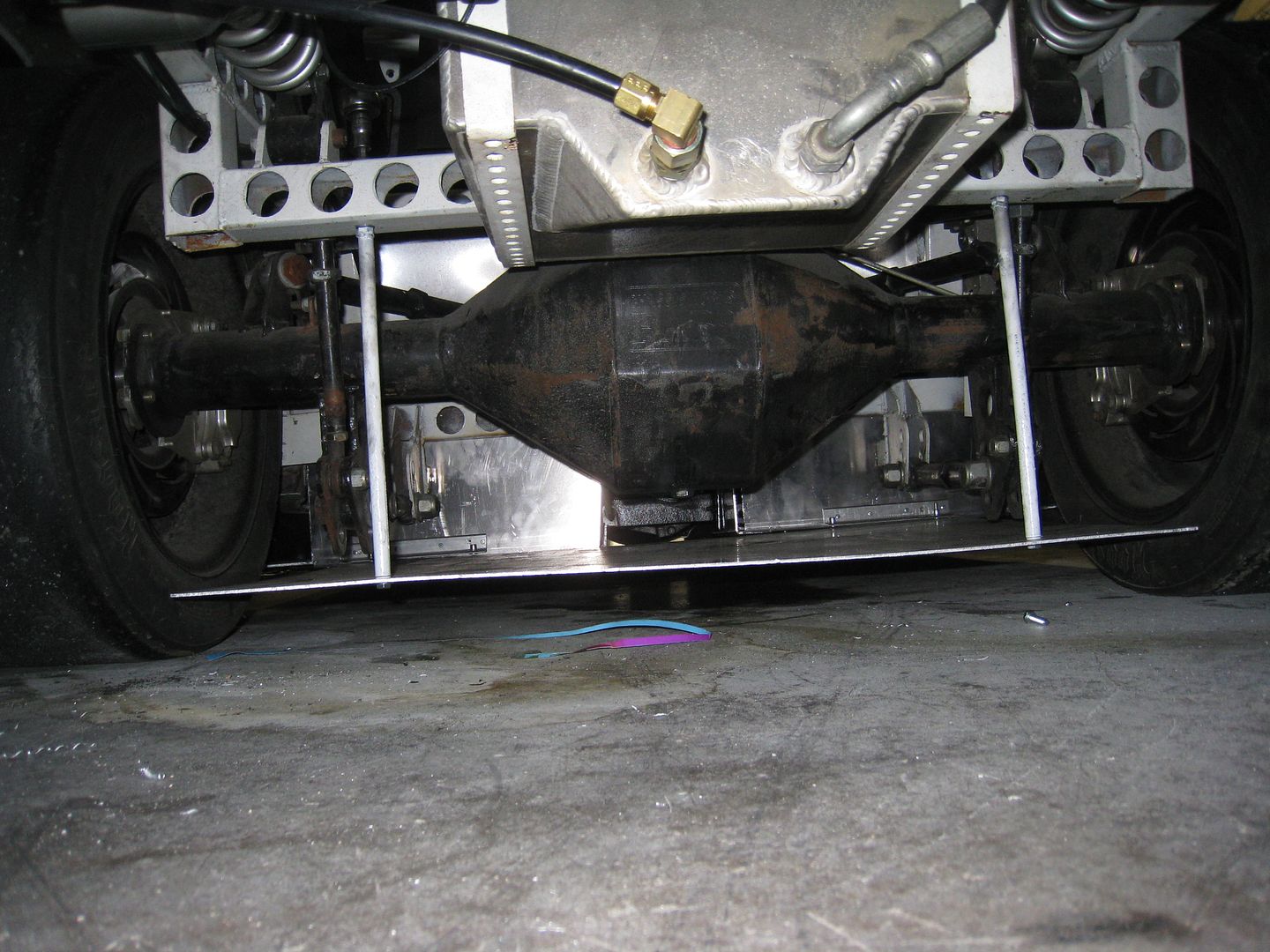

With the new lowered floor, the belly pan under the rear suspension and the diffuser had to be lowered as well. Here is the belly pan, notice it is now low enough to go completely under the diff where before I had to cut a hole for the center section to poke through:

And the diffuser bolts onto the belly pan. A lot of material was cut off the vertical pieces in order to make it fit.

And from the side. The rear diffuser supports are adjustable and right now are in their highest position.

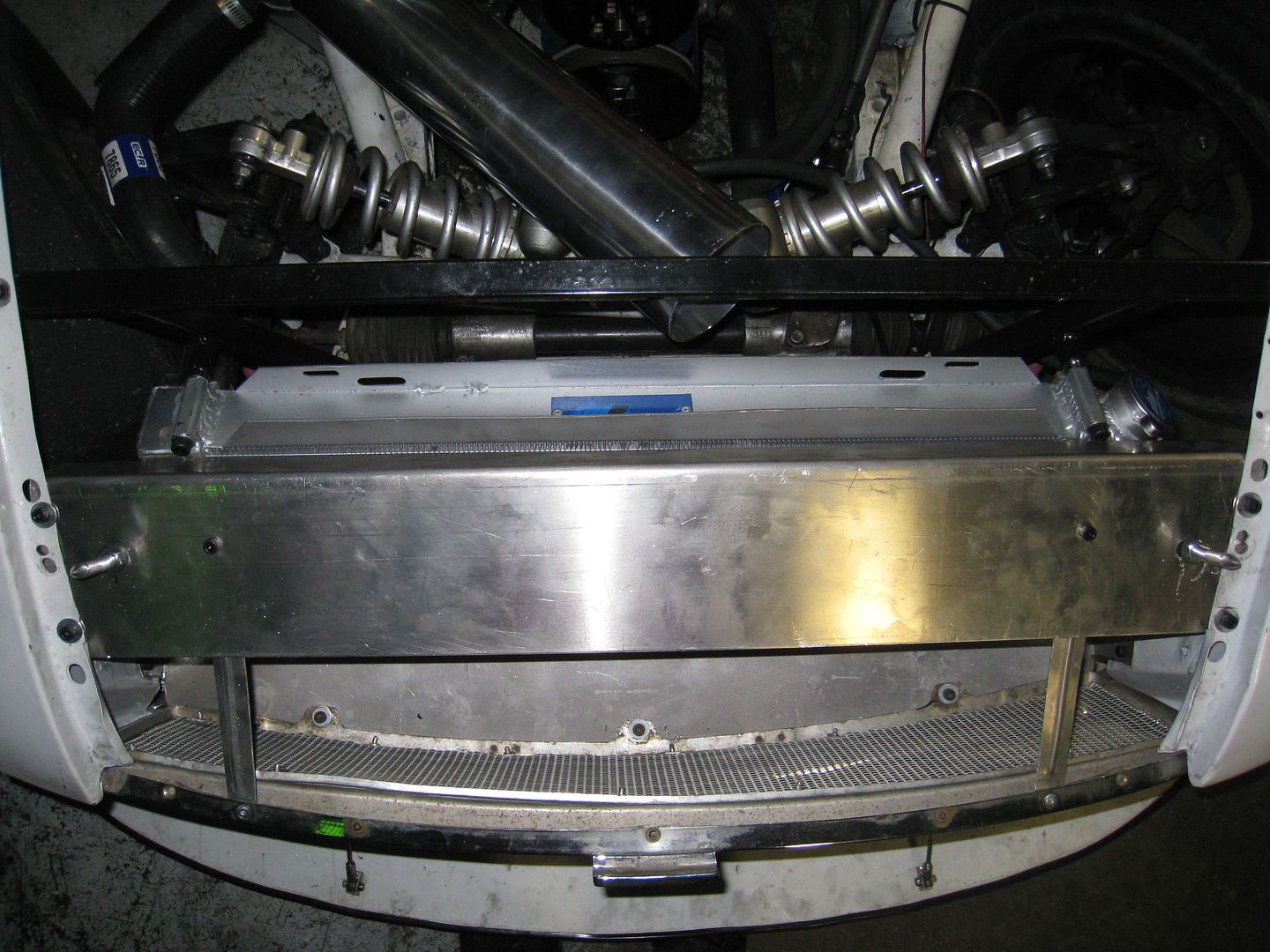

My idea to put a bellmouth in one headlight opening and use it for a ram air system was a fail, so I built something else using the opening above the radiator. Here is a pic of the aluminum piece I use to keep air from going over the top of the radiator:

Underneath it is a large gap between the rad and the fender/rad support structure:

I built a box which takes air from that gap and directs it towards a 4" pipe which then shoves the air through the MAP and into the engine:

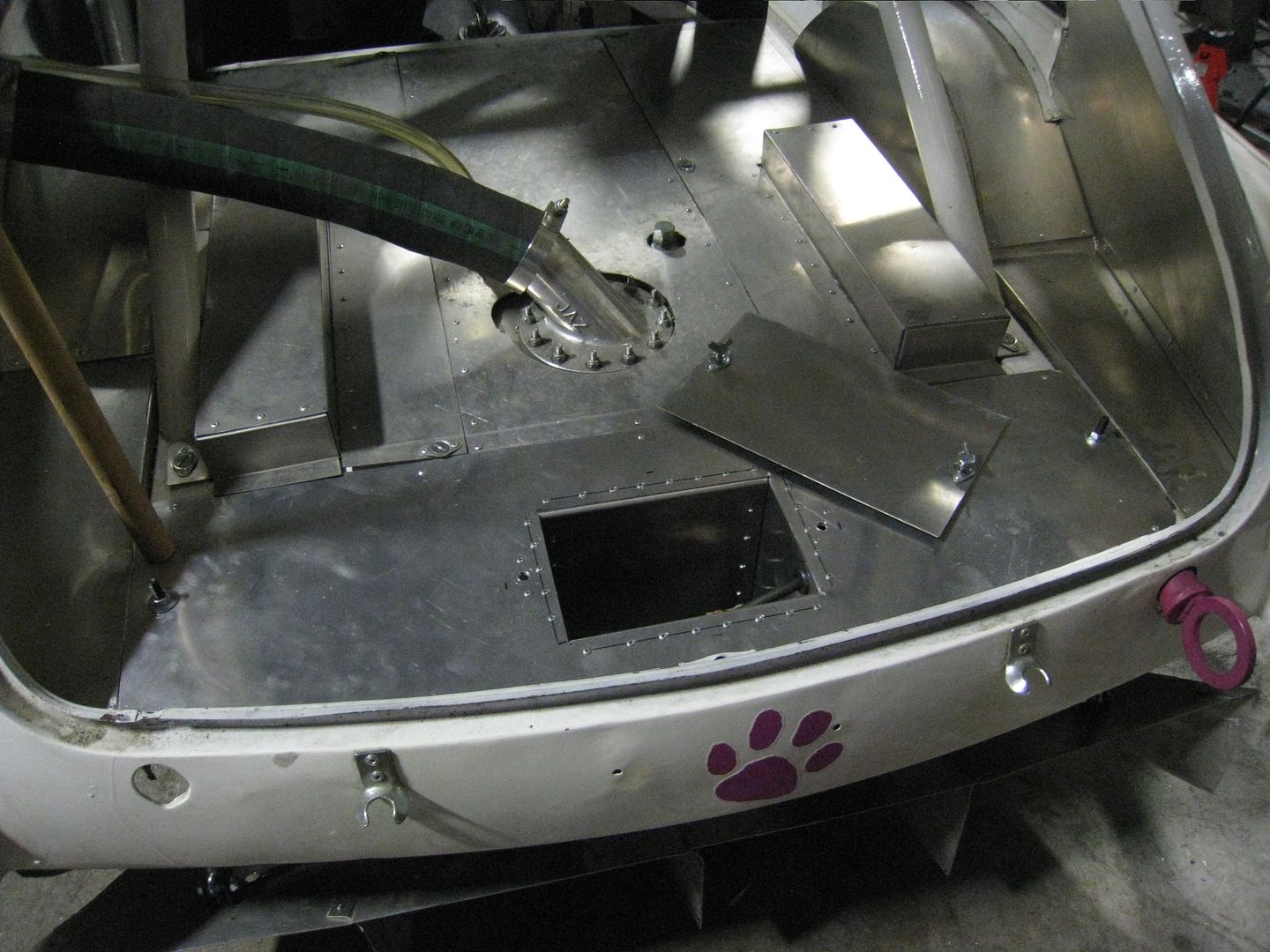

I wanted to improve the weight balance even more so I moved the battery to the very back of the car. I built a battery box out of aluminum and incorporated it into a cover panel under the rear hatch:

This thread makes me smile every time it comes up, that MGB is ridiculousness wrapped in awesome, with a side of Chuck Norris...![]()

mguar wrote: In reply to loosecannon: If You want I can locate V12's around here relatively cheaply.. (I'm in Minneapolis) lately other than the work of pulling them I got a few free. Your best bet might be to buy a rust bucket for a few hundred and haul it home.. I just got another last week.. Interested?

No thanks. The V12 was cool and I did it for nostalgia reasons because my dad gave me the engine 27 years ago, but since that engine is now no good, I'll stick with the V8.

Oh sadness. The V12 was fantastic, even if the V8 is likely faster. The V12 just screamed unbeberkingleyawesome in every way. What would it take you to reconsider?

SkinnyG wrote: Oh sadness. The V12 was fantastic, even if the V8 is likely faster. The V12 just screamed unbeberkingleyawesome in every way. What would it take you to reconsider?

Winning the lottery. Then I would spend the $5000+ that it would take to properly rebuild the V12 with good pistons, induction system and cams.

mguar wrote: In reply to loosecannon: You could approach 500 hp with about a $300 expense over a decent running stock V12 by simply using a pair of used turbo's from Volvo/Saab. I've got a local guy who will sell me used turbo's for $75.each (w/intercooler) It's easy to find good ones.. Take a magic marker and mark a blade and spin the turbo.. if it stops at random spots it's still good.. Then all you need is the early fuel injection system (it has the biggest injectors stock) with the addition of an $85 FMU (fuel management unit) that tricks the injectors to give more fuel the more boost is created. Yes if you want you can use a megasquirt but the early system is workable even if not laptop adjustable.. Your engine is begging to be turbo'd it's got 7.8-1 compression. If you want a modest cost normally aspirated V12 I've bought forged pistons as cheap as $75 each. Typically when going that route I go to 13-1 compression but you could stop at say 10-1 if you want to use pump gas and not race gas. You've already found out how cheap it is to regrind your stock camshafts. On a modest budget go for something like ISKY''s XM3 (.424 lift, 268 duration) rather than their V199 (.444 lift, 258 duration) or the XM5 (.440 lift, 278 duration) The XM-3 actually will make more average power than the the other two which make more peak power over a narrow RPM range. A little port work on the intake side and with the stock fuel injection you should be near 443 tq. & 498 hp. Use ethanol and you'll pick up about 35 extra Hp. & a similar amount of torque.. Plus it's cheaper than unleaded regular! (if you buy it at the plant and denature it on-site to avoid paying the drinking tax) You've paid for some expensive education with your V12. You now know that to use that 5 speed you'll have to shim the gearbox back. That wasn't your fault, blame it on the people who sold you the kit.. Yes you can make power with a pushrod engine. so- what? That V12 is really unique.

You must have incredible luck or generous friends because I don't believe anybody can get that kind of power out of a Jag V12 for so little money. Besides, there is no room for a single, let alone dual turbos in the MGB when that V12 is in there.

Project update: anybody who has seen the car run knows it smokes pretty badly. The stock computer was not set-up to run the 24lb injectors I have and fuel was dumping into the cylinders. I got a custom tune using a product called Tweecer and the problem didn't go away. The Tweecer software shows real time readings of all engine sensors and my MAF sensor appeared to be faulty, so I bought a new one :( The new one showed the same low voltage and a tech at Painless (wiring harness manufacturer) said I have a bad ground.

I re-did all the ground connections, going as far as welding bolts to the frame that are used to attach the ground straps. Still no changes in the MAF readings so I put a voltmeter on it and lo and behold, the voltage was exactly what it's supposed to be. It turns out that I got a bad version of the Tweecer software and once that was corrected, the voltage displayed correctly. Still, the engine smoked. In the process of all these checks, I discovered that I had done my initial ignition advance based on the wrong marking on the timing tab and it was around 20 degrees too advanced. Corrected that and it ran 100% better but still smoked. I assumed that it was just a bunch of oil/gas coating the inside of the exhaust and would eventually burn off. Then I noticed that my air charge temperature reading was -20 C. I was not running the car outside so how could it be -20 C degrees? I replaced the ACT sensor and voila', the smoking seems to be going away and the car runs and sounds amazing.

oldtin wrote: Glad to hear you're getting it sorted out. I <3 this project

That makes me happy :) A new video of me driving it around the kart track, there is much less smoke now: http://www.youtube.com/watch?v=WF39_gv77kI

This car is so bad ass. I really doesn't even matter what engine is it; V12 or not, it's just plain awesome.

pres589 wrote: What'd you think of the Tweecer software?

I don't know the first thing about programming a base tune to I farmed that out to http://www.tecmotion.ca/ in Calgary. Matt at Tecmotion highly recommended the Tweecer and said he has had no problems with it so that's why I purchased it. It's easy to install and change the tune plus it allows you to datalog and I like that I can have 5 tunes loaded and can switch between them at the turn of a knob.

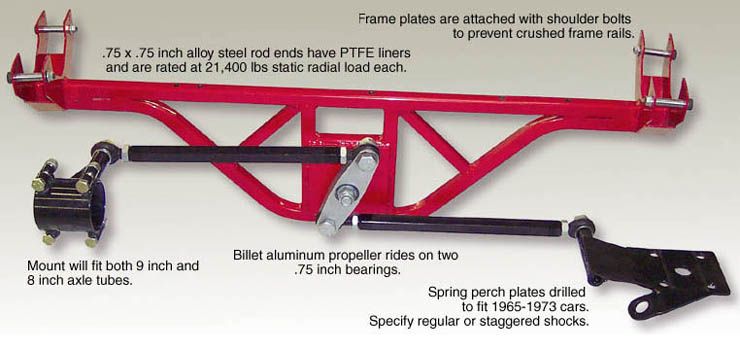

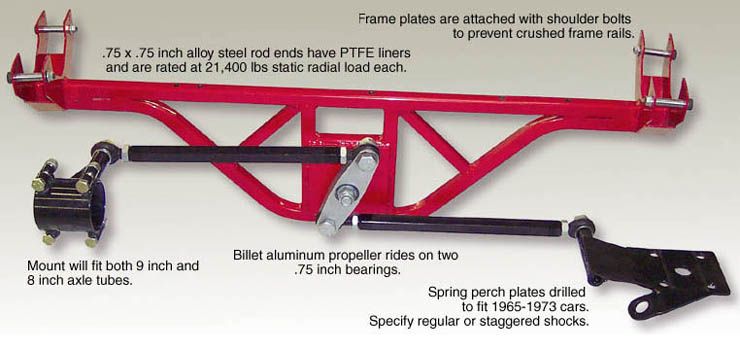

With the car all together, running and driving with the whole winter ahead of me, I have time to stare at it and wonder how I can make it better. This led me to purchase some software ($29.99!) which allows me to punch in all my data and it spits out results about roll center, anti-squat, roll stiffness, etc and I found some interesting things. The biggest thing is that my front roll center is 3 inches (good) but my rear roll center is 14 inches (bad). No amount of adjusting of my tri-four link suspension was going to correct this so I have decided to just chuck the whole thing and start fresh with a new, and better design. I chose a 3 link suspension with a Watts linkage because it's light, fully adjustable for roll center, squat etc and I can use all my old rod ends and bars. The 3 links will be two lower links in the same location as the current lower bars and one top link from the middle of the diff to a crossmember. Since I am making my own mounts, I am moving the lower front mounts so I can make the lower bars 2 inches longer, which reduces the arc that the rear end moves in and should make the handling more predictable. I included a picture of a Watts linkage. The red part is the crossmember that holds the pivot and the the black rods attach to each side of the diff. The center of the pivot becomes the roll center and if it's adjustable up and down, the roll center is adjustable up and down.

Here is the new top link and the right side will be welded to the crossmember and the left side will be welded to the diff.

And the new front brackets for the lower links, with holes cut in an arc to match the lower bars so I don't need to adjust bar length when changing mounting holes:

Are you going to mount the watts pivot to the diff so RC stays fixed relative to the ground or to the chassis so it stays fixed relative the CG?

loosecannon wrote:

Here's the missing text above the first pic:

Since I am making my own mounts, I am moving the lower front mounts so I can make the lower bars 2" longer, which reduces the arc that the rear end moves in and should make the handling more predictable. I included a picture of a Watts linkage. The red part is the crossmember that holds the pivot and the the black rods attach to each side of the diff. The center of the pivot becomes the roll center and if it's adjustable up and down, the roll center is adjustable up and down.

Curmudgeon wrote: Nice! What program did you get?

I am using Speed-Wiz and some freeware I found online.

nocones wrote: Are you going to mount the watts pivot to the diff so RC stays fixed relative to the ground or to the chassis so it stays fixed relative the CG?

No, the pivot will be attached to a crossmember so I am not adding all the unsprung weight. The front RC will move up and down with the chassis, too so having the back RC move up and down isn't such a big deal, especially with the small travel amounts in E-Mod

You'll need to log in to post.