mguar wrote:

In reply to loosecannon:

Sadly headers wouldn't really improve the power in a stock V12.. In fact you'd have to make some really serious power ffor headers on a V12 to make any difference..

I've explained the reasons so often my fingers type it automatically now but ask and I'll reexplain..

Out of curiosity what sort of camber are you thinking about in the rear? Do you anticipate more camber for turns in one direction over another? I've never worked on autocross cars so it's a whole other area to learn about..

I know that at most tracks I've found straight up rear axles work best. However to be fair I'm accelerating and braking at far faster speed than a typical auto-crosser would ever get to.

When I've made serious camber changes the car slowed down. While corning speed might be slightly higher with camber time spent under braking and accelerating is far more than time spent in corners..

I suppose I should separate out long corners like the carrousel from typical turns. However with 13 relatively tight corners and only one carrousel the balance is clearly in favor of straight up..

You don't have to convince me about Jag v12 headers, I didn't need them to make decent power. As for camber, on a live axle it hurts acceleration and braking but autocross is mostly rapid direction changes and the guys who win use full floating axles or tweaked axle tubes to get a little negative camber. This isn't limited to autocross cars, Australian V8 Supercars use camber on their live axle as well. I would be happy with .5 negative in the back.

mguar wrote:

I know NASCAR uses cambered axles for some tracks but they use floating rear axles to achieve it. Then the ends of the axles have a slight radius ground into their ends and are heavily lubed in order to survive. Even still for a long time drivers needed to be very ginger when leaving the pits because it was all too easy to snap axles..( that was with 850 horse power engines though).

By the way let me once again congratulate you on the brilliantly simple idea of eliminating the dog leg on your carb manifold for the V12. I'm taking it one step further and going to use 3 carbs per side onto a fuel injection manifold modified to take carbs rather than injection.

Your carbs flowed around 200CFM each for a total of 800cfm and three per side (total of six) are capable of 1200CFM the same amount the modified Fuel injection manifold can handle.

Couple of reasons for that. While 1200CFM would be too big if the carbs were fixed venturi's since the venturi's are self adjusting on Strombergs and SU's that much carb will still work..

Low cost, (just a little welding) Simplicity, and ease of adjustment plus a very different look are the reasons I'll go with carbs rather than fuel injection.

I will sell you those custom manifolds if you want them

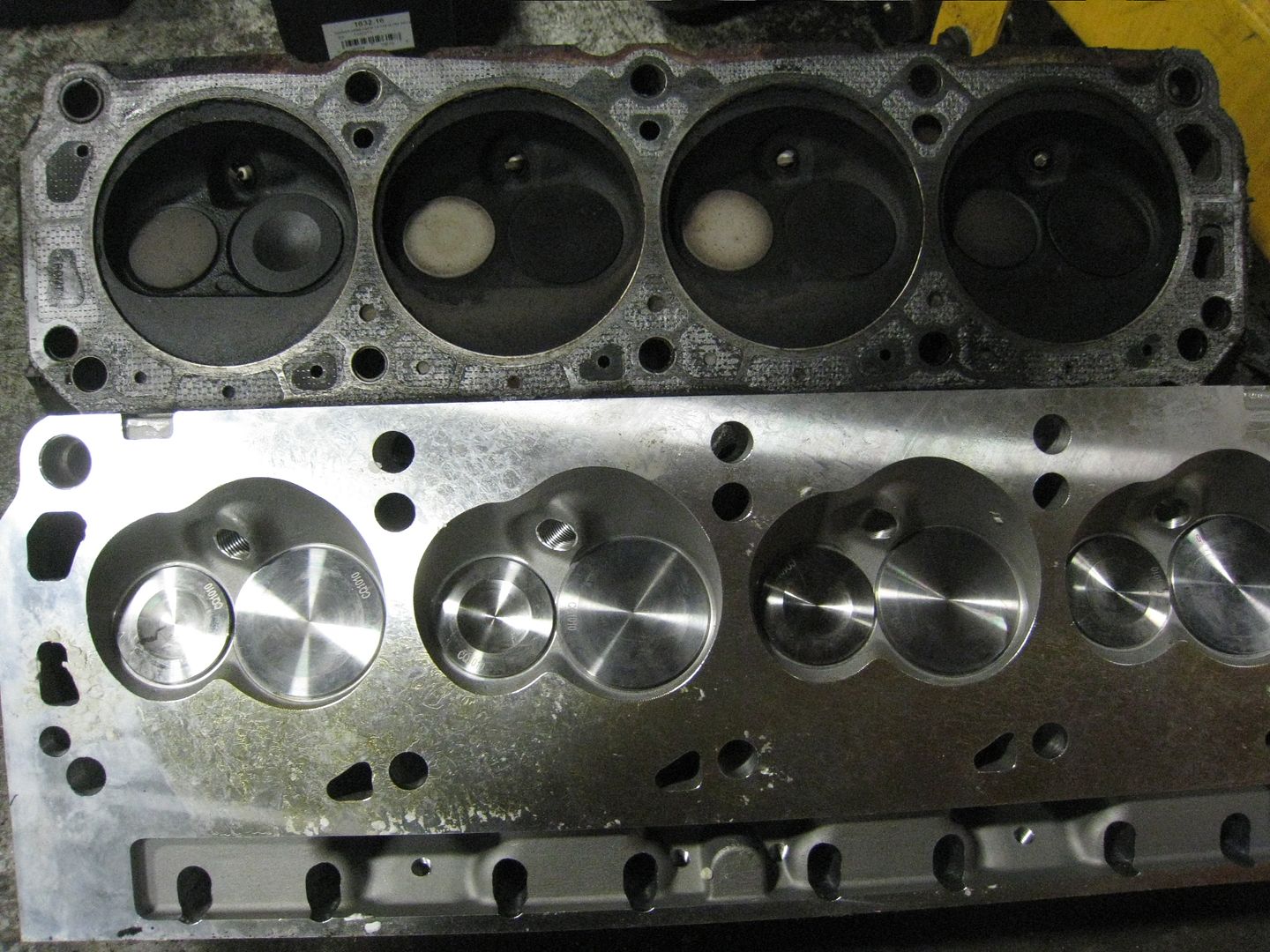

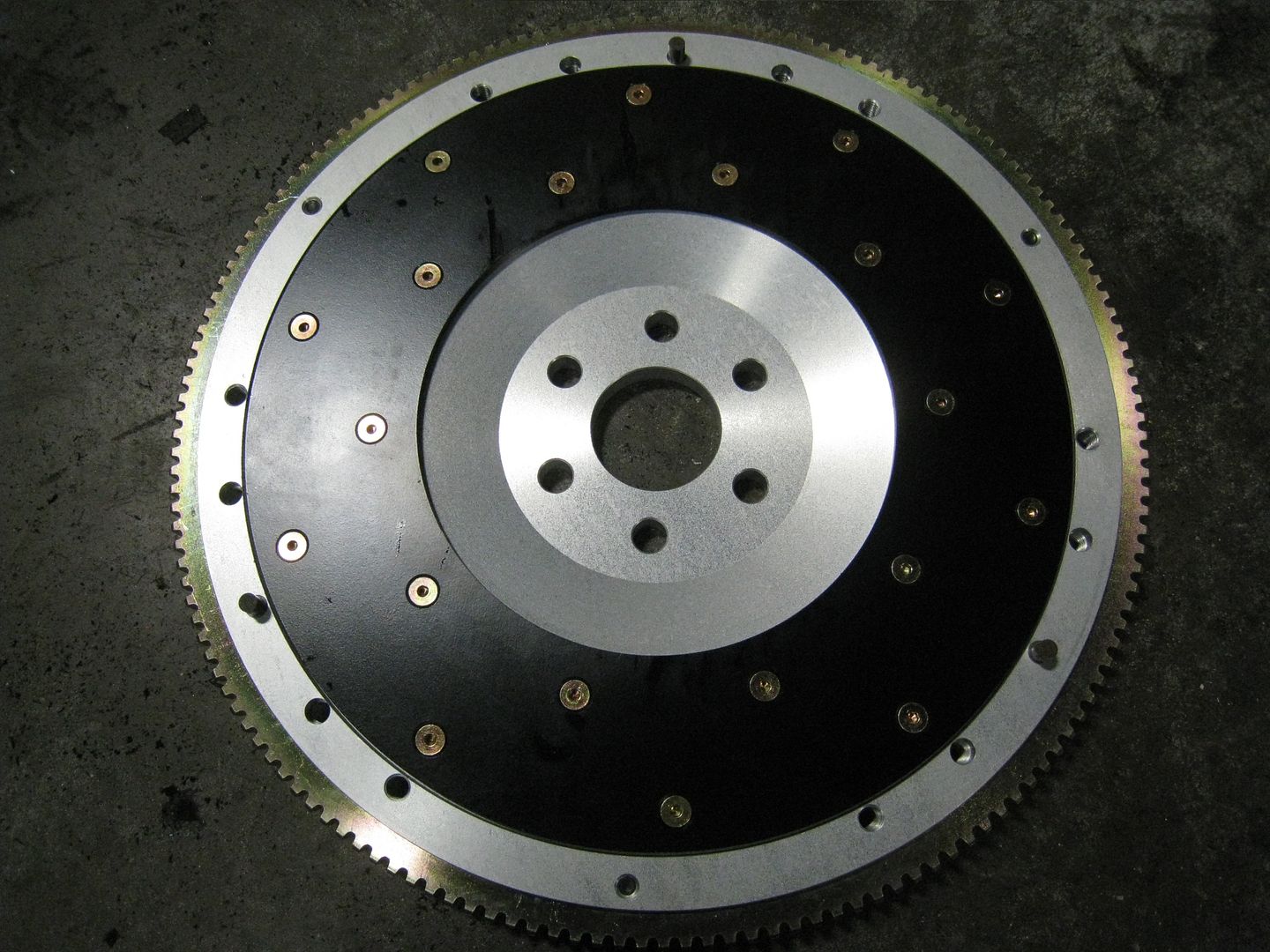

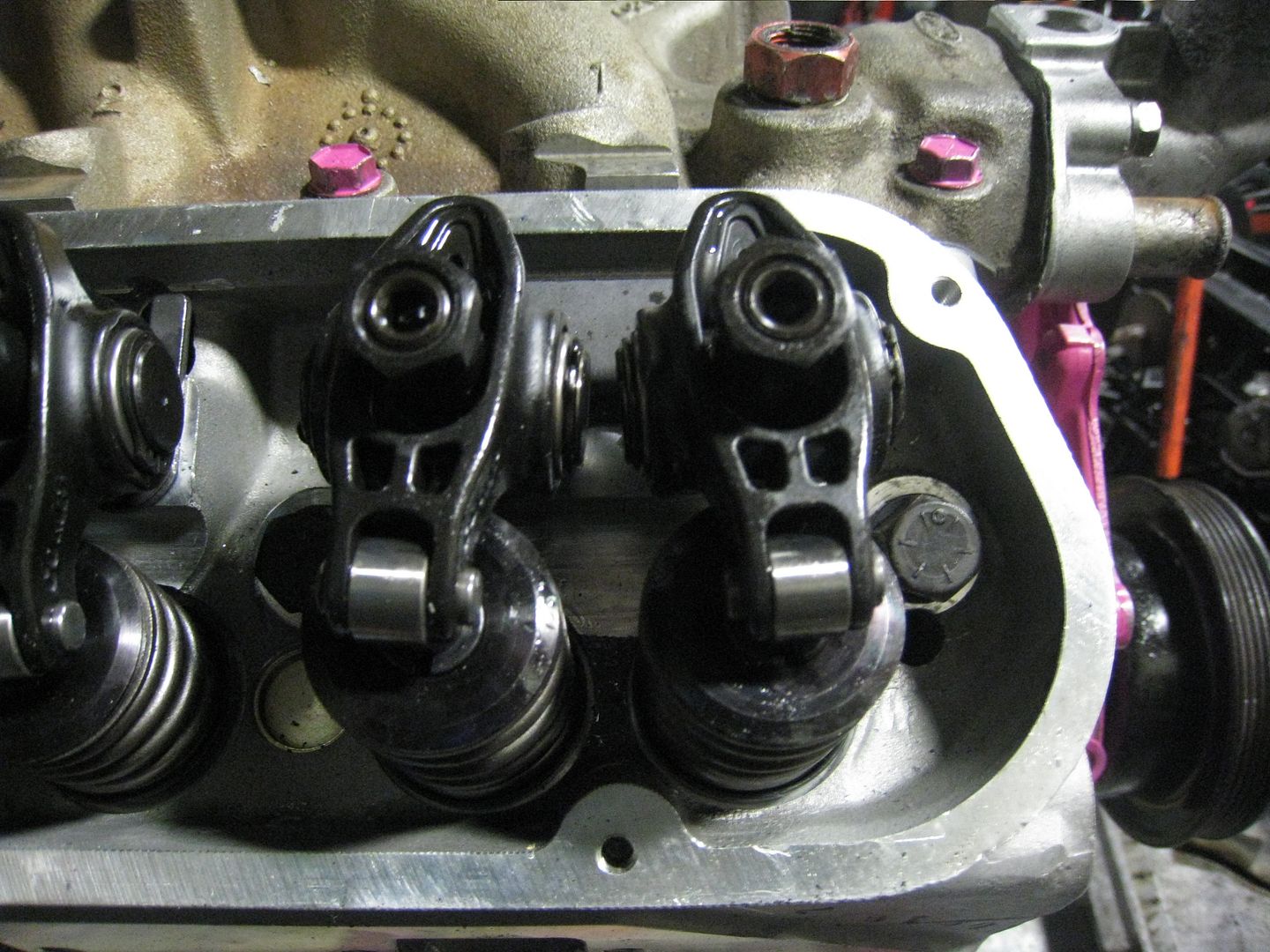

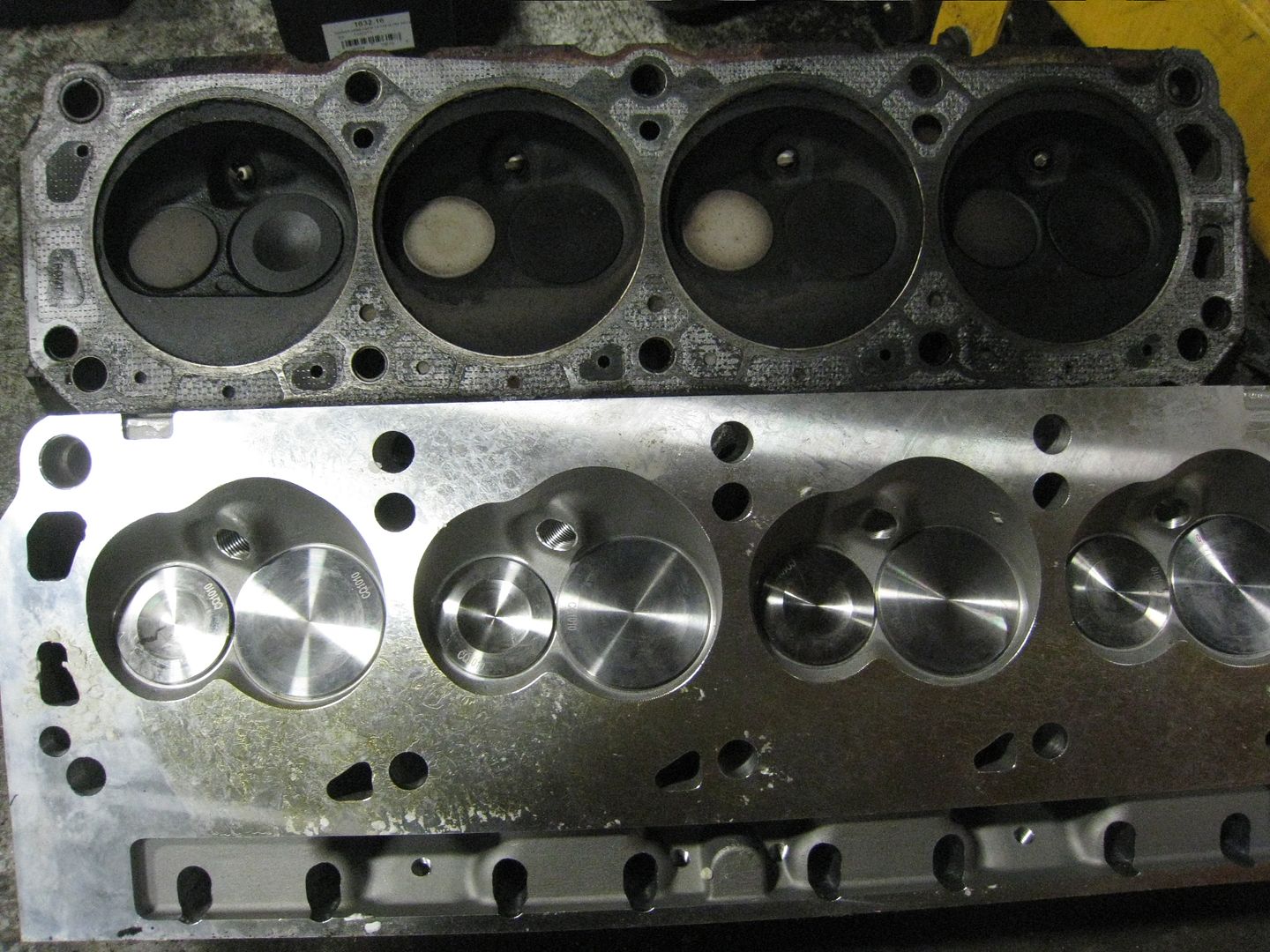

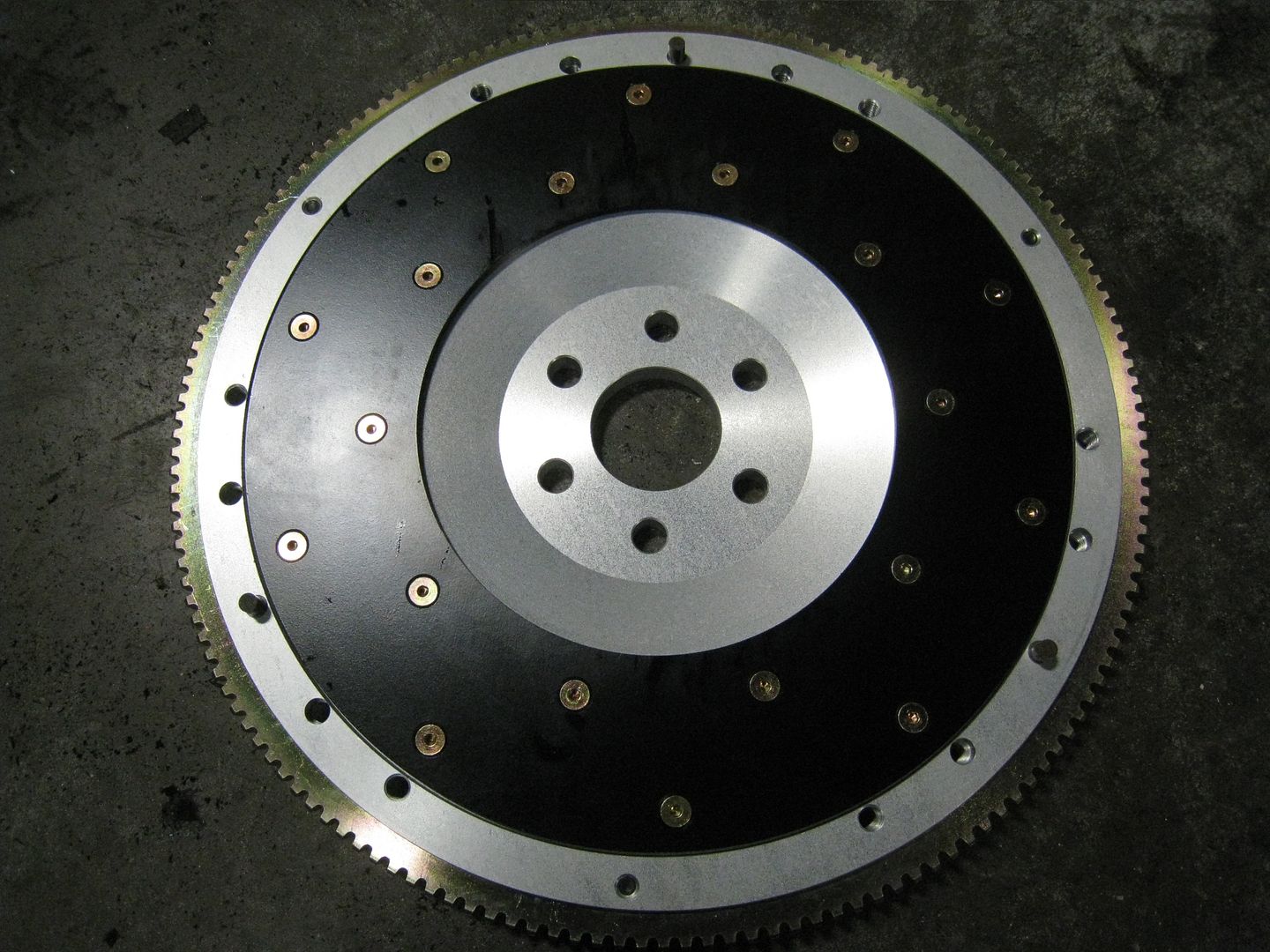

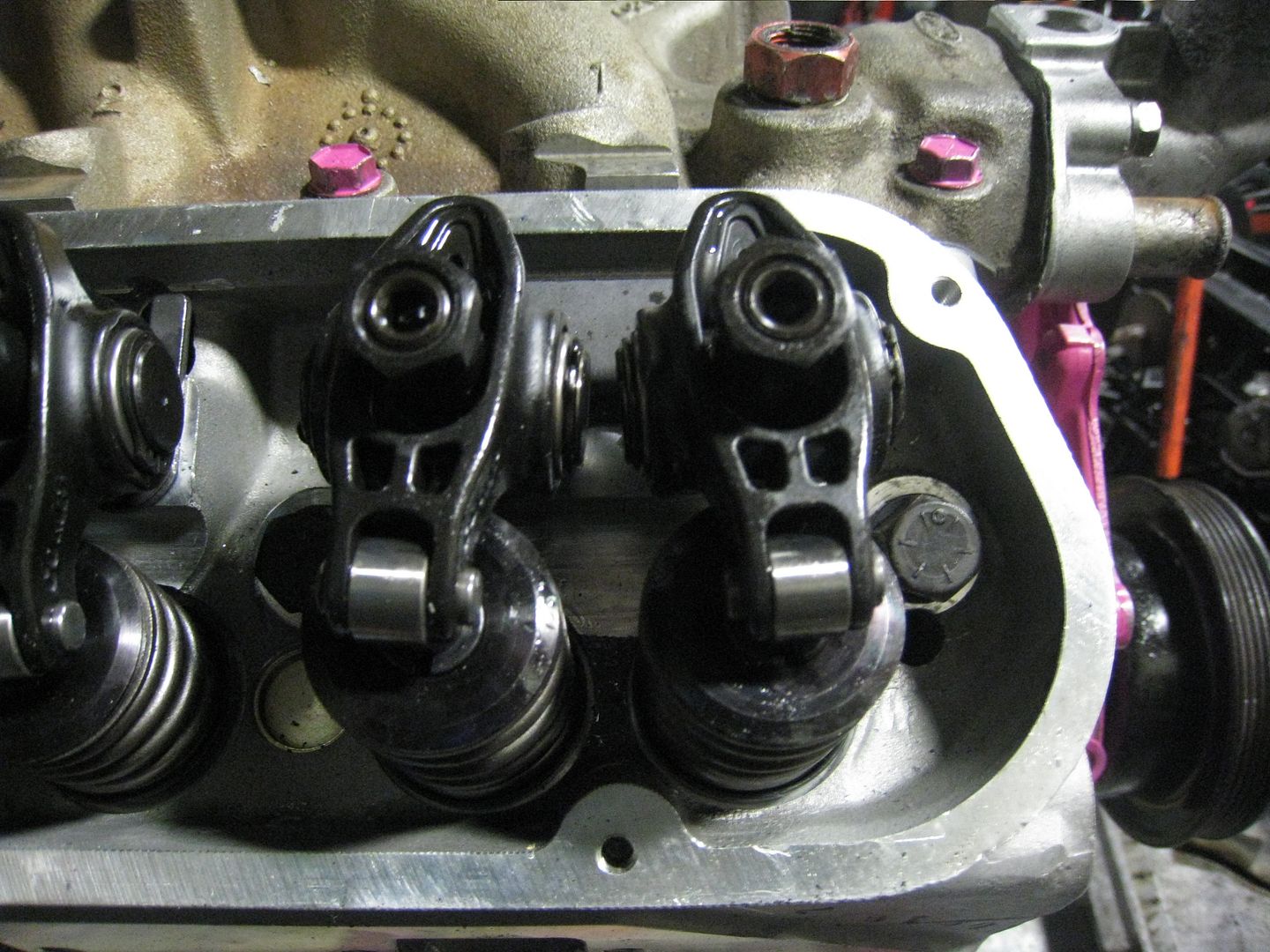

Some new parts arrived! :) The new heads weigh a total of 46lbs less than the iron ones and have much bigger valves and ports. The aluminum flywheel weighs only 12 lbs and the roller rockers are little jewels.

oldtin

SuperDork

2/27/12 5:16 p.m.

Very pretty! That's the key to 5.0s - getting them to breathe. There's a big lump of metal right in the flow of the stock exhaust passages.

I spent a significant amount of time removing those stupid thermactor bumps from the heads I had on my old 351W. I'd like to think it made a noticeable difference for the cost (just time and a die grinder I borrowed from work).

Hm, two inner exhaust valves look happy (nice tan colour), outer ones less so.

I have been working on the car but it's been a zoo at the track with a roof that is leaking, staff being let go, karts dripping brake fluid all over the place and changing the direction of the track. So, Briget cleaned and painted the new engine (Panther Pink, of course), I have installed the cam, cam drive, oil pick up and pan. The old engine is out of the car and I am stripping off what I need for the new one. Here's a pic of the mayhem that is my work space:

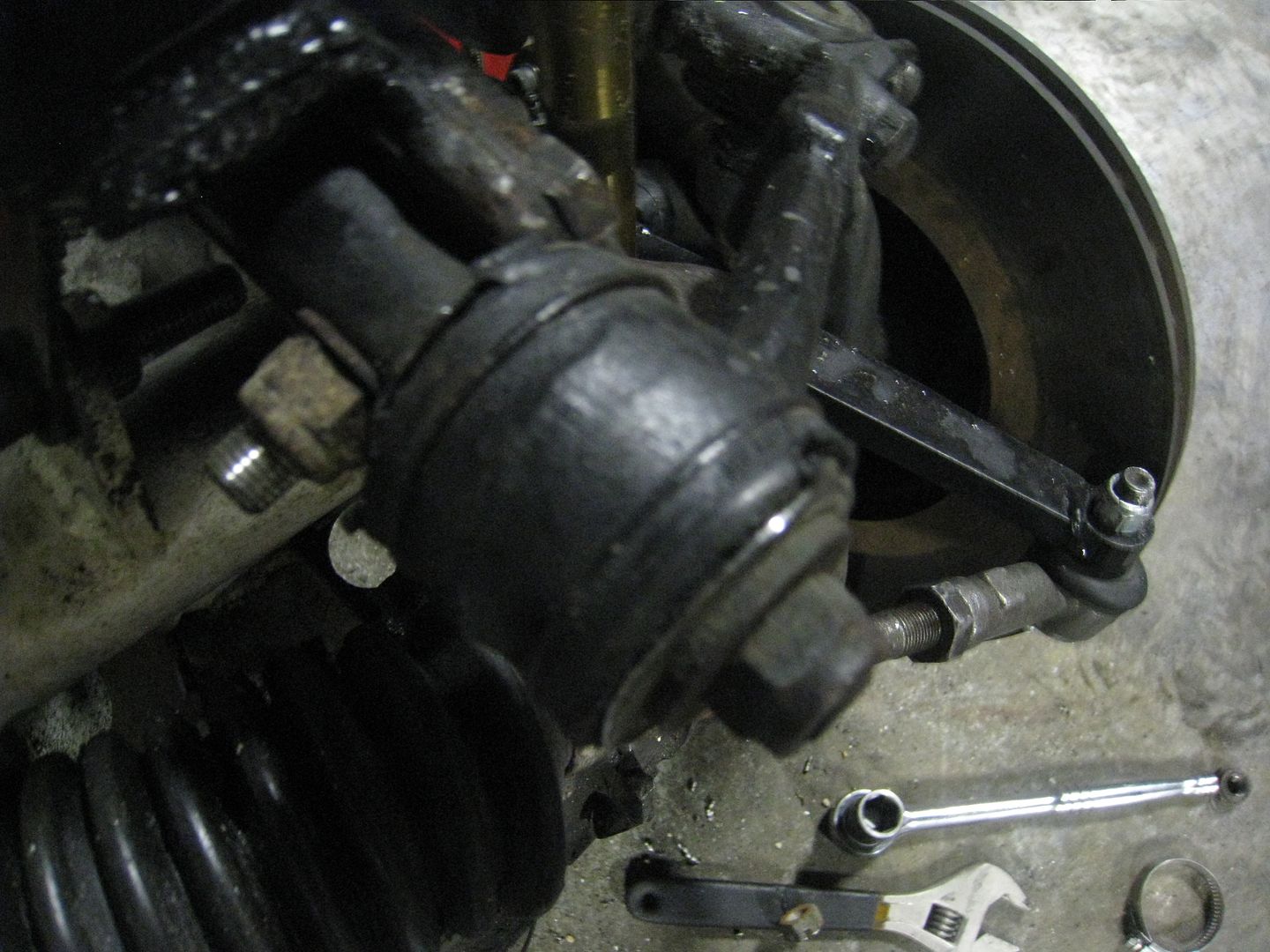

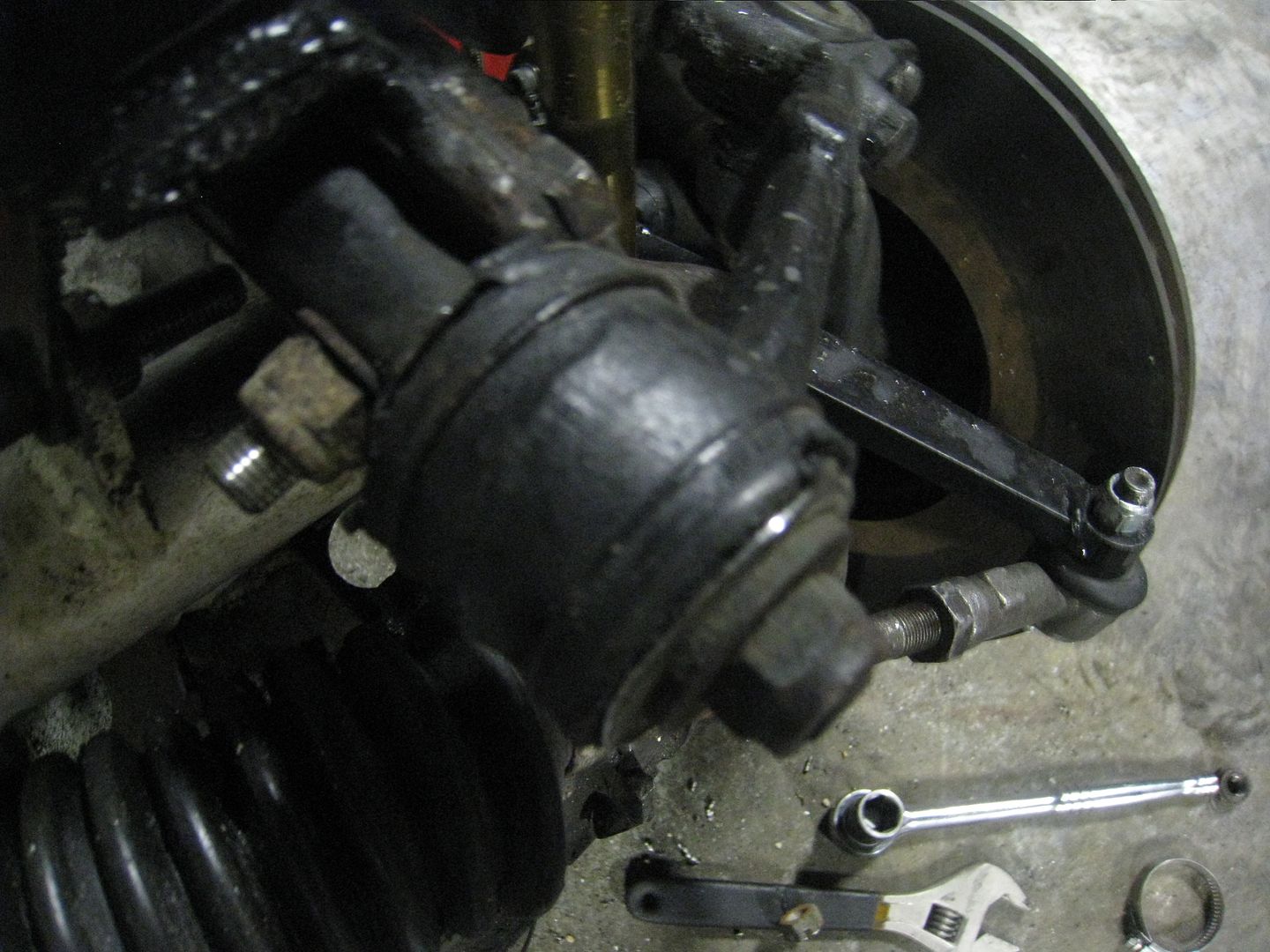

I changed the suspension bushings and balljoints. The shafts holding the lower control arms have been there since 1968 so they needed some rather unfriendly persuasion. The old rubber bushings

And the new ones:

Check out the old school ball joint on the right, with shims for adjusting.

mguar wrote:

regarding bushings you can use either aluminum ones which are easy to fabricate but need greasing or just buy the polyurethane ones..

These are poly bushings. If I ever re-do them, I will make aluminum ones or maybe even fabricate new (lighter) arms and use heim joints.

The GT40 intake manifold I have is an improvement over the stock Mustang intake but doesn't flow as well as the aftermarket intakes. That is, unless it's ported and then it makes just as much power as a good aftermarket intake. There is a fella in Texas who has spent a good deal of time figuring out how to port the GT40 and has a whole write up on it, found here: http://www.eectuning.org/forums/viewtopic.php?f=17&t=14018

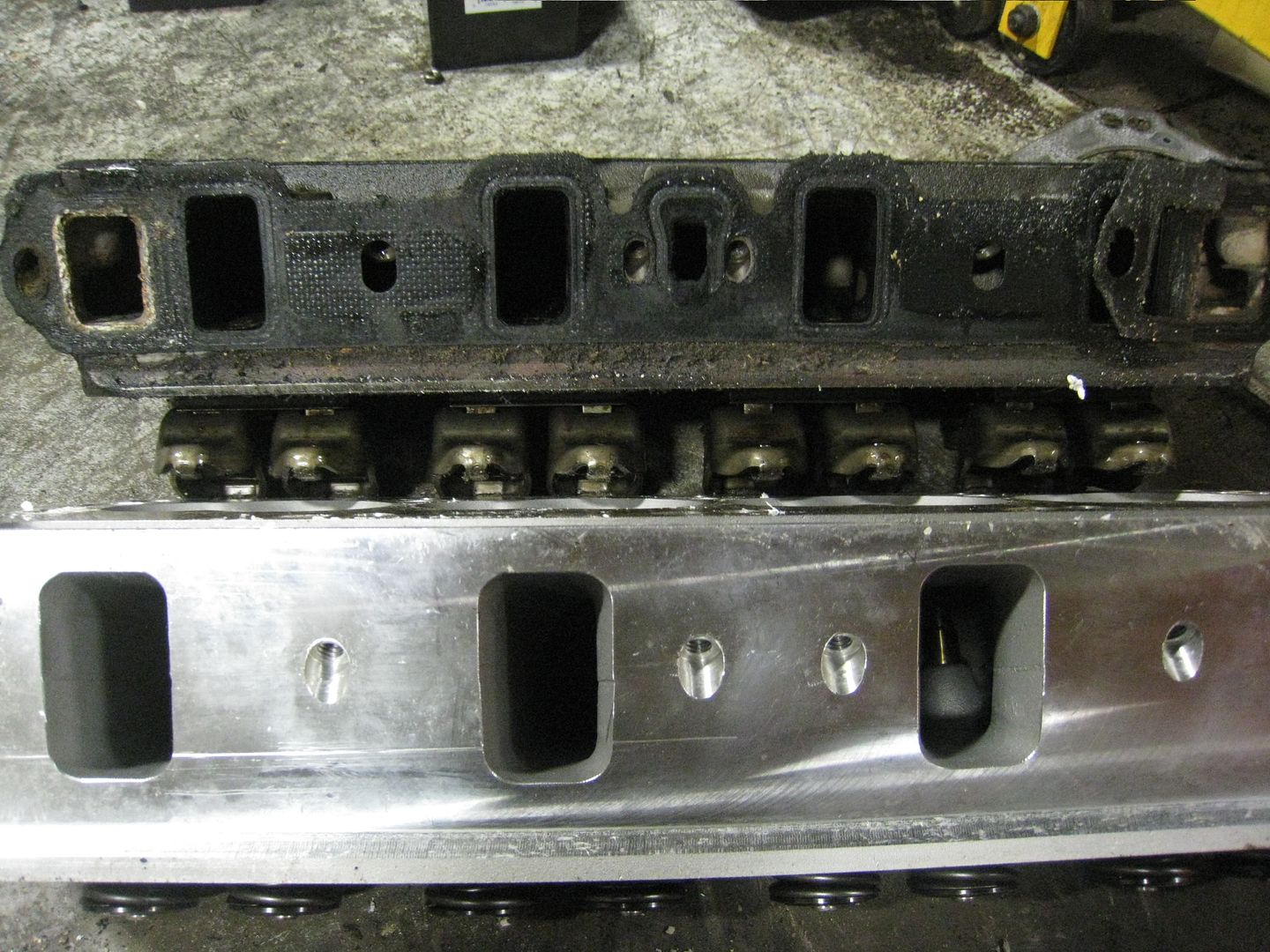

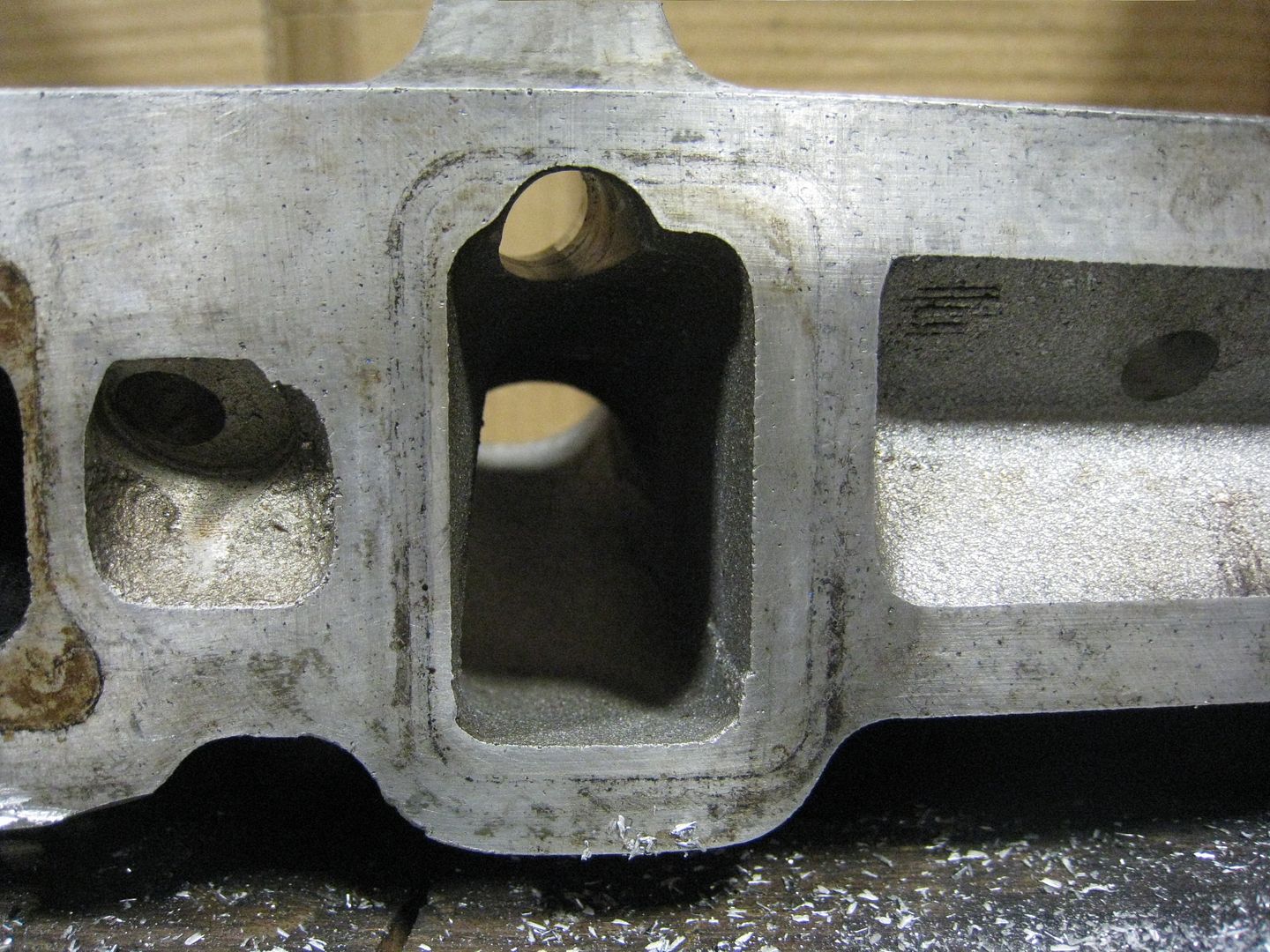

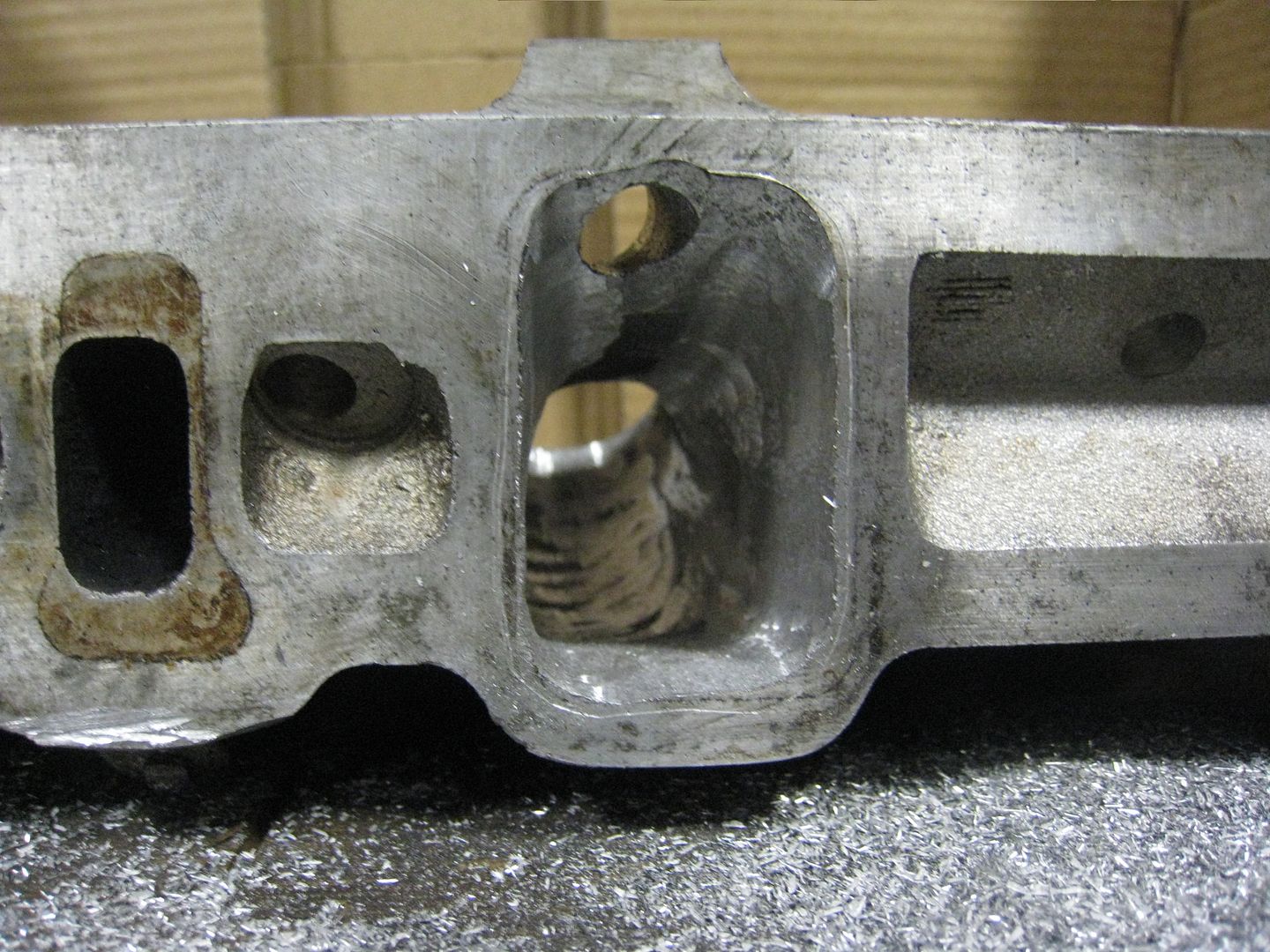

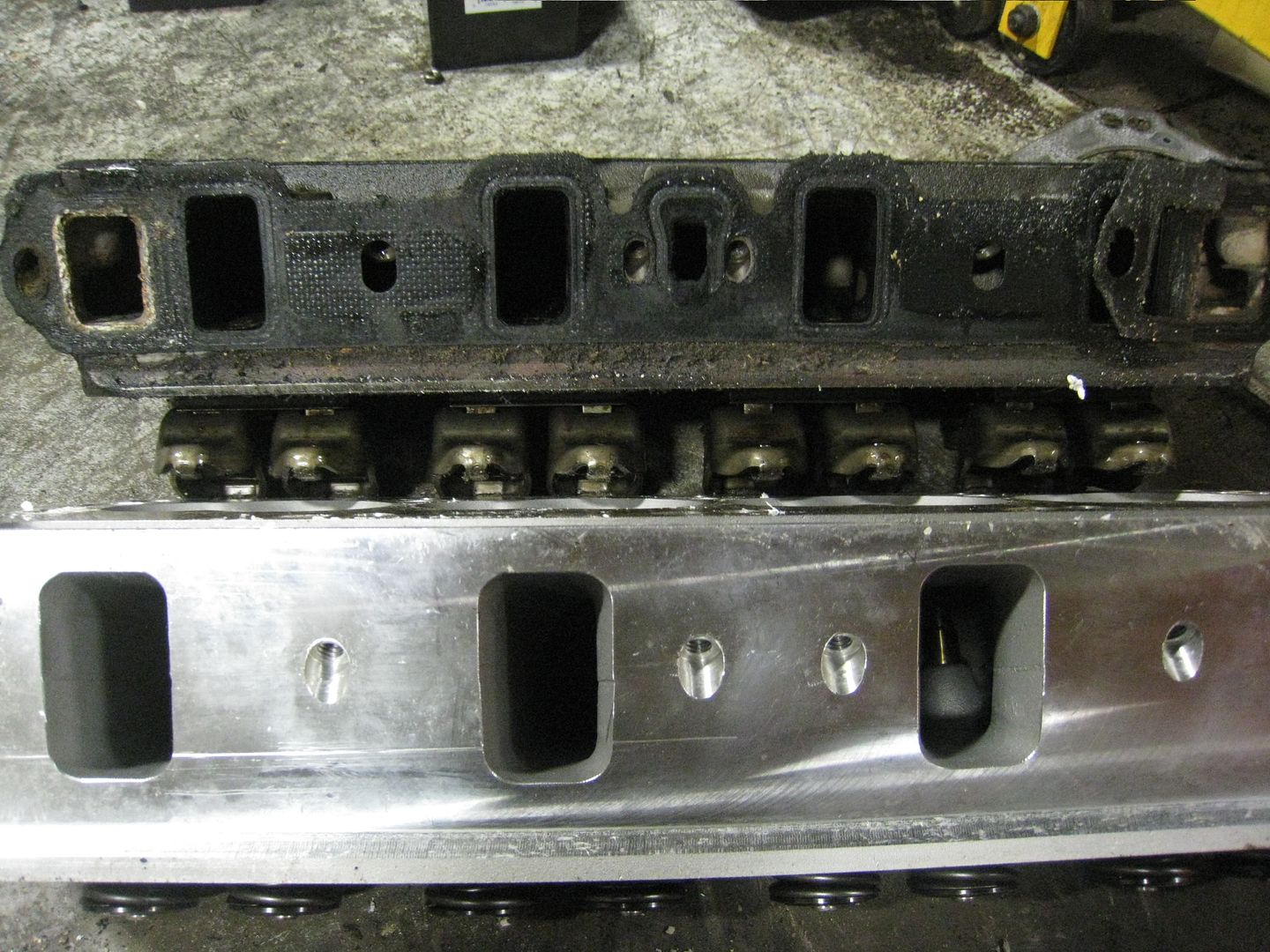

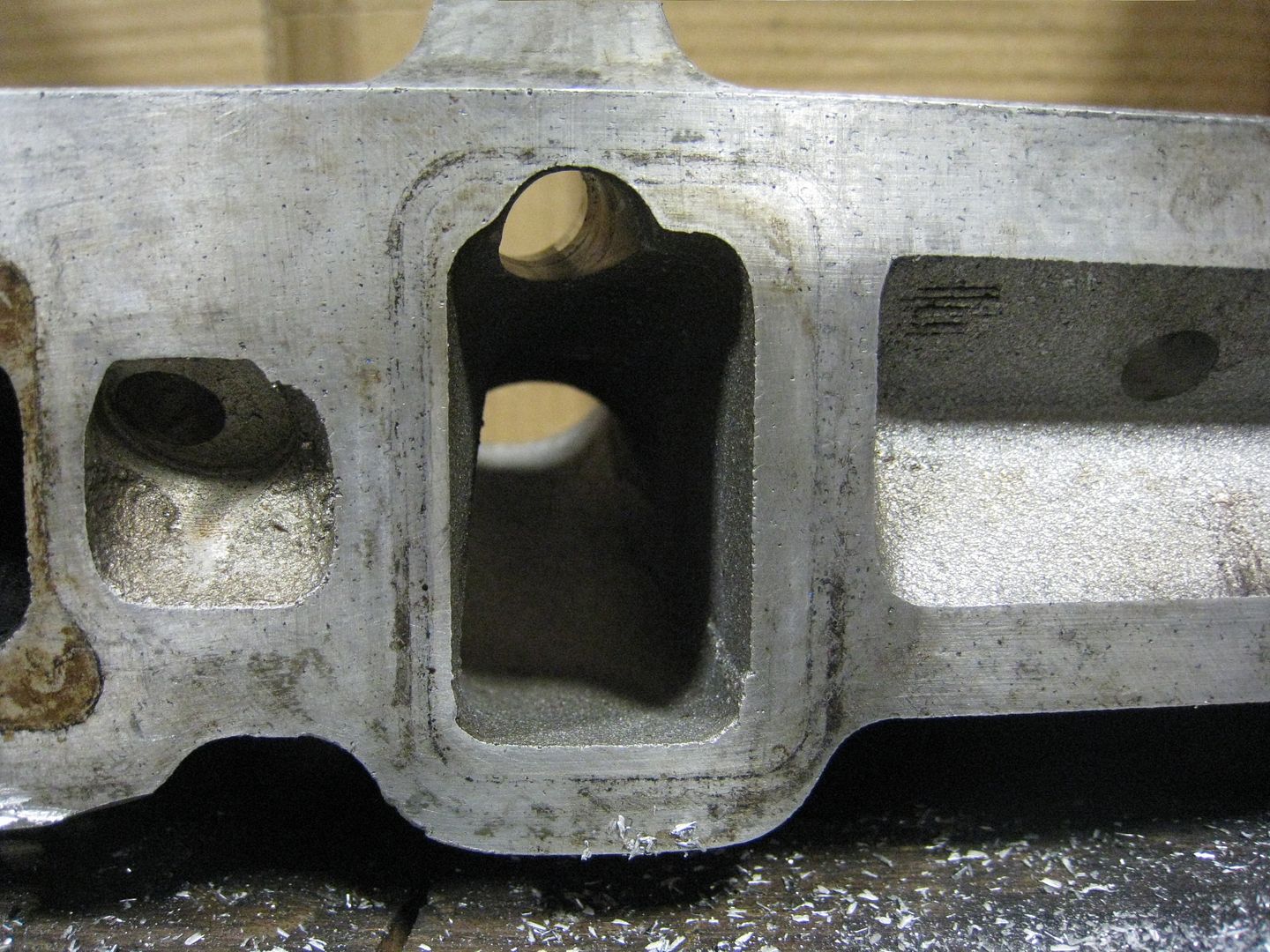

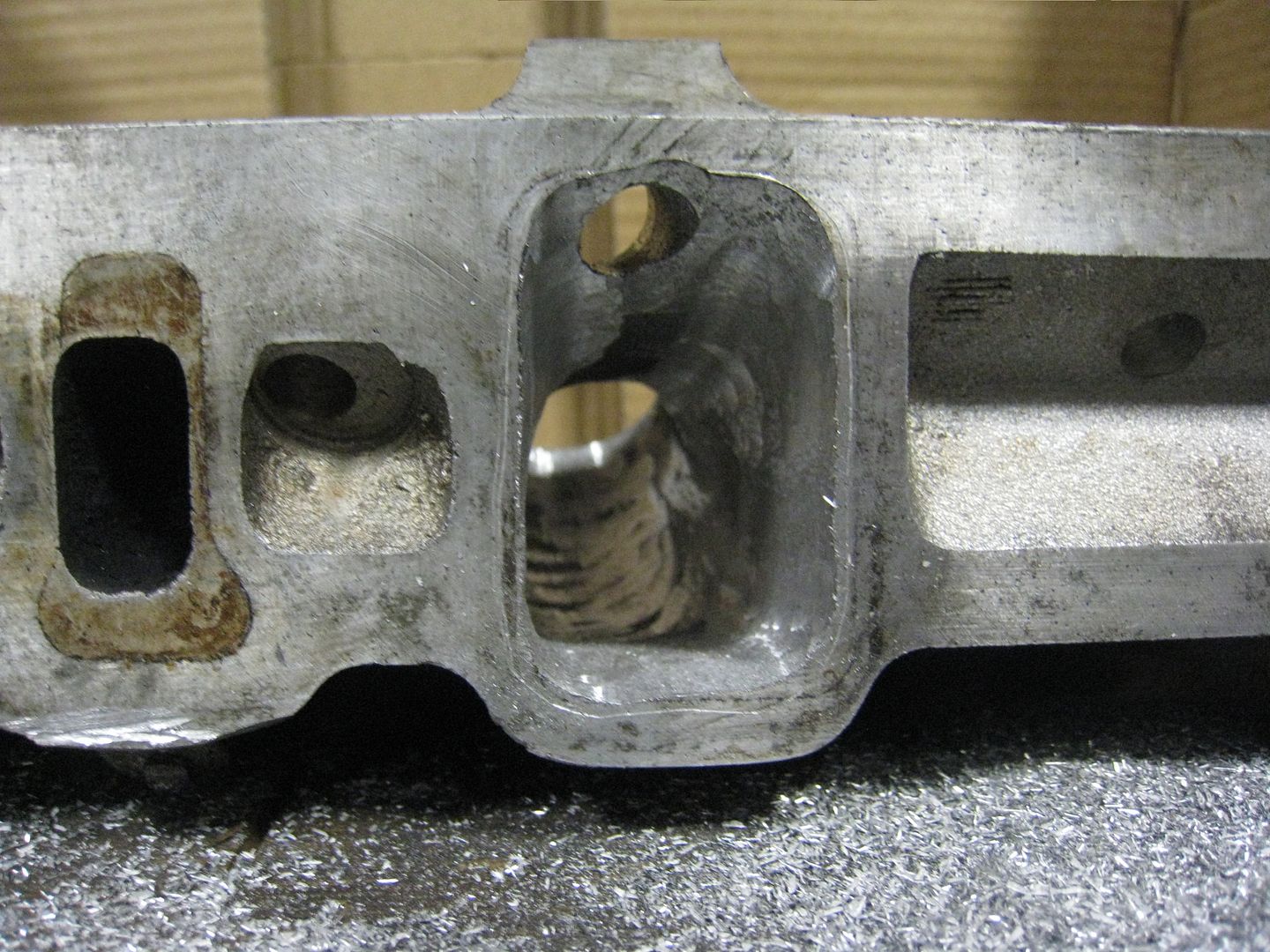

I followed these steps for my own intake and hope to get it on a dyno soon to confirm results. Here are some before and after pics:

I had to open up the intake gasket just to match the head and intake ports.

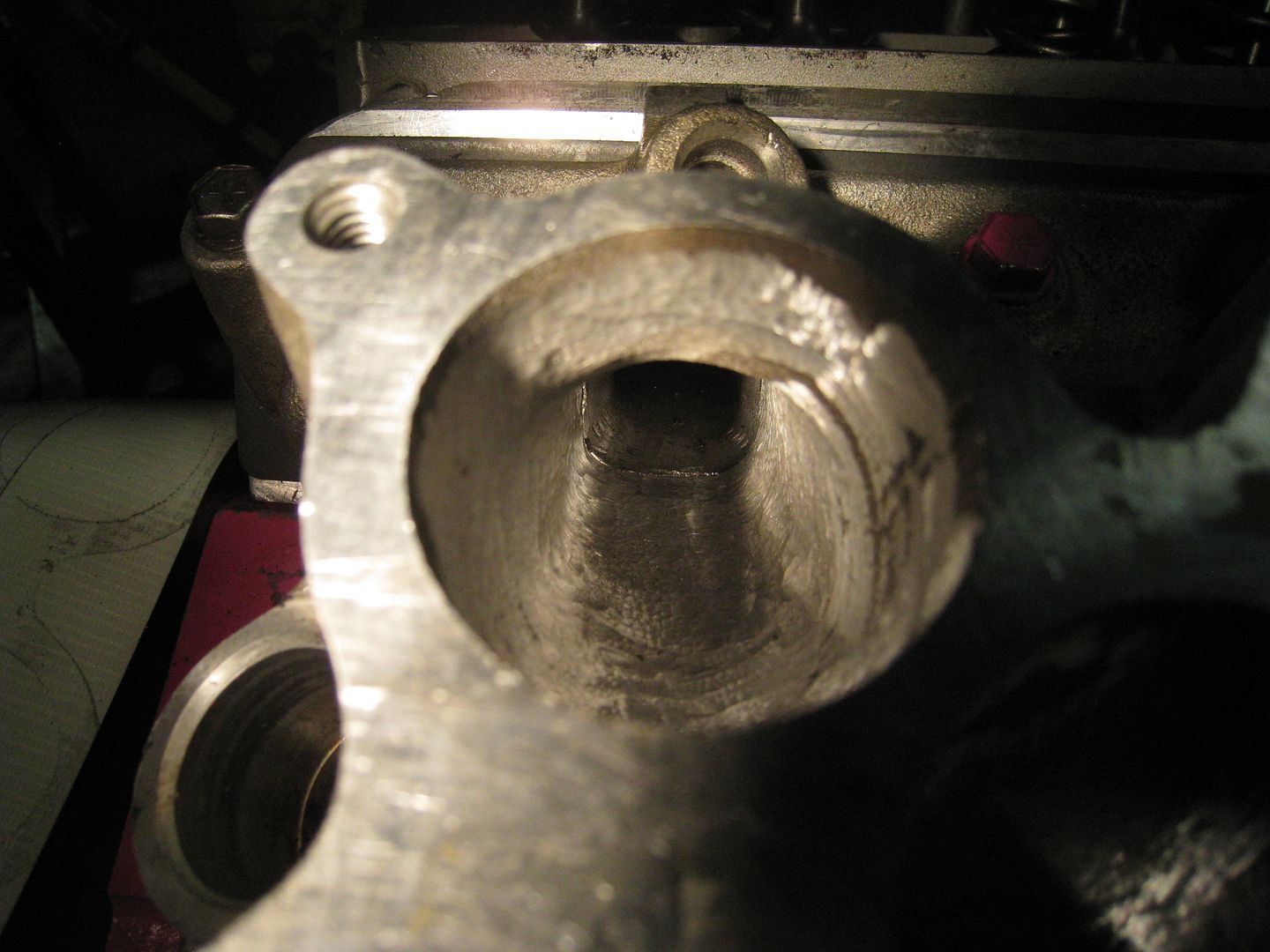

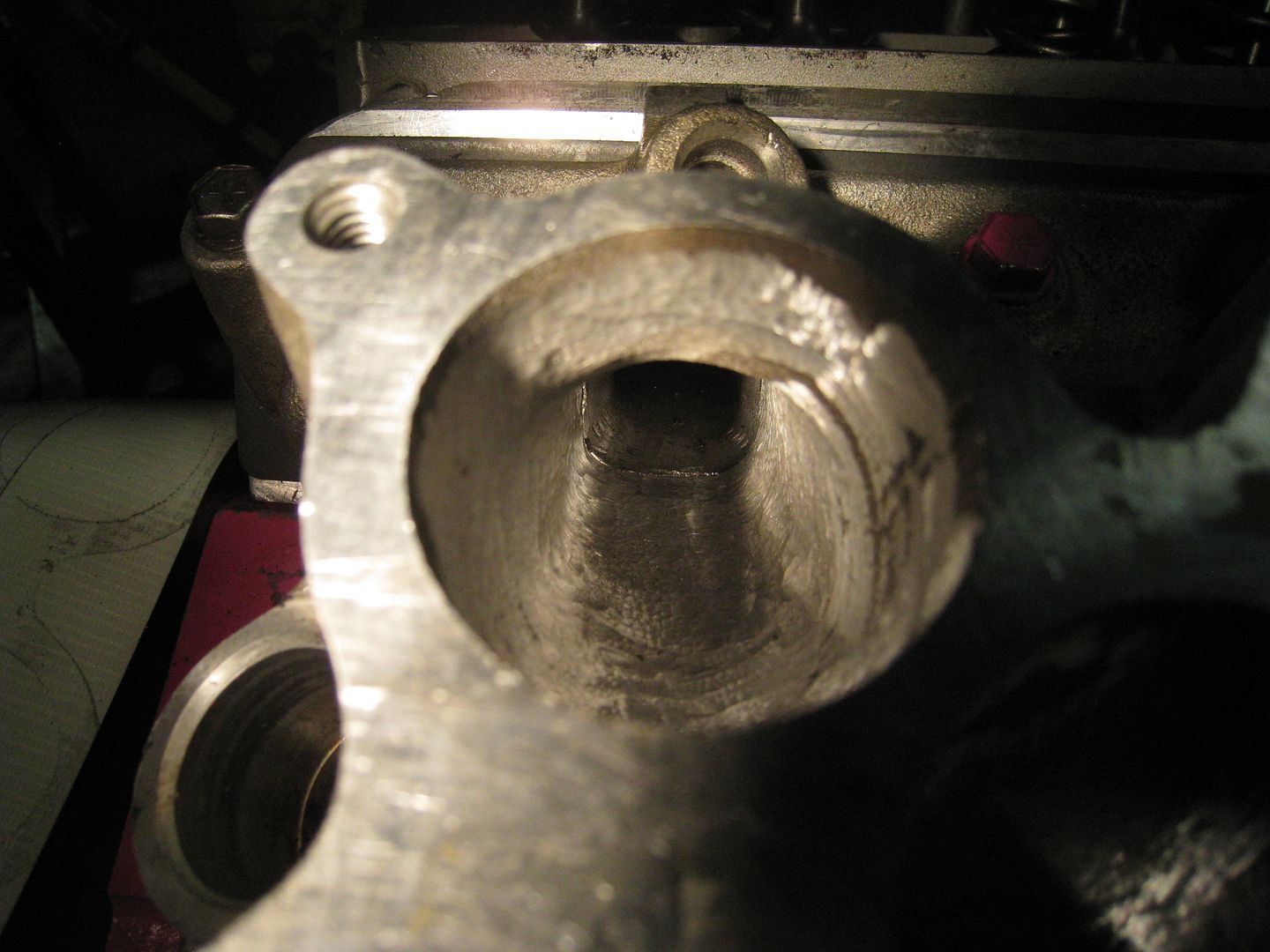

I bolted the intake on and took a picture down one of the ports, you can see how it lines up with the port on the head:

With the new heads, I had to recheck pushrod length to avoid premature valve failure. I did this by disassembling a lifter and putting washers inside it to simulate a fully pumped up lifter. I also cut a stock pushrod in half, threaded the inside of it and added a 6mm threaded rod so it was adjustable for length. Then I took a sharpie to the top of the valve stem and installed the roller tipped rockers as per the Comp Cams directions. After spinning the engine over two full rotations, a line was formed in the sharpie ink across the top of the valve stem. By adjusting the pushrod length, I could change where the line formed on the valve stem and once it was right across the middle of the stem, I measured the pushrod and ordered more just like it. Once they arrived, I installed all the rocker arms and here is a picture:

NOHOME

HalfDork

3/27/12 1:23 p.m.

OK. Ijust learned something new; how to set pushrod lenght with hydraulic lifters.

On a solid cam, would this not be automatic when setting valve clearance?

This car officially receives an award:

Simply amazing...

Thank you and please continue.

Since you guys like it so much, here is a picture of my adjustable pushrod and the new Manley pushrods. I was certain I had taken pics of the whole checking process but couldn't find them.

I thought I saw a light at the end of the tunnel but it turned out to be a train coming right at me. I was bolting the upper intake manifold on and the book calls for 34 Nm torque. My 3/8" clicker torque wrench has the gradients etched into the shaft (10,20,30, etc) and smaller gradients (1,2,3 etc) in the part that twists around. The top gradient in the shaft is 29 Nm so I turned the handle up to that, then added 5 more to get 34 Nm, the recommended torque. The wrench definitely clicked but then I felt a different sort of click, the pictures explain the rest.

pigeon

SuperDork

4/2/12 8:10 p.m.

Doh! Damn, that sucks. Can you weld that up or is the head a goner?

pigeon wrote:

Doh! Damn, that sucks. Can you weld that up or is the head a goner?

No, it's cast aluminum and the only local shop that will touch it is the one that welded up my Jag manifolds and that would cost far more than just buying another upper manifold. I tried that aluminum solder stuff that is advertised as the cats meow but it didn't work for $hit. I have already bought another one on e-bay for $75.00 but now I have to wait for it to arrive.

I started it for the first time and took a video. I didn't realize that I could manually turn up the idle so it's pretty lumpy. I don't know if it comes across in the video but it definitely sounds far healthier than the old engine. http://www.youtube.com/watch?v=8aUl_3KWYjQ

i thought it sounded pretty sweet! That thing revs pretty fast, I bet its a rocket...and man, at full song, that thing is gonna sound killer. Cant wait to hear about her maiden voyage....

new vid in less than 48 hrs or ban...

Sounds really mean. The idle sounds low and lumpy like it's running monster cams!

GameboyRMH wrote:

Sounds really mean. The idle sounds low and lumpy like it's running monster cams!

It is running a monster cam-a Comp Cams XE282HR, which is normally used in stroker engines. I want the power up high, that's why I chose this cam

4cylndrfury wrote:

i thought it sounded pretty sweet! That thing revs pretty fast, I bet its a rocket...and man, at full song, that thing is gonna sound killer. Cant wait to hear about her maiden voyage....

new vid in less than 48 hrs or ban...

http://www.youtube.com/watch?v=QWx21BHeKWg

oldtin

SuperDork

4/12/12 5:16 p.m.

Looks pretty strong - every touch of the accelerator resulted in opposite lock.

Just a random observation - upper radiator hose looks like it's bouncing around a lot.

In reply to loosecannon:

That sounds most excellent!!

Please keep up the good work...