Stang_guy03 wrote: In reply to loosecannon: Driveshaft safety loop is almost as big as the driveshaft.Question, what kind of welder are you using for all this. I'm looking into buying a welder and starting learn to weld. Always interested in what others are using?

I started with a Lincoln 120 V MIG but the power in my building is wonky so I now have to run a generator to power my welder. The Lincoln doesn't like the generator so I started using the Hobart 120 V MIG I picked up at Tractor Supply. The local welders supply says that the Hobart is made by Miller and they are less sensitive to electrical fluctuations. If I had proper power in the building, I would switch back to the Lincoln because I like it's gun and finer adjustments more.

The modern engine needs a vehicle speed sensor (VSS) and Dakota Digital makes this slick little adapter that screws right into the speedometer drive of the early 80's transmission and sends the right signal to the computer-amazing!

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_3754_zpskhiv9lrx.jpg.html] [/URL]

[/URL]

The electric steering motor moves around a little when I'm cranking on the wheel so I added these two aluminum braces

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_3760_zpsmvkiy3ys.jpg.html] [/URL]

[/URL]

Haha, cool walk-around. The rear suspension alone is kind of mind blowing to see all together. Really impressive build.

In reply to pres589:

Thanks. It's been a lot of work and a steep learning curve (lots of mistakes) but I'm pretty happy with how it's coming together

Made the engine side floor today, I'm definitely running out of things to do until I get more parts

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_3806_zps0lrm0s6u.jpg.html] [/URL]

[/URL]

did you consider making that floor plan slightly concave (upward) in the middle to try for some cheap aero ?

wbjones wrote: did you consider making that floor plan slightly concave (upward) in the middle to try for some cheap aero ?

That is funny you should say that. I thought long and hard about it but the rules say " The belly pan shall be flat within 1.0” (25.4 mm) total deviation. No tunnels or other underbody aerodynamic features are permitted. Chassis rake is free. Additionally, no side skirt or body side, etc., may extend more than 1.0 cm (0.394”) below this lower surface anywhere on the car to the rear of the front axle unless specifically permitted by these rules. "

Sounds like a 1" curve upward towards the rear would be legal...that would act like a tiny diffuser.

Even with the installed driveshaft safety loop, would a failed driveshaft (or parts thrown from it in failure) be able to puncture your fuel cell?

Love your build, keep at it!

GameboyRMH wrote: Sounds like a 1" curve upward towards the rear would be legal...that would act like a tiny diffuser.

A 1" deviation in such a short span is quite a bit.

GameboyRMH wrote: Sounds like a 1" curve upward towards the rear would be legal...that would act like a tiny diffuser.

But I might be protested because that could be seen as an underbody aerodynamic feature

Apexcarver wrote: Even with the installed driveshaft safety loop, would a failed driveshaft (or parts thrown from it in failure) be able to puncture your fuel cell? Love your build, keep at it!

Not likely but nothing is impossible

I admit my idea flies in the face of the spirit of the rules but it does conform to the letter ![]()

Edit: Hey I remember you used to run a big diffuser way back when this car was mostly a Jag. I'm guessing the cars started to become too underbody-downforce-dependent and the SCCA didn't like the safety aspects of that?

GameboyRMH wrote: I admit my idea flies in the face of the spirit of the rules but it does conform to the letterEdit: Hey I remember you used to run a big diffuser way back when this car was mostly a Jag. I'm guessing the cars started to become too underbody-downforce-dependent and the SCCA didn't like the safety aspects of that?

If you look at the people at the top of the class, they are following the letter of the law but not so much the spirit. Just take a good look at the rear spoiler of the winning EM car fi you're wondering what I'm talking about. I have some ideas for what I can do to the floor that aren't as permanent as curving the underside. Diffusers are allowed and I will be using one on this car. There is a limit how big they can be.

I love Nitinol.

Think of the possibilities if the exhaust developed a leak in a certain spot on the under-tray. Or if the under-tray were supported in the middle by brackets made from Nitinol.![]()

In reply to NOHOME:

We are allowed blown diffusers and I can have exhaust vent out the floor, too-but these things only work at full throttle and make a car unpredictable when you lift for a turn.

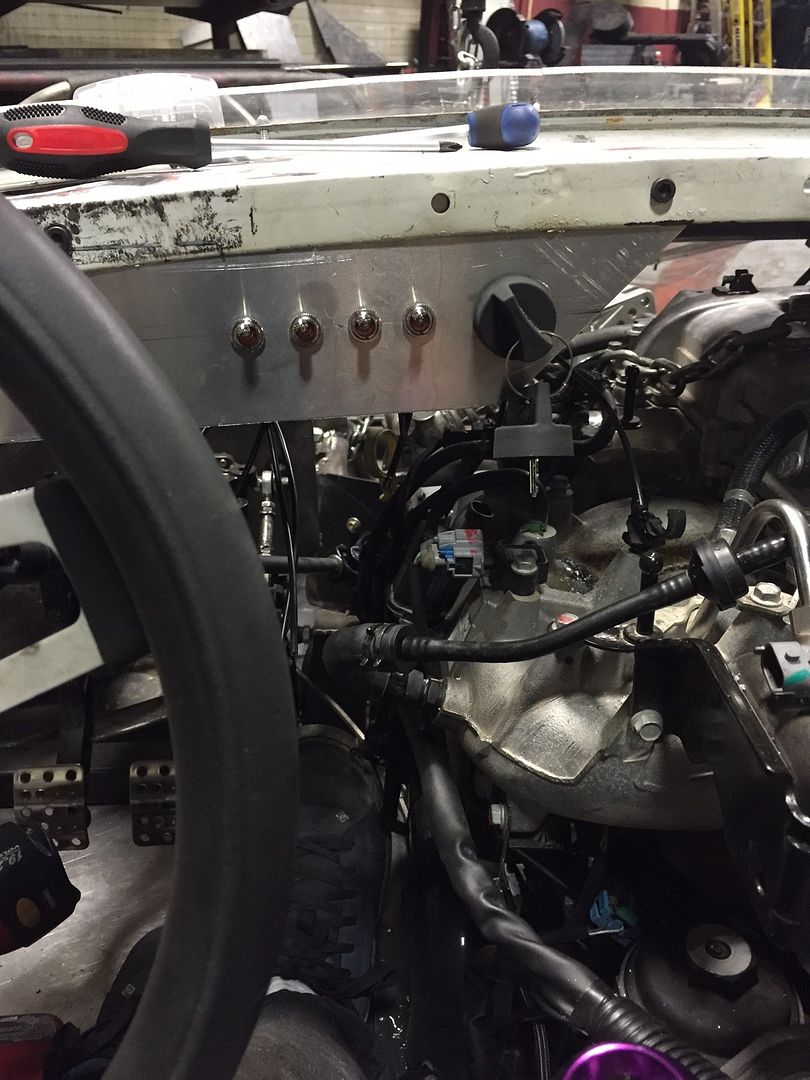

The wiring harness and intercooler pipes/connectors arrived so I got started on the electrical. I got some aircraft quality waterproof switches and keyed switch and put them in the dash. However, the keyed switch has a wiring harness from the space shuttle so I'll be swapping it out for something simpler.

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_3849_zpsuolmugas.jpg.html] [/URL]

[/URL]

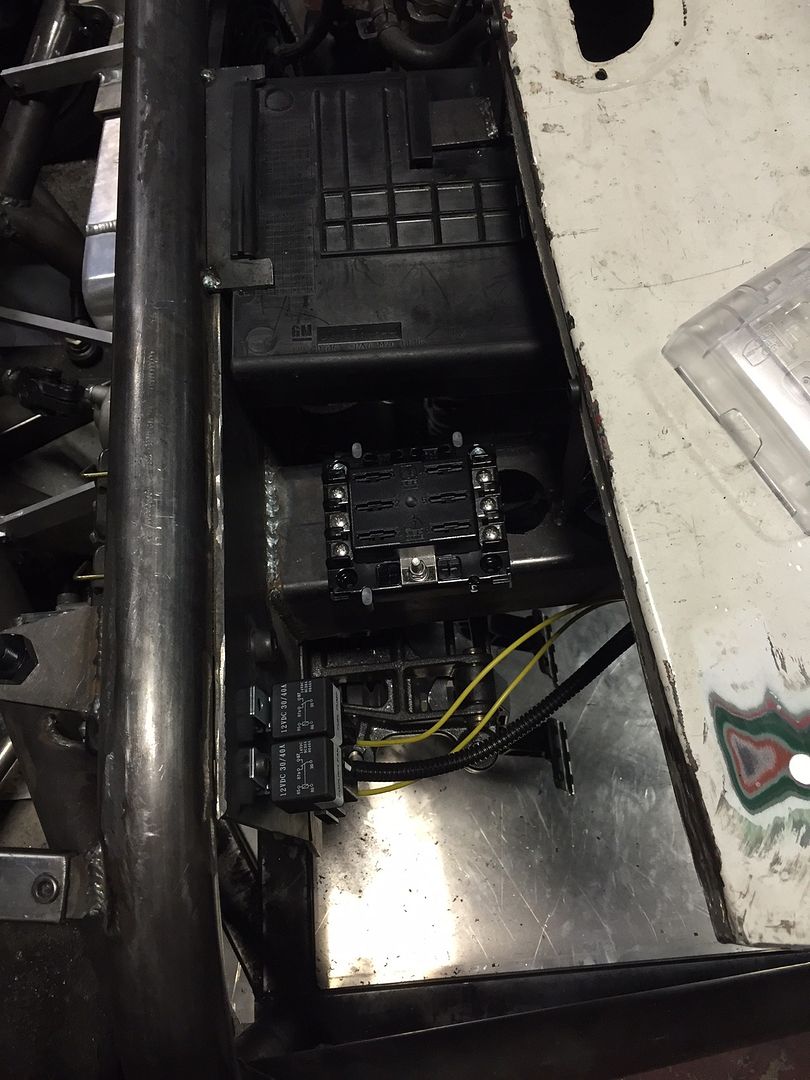

That black piece of plastic at the top of this picture is the ECM holder, and beside it is the fuse box (not wired up yet) and the relays for fans and fuel pump

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_3852_zpsmqvwhoh1.jpg.html] [/URL]

[/URL]

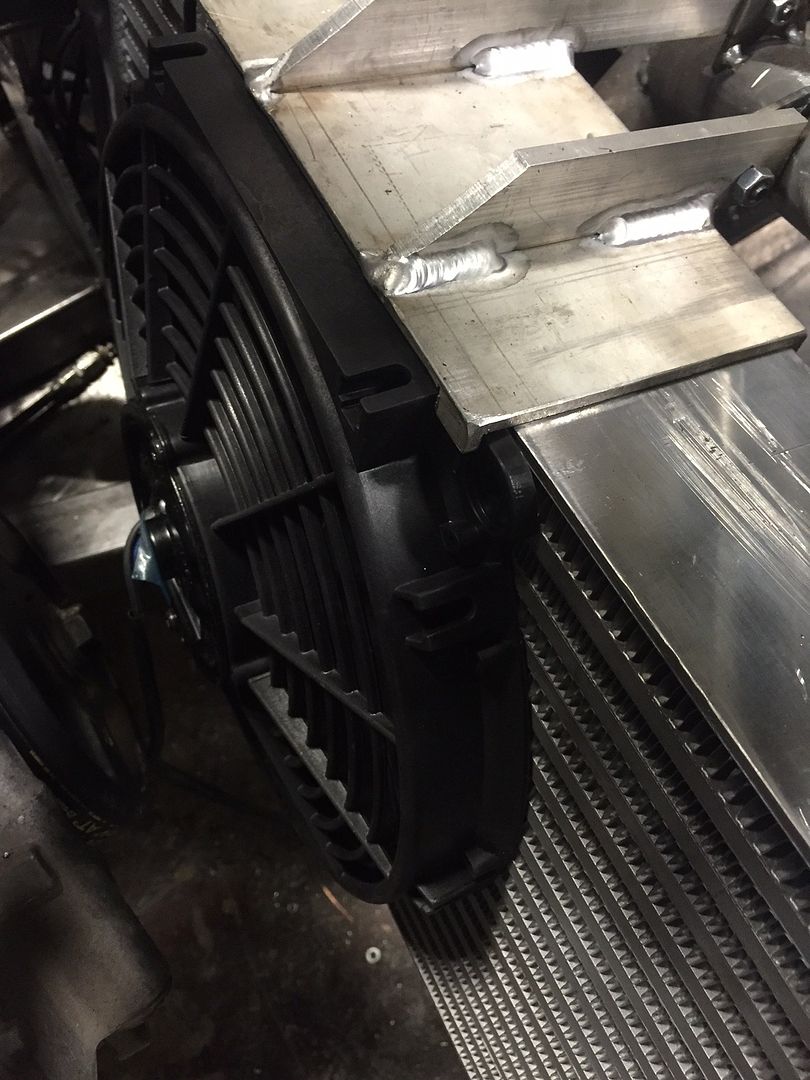

I rebuilt the intercooler mount so it can also hold the fan in place also. Simplify and add lightness

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_3836_zpsydwgoxqi.jpg.html] [/URL]

[/URL]

NOHOME wrote: Are you doing the aluminum welds with a spool gun?

I can't weld aluminum, it's farmed out to a friend and I believe it is TIG

Another part from the old car is recycled. I bolted the old battery box just behind the passenger compartment and ahead of the rear tire. I also bolted on the master kill switch and started on the wiring. The engine is drive-by-wire but it's more like 10 little wires that had to be soldered and heat shrinked. The intercooler fan is now hooked to a switch and works great. I'm not a fan of the wiring, it just seems to look like a rats nest no matter what I do.

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_3857_zpscmabkezk.jpg.html] [/URL]

[/URL]

would wire looms help with the rats nest look ?

and keep in mind that some SCCA Solo tech guys are really anal about the relocated battery boxes (our tech chief … for whom I "work" is that way) he'll turn down any vehicle that doesn't meet the letter of the rules … if I remember correctly it has to be, and I'm not sure of the actual wording, a sealed marine grade box … or words to that effect … yours looks great, but I'm pretty sure he would have a problem with it … don't know how anal they are at national tour events

FWIW, the other tech guy and I both know the ones in our region that have great builds but open battery boxes relocated to the back, and we've gotten them to cast an eye at tech and make sure the boss is off walking the course before they bring their car to us …LOL

You'll need to log in to post.