I have one upper control arm made. I tried to make the main roll hoop but the tubing kept kinking, I think I'm using the wrong sand inside.

I have one upper control arm made. I tried to make the main roll hoop but the tubing kept kinking, I think I'm using the wrong sand inside.

SkinnyG wrote: There's "right" sand?

Yes, apparently, I bent all the tubing for Pink Panther 1.0 using sand and a hydraulic tubing bender, no problem. Now, I can't bend anything beyond 45 degrees and have even tried using a piece of the tubing from the original car.

loosecannon wrote:SkinnyG wrote: There's "right" sand?Yes, apparently, I bent all the tubing for Pink Panther 1.0 using sand and a hydraulic tubing bender, no problem. Now, I can't bend anything beyond 45 degrees and have even tried using a piece of the tubing from the original car.

Strange... we use sand to bend 6-8-10-12 inch stainless pipes per B31.3 at work - I never knew that it could be done with inappropriate sand...

Curmudgeon wrote: I've never tried sand bending. Can you post a pic of your setup?

I just duct tape one end of the pipe, fill it with sand and tap with a hammer to get it settled. Then tape up the other end and put in this bender. It has always worked amazingly well but I'm doing something wrong now.

In reply to loosecannon:

'splain it a little more, please. Does this result in mandrel bends or something? Looks like it. Very interesting.

I think the sand technique works best in you cap one end as you say and fill with water 1st and then add the sand to displace the water.The sand will be better compacted and dense to better support the pipe from kinking.

OHSCrifle wrote: In reply to loosecannon: 'splain it a little more, please. Does this result in mandrel bends or something? Looks like it. Very interesting.

It's an old technique which keeps the interior volume the same. If you do it right, you can make a mandrel-esque bend.

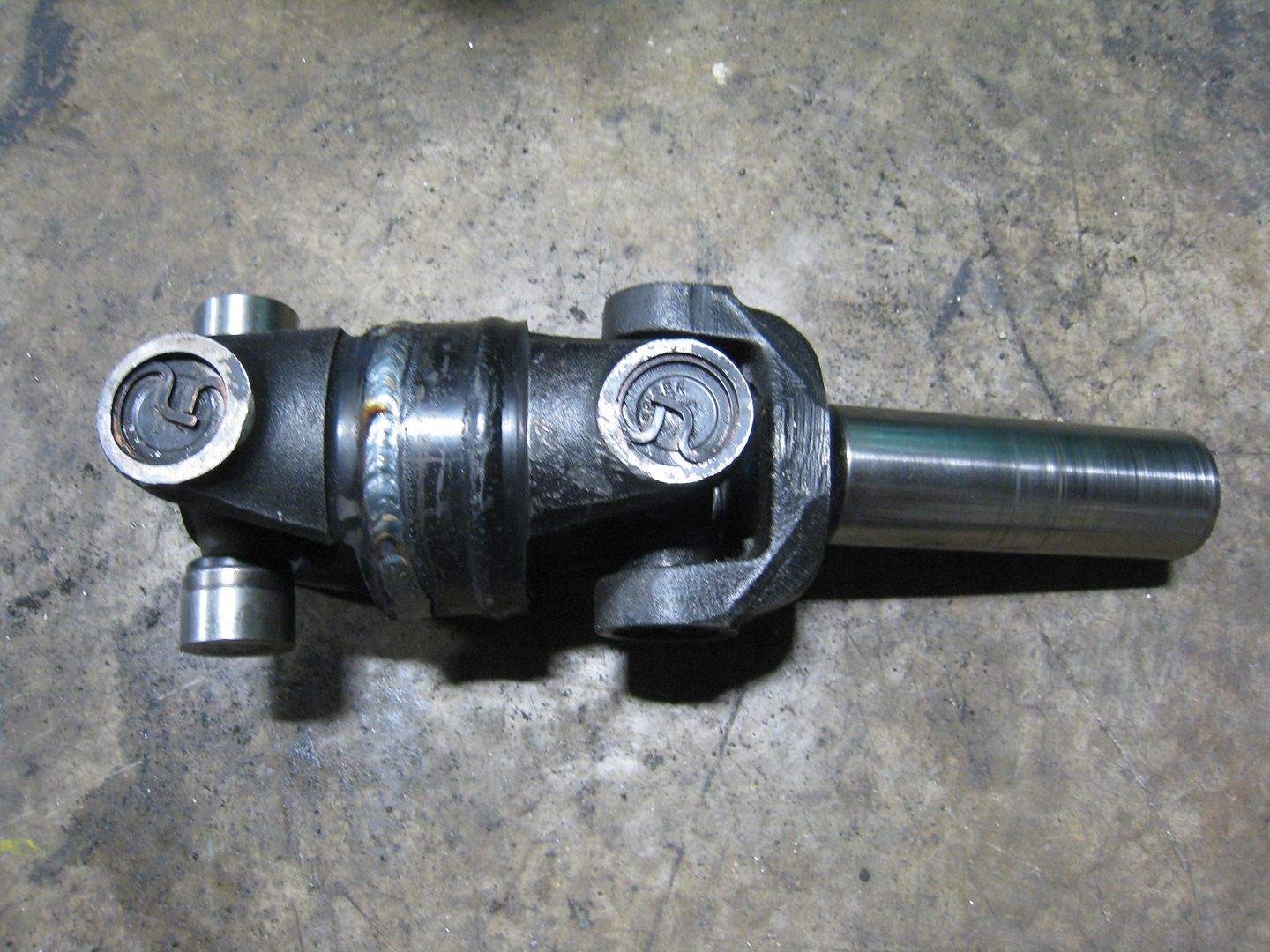

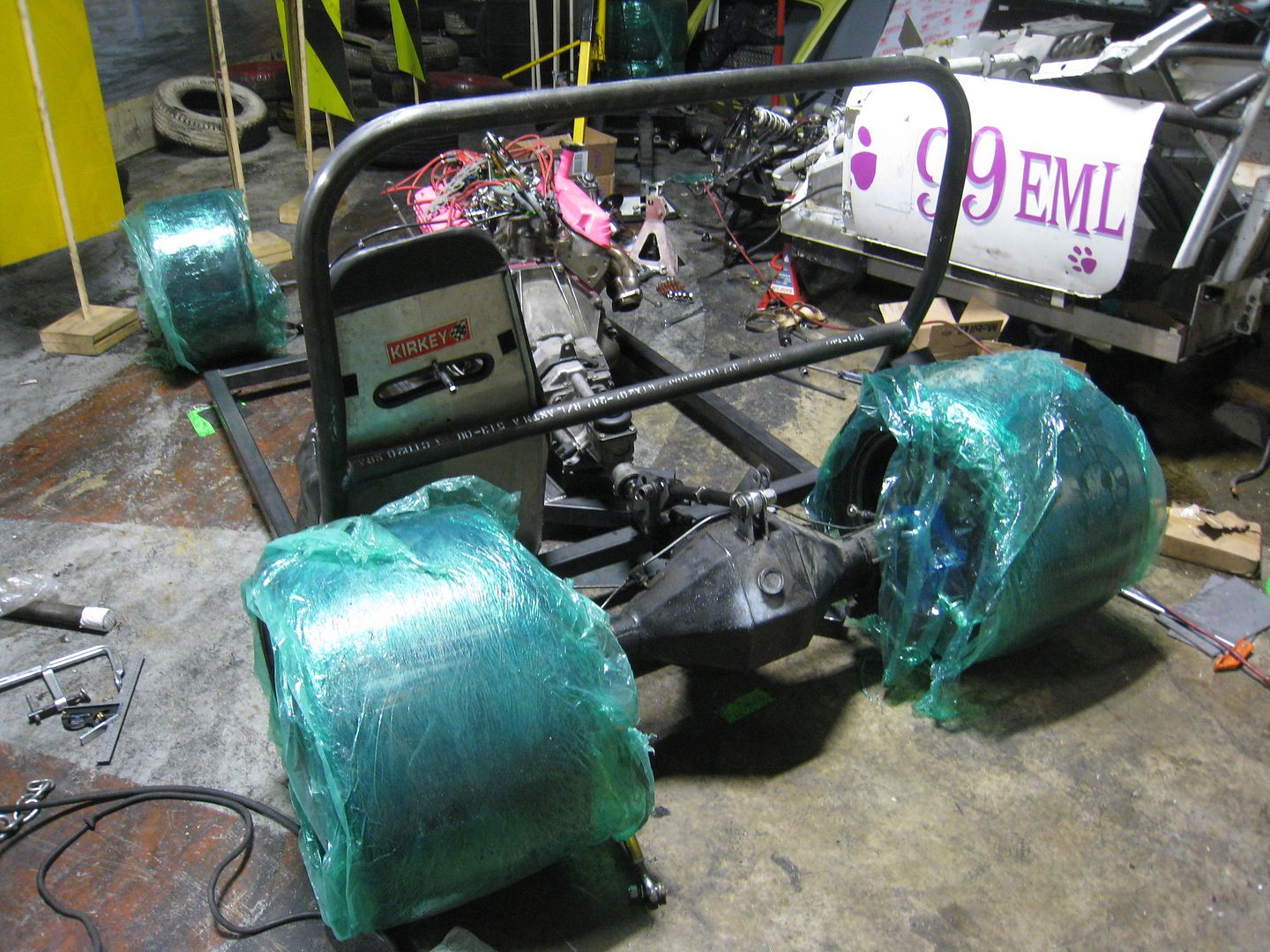

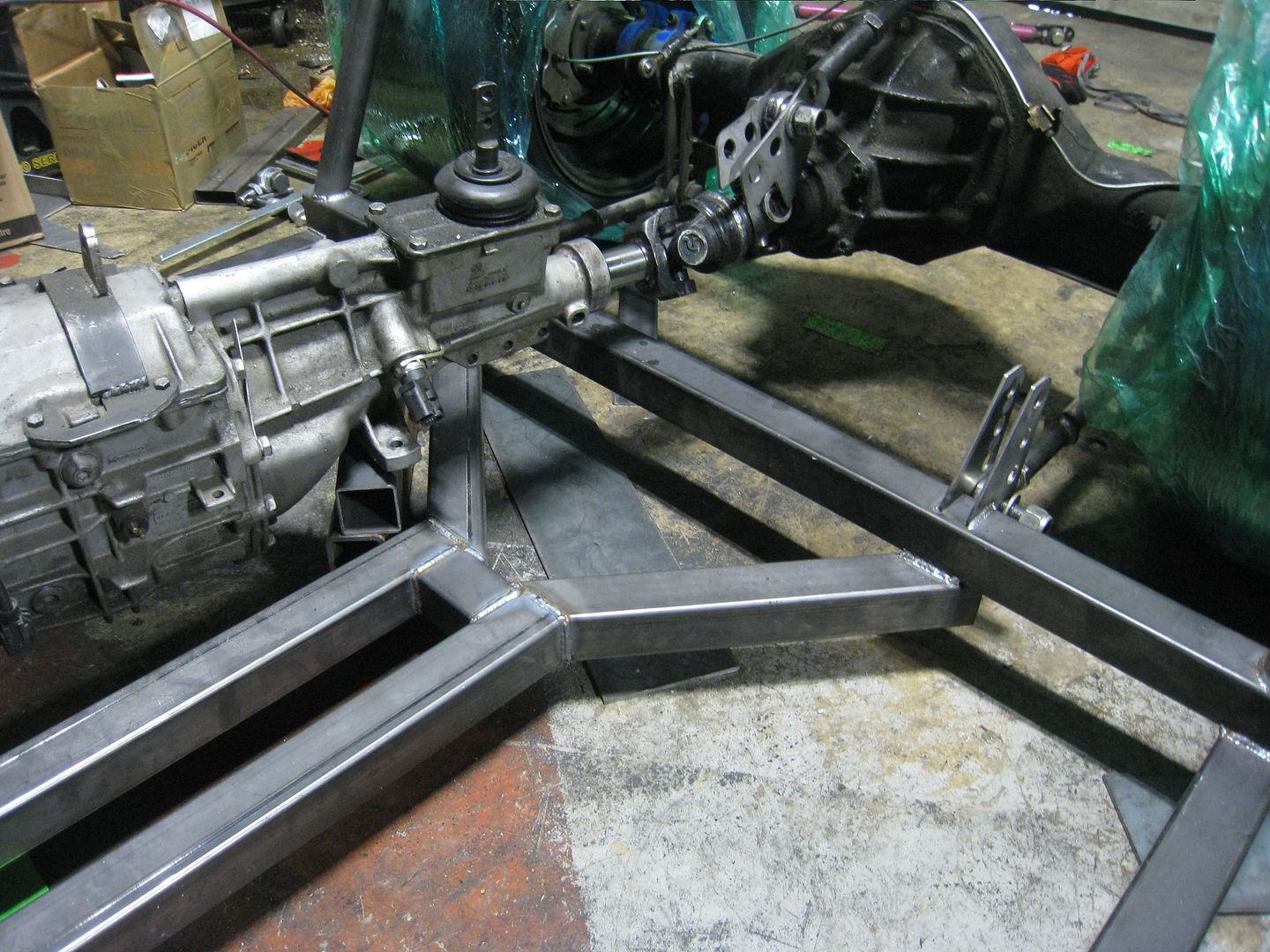

Work on the frame continues, and the CAD program tells me exactly how long each piece is and how much it weighs, I love it. Check out the new driveshaft:

Mmm yes this is good ![]()

You should try to jam as much of the heavy stuff as you can into the driver's foot area to prevent a nasty crossweight situation.

What's the story with the U-joints on that driveshaft? Are you using something special that can handle the huge angles that you'll have as the solid rear moves through its range of compression and droop? Asking because the Wreck Racing MG has a similar super-short driveshaft.

Good point, I guess you're going to set up the rear suspension geometry so that the diff input will always be pointing at the trans output to minimize the driveshaft angle?

I am going to use a CV axle instead of the u-joints. Others in the class with similar space between trans/diff use them successfully because the diff only moves 3 " or less in this class.

Damn, but that's a short driveshaft. ![]() I am thinking even 3" is going to be enough to snatch the slip yoke out of the transmission. If the engine pretty much needs to stay in that position, I'd consider sectioning the tailshaft housing to shorten it as much as possible and having the output shaft resplined, then use a CV shaft with a slip yoke in the middle of it or even a 'plunge' joint on one end.

I am thinking even 3" is going to be enough to snatch the slip yoke out of the transmission. If the engine pretty much needs to stay in that position, I'd consider sectioning the tailshaft housing to shorten it as much as possible and having the output shaft resplined, then use a CV shaft with a slip yoke in the middle of it or even a 'plunge' joint on one end.

Long shot and probably a really stoopid question: is it possible to set the rear axle up so that it can pivot from side to side but not go up/down?

If you did a Corvette IRS, you could do like the Bill Thomas Cheetah and just use one u-joint. Think of the weight savings!

How would the snout of the diff remain in line vertically with the tailstock?.With the driveshaft being essentially none existant they would need to remain in line otherwise the diff will bind.I can't see getting the diff housing to rotate perfectly with vertical movement to stay pointed at the trans.

The diff definitely will move up and down with a total range of 3-4", and forward and back slightly, too. I have to find out how short a CV axle I can buy and move things around that. There are some expensive ways to shorten the transmission but I'm not interested in going down that road.

Oh that is gonna be a tough problem...oddly the little double U-joint thing above is similar to something used to replace CVs in the offroad world.

I'm no expert but I can't see that much movement combined with essentially no driveshaft working out at all.As the diff moves vertically it'll have to load either the tailstock or the snout of the diff quite alot I think. What about some kind of rotating engine mounts to allow the transmission to rise/fall with the diff??.

Corvette center section with dedion rear end. You can maintain your current rear geometry plans and gain a large reduction in unsprung weight and the ability to easily and reliably adjust camber. Something to consider.

GameboyRMH wrote: Oh that is gonna be a tough problem...oddly the little double U-joint thing above is similar to something used to replace CVs in the offroad world.

A double cardan joint.

DeDion is certainly a possibility, but I'm not a big fan of it. Takes up more room than a live axle or an IRS with nowhere near the adjustability of a short/long arm IRS.

You'll need to log in to post.