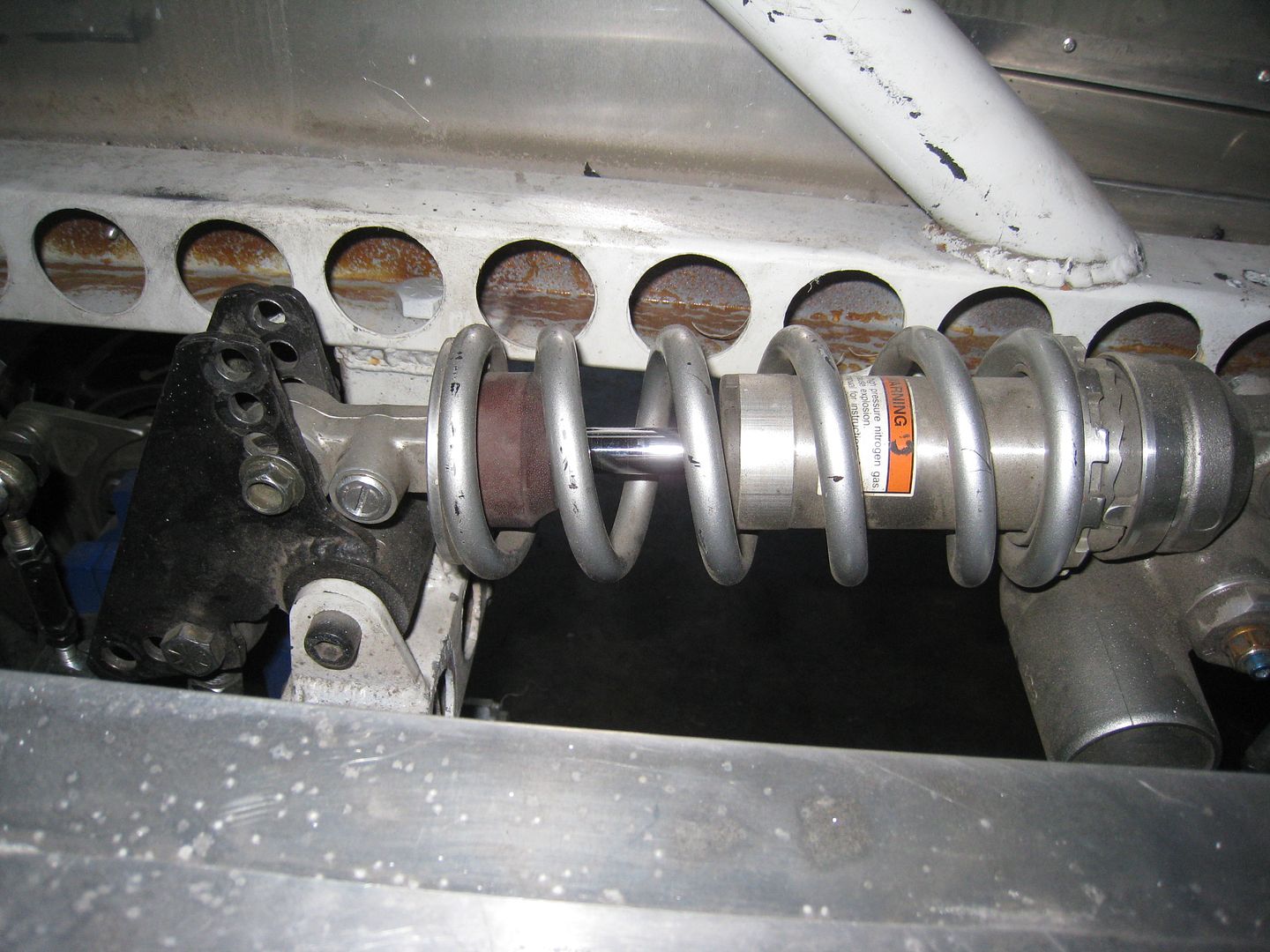

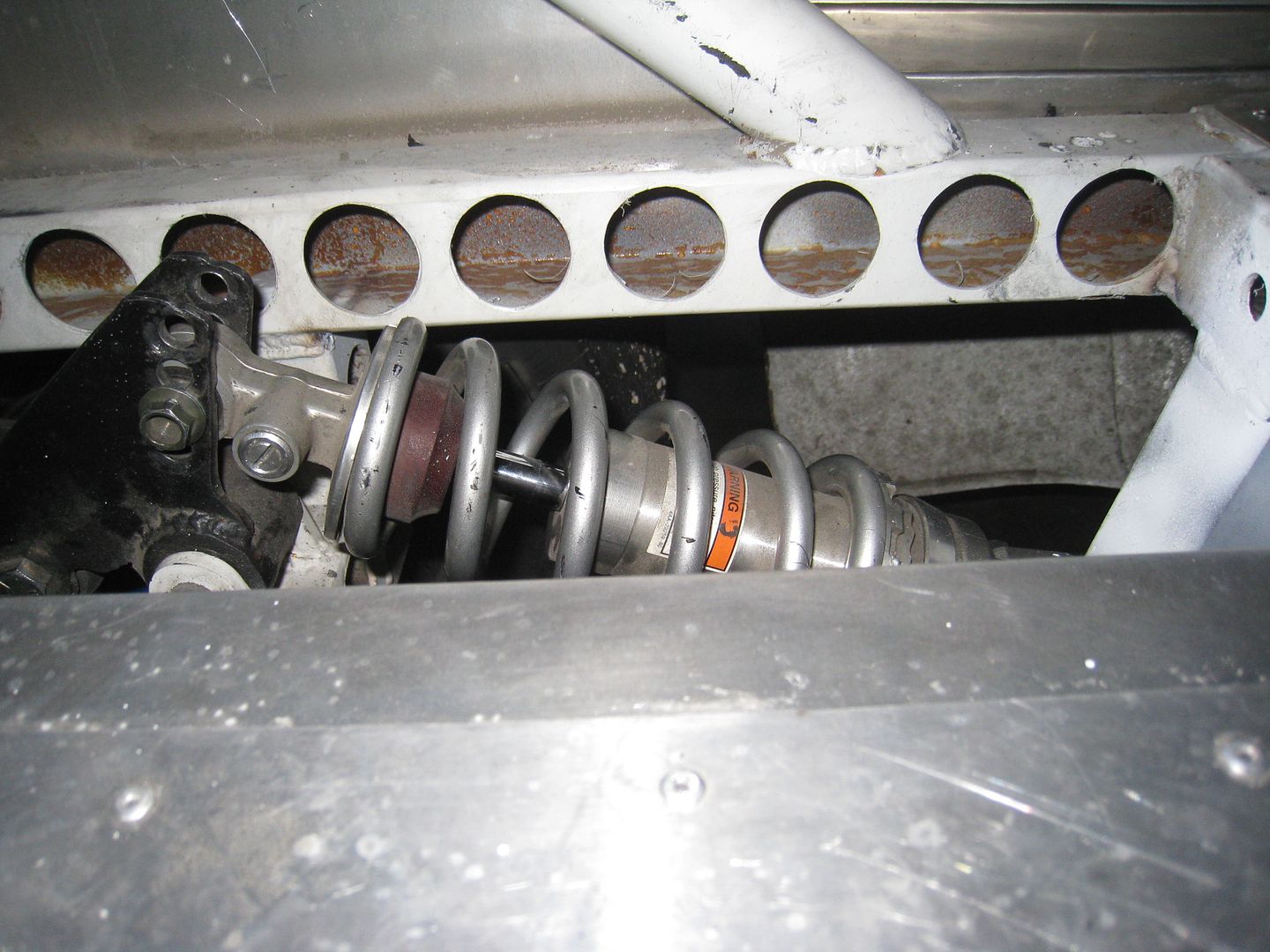

I was still trying to understand what the rear suspension was doing (other than breaking) so today I put zip ties on the shock shaft to see how much compression they were getting, and I aimed a camera at them. The car was really unstable under braking but was better over the big bumps.

I was still trying to understand what the rear suspension was doing (other than breaking) so today I put zip ties on the shock shaft to see how much compression they were getting, and I aimed a camera at them. The car was really unstable under braking but was better over the big bumps.

When I got back, the zip ties were shoved up against the bump stops. I changed the high and low speed compression settings from full soft to full stiff and sent Briget out. When Briget was on course I could see the axle moving back and forth and for a moment thought that the newly fixed bracket broke again, but that was not it. The zip ties were not up against the bump stops this time so that was positive.

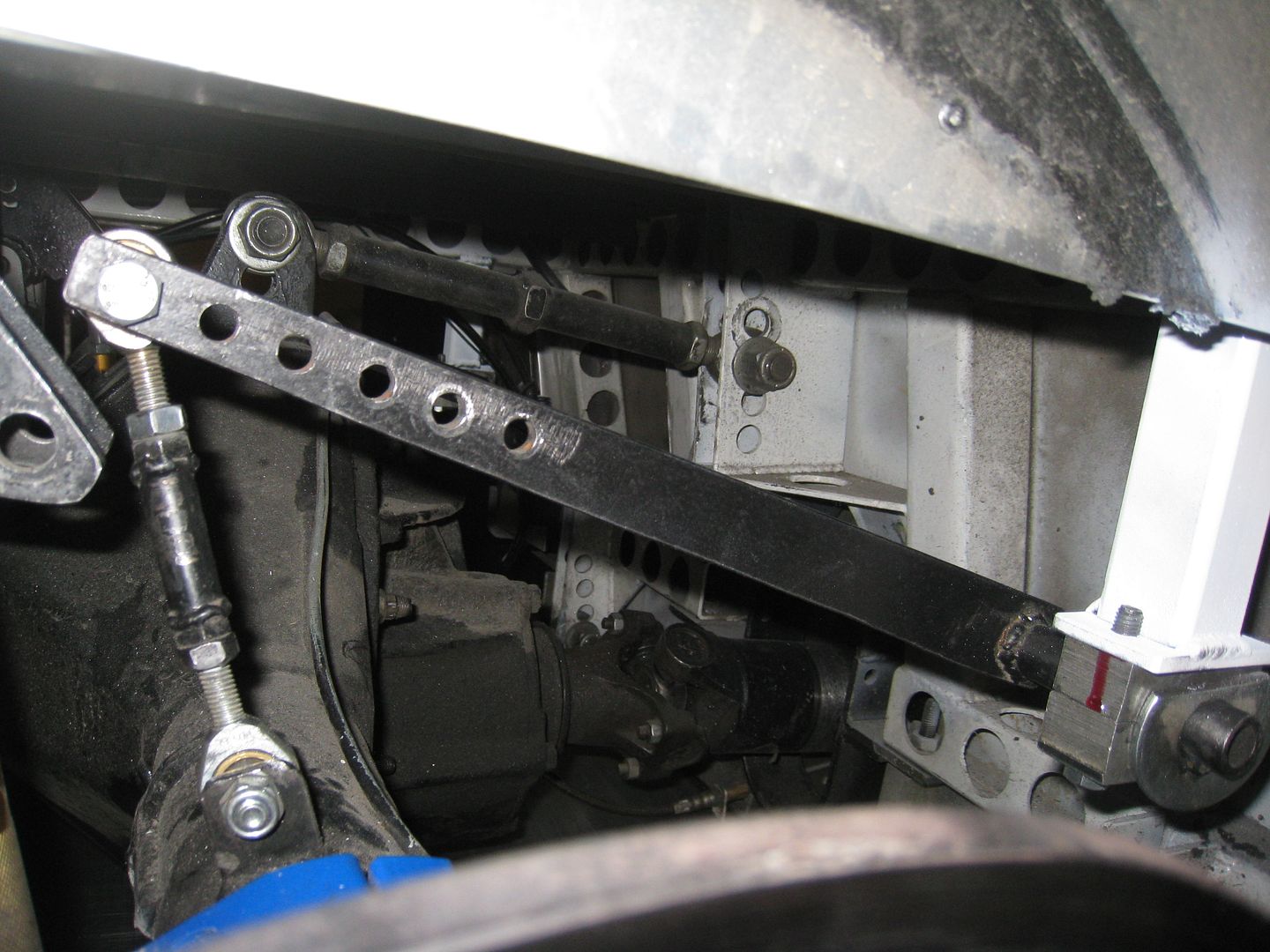

Once in the pits I tried to determine how the axle was moving back and forth and couldn't find anything at first but once I had Briget shake the car back and forth really hard, I found a fracture in a different bracket. Obviously the forces on the Woblink are greater than a typical lateral link like a Panhard or Watts because these brackets were pretty robust and were still snapping solid steel plate.

I know from trying different roll center heights at the lapping session and autocross that the car likes it set above 8" high, so I am going to remove the troublesome Woblink and install an adjustable Panhard around that height. Here is a very interesting video of the rear suspension during a run, once you stop being mesmerized by the shocks moving around, notice how much the diff is moving back and forth due to the broken Woblink.

In reply to loosecannon:

Roughtly which page did you post the pictures of the Woblink? It would be interesting to see what it is, and why there may be reasons it's failing.

What's it supposed to do over a normal lateral locating device like a Panhard or Watts link?

(oh, and i'm a fan of the panhard rod- I found 3/4" rod end fitting panhard rods cut to fit at most speedway kind of stores. so massive... and not all that heavy.)

alfadriver wrote: In reply to loosecannon: Roughtly which page did you post the pictures of the Woblink? It would be interesting to see what it is, and why there may be reasons it's failing. What's it supposed to do over a normal lateral locating device like a Panhard or Watts link? (oh, and i'm a fan of the panhard rod- I found 3/4" rod end fitting panhard rods cut to fit at most speedway kind of stores. so massive... and not all that heavy.)

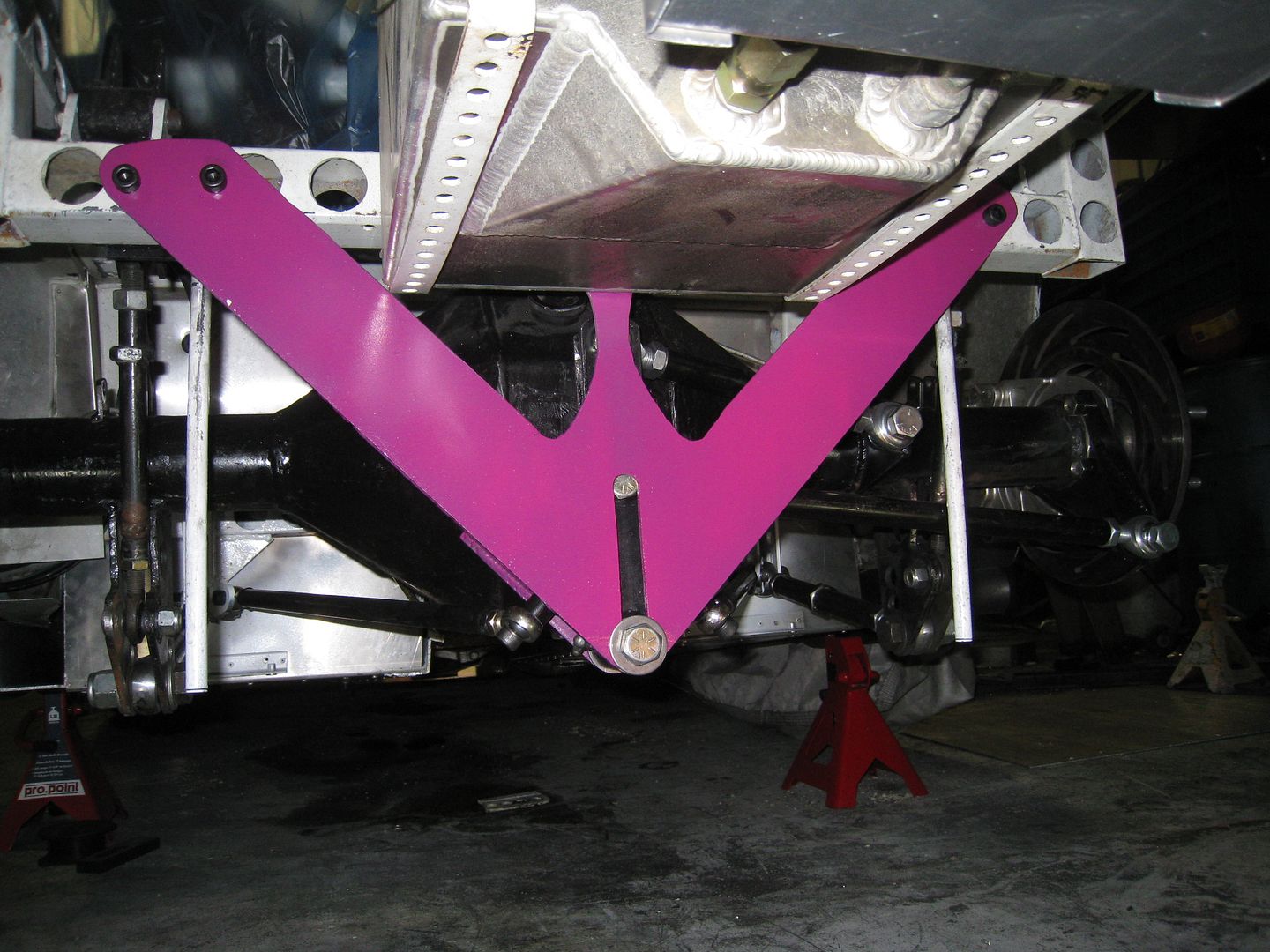

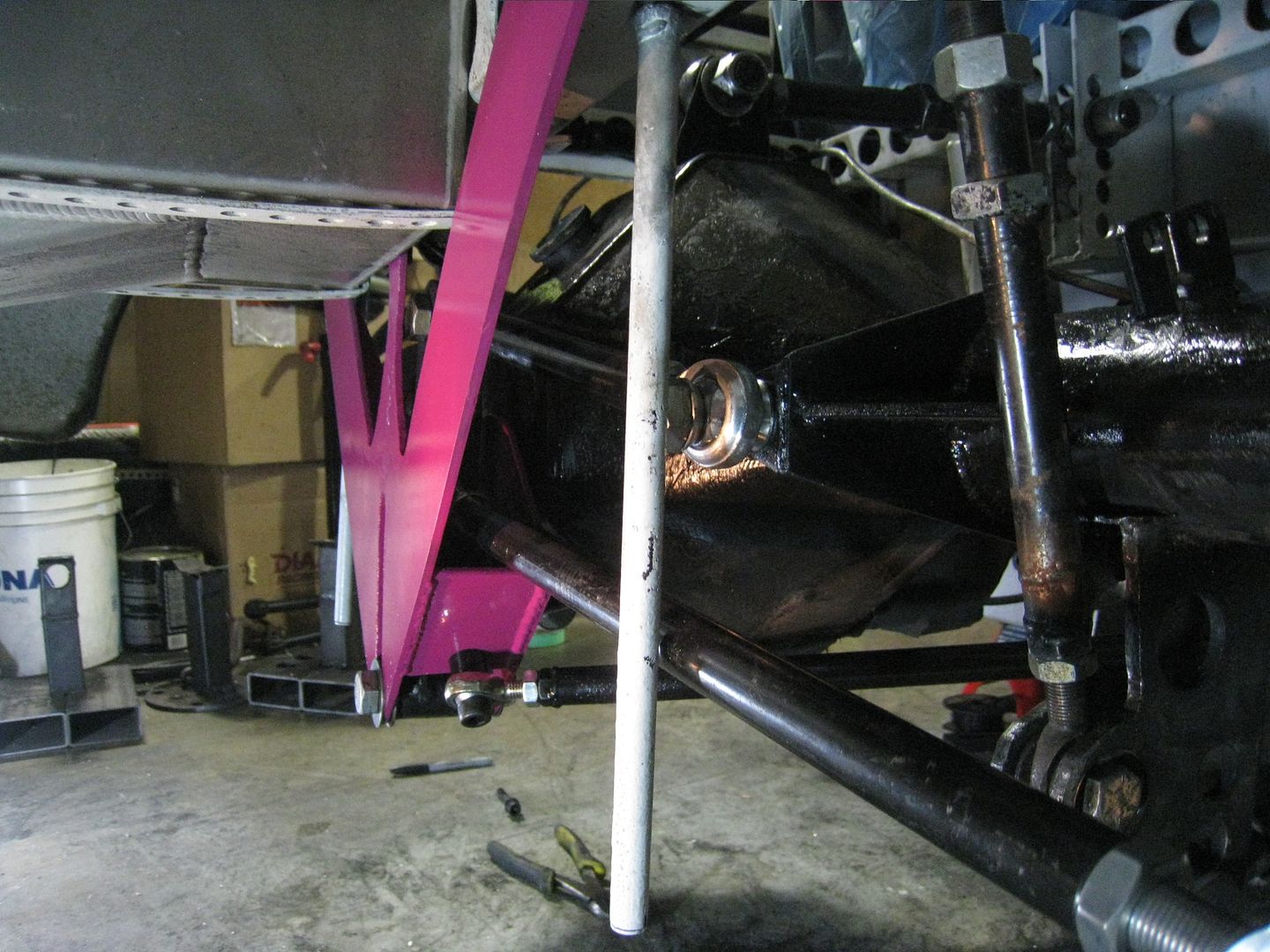

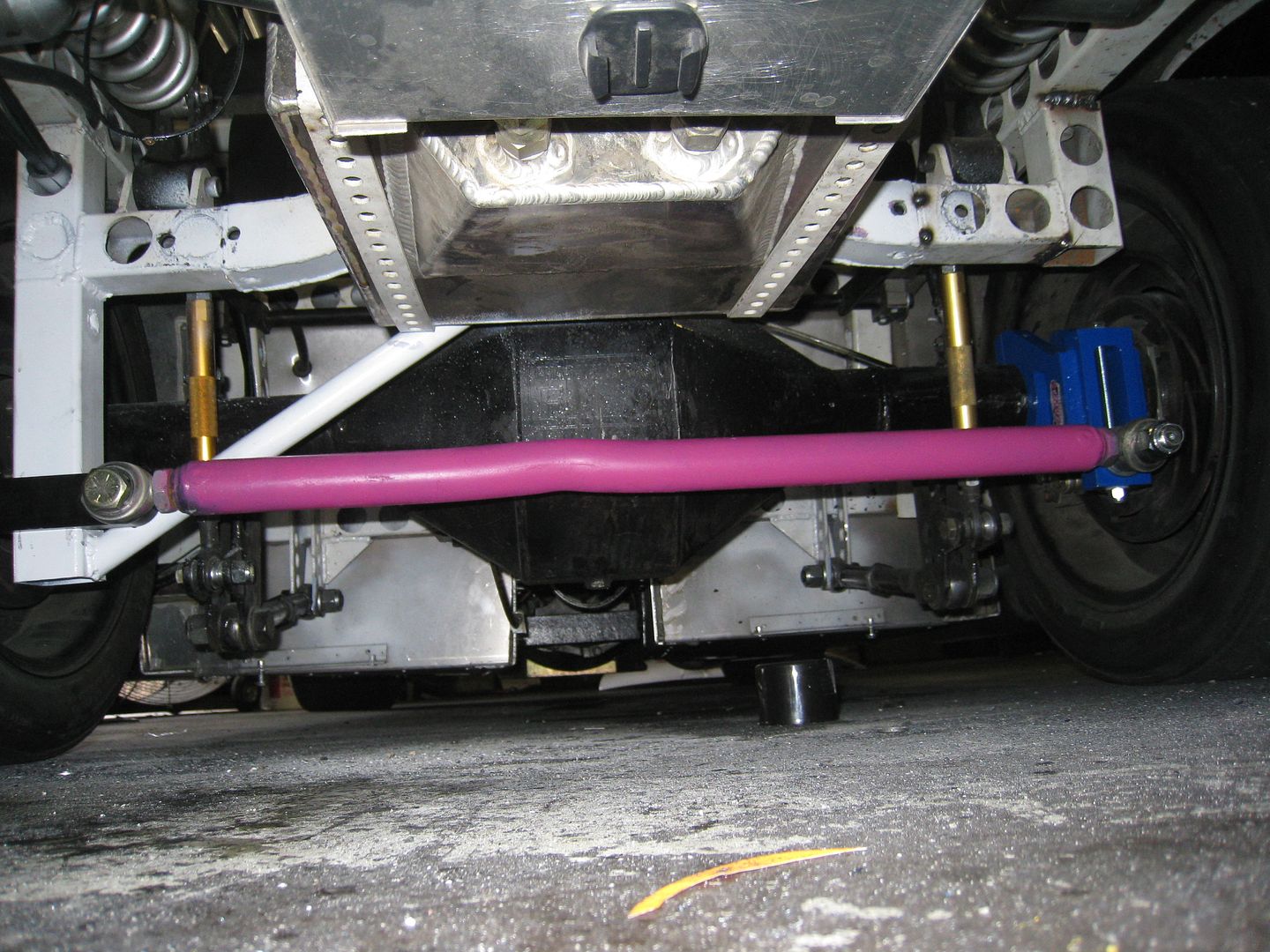

Here are pics of the Woblink off the car and on. The advantage of the Woblink is the ability to have a roll center as low as 3 inches off the ground. Once out on course, I discovered that the car doesn't like the R/C that low, it likes it above 8 inches and I can do an 8 inch R/C using a Panhard bar, which is lighter and simpler.

I could tell from the autocross video that you needed the shocks set much harder overall. That's the roughest ride on smooth pavement I've ever seen, hopefully the harder shocks will smooth it out.

GameboyRMH wrote: I could tell from the autocross video that you needed the shocks set much harder overall. That's the roughest ride on smooth pavement I've ever seen, hopefully the harder shocks will smooth it out.

Which video? It was obvious on day 1 that I needed stiffer shocks but on day 2 with the motion ratio higher and compression settings stiffer, I wasn't using all the shock travel. I bolted the rear sway bar back on today so that adds some roll stiffness as well. I expect the real quality of the suspension will reveal itself in Lincoln where I won't have massive bumps, dips and pivot cones waiting for me.

I was looking at this one:

https://www.youtube.com/watch?v=bpaycLEkkTE

Maybe the surface was much worse than it seems in the video, I can see where there was a bump, but if that was smooth pavement otherwise then it definitely needed much stiffer shocks.

GameboyRMH wrote: I was looking at this one: https://www.youtube.com/watch?v=bpaycLEkkTE Maybe the surface was much worse than it seems in the video, I can see where there was a bump, but if that was smooth pavement otherwise then it definitely needed much stiffer shocks.

The pavement we use is unbelievably bumpy, even stock STi's and Corvettes are upset by the bumps. I have to raise my ride height by 2 inches just to keep from bottoming out. Sadly, it's the only venue we have right now but are working on getting some better ones.

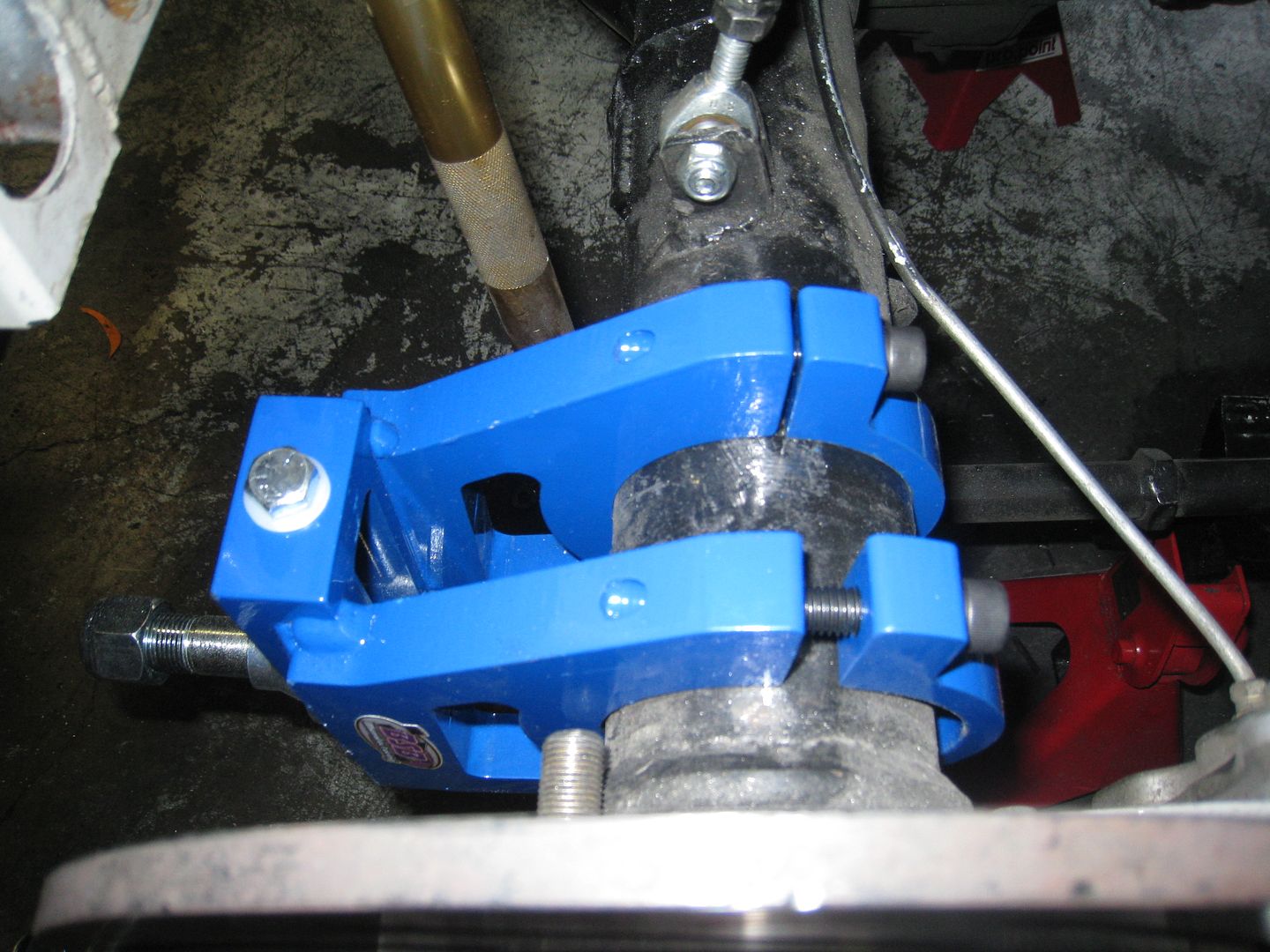

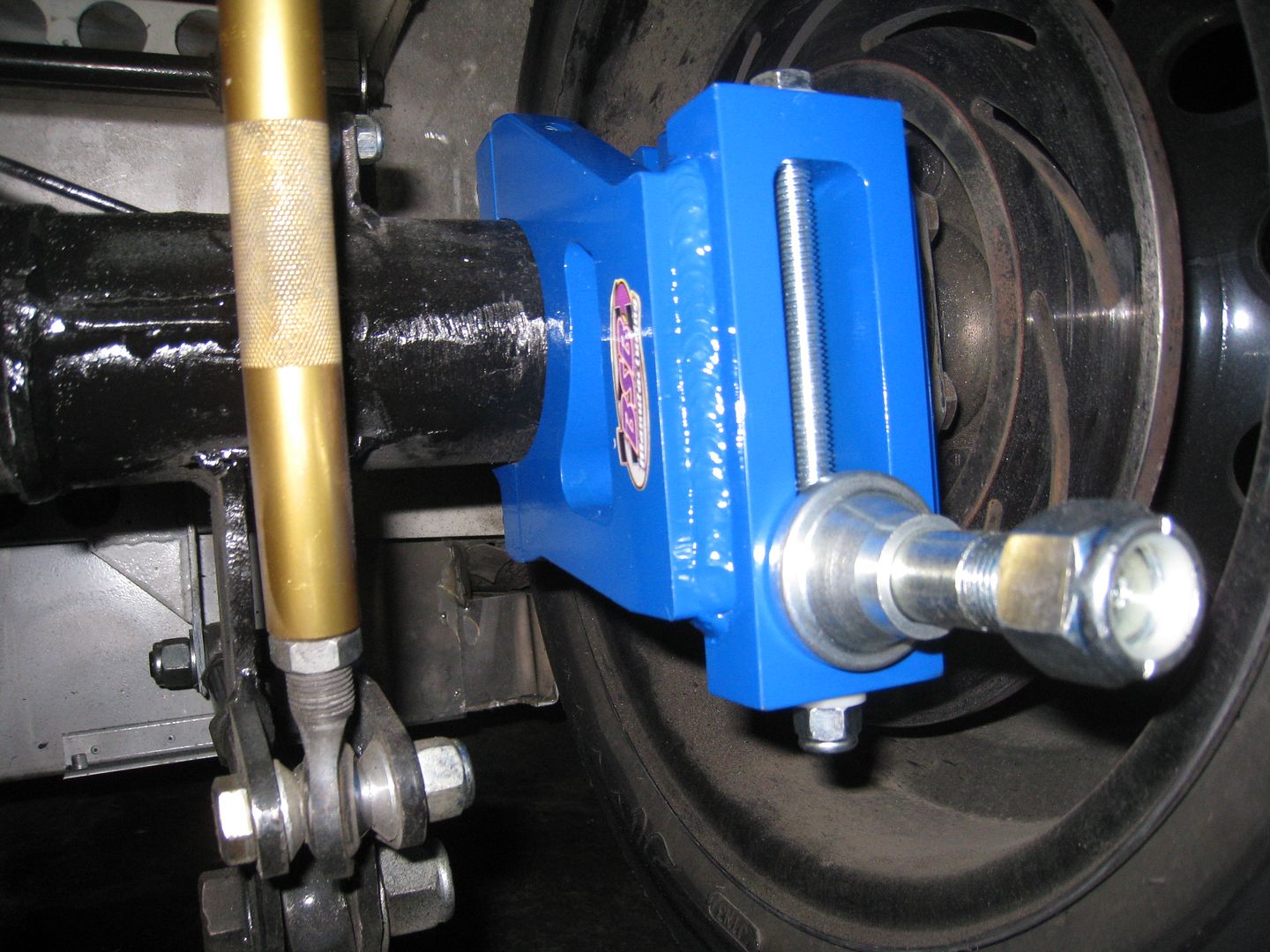

I cut all the Woblink stuff out and ordered bolt-on Panhard bar mounts. When they arrived I was blown away by their robustness, clearly I had underestimated the forces involved.

I welded and braced 2" square tubing on the drivers side for the frame mount

The new mounts use 3/4" rod ends instead of 5/8" rod ends, just look at the difference

And all bolted in place. the kink in the Panhard bar is because I got it from a local dirt oval racer (Ricky Weiss) and in his application, the bar was bent slightly.

I wanted to test the car with the Panhard bar so I went out to our site and put down a 75' slalom and some fast back and forths. Initially, I had the Panhard angled slightly upwards from the frame mount. I expected this to make the car a little loose upon initial acceleration and I was so right. Raising it 1 inch made a world of difference and another half inch made it even better. I messed around with shock valving and rear sway bar settings and it all reacted with expected results, which is nice. According to my data, I was doing 58 mph through the slalom, was pulling .76 G @ 58 mph under acceleration and .91 G under braking. I would have expected more under braking but even with bias put full forward, the rears lock up first. Plus the hottest tire temps I saw were 95 F front and 105 F rear, even after 3 minutes of hard driving.

The car was huge fun to drive, maybe the most fun car I have ever driven, and I am really looking forward to the Lincoln Tour this weekend. I will be switching from the Hoosier Radials to Avon Bias slicks so hopefully it gets ever better. I hope to get some good video.

We loaded up the Pink Panther and traveled from to Lincoln, Nebraska for the Pro Solo and Solo Tour event known as Spring Nationals. Because of a strong headwind and lack of towing power, we were down to 45 mph with the heat cranked and windows opened to keep our Suburban tow vehicle alive until we got to Lincoln.

We tested the car last Sunday and everything was fine except after 3 minutes of continuous hard running through a simulated autocross course, the clutch stopped fully releasing. I assumed that I would just have to bleed the clutch and add a heat shield to the hoses and all would be well. When we unloaded in Lincoln, the problem persisted and made practice launches for the ProSolo very difficult because as soon as I took my foot off the brake, the car would roll through the start lights. In order to adjust the hydraulic release bearing, the transmission would have to come out.

The shifter, drive shaft, seat, tunnel and crossmember all had to come out in order to remove the transmission and finally I could get to the release bearing and adjust it out a little. I got it all back together in time for ProSolo practice launches but couldn't do much because we could stage the car correctly but as soon as we took our foot off the brake, the car would roll forward, causing a red light. It occured to me that maybe I could adjust the pedal travel to correct this and amazingly, it worked-except it means that removing the transmission was a waste of time.

I went back to do some practice launches and after a couple of 4000 rpm clutch dumps, I snapped a rear suspension mount. Those 14" rear slicks really hook up! Briget and I fanned out in the paddock area asking everyone if they had a welder, none were on site. Many calls to local welding shops also turned up nobody that could come to the site and weld my car. I was forced to drive to Tractor Supply and buy a welder, grinder, helmet and steel for reinforcing the bracket.

They told me the welder came with a sample spool of wire, what I discovered when I got back to the site was that it was flux core, and I have never welded with flux core. I got the car done but it was too late for running the test course or doing any more test launches, the next opportunity was the ProSolo the next day. Briget was scheduled to run first and was worried about breaking the car, I told her to go for it and not worry about the car.

Briget came back from her runs reporting that the car felt fine but was a little understeery. I attempted to correct this by stiffening the rear sway bar but during my runs I was spinning the inside rear tire a lot. Also, Briget got warnings for exceeding the sound regulations but curiously, I received no warnings. In an attempt to cure the wheelspin, I installed the front sway bar and softened the rear sway bar again. Briget went out for ProSolo session 2 and came back reporting that the car felt better but she couldn't get it to rotate properly.

For my second session I tried stiffening the front spring rate and going full soft on the rear sway bar and the car felt better to me as far as wheelspin goes but it could have also been that I was driving better. the Avons were not overheating despite the back to back runs but we were also only pulling 1.3 peak lateral G, which is significantly less than what we should have. We started to notice a strange wear pattern on the outside shoulder of the front tires and pumped up the pressures for the next days runs. I also changed the angle of the exhaust tips from pointing out to pointing in in an attempt to pass the sound regulations.

For session 3 of ProSolo, Briget wanted the same settings she had from session 2 so I softened the front spring rate and stiffened the rear bar again. She set her most competitive times yet and the front tires looked a little more normal. I went out for my 3rd session but was late to grid and penalized two runs so I managed only one run on each course. The car still had wheelspin but wasn't hopping around as much in the back so some of the adjustments were working. Briget and I didn't do very well relative to our competition in the ProSolo but the car didn't miss a beat even with 22 hard launches and aggressive runs, which is a victory. However, the car was still hitting 103 dB on the sound meter and something drastic would have to be done.

We went to Speedway Motors and purchased two long bullet mufflers and a side pipe kit. Then I got to use my new welder again and added the mufflers to the current ones I had on the car. This significantly reduced the noise level of the car. Now I could hear the gears in the transmission whining and the rubber chunks flying off the rear tires and hitting the wheel wells.

Briget was the first to run in Solo competition and had some trouble steering the car due to an arm injury sustained in a motorcycle crash. Her times were close to or quicker than her competition but cones jumped out in front of her on her best runs. Also, ambient temperature was now higher than during the Pro and when she came back from her runs, we needed to spray them with ice water. I went out for my runs later in the day when it was even hotter and tire temps were higher than I was comfortable with. I drove very badly and missed critical braking points, losing a lot of time in acceleration zones. I was second last in class by the end of the day, happy that the car was running but disappointed in the results.

For day 2 of Solo competition, Briget started out in wet conditions and had her hands full keeping the car pointed in the right direction. This got better for 2nd and 3rd runs but she couldn't dig herself out of the hole she was in from day 1. I had an hour or two until I ran and during that time, several people came over to discuss the car. They all said that out on course, the car appears to go into a positive camber situation up front, causing rollover and tire smoke. I was so caught up with spring rates, panhard bars, high and low speed compression and tire pressures that I forgot about alignment. I was running very little toe-out and only -.5 degrees camber and wondered how quickly I could change these things because I was already parked in grid. I decided to go for it and loosened off the upper control arm bolts and added some spacers to increase camber, which also increased toe-out.

The car responded well to the changes and understeer was significantly reduced, but my driving was still shabby. For my next two runs I removed the spoiler and diffuser and tried to be smoother out on course. The car was actually a little oversteery in places, which was a good sign that the alignment helped. Plus, the car was hitting 1.38 lateral G. I still finished 2nd last in class and way off the leader but the car held together, felt great and is easy to drive. After a lot of discussion with people more knowledgeable than me, it was determined that I need a wider tire and wider track width up front on the car. I already have a set of wheels that will widen the track width by 3 inches and a set of Avons are on the way, bumping tire size from 10.7" to 12.3". In the meantime, I will continue to play with alignment, Panhard bar, tire pressures and shock settings.

I am uploading all kinds of pictures and video to my blog right now so check that in the next day or two for even more detail on the event in Lincoln. http://ultimatemgbbuild.blogspot.ca/

Remember: When you finish building the car, you're only halfway home. It will take time to sort it out. You have the basis for an excellent car. Just keep working on it steadily and improving both the car and your driving every week. If you're not competitive by the end of the season.....that's what next season is for. You were so anxious to get out there you forgot to align the car. Good thing the course workers spotted it. They saved you a lot of development time. ![]()

Sometimes you have to slow down in order to speed up.

Great post - I love stuff like this. If I cant build and tinker with a car, Im glad to have guys like you on the forum who let me live it through you ![]()

Im glad to hear that theres a lot of room for improvement. It would be one thing if you said "Ive got this thing almost as good as its gonna get, and im near the back of the pack". The fact that you totally forgot about alignment, and were able to make IN GRID adjustments that paid dividends, means that some real time back home in the garage will pay out bigtime! It all shows youre on the right track. Keep it up!!!

I didn't forget to do an alignment, I had it exactly at the recommended toe and camber for Avons. What I did forget was that I can use alignment to reduce understeer and cure the overheating of the outside edge of the tires. I can't wait to try the wider tires and different track width, but that's probably a couple of months away.

loosecannon wrote: I was so caught up with spring rates, panhard bars, high and low speed compression and tire pressures that I forgot about alignment. I was running very little toe-out and only -.5 degrees camber and wondered how quickly I could change these things because I was already parked in grid. I decided to go for it and loosened off the upper control arm bolts and added some spacers to increase camber, which also increased toe-out.

You can see how, after the first sentence, it sure sounded like you forgot to align the car. Only after re-reading the next sentence did it occur to me that, since you knew the alignment specs you already had, you aligned the car previously. Anyway, I hope you can find another local meet to prepare you for the next big competition. I also hope you find another 100 horsepower for the Suburban.

Jerry From LA wrote:loosecannon wrote: I was so caught up with spring rates, panhard bars, high and low speed compression and tire pressures that I forgot about alignment. I was running very little toe-out and only -.5 degrees camber and wondered how quickly I could change these things because I was already parked in grid. I decided to go for it and loosened off the upper control arm bolts and added some spacers to increase camber, which also increased toe-out.You can see how, after the first sentence, it sure sounded like you forgot to align the car. Only after re-reading the next sentence did it occur to me that, since you knew the alignment specs you already had, you aligned the car previously. Anyway, I hope you can find another local meet to prepare you for the next big competition. I also hope you find another 100 horsepower for the Suburban.

Yup, I see how people could get confused. I have a bunch of local events before Nationals but hopefully the wider tires will arrive in time to get some practice on them. As for the Suburban, it's going to be put up for sale. I have a more powerful truck but it's a shortbox regular cab and the shorter wheelbase and 1500 lb lighter weight means it gets pushed around by the trailer more. I'm hoping an equalizer hitch will help with that.

While in Lincoln, some other Mod class drivers gave me advice on my car: increase negative camber and soften the rear suspension. I adjusted the camber to around -1.8 degrees and while I was in there, I decreased caster to reduce steering effort and gave it a little toe out. As soon as I went out on track I felt the difference, understeer was completely gone but I was still spinning the inside rear tire.

Between runs I quickly changed the rear spring rate and aimed a camera at the rear suspension to see what it was doing. http://www.youtube.com/watch?v=w67Bwfh9Lvs&feature=youtu.be

The car felt great, I had so much fun driving it that I forgot all about getting on the backside of cones and looking ahead. It's not perfect but it's a lot closer now. Here's a video of my final run with data overlay: http://www.youtube.com/watch?v=w67Bwfh9Lvs

I have always known that the rear suspension (actually, the front one, too) had a falling rate. In other words, as the suspension went through it's motion, it's stiffness decreases, which is not ideal. I have tried to change the rocker arm shape to improve this but it didn't do much. Today I realized that all I had to do was change the angle of the shock in relation to the pushrod, an easy fix. Here's the before:

And the after:

When I installed the rear sway bar, I had to move the center suspension link down one notch. Today I plugged the numbers into the suspension calculator and it told me that this moved my anti-squat from 50% to 88%. An internet search revealed that in an autocross car, 50% is far better than 88% so I had to find a solution. what I did was add an extension to the sway bar mount, lowering it below the center link. This also allowed me to reposition the sway bar back which cured some geometry problems when the bar was adjusted in it's stiffest position. In this pic you can see the extension on the right and the center link in the background.

I also attached this slick aluminum hinge that I found at Speedway Motors so no more stick to hold up the hatch!

Thanks for the development updates! Good reminder the build is just the beginning and great to see the car evolving and improving.

DaewooOfDeath wrote: Dumb question but, how does one calculate anti-squat?

Back in the old days you would draw a scale model of the suspension on the floor but nowadays you can find calculators for it online. I use Speed-Wiz http://www.speed-wiz.com/

DaewooOfDeath wrote: Dumb question but, how does one calculate anti-squat?

Not dumb at all. The math/forces involved are the same as those dictating roll center location. When viewed from the side the forces from accel (an inversely braking) will be transmitted to the chassis along the axis of the links (The imaginary line between the actual pivot locations). Extending these lines out until the bottom link axis and the top link axis intersect will give the the instant center (Again think upper and lower a-arm geometry which people are more familiar with) or the effective location that the axle will be pushing on the car. This instant center will be the point that the chassis will try to pitch about. The height that this center is located at relative to the height of the center of gravity of the car determines the amount of anti-squat that the supspension will generate. If the center is above the CG you will have anti-squat, the force through the links will attempt to resist the natural squat brought about by weight transfer due to normal acceleration. If it's below the opposite is true. If the links never intersect you will have no anti squat. Under braking you will get the opossite effect, so if you have anti-dive geometry you will get a jacking force under braking.

Generally Anti-squat is good as it allows your spring rates to be lower and still keep the rear suspension from moving to much under accel, however you have to deal with the jacking during braking and under heavy acceleration you are effectively binding the rear suspension so you may have issues due to loss of traction on bumpy surfaces.

My MG is designed to have none and i have no provisions to add it as the CG is very low and my spring rates high so I anticipate relatively minor amounts of squat under acceleration. On dual A-arms you use the intersections between axis between the upper inner pivots with those through the lower pivots. Because the impacts to actual suspension behavior are lower on a IRS type suspension that a solid axle it can be more easily divorced from the rest of your suspension calculations.

Good luck!

To LooseCannon please keep documenting the development of this car. I'm actually even more interested in your evolution of the suspension than the build which I was very intersted in.

Sorry about the novel.

Nocones,

Ah, okay. Thanks for the info. I had a general idea of how that worked before, but I never could figure out how the % value related to anything.

Just to make sure I understand. Let's say I'm dealing with a parallel four link stick axle. If my bottom control arm is parallel to the floor and my upper control arm is higher at the axle then at the chassis, I have "pro squat." This would result in a lot of squat under acceleration and very little lift under braking.

If I had exactly parallel arms, it would have no anti-squat.

If I had a top link parallel with the ground and a lower link that was lower at the axle than at the chassis, I would have anti-squat. This would resist squat under acceleration but jack up the rear under braking, right?

As much as I liked the ram air system I built, it weighed more than necessary and prevented easy adjustments of the front suspension. I pulled all that out and just attached an air cleaner to the mass air flow sensor. I also added a sheet of aluminum behind the tire to protect the air cleaner from debris (after pic was taken).

I don't know if you made other changes at the same time that you adjusted the anti-squat so this may be difficult to discern, but do you have a good comparison of the car at different levels of rear anti-squat? Were you getting wheel hop under hard braking when you had it set up near 80%? Was it resolved by lowering the anti-squat? I've been messing with the design of a similar 3-link and would be interested to hear some anecdotal reports on how different levels of anti-squat feel on the auto-x course.

JohnyHachi6 wrote: I don't know if you made other changes at the same time that you adjusted the anti-squat so this may be difficult to discern, but do you have a good comparison of the car at different levels of rear anti-squat? Were you getting wheel hop under hard braking when you had it set up near 80%? Was it resolved by lowering the anti-squat? I've been messing with the design of a similar 3-link and would be interested to hear some anecdotal reports on how different levels of anti-squat feel on the auto-x course.

I did not experience wheel hop under braking but even with brake bias set full to the front, the rear tires would lock up. I have an event this Sunday so I'll get a better idea what differences the changes made.

You'll need to log in to post.