Update (New goodies in the car):

Dual Stage Boost Controller, currently setup for 8 PSI low and 18 PSI high. A nice cam with 9 degrees of overlap @ .050, which should sound great with my uneven cylinder pairing and sidepipes. New valve springs to handle the lift and fix my valve float issue. New seat belts. I'm also currently working on a $26 methanol injection setup that should work every bit as good as the $200 one I bought from Cooling Mist.

I'm hoping with the cam, valve springs, and methanol setup, I'll double the power at 8-10 PSI that I had before on 8 PSI with the stock cam and springs.

18 PSI should drop me right in the 800-1000 HP Goal I set.

AwesomeAuto said:I'm also currently working on a $26 methanol injection setup that should work every bit as good as the $200 one I bought from Cooling Mist.

Please post up a build list when you get this sorted out. I have been looking at dyi building soon.

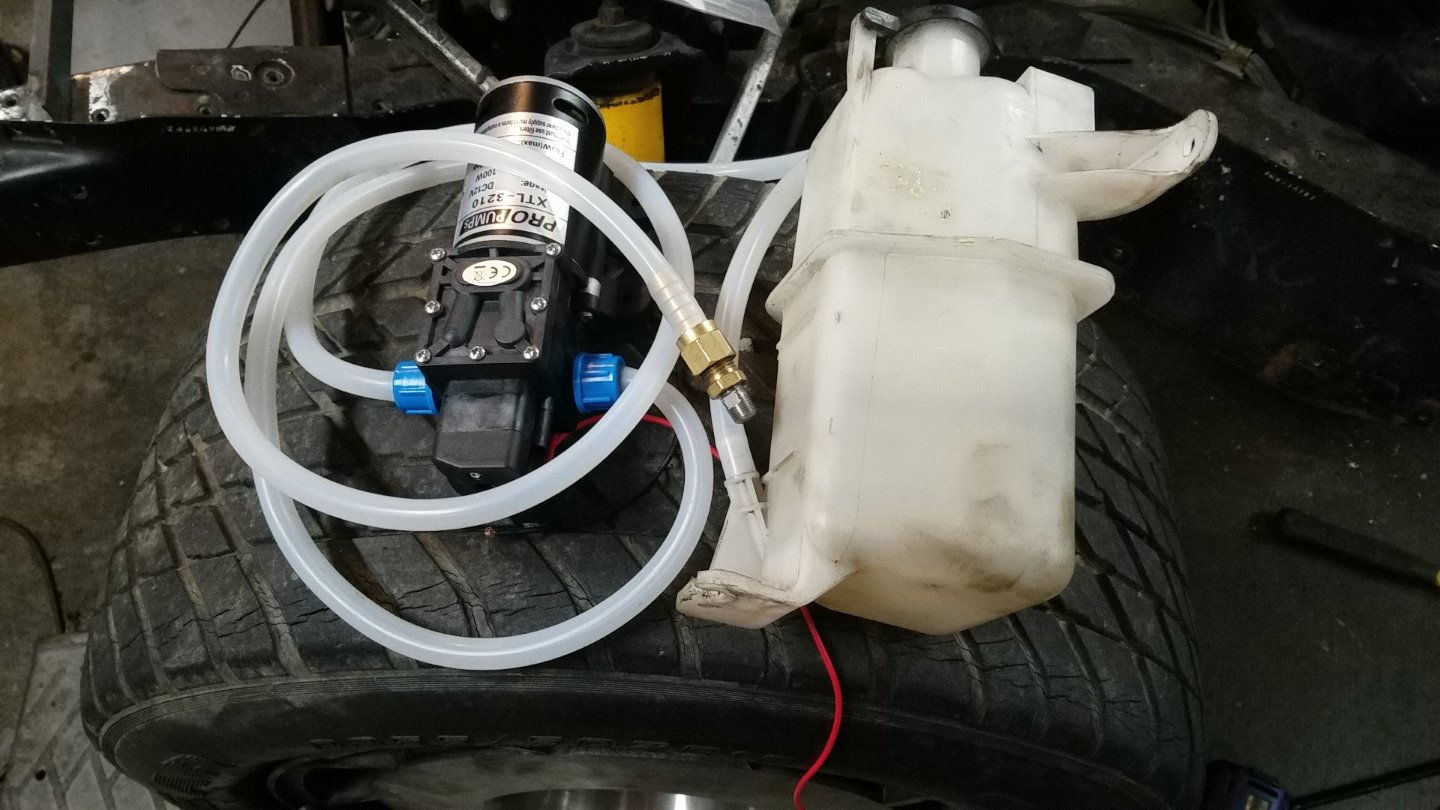

Well, I noticed everyone has stopped using the pumps offered by the methanol companies for DIY setups because of price. They've all started using the Shurflo pumps from Northern Tools which are $70. After about an hour of research, I found that the Shurflo pumps are just rebranded $20 chinese water/chemical irrigation pumps that you can buy on Amazon or ebay.

For the nozzle, you don't have to spend $25-40 on a nozzle from one of the meth companies and then another $30 on the holder for it. Just get a $5 water misting nozzle from ebay, local hardware store that has a garden section, or worst case spend $8 and get a misting nozzle from McMaster Carr. Then you can use an NPT to pushlock adapter for $2-4, some cheap ebay nylon pushlock tubing, and you're done. Use whatever you want for a bottle. 2 liter, 20 oz, or even use the gallon jug that the windshield washer fluid comes in (I typically spray washer fluid anyway). In my case, I can just 3D print a bottle of any size/shape.

It looks like I can score the nozzle for $5, pump for $18, nozzle holder for $3, print my own bottle, and use some spare nylon pushlock tubing I have laying around leftover from Snow Performance and I'll have $26 in my single nozzle methanol kit. It'll cost me $67 if I decide to use the old boost reference ports on each of the compressors and make a 4 nozzle setup.

In reply to AwesomeAuto :

Here's my ancient parts list for that sort of hardware that might help someone: http://not2fast.com/thermo/water_injection/hardware.shtml

I like kart fuel tanks for the reservoir, they are expensive, but have super-robust mounting which saves you a lot of time in that regard.

My $15.40 meth kit. It sprays very very nicely.

Also, I'm taking up the ambitious project of creating an electronic paddle shift system to control a manual TH400. The software behind it is fairly simple. Right button would be the same as pulling the shifter back, left button would be the same as pushing it forward. A GPS module will send MPH data to the controller that would only allow it to shift into Park, Reverse, or Neutral while not moving. It will also prevent downshifts based on MPH for each gear. If I really wanted, I could have it turn a manual valve body back into an automatic. The hardware part is the only complication. The high speed actuator and paddle shift setup will be a tad expensive. I still think I can do the whole thing for $200. It will make autocross and road racing this thing way more fun with a quick ratio steering rack.

conesare2seconds said:Looks like those are some very old GY GSCs. They will try to kill you, use caution driving on them.

LOL those are spare burnout tires. I grab used tires for pretty much nothing and then go smear them into the pavement. No worries, they won't make it far.

I figured out the paddle shift project. I'll be starting on it in the next few weeks. I bought some paddle shifters today and a way to actuate the shift lever on the trans. I honestly think that the total cost for a control board, LCD screen for gear indicator, actuator, paddle shifters, GPS module is going to come in for under $100 for the finished product, and I'll have a fool proof way to paddle shift a manual valve body.

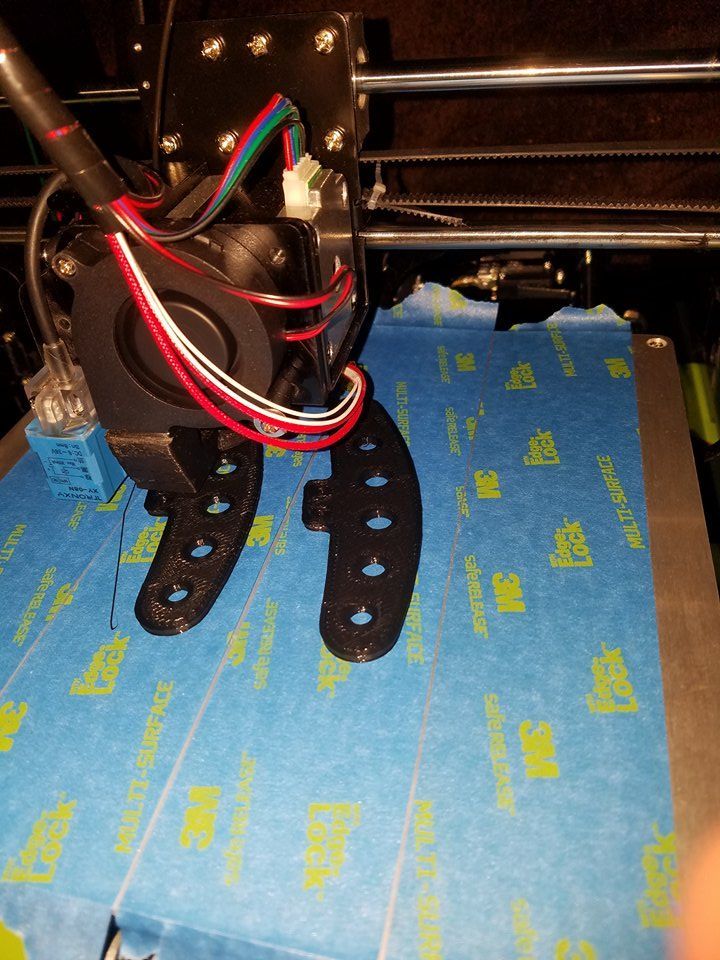

I was up until after 4 AM this morning. I 3D printed some paddle shifters, used some limit switches to activate them. I just need to mount them now. I dug up an old cruise control module and after slightly modifying the code I use for my idle air control stepper program, I had the cruise control module controlling the shift cable to my transmission, and TADA, working paddle shifters. I'm going to be in this whole thing for probably $20.

In reply to AwesomeAuto :

Interested in selling them? That sounds like exactly what I want to do to my C4 after I LS/4l60e swap it.

A 4L60e is slightly more complicated. My transmission will be getting a manual valve body, so shifting through the gears is no problem with paddle shifters. Each click is a gear, cut and dry.

A 4L60e is electronic and uses solenoids. You can use the paddle shifters to physically control the shift level position, but the trans won't always be in that gear. Put it in a particular gear, and it will have access to that gear, and each gear below it. So if you click it into 2nd and come to a stop, you will have 1st and 2nd gear when moving again. Click up to 3rd, and it'll be able to shift itself from 1st/2nd/3rd.

You could either add a transgo stage 3 increasing trans durability and converting it to full manual, or I could play around with tapping into the wiring harness to take control of the shift solenoids to force a specific gear.

AwesomeAuto said:I was up until after 4 AM this morning. I 3D printed some paddle shifters, used some limit switches to activate them. I just need to mount them now. I dug up an old cruise control module and after slightly modifying the code I use for my idle air control stepper program, I had the cruise control module controlling the shift cable to my transmission, and TADA, working paddle shifters. I'm going to be in this whole thing for probably $20.

Cool. I'm a little surprised that a cruise control module is strong enough to move the shift lever on a TH400.

In reply to AwesomeAuto : I really like your approach. What's more you tend to demistify complex subjects and get right to the nuts and bolts.

How about helping an old geezer who is terrified of computers? What did you have to do to make the stock computer accept your turbo's?

When you put your motor on the pump to check its power will you be using E85, racing gas, or something else? I'd think the potential power gain from E85 would be extremely enticing.

stuart in mn said:AwesomeAuto said:I was up until after 4 AM this morning. I 3D printed some paddle shifters, used some limit switches to activate them. I just need to mount them now. I dug up an old cruise control module and after slightly modifying the code I use for my idle air control stepper program, I had the cruise control module controlling the shift cable to my transmission, and TADA, working paddle shifters. I'm going to be in this whole thing for probably $20.

Cool. I'm a little surprised that a cruise control module is strong enough to move the shift lever on a TH400.

Only barely. It uses a plastic worm gear which isn't going to last much longer. The stepper motor is plenty strong, but slow. I'll be upgrading them both for rapid shifts, or I may just take a 12 volt lithium battery with me to a junkyard and walk around jumping cruise control motors, but first I'm going to take apart an old 5.3 drive-by-wire throttle body and see if I can make it work. They are much much faster than cruise control motors, and the throttle bodies are pretty much throw-aways.

frenchyd said:In reply to AwesomeAuto : I really like your approach. What's more you tend to demistify complex subjects and get right to the nuts and bolts.

How about helping an old geezer who is terrified of computers? What did you have to do to make the stock computer accept your turbo's?

When you put your motor on the pump to check its power will you be using E85, racing gas, or something else? I'd think the potential power gain from E85 would be extremely enticing.

I'm using microsquirt on this one so it isn't a stock computer.

A stock computer will accept turbos just fine with a good tune. A tuner can flash it over to recognize a 3 bar MAP sensor and then it will recognize and tune for boost from turbos/superchargers. Its really not too complicated once you've done it a couple of times.

I'll be using pump gas and windshield washer fluid, since that's what I use in all of my street cars and what I'll be using after I get it off of the dyno. I may mix in a little bit of race gas while tuning just to make sure that I don't grenade it from a hiccup.

3D printing the paddles for the paddler shifters.

It looks like I'll have $3.60 in the paddle shift mechanisms, including magnets and switches.

Paddle shifters are in. High Torque DC stepper is shifting the trans via the shift cable (Its not waterproof enough to put under the car).

I have a GPS module programmed as speedo, boost control, traction control, and shift control. It will not let the car shift into Park, Reverse, or Neutral unless stationary. I'll also use it for a boost-by-speed control of a 3 port MAC valve. I'm reading the rear ABS sensor and comparing the speed to the GPS to determine wheel spin and lower duty cycle on the boost controller. Should work great as boost based traction control.

Car is gutted for cage and paint. I've stripped another 50 lbs out of it, and plan on another 50 more before cage install.

End goals for the car:

-800-1000 HP

-2000 lb race weight.

-Full Cage

-Manual TH400, trans brake, engine braking, very well built, able to handle road racing.

-Road race wing with active aero capabilities.

-Paddle shifted transmission controller.

-Full boost and timing based traction control.

-Multi-stage configurable boost control.

-Flex fuel capable, GM flex sensor to adjust tune on the fly based on ethanol %.

-Fingerprint scanner start. Keypad coded remote starter.

-C6 Z06 wheels/tires for street use.

-LARGE slicks for drag racing use.

-Coilover front and rear conversion

-4-channel backpressure/EGT/wideband monitoring (one for each turbo)

-TOTAL BUDGET: $10,000.

All of that minus Coilovers, 4 channel exhaust monitoring, built TH400, and lowering the HP goal by ~200 HP will be done on my original $5,000 budget.

You'll need to log in to post.