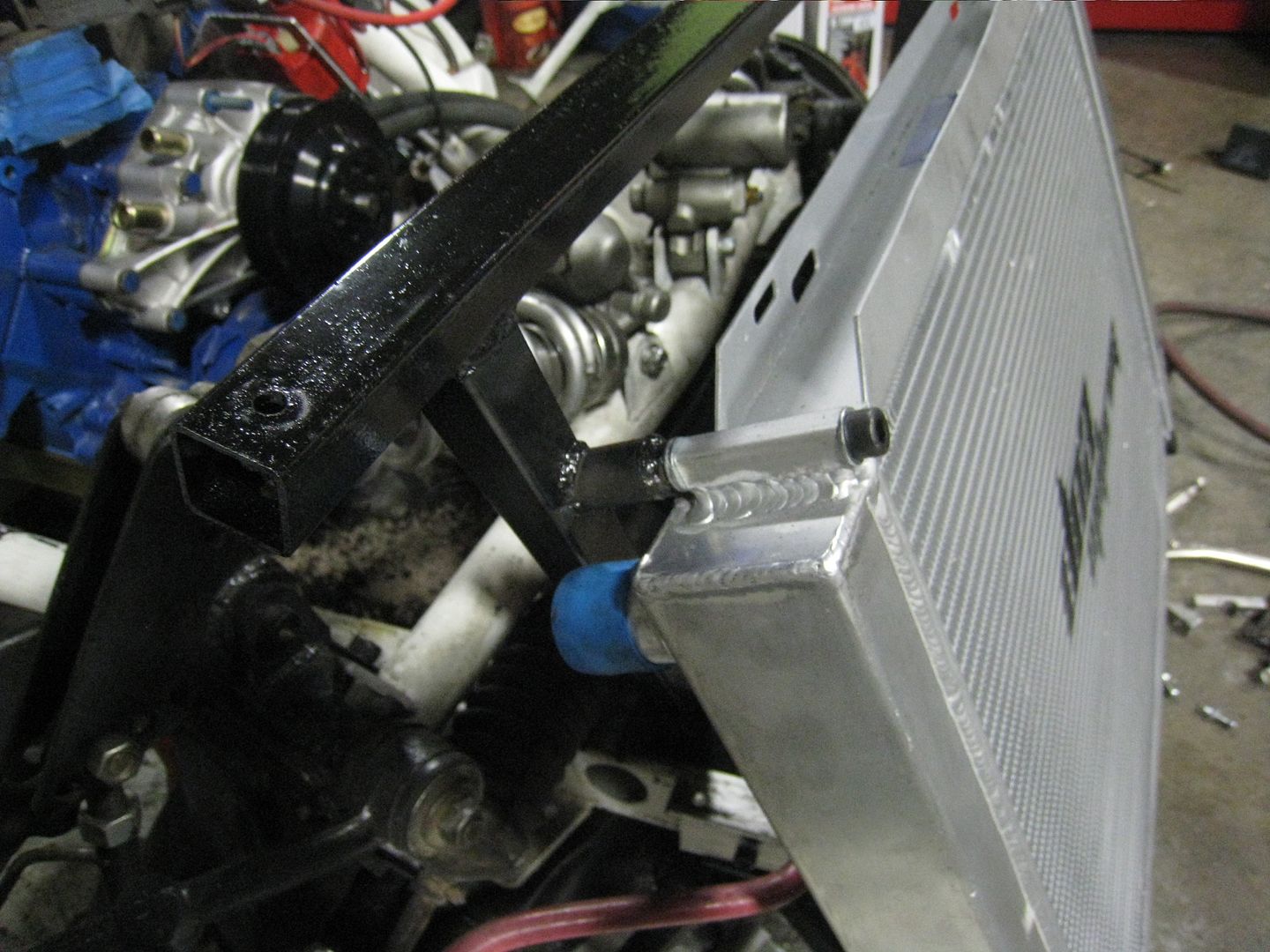

The giant radiator I had for the V12 was so heavily modified that I decided to start fresh with a new, built for a 5.0, aluminum racing radiator. A mistake I made with the other one was that the uprights holding the rad also got in the way of shrouding the radiator. For this one I mounted it lower and farther back for improved weight distribution and I allowed lots of room for shrouding. Here is the passenger side lower mount bolted to the frame:

And upper passenger side:

And here you can see there is plenty of room behind the rad for shrouding some fans in:

You'll need to log in to post.