tuna55 wrote:

loosecannon wrote:

unevolved wrote:

I don't know if anyone's made this joke yet, but that's the best embodiment of "front-mid engine" I've ever seen!

Thanks. I am building it in such a way that I can fit a different engine down the road, maybe some kind of turbo 4 cylinder.

Have you tried a V12?

hehehe

I think I have one of those laying around ;) I hope to make minimum weight with the current engine but if the car is still too heavy, I may have to look at something lighter for power.

I'm thinking ecotech turbo.

N/A Duratech and drop down to D Mod. Or staying in E Mod a twin turbo Rover/Buick/Land Rover V8

Too bad you can't run bike power,mount transverse up front and use a normal driveshaft.While I hope your set-up works I can't see how it will,I see broken parts and binding diff/suspension.My bike powered build used a sharp angled short cv shaft but with a fixed diff irs,the joint had no troubles but I went thru boots FAST untill I figured out how to fix it.

kevlarcorolla wrote:

Too bad you can't run bike power,mount transverse up front and use a normal driveshaft.While I hope your set-up works I can't see how it will,I see broken parts and binding diff/suspension.My bike powered build used a sharp angled short cv shaft but with a fixed diff irs,the joint had no troubles but I went thru boots FAST untill I figured out how to fix it.

I agree, bike power would be sweet. The set up is definitely unconventional (has this car ever had anything normal?) but the distance and angles are very similar to what Jeff Kiesel uses in the Bugeye and I am actually using a more robust CV joint than he is (108mm vs 90mm). The Driveshaft Shop has all my specs including angles, hp/torque and max rpm of shaft and they feel it will work so I'll trust the professionals.

Yes much better chance of them being right over me for sure.So just a single cv at the diff end?.

Wow... I know you are not drag racing... But how about a scattersheild or at least a trans blanket to contain flying clutch parts......?

kevlarcorolla wrote:

Yes much better chance of them being right over me for sure.So just a single cv at the diff end?.

No, it gets a 108 mm cv at both ends, not sure if there is some kind of sliding mechanism in there or what. I'll know more when I get it.

noddaz wrote:

Wow... I know you are not drag racing... But how about a scattersheild or at least a trans blanket to contain flying clutch parts......?

SCCA rules require a blanket, scattershield or 1/4" thick bellhousing-I'll have one of those things.

There have been a lot of compliments about how quickly I am getting things done on the car and I appreciate that but haven't really shared what my "secret" is for doing a project quickly. This weekend I helped a friend with his automotive project and it became painfully clear that maybe some people could benefit from my system.

Quick background, I was a long haul truck driver for 10 years and logged 1.3 million miles. While on the road I would do projects on my Porsche 911 in my head to keep my mind occupied. Paying attention to the road was always front and center (I specialized in oversize loads) but there was always room for thinking about other things. As an example, I would go through the process of rebuilding the Weber carbs in detail from beginning to end. Starting with pulling the handle to release the engine cover, getting the flat screwdriver to loosen the hose clamp for the fuel line (the medium flat, NOT the big flat screwdriver), grabbing the 13mm wrench to loosen the nuts, etc, etc until the carbs were rebuilt and back on the car. I didn't rush the process, as far as my brain knew, I was really doing this project. BTW, when I started losing track of tools and parts, I knew it was time to pull over and take a nap.

When I got home and actually rebuilt the carbs, it all went so quickly and smoothly because it felt like I had done it a bunch of times. I do the same thing with the race car. I pick a project, like putting the new diff in and start imagining the process, and what tools I need and what order I'm going to do things. I can't express enough how much quicker things will happen when you do it this way. Try it before disagreeing with me. The project that prompted this was fixing a leaky rad on a military truck. The side tanks on the rad are bolted to the rad with a hundred bolts and there's a gasket between them. My buddy announced that we are taking the truck to his dads shop to fix the leak. I immediately thought of the process of draining the coolant, removing a hundred little bolts, making a new gasket and bolting it back up. Then I asked "Got containers to hold the coolant?", "Cordless drill and chuck to make removing the bolts go quicker?", "Got cork to make a new gasket?". He hadn't thought of any of this, he was fixated on "Drive to dads shop, fix leak". Just do your project in your head while driving to work, or sitting at work and during a boring church service or while waiting at the DMV. I hope this helps all your projects get done more quickly.

loosecannon wrote:

There have been a lot of compliments about how quickly I am getting things done on the car and I appreciate that but haven't really shared what my "secret" is for doing a project quickly. This weekend I helped a friend with his automotive project and it became painfully clear that maybe some people could benefit from my system.

Quick background, I was a long haul truck driver for 10 years and logged 1.3 million miles. While on the road I would do projects on my Porsche 911 in my head to keep my mind occupied. Paying attention to the road was always front and center (I specialized in oversize loads) but there was always room for thinking about other things. As an example, I would go through the process of rebuilding the Weber carbs in detail from beginning to end. Starting with pulling the handle to release the engine cover, getting the flat screwdriver to loosen the hose clamp for the fuel line (the medium flat, NOT the big flat screwdriver), grabbing the 13mm wrench to loosen the nuts, etc, etc until the carbs were rebuilt and back on the car. I didn't rush the process, as far as my brain knew, I was really doing this project. BTW, when I started losing track of tools and parts, I knew it was time to pull over and take a nap.

When I got home and actually rebuilt the carbs, it all went so quickly and smoothly because it felt like I had done it a bunch of times. I do the same thing with the race car. I pick a project, like putting the new diff in and start imagining the process, and what tools I need and what order I'm going to do things. I can't express enough how much quicker things will happen when you do it this way. Try it before disagreeing with me. The project that prompted this was fixing a leaky rad on a military truck. The side tanks on the rad are bolted to the rad with a hundred bolts and there's a gasket between them. My buddy announced that we are taking the truck to his dads shop to fix the leak. I immediately thought of the process of draining the coolant, removing a hundred little bolts, making a new gasket and bolting it back up. Then I asked "Got containers to hold the coolant?", "Cordless drill and chuck to make removing the bolts go quicker?", "Got cork to make a new gasket?". He hadn't thought of any of this, he was fixated on "Drive to dads shop, fix leak". Just do your project in your head while driving to work, or sitting at work and during a boring church service or while waiting at the DMV. I hope this helps all your projects get done more quickly.

this needs to go in the mag.

and i need to start doing it.

THANK YOU!

In reply to loosecannon:

Your method is very much how a lot of athletes work.

In reply to Dusterbd13:

That technique helped me get through the one opera I went to. 8)

It also helped me sleep when my brain was spinning during a last minute challenge build. I just wouldn't let my thoughts go beyond one certain aspect. Mentally building the front suspension over and over was way better than counting sheep.

As a carpenter if I spent too much time thinking about my car ADD problems at work I'd lose a limb-that won't help getting them done any faster.

I agree about planning ahead,I'm the site foreman so I'm always planning stuff out for others to do(plus my stuff) and its amazing how many people start something at the middle step and then backtracking to catchup.

kevlarcorolla wrote:

As a carpenter if I spent too much time thinking about my car ADD problems at work I'd lose a limb-that won't help getting them done any faster.

I'm only talking about doing this when you have the available mind space, not when you're doing hostage negotiation or landing a helicopter that's lost power ;)

Haha,yeah I know buts part of the reason why I give truckers lots of room as I pass-ya never really know which one of them is rebuilding carbs for fun in their head.

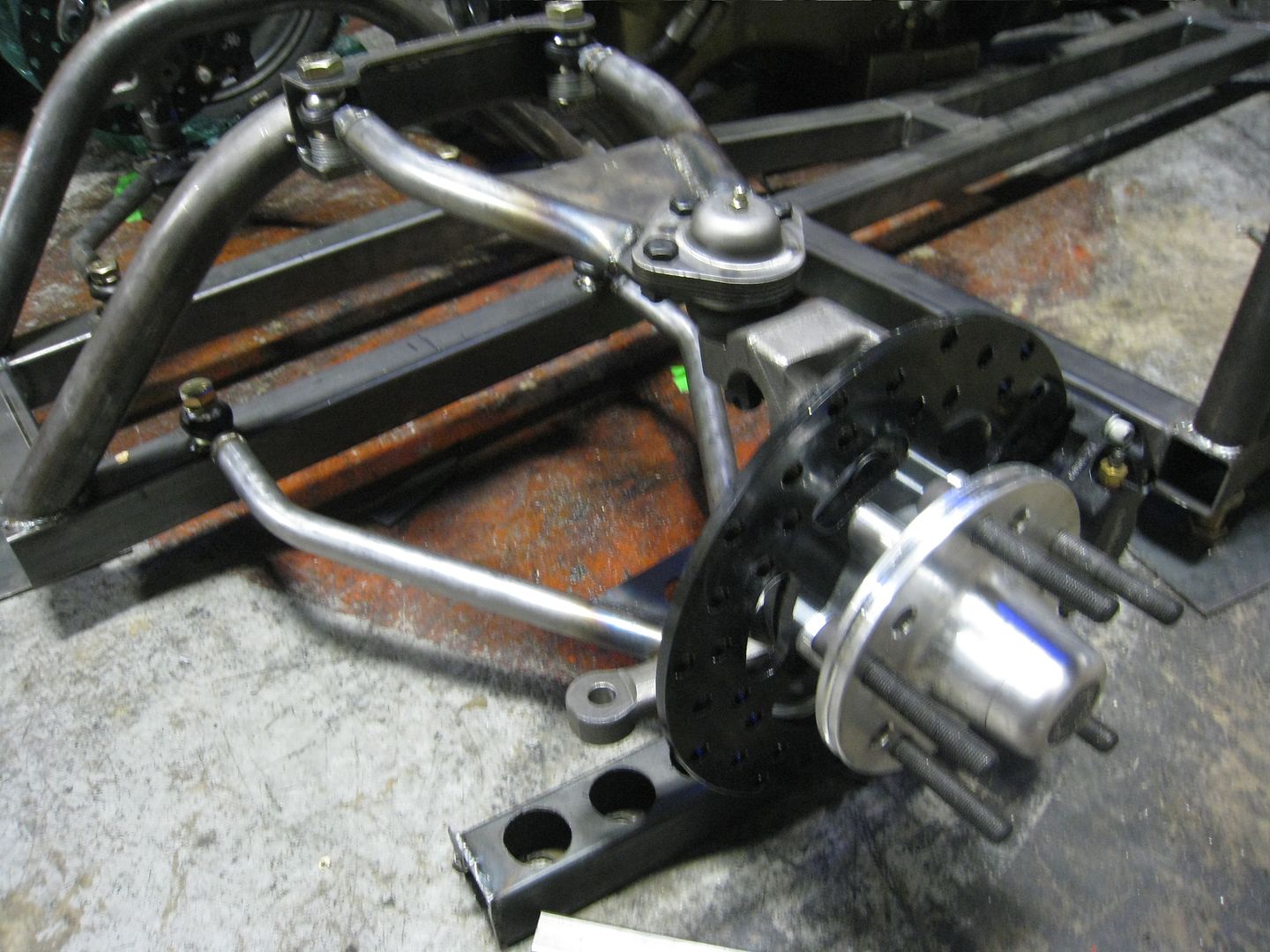

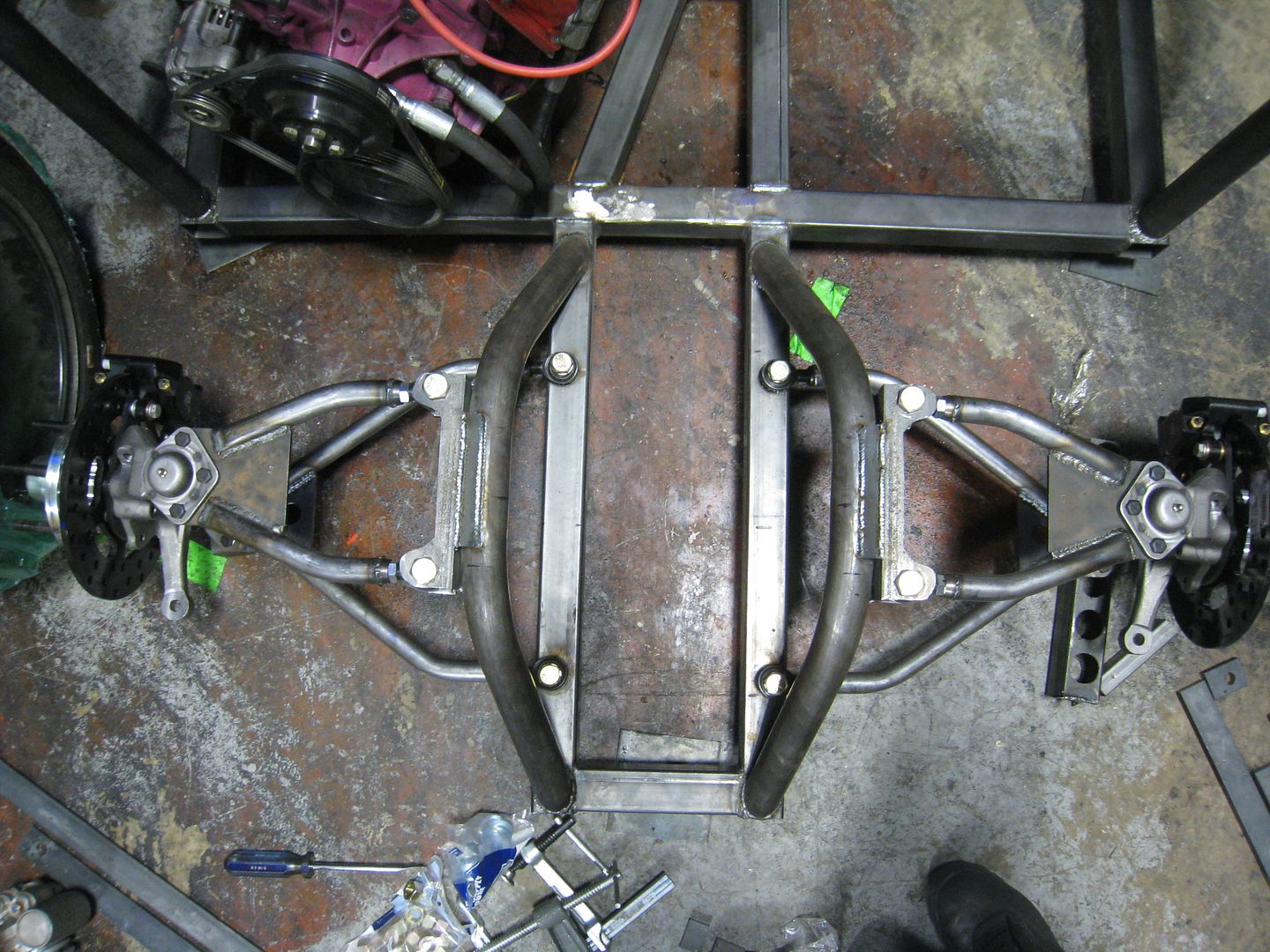

Got a little more done at the front of the car. The upper control arms will actually bolt to tabs welded to the tubes, they are just laid on top to get a visual of how the front will look.

Hey why didn't you attach the back end of the hoops to the lateral "firewall bar?" that would have given you both the welds in the square tubing and the welds at the back of the hoops sharing the loads from the front suspension. This way it's all up to the square tubing.

GameboyRMH wrote:

Hey why didn't you attach the back end of the hoops to the lateral "firewall bar?" that would have given you both the welds in the square tubing and the welds at the back of the hoops sharing the loads from the front suspension. This way it's all up to the square tubing.

Because I have other braces attaching there

The Pink Panther was put on hold while I finished my Ayrton Senna bike but now that it's on the road, I'm back to the MGB.

[URL=http://smg.photobucket.com/user/loosecannon/media/Motorcycle/photo8_zpsa6ddd044.jpg.html] [/URL]

[/URL]

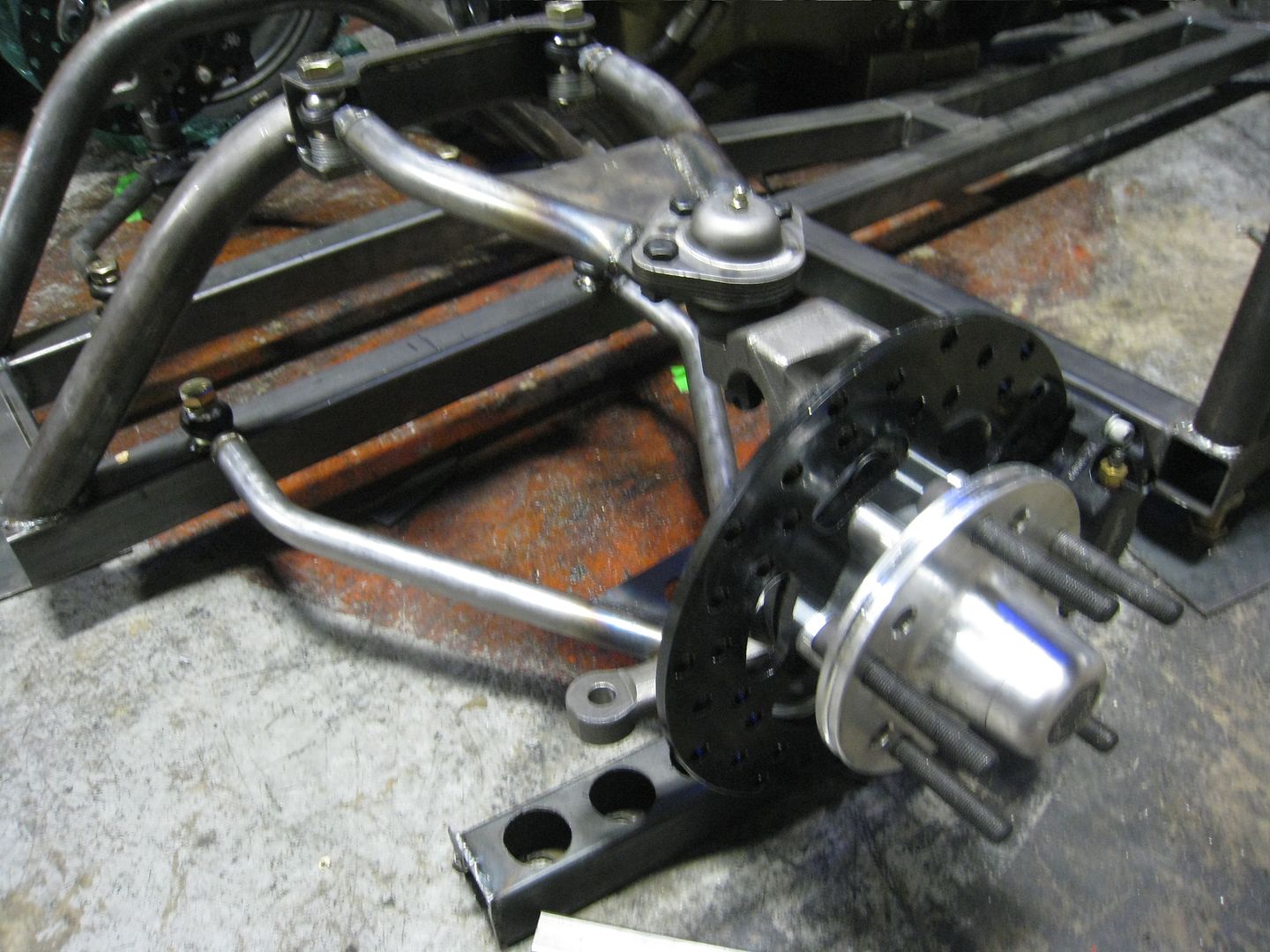

The beautifully machined flange for the diff finally arrived from The Driveshaft Shop and I bolted it on so I can get accurate measurements for the driveshaft:

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_7361_zps54556e20.jpg.html] [/URL]

[/URL]

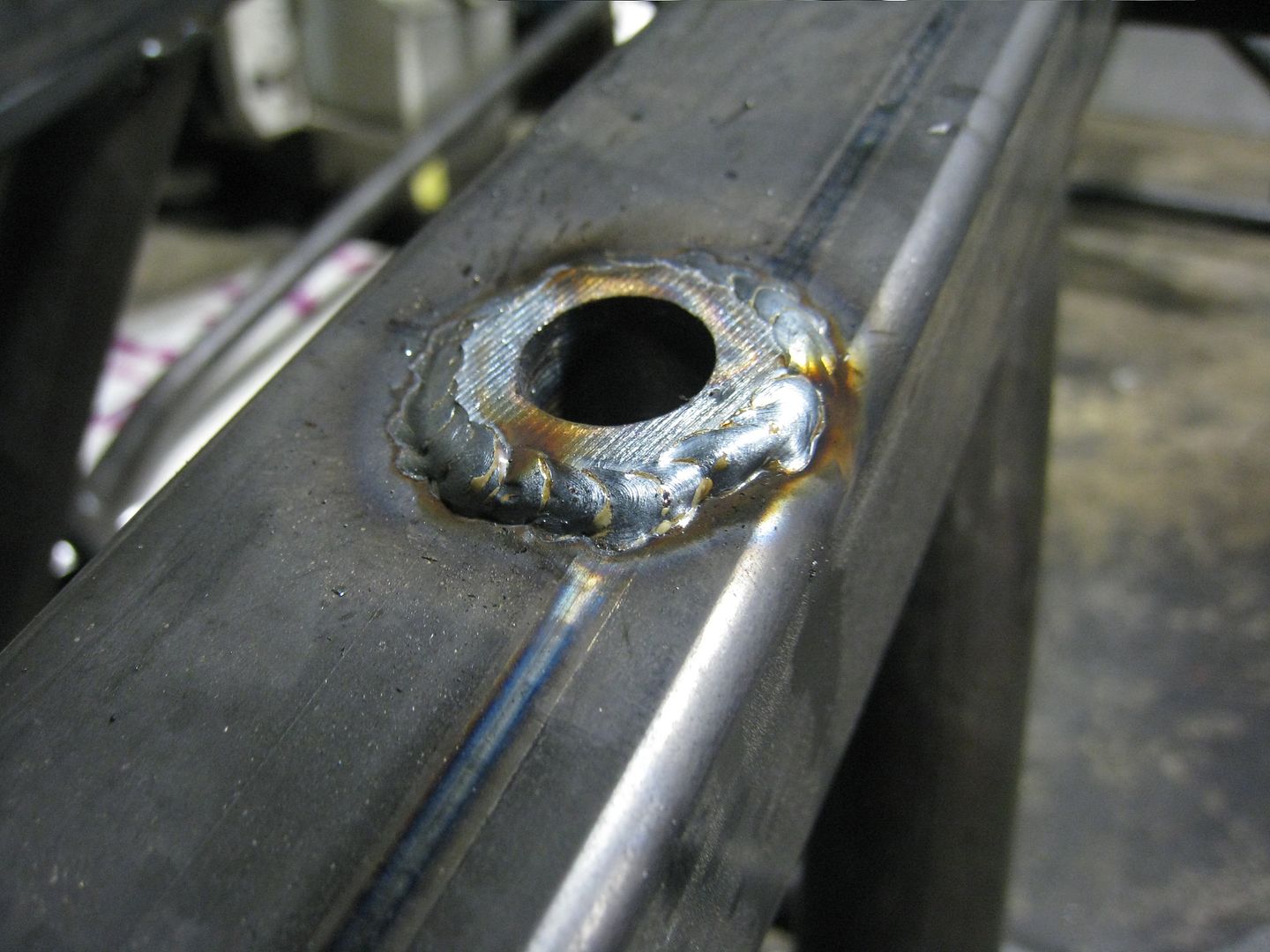

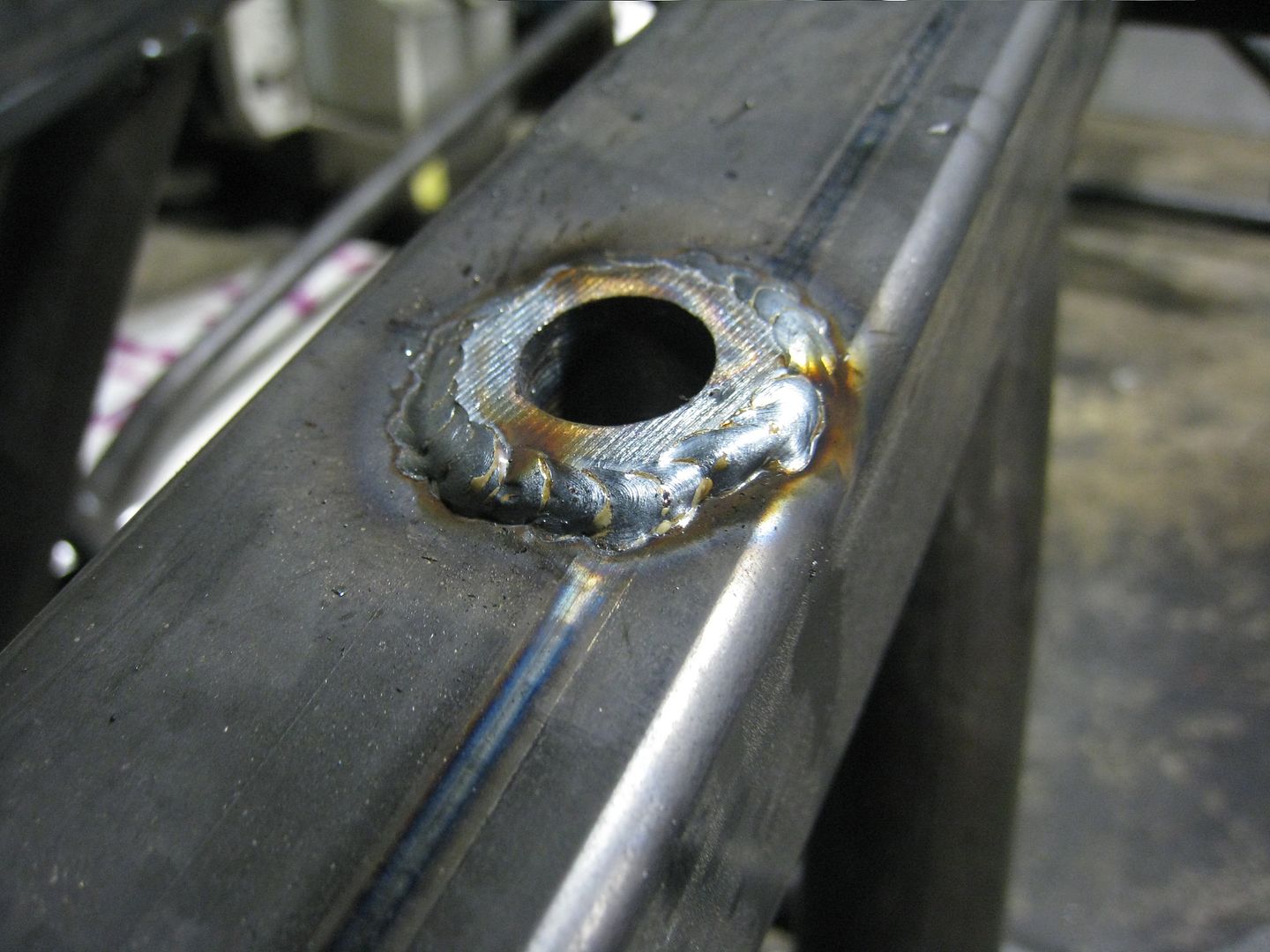

I also made front suspension mounting points by taking thick wall tubing and threading it for 5/8" bolts, drilling holes through the frame to slide the tube through and welding top and bottom:

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_7360_zps384291b5.jpg.html] [/URL]

[/URL]

And I flipped the frame upside down to weld all the stuff I missed earlier. The whole frame weighs less than just the front end of the old car.

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_7362_zps90f25018.jpg.html] [/URL]

[/URL]

This is od. This thread shows up in recent topics as having been updated 1 minute ago, yet there doesn't appear to be any update since 4/12?

EDIT Ah, despite reloading twice and nothing appearing, after I posted this, todays update appeared :)

Adrian_Thompson wrote:

This is od. This thread shows up in recent topics as having been updated 1 minute ago, yet there doesn't appear to be any update since 4/12?

EDIT Ah, despite reloading twice and nothing appearing, after I posted this, todays update appeared :)

Is your computer showing the extra code above and below pics? Mine shows it so I tried hotlinking the pics differently but it didn't work and I deleted the post to re-do it.

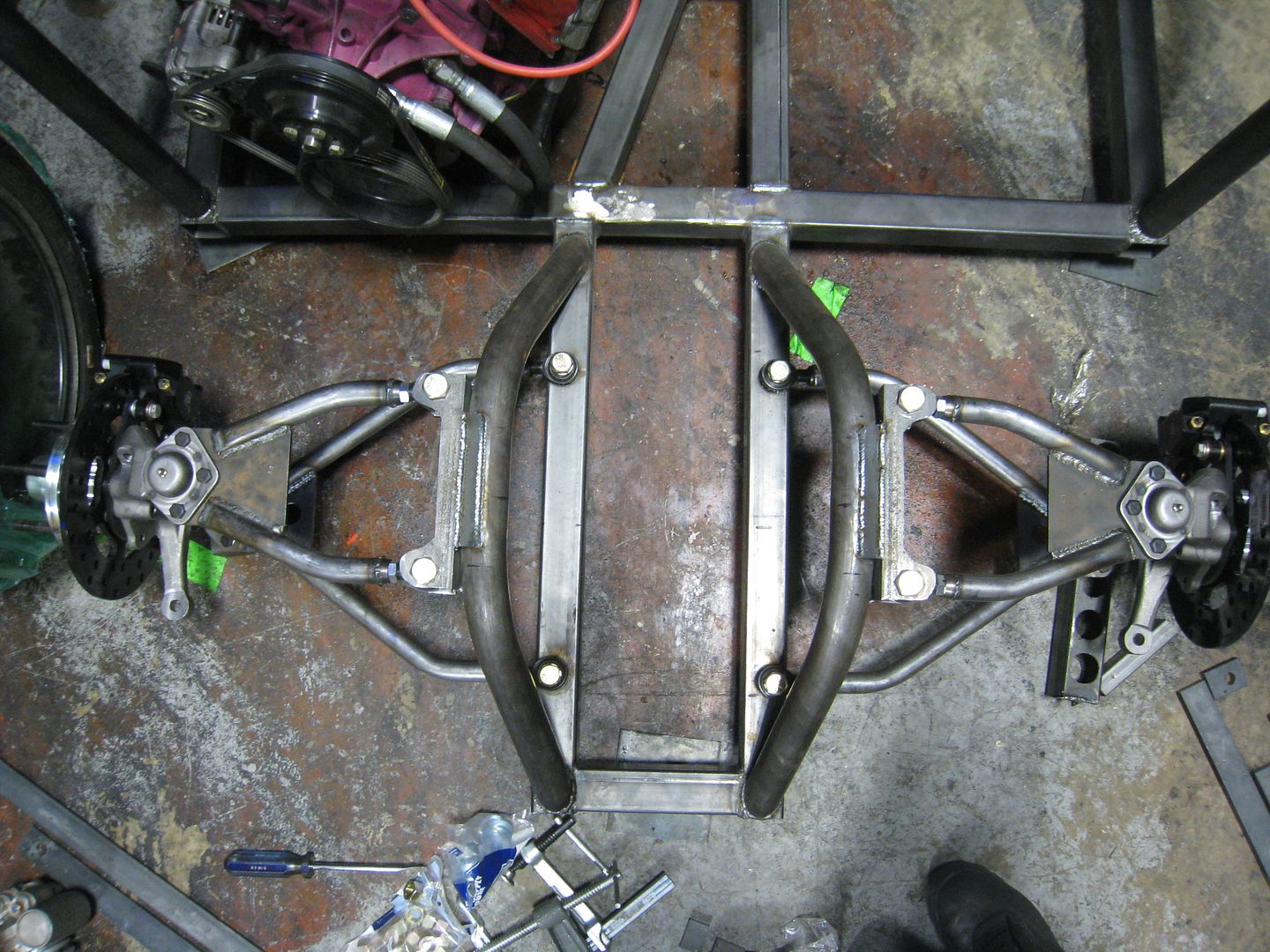

Took hours and hours of measuring, re-measuring, making a mounting jig and some more measuring but I got the front suspension all mounted. Spacers are used for anti-dive and roll center adjustments and turning the rod ends in or out for camber/caster.

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_7373_zpsd5c1d740.jpg.html] [/URL]

[/URL]

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_7374_zpsb00e6c17.jpg.html] [/URL]

[/URL]

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_7375_zpse1b4b751.jpg.html] [/URL]

[/URL]

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_7376_zps59ae3879.jpg.html] [/URL]

[/URL]

[/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]