I haven't posted in awhile because I haven't really done much Rx7-wise. I've been spending my time on other projects, and frankly my Rx7 has been working fine. There are exactly three things that have happened with it, so I figured I'd make a brief update to show them here.

First, I finally addressed my speedometer cable issue. When I replaced the speedo-drive seal awhile back, I apparently didn't actually press the seal down onto it's shaft. This led to it not actually sealing anything, and the transmission fluid seeping up through the cable into the back of the speedometer (and consequently the back of my dash). Not a fun time. It also led to the speedometer sometimes jumping up higher than my actual speed. I assume this has something to do with the weight of the little drum inside being thrown off.

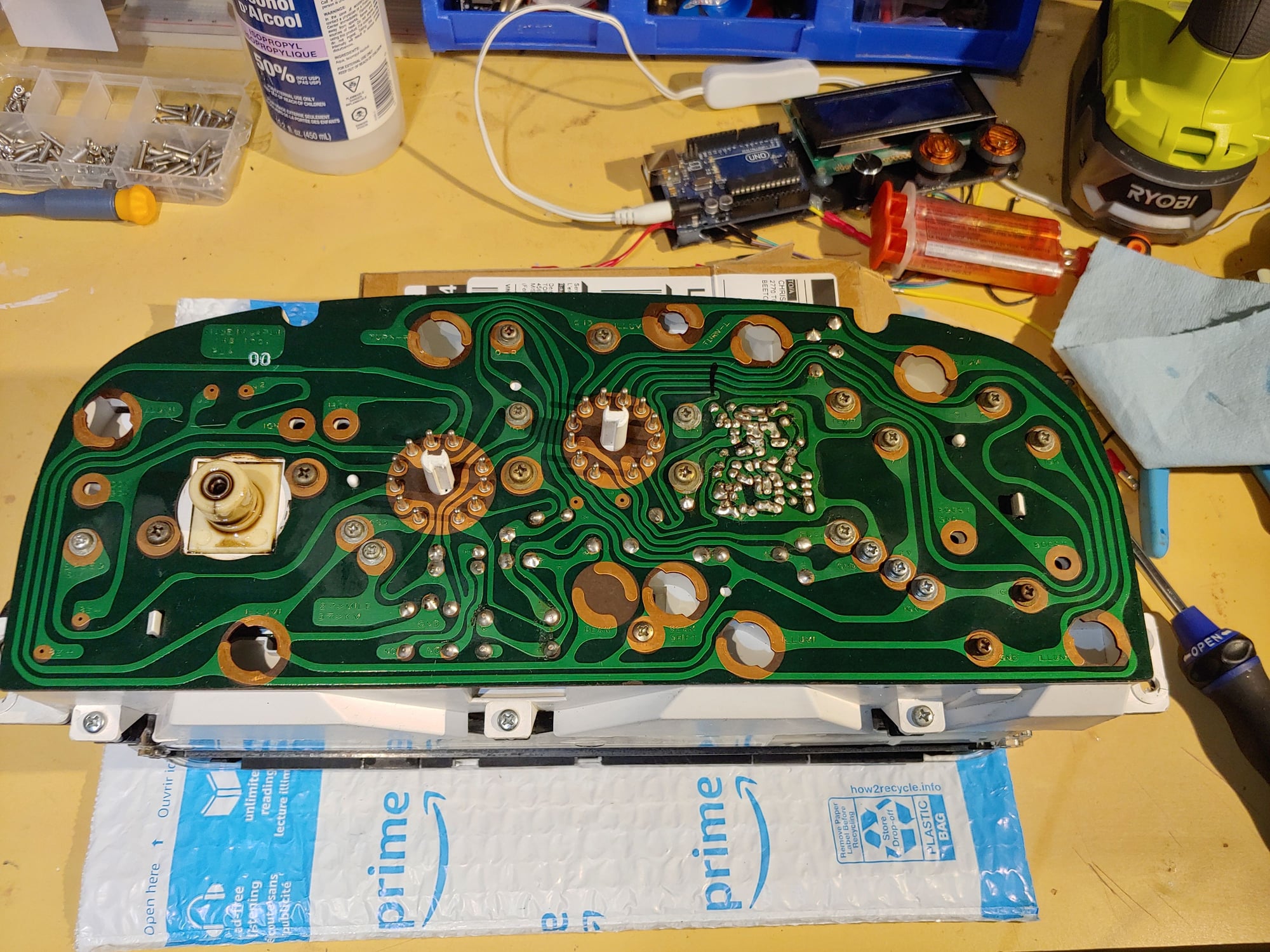

I had fixed the issue with the seal, but fluid kept coming out. It turns out that cable holds a lot of fluid. First things first, I had to clean out the instrument cluster:

This stuff gets everywhere. Just remember, this is about 1/10 of what was soaking the back of the dash...

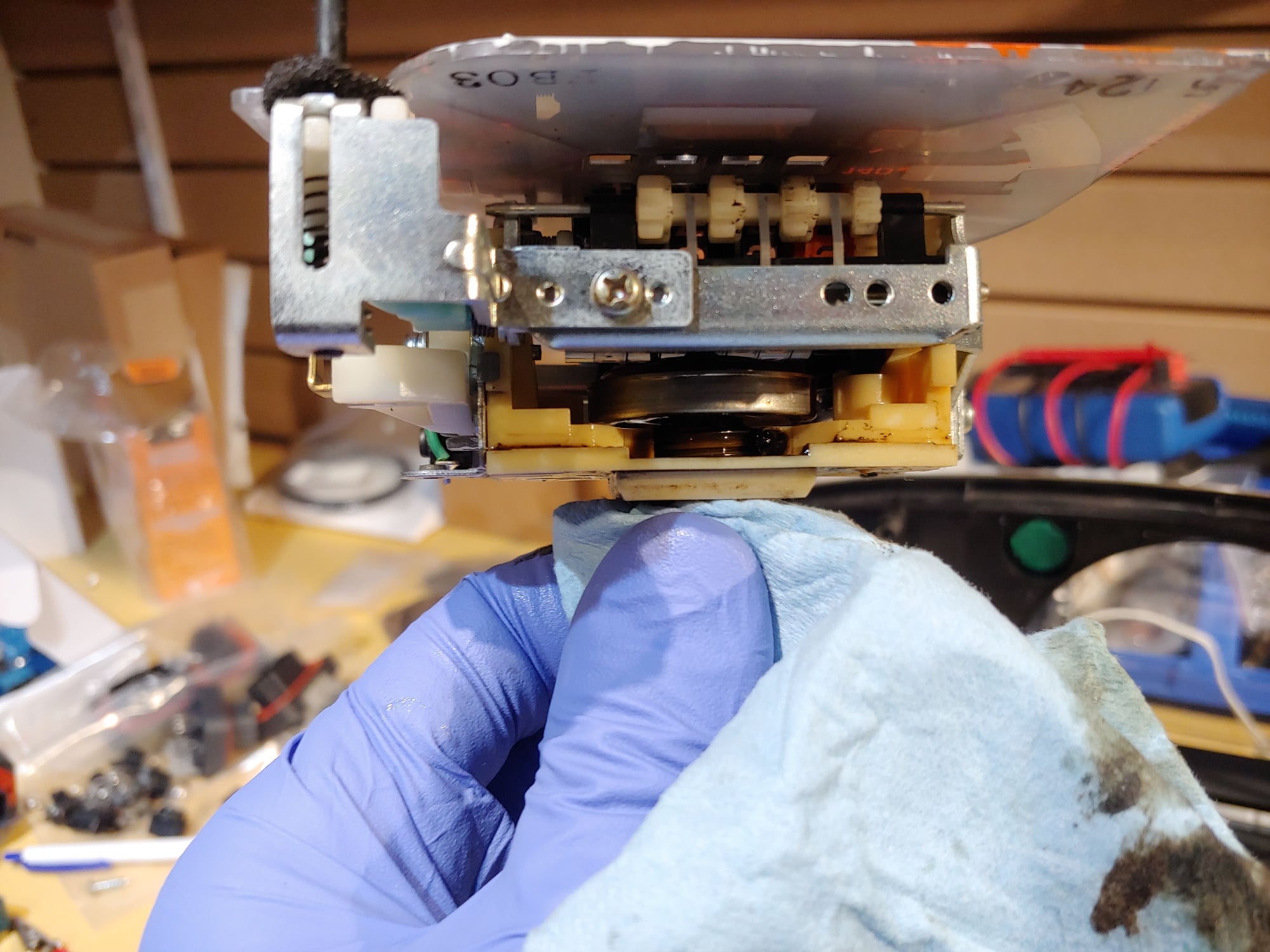

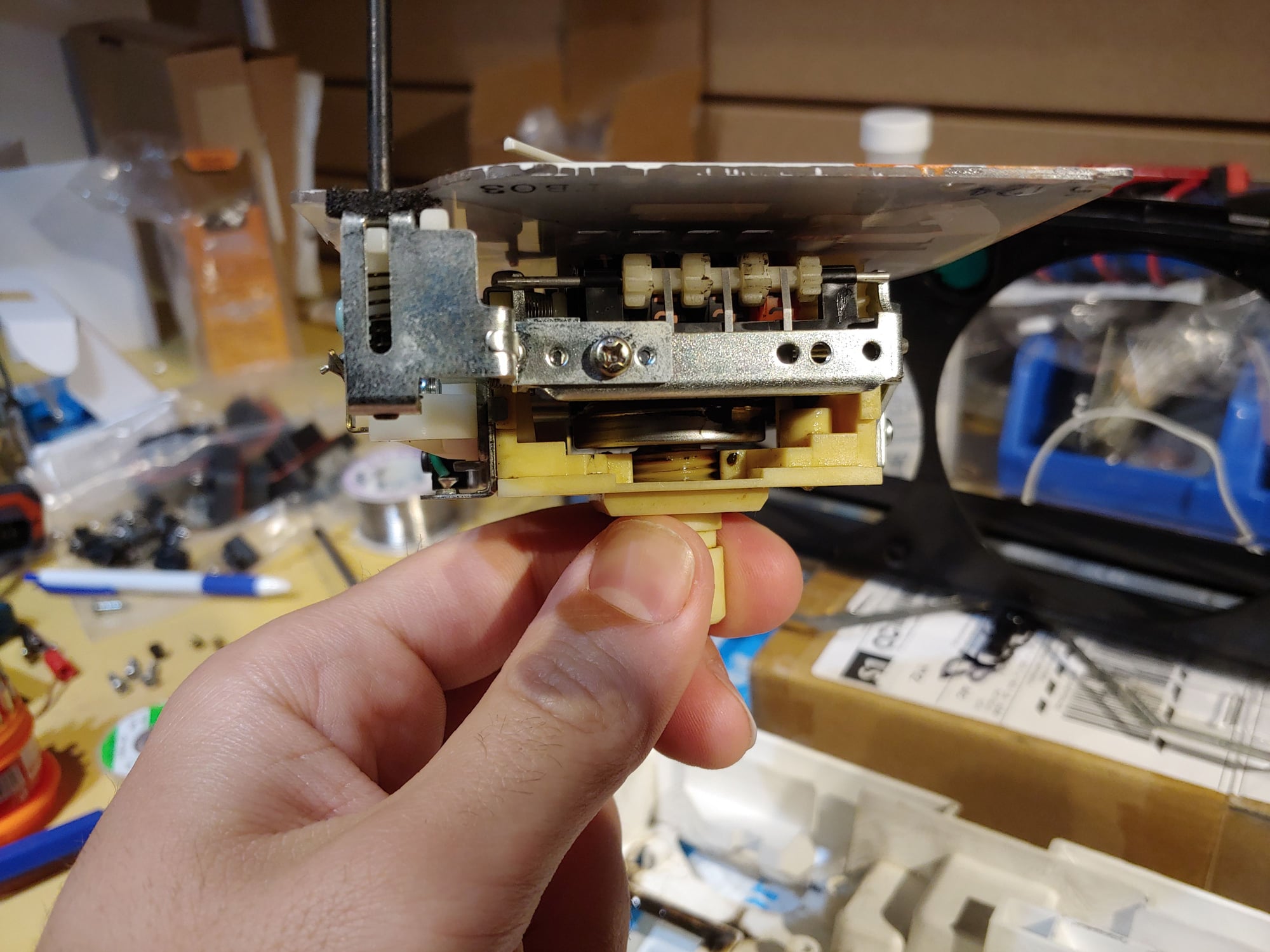

The speedo itself had a lot of goop in it. The gear at the bottom is the area where the reed switch for the VSS signal goes...

There's a reed switch under there, trust me!

I cleaned everything using carb cleaner. I couldn't think of a better solvent or a better way to clean the inside of the metal drum thing. It worked very well, but a warning for anyone else who does this, it will absolutely dissolve the paint used on the odometer numbering and on the speedo face. The only casualty of my repair was some smudging on the "3" in the 1000s column of the odometer, so I'm fine with it. And after all that I forgot to get a picture of the cleaned reed switch.

With that cleaned and reassembled, I needed to clean out the cable. It turns out it's actually very easy:

The cable itself pulls out from the transmission side:

Then I let it soak in carb cleaner for awhile, and spent the time scrubbing the outer sheath:

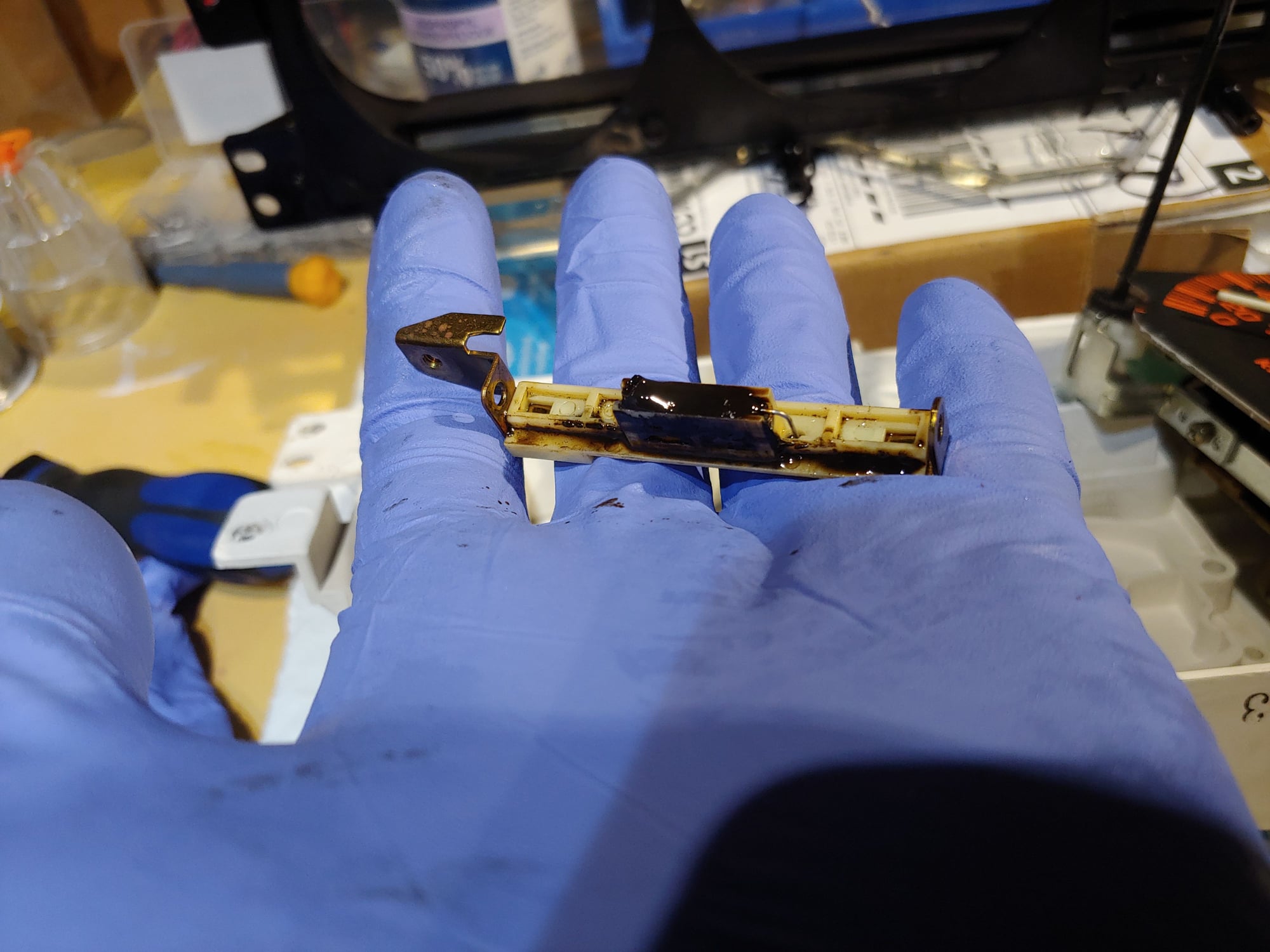

The stuff that came out of the cable was pretty gross:

Then I hung everything up and let it air dry for awhile:

And reassembly was the reverse of removal.

A but underwhelming since nothing has changed, but it was worthwhile just to stop transmission fluid dripping onto my shins.

To be continued.

Continued:

The next thing I did was an impromptu roadside repair. The on-ramp I was going to use to get onto the highway was closed, so I used the access road running parallel to it. At some point the road turned away from the highway, and then into dirt. Of course that's the moment my Rx7 decides to quit on me:

Not a fun place to break down. I had cell reception, but otherwise there was not a soul around. So I got to diagnosing.

Engines need air, spark, fuel and compression. It was reasonable to assume I still had air and compression, and losing all spark at once would be a bit odd. So I started diagnosing the fuel and I realized my fuel pump relay that I added in the rear wasn't clicking.

I first swapped out a spare that I had laying around:

Nope, nothing. Then I realized something:

The relay and socket I had installed came as a kit. I guess whoever did the crimping in the factory that day wasn't doing a very good job.

One tool I didn't have at the side of the road was a crimper. So instead I straightened out the wiring a bit and jammed it back into the crimp, then the crimp back into the housing. Then I used a small section of the green wiring to wedge the wiring in, and some harness tape plus a zip tie to hold it all together:

It was good enough to get me home, and then when home I replaced the crimp terminal. I also flowed some solder into all the terminals as insurance. All in all it was <10 minutes to get back on the road, so I'm glad I was carrying some basic tools and supplies.

One more little project to come momentarily.

This last project probably goes beyond "minor maintenance" but it only took a few hours so I'm lumping it all together.

Occasionally I would get a whiff of fuel from the rear of the car. This was more frequent on hot days, but sometimes weeks would go by without smelling anything. I had inspected multiple times and found no issues, so I chalked it up to the fuel tank venting pressure or something.

This weekend I was pulling into the driveway and I noticed the smell was a lot stronger than normal. So I took another look and still found nothing amiss from the outside. But after pulling the access panel I found a rust hole through the steel breather tube:

It's under the tape in this photo, as I wanted to minimize the fumes escaping. Here's a close-up I took afterwards:

Surprising that the fuel smell could be so strong out of such a tiny crack.

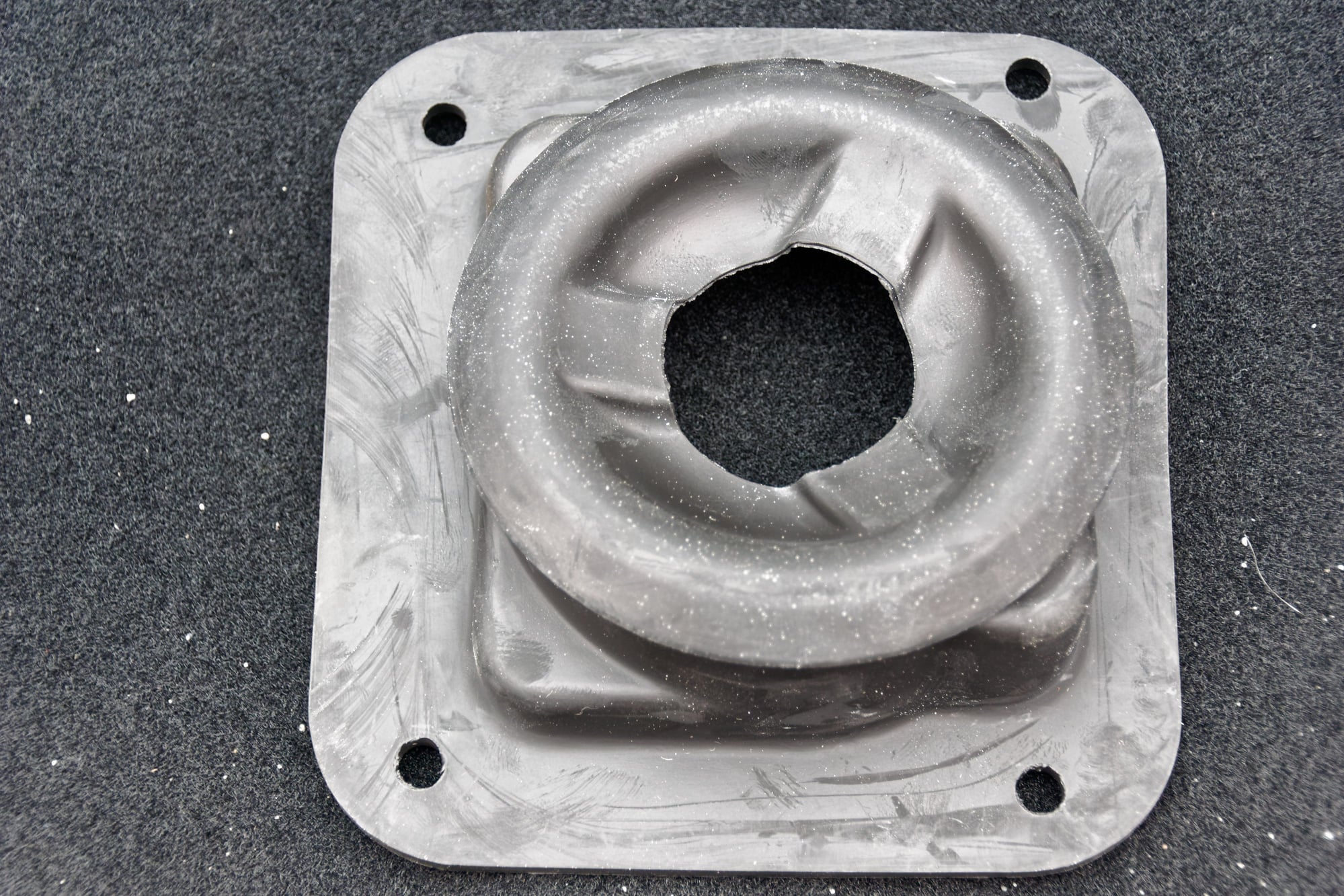

Anyways, I needed a new part. Unfortunately it's NLA from Mazda, and nobody I know locally has one. Someone was able to refer me to someone who may have one, but he's out in Guelph which is about 1 1/2 hours from me (one way). So instead I figured it would be faster to just fabricate a new part.

On removing the old part, you can see it was pretty crusty.

It also has this sock-thing on it, which goes on the filler side of the tube.

Looking down the sock, I thought I might have bitten off more than I could chew. There is a little one-way valve inside, which would have been beyond my ability to replicate:

Conveniently it's a removable insert though:

I got the materials next-day shipped from Amazon. One scratch-and-dent exhaust tube (1.875" OD), and another steel tube for the breather (5/8" OD):

Then I cut the tubing to the appropriate length:

And rolled beads:

I used an Amazon bead roller for the larger tube. I do not recommend it, since it doesn't have any adjustment for the backstop and it causes the bead to drift around a little bit. Probably fine for intercooler pipes, but really not a great tool.

The smaller tube was too small for the bead roller as well (advertised for 5/8" pipe, but they didn't specify ID or OD). I ended up heating the ends with a torch and banging them down onto the end of the vise handle to flare them out just a bit.

To be continued

Continued:

I cut and bent some metal brackets to hold the tubes together, then de-burred everything and aligned all the parts:

The two pipes are not directly parallel, so I tacked it together and then massaged the brackets until the angles were correct. Then I finish welded it:

My welds got a bit messy due to the confined space, but overall I'm fine with it for a part no one will see.

I'm pretty happy with how it turned out. The two parts are functionally identical. Regrettably only the breather tube is stainless, so I did have to find a way to prevent rust. Electroplating the part was an option, but some of the parts I have plated in the past haven't lasted. So instead I just opted to paint it:

Then the insides of the tubes got a coating of motor oil before installation. It doesn't see a lot of moisture, so hopefully the gasoline coating the inside of the tube periodically will be enough to prevent it rusting from the inside out.

I forgot to photograph the little valve being installed, but basically I just notched the end of the tube in a few places to let the valve slip in like it did on the OEM part and then reinstalled the sock. Then the whole thing got reinstalled into the car. Again, underwhelming since the car functions the same as before. But I saved myself some time and money driving all the way out to find an OEM part, so I'm happy with it overall.

That's it for now. I have a few things on the go but no other completed work to show yet. Until next time :)

This afternoon on my way to work I filled up the car, and I noticed two things. A. A loud "psssht" noise that indicated my tank wasn't venting, and B. I could only fill about $0.20 of gasoline at a time before the nozzle would click. It took me about 15 minutes to pump in 1/2 tank worth of fuel. I figured that maybe the cracked breather line was actually helping to mask another issue with a blocked tank vent or something.

I could maybe band-aid the breather problem with a vented cap until I figured out the issue, but the filler flow-rate would need to be addressed quickly. After work I did some minor diagnosis. I tested the evap line from the charcoal canister, and found it was unblocked. Then I had a think about the fuel filling so slowly, and decided to take a look in there and see what was up.

I have one of those articulating borescope camera, and conveniently it fit down the filler neck. I immediately saw the problem. Remember this sock thing?

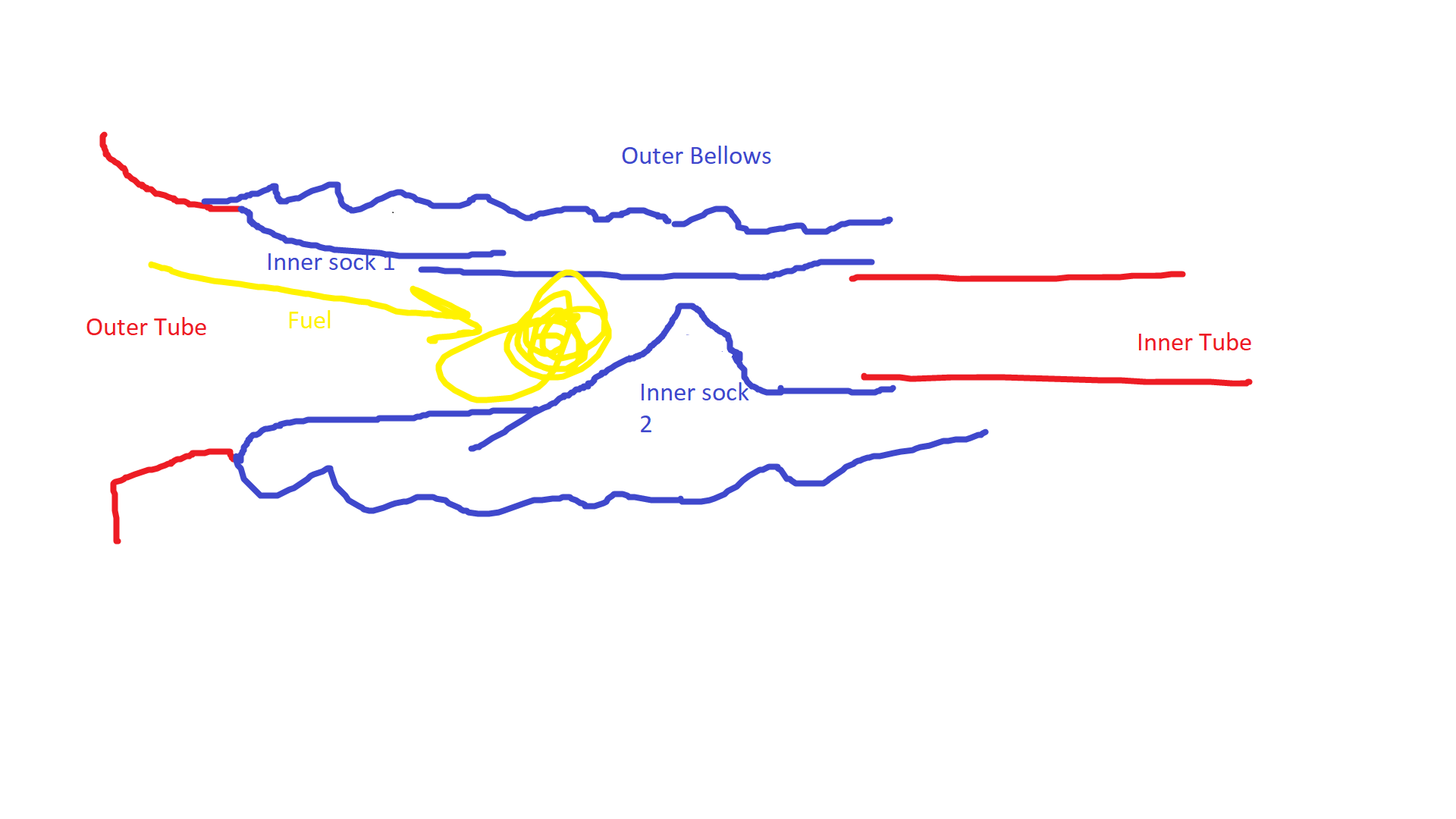

Putting the borescope down the filler neck, I could see it was folded over. My borescope doesn't have a feature to capture the images, so here's a quick 11:45pm MS Paint depiction of what I'm talking about:

That sock thing is one of two socks, both of which sit inside of the outer bellows thing. The idea is that one sock's OD nests into the ID of the other, and then the outer bellows acts as a backup. The bellows looks sort of like the exhaust coupler on a boat, and I think it's just there as an outer seal.

Anyways, the borescope revealed that one sock was folded over and was obstructing fuel flow. This may or may not affect venting, but it's definitely the cause of my fuel-filling woes.

That was all the diagnosis I was going to do for today, but then I was feeling a bit defeated. And I have a rule that I never go to bed feeling defeated. So I went back out and started trying to fix it. I dropped the muffler off it's hangers and removed it's heat shield so I could access the sock, and then this presented an issue.

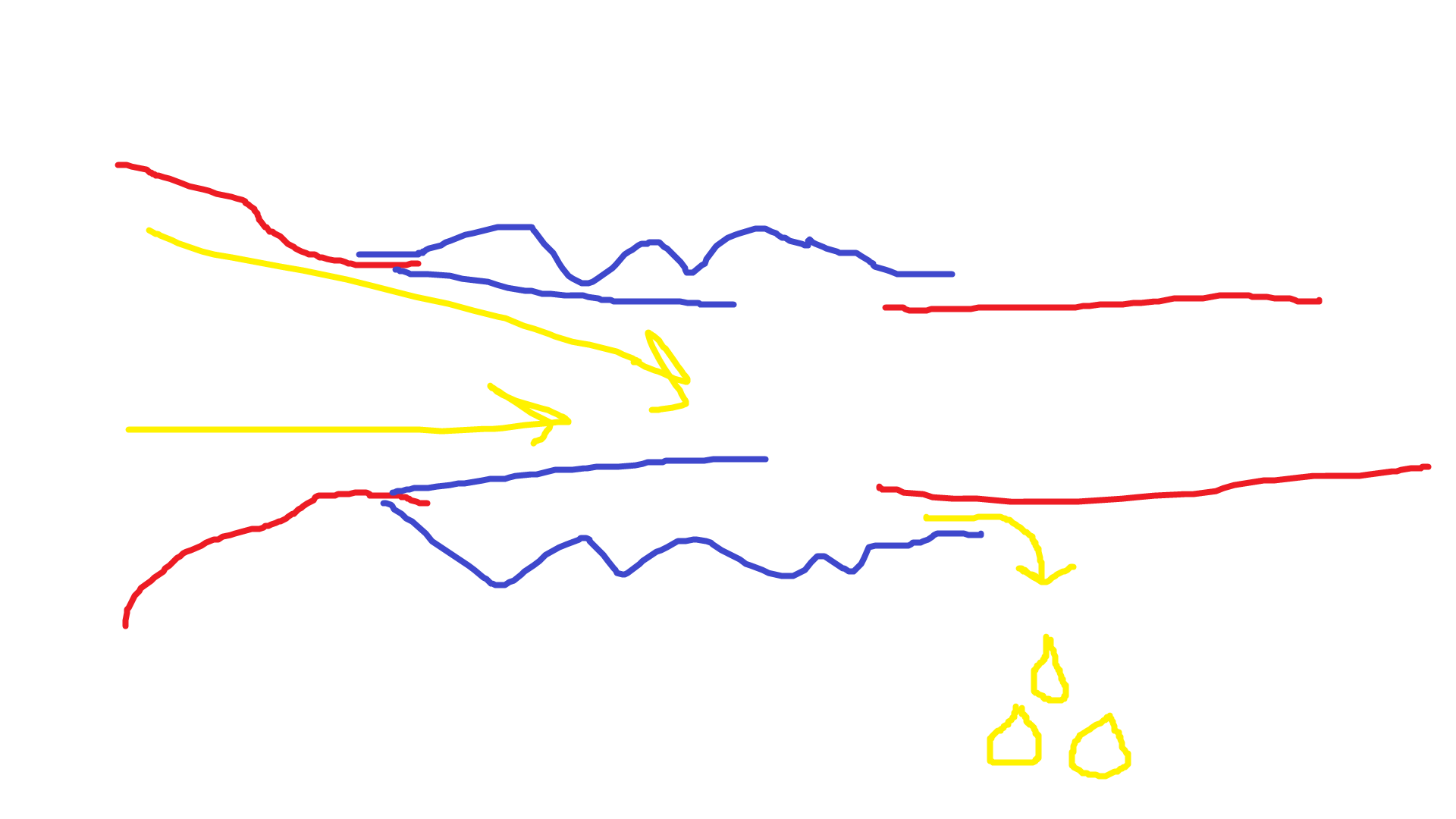

The order this was intended to be installed doesn't seem to be the order I was installing it. The outer sock (coming from the filler side) is supposed to nest inside of the inner sock (the photographed one, coming from the tank side). Then the bellows fits over them. I think the proper way to install this is to remove the outer fill neck and install the bellows over the socks first, then attach it to the outer neck and pop it back in. I investigated that possibility and realized that the inner side of the outer neck (I know, I'm sorry about the bad terminology) is held in with two 10mm nuts.

I looked up and found two vaguely cylindrical things that MAY have once been 10mm nuts, but they certainly weren't coming out without snapping the studs. Snapping the studs means I couldn't secure the filler neck bellows onto the neck again, which means replacing the studs, which are only accessible by de-skinning the quarter panel. That is a non-starter.

I did try removing the inner sock and just using the bellows, but that resulted in the following:

No matter how much I tightened the clamp, fuel would still leak out of it. The ID of the bellows is sized to include the sock, and it just won't work without it.

So what I ended up doing over the course of about 2 hours is meticulously rolling the outermost inner sock up (ironically as one would an actual sock). Then I installed the other sock into the bellows, and from the gas cap side used a screwdriver to feel around inside the bellows and unroll the outermost inner sock into the innermost inner sock. Then I had to manhandle the bellows and sock over the end of the fill tube I reproduced in my last post, which was no easy feat since they did not want to stretch over the end as a unit. This resulted in the following, which is how it is supposed to be:

That doesn't fully capture how much of a pain in the ass this was to achieve, but I tested and I can now see the butterfly valve clearly through the filler neck with the borescope, and I also found no leaks when I did a test fill from a jerry-can. This may or may not fix the venting issue, but it will almost certainly fix the filler flow-rate issue.

I apologize if that was incoherent, but it's the best I can do at this hour. All of the above took about 4 hours beginning to end. I'm going to go wash the Rx7 out of my hair, then go to bed feeling accomplished.

I'll report back with my findings next fill-up. Until next time :)

I'm happy to report that my fuel filler now works properly, and fills at the normal rate. Which is a good thing, since my testing methodology was to coast into the gas station on fumes, so failure was not an option.

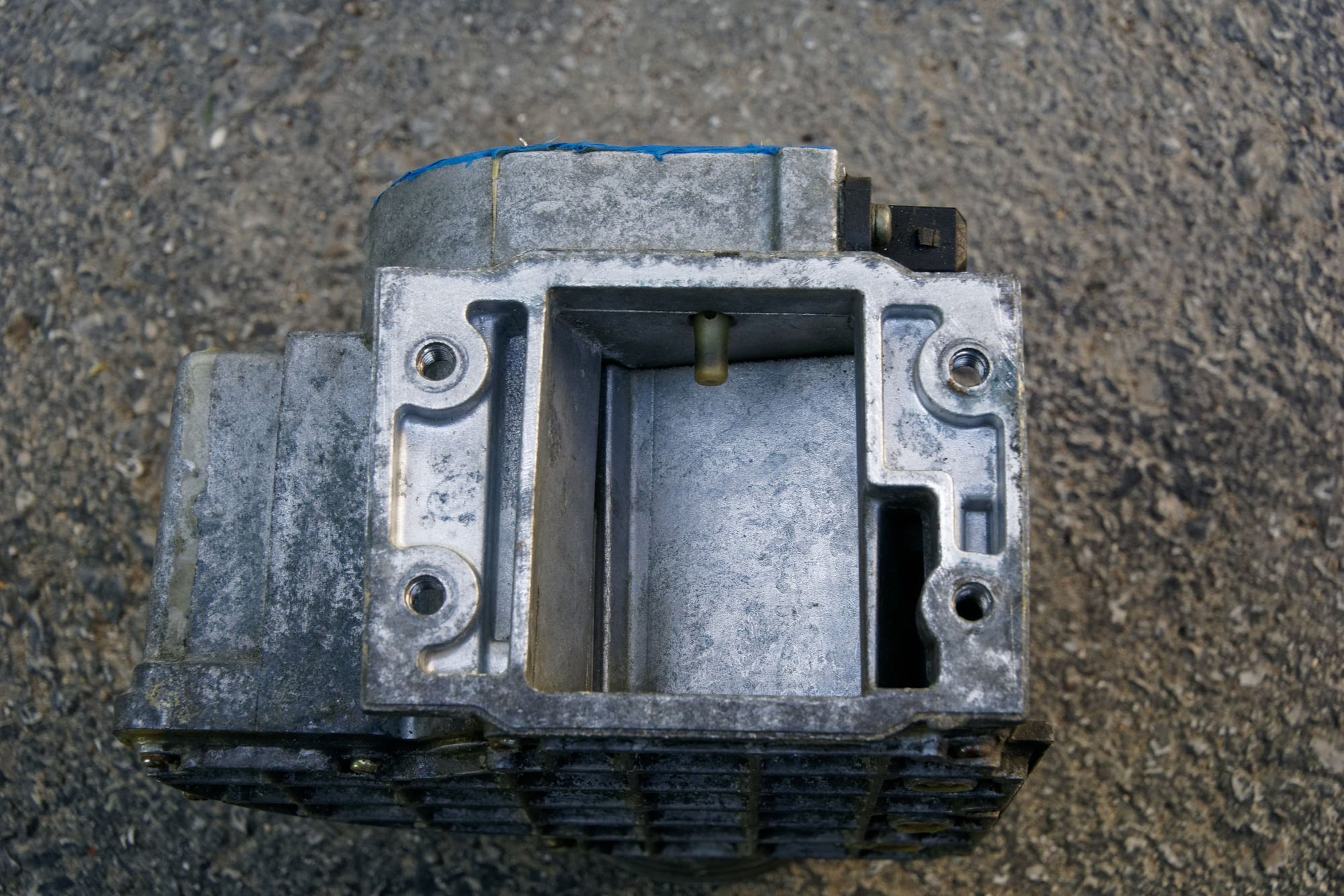

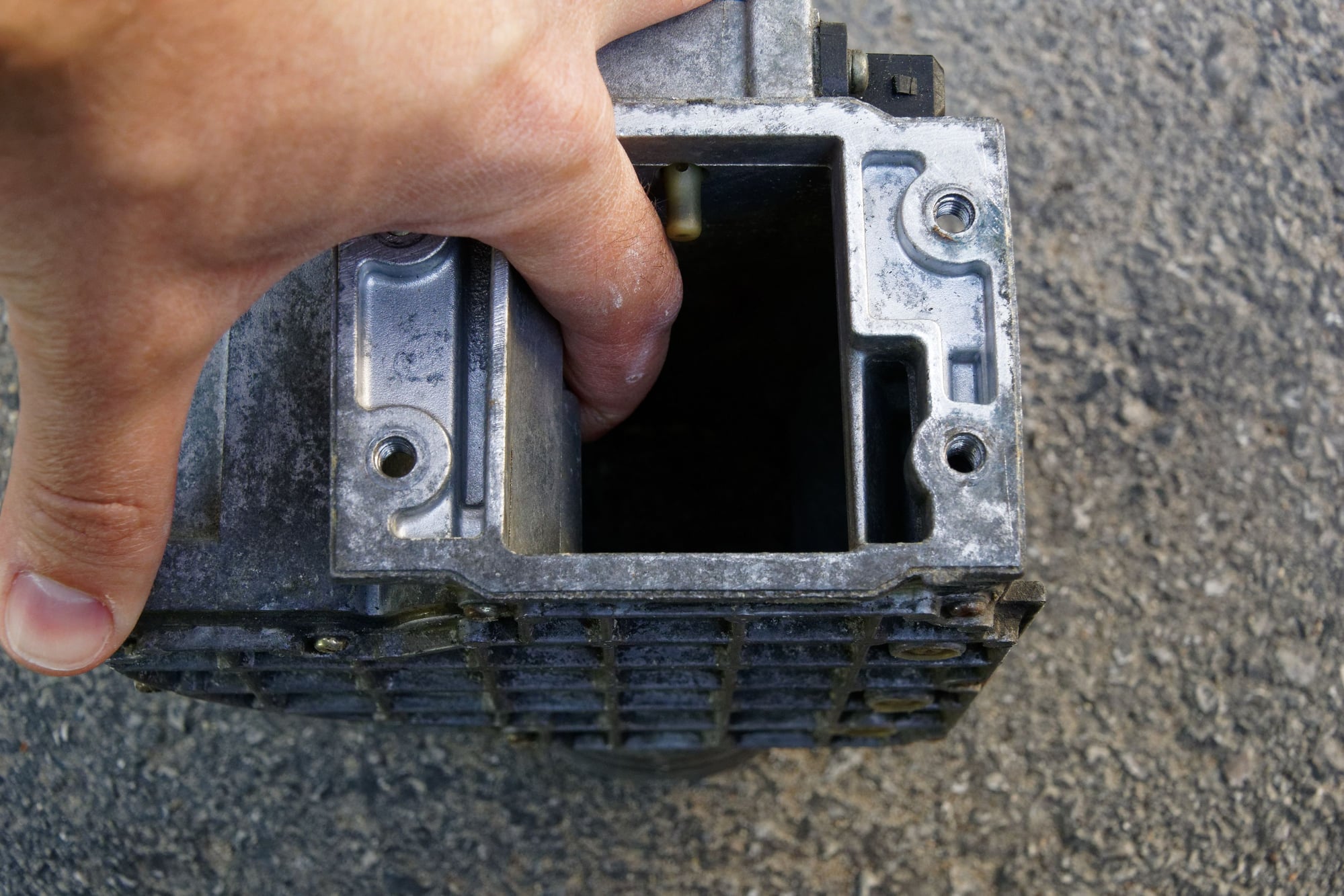

I had some plans change unexpectedly yesterday which gave me a little bit of time for some car stuff. The Bosch L-Jetronic fuel-injection system that came with our cars uses a MAF. In S4 models, it's a big flapper-door inside of an aluminum housing. This flapper door gets pushed open by the flow of air past it, which outputs a 0-5V signal to the ECU and tells it how much air is flowing past.

Since I'm running speed-density with my MS3X, the MAF does nothing at all. I have basically been ignoring it as it's only job now is to adapt the square outlet of the airbox to meet the round tube that goes up to the throttle-body. I've also said many times that the stock intake is excellent and the MAF doesn't pose a restriction, but I may need to eat my words on that (details to come). This is why I didn't delete it in favour of a cone filter, especially since a cone filter will be inhaling hot engine-bay air instead of cool outside air like the stock system.

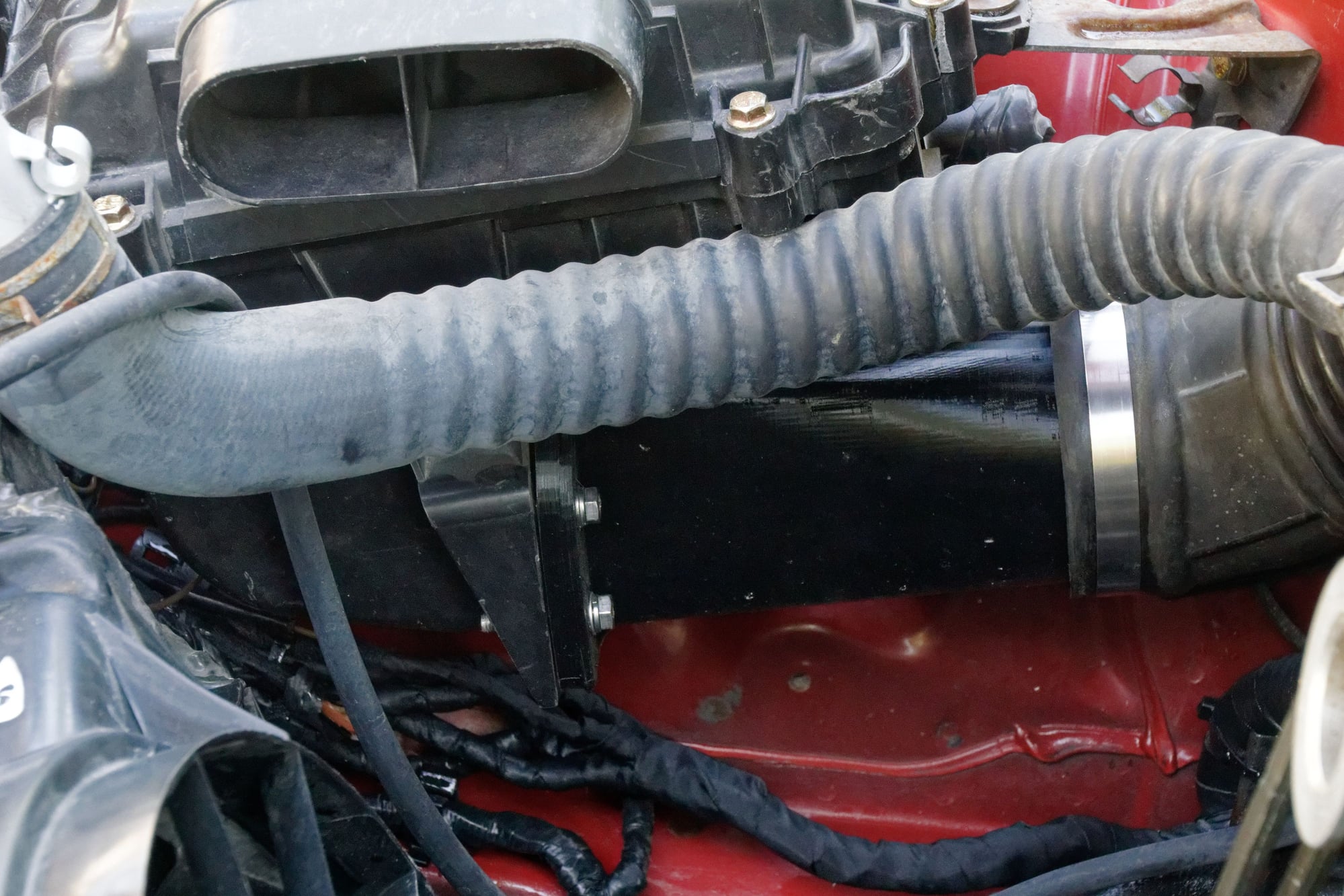

Anyways, forum member Malic was kind enough to share this design he found on Thingiverse that allows you to eliminate the stock MAF entirely. I had been thinking about designing one of these, but this saves a ton of time. After about 18 hours printing I pulled out the airbox to install it:

I printed in PETG since it's what I have on hand, and it should be resistant to engine bay temperatures. 100% infill for rigidity.

Here's a comparison between the two parts:

I think the pipe is a bit longer than the MAF, but fitment is excellent. One weird thing I noticed though:

The person who designed this pipe made the [wise] decision to use all of the available height for the rectangular opening on the airbox side. The opening fits the MAF perfectly but is smaller than the actual opening on the pipe. The thing is, there's nothing behind that piece of plastic. Mazda could have made it larger, but chose not to for some reason.

Then if you look inside the airbox:

That odd looking piece with the half-cylinder at the end is also just a piece of flat plastic. If one were to cut out both of those pieces they would increase airflow, with seemingly no disadvantages. I didn't because I thought there might have been an engineering reason behind it (airflow is a complicated topic), but thinking about it, I wonder if this was a decision made to make it match up with the Nippon Denso MAF rather than for actual engineering purposes. I've seen similar MAFs on the internet for other cars, so it's possible that Mazda added that plastic piece because Nippon Denso used the same MAF housing in multiple applications.

Adding to this, I used to always say the MAF was not a restriction. The reason for this is that A: Many people make lots of power on the stock MAF and B: A small opening flows a lot more air than people think.

But then I started the car with the intake tube open, and held my hand near it, and when I pushed down on the throttle with my other hand I was shocked at just how much air it inhales. It actually almost pulled my hand in.

My fist is here for scale:

I installed the airbox back in and re-tightened the clamps:

And now that I've tested it out, I have to say, it absolutely makes a difference. I don't think there is any difference at WOT, but on snapping the throttle open or taking off from a stop, there is a definite difference. To the point that I had to add fuel in the 1200 - 2000 RPM range of my VE table because it had started to buck slightly, and I'm going to have to play with Acceleration Enrichment as well. I'm thinking that maybe the flapper door isn't a significant restriction for overall flow, but does have a dulling effect on throttle transitions since the air has to push the door open before making it's way to the engine.

I'm really surprised, and this has me considering taking a spare airbox and cutting out those two plastic pieces to see what happens. The top of the airbox where the snorkel enters can also be trimmed back for an easier transition for the air (photos will make this clearer) which might also help.

Is it a huge difference? No. But for about $3 in PETG and < 20 minutes to install, it's absolutely a worthwhile change.

While in the area I decided to save some weight by removing some of the other stock EFI stuff I had around. I like everything to be reversible (and it still is, since I haven't altered the harness), but at a certain point you have to accept you aren't going to be returning your car to stock. I don't know where exactly that point lays, but I've definitely passed it.

I took out the stock MAP sensor (not in use), idle mixture varistor (not necessary), TPS check-light (redundant), Air-Bypass Relay (controls something that is no longer needed or installed), and some miscellaneous brackets. Then I tied all of the harness stuff down with some zip-ties:

Remind me to get a 6 pin Yazaki for that relay that has been installed with spades into the harness connector. It only controls the retractor headlight motor, but still, better to do it right.

That ring terminal ground is there just to replace the low-coolant sensor since mine broke, and it makes a very loud noise when not grounded. I relocated it under the airbox.

The next thing to remove would be the stock CAS, but removing it would leave a hole in the front cover. I did design and print this part for use as a plug on the Turbo II engine:

However, I don't want to put it on an engine that will actually be running, since I don't feel comfortable leaving it exposed to such heat. Clogging my oil pickup with PETG would be a bad time. I might have some carbon-impregnated Nylon filament coming for a future project, so I would probably print this part and another MAF tube with that since I can reduce infill and optimize both parts.

Since I'm using a Ford Taurus alternator and custom bracket, installing that plug would make it easier to run shorter belts and tuck the alternator lower. This prevents it colliding with the intercooler on the Turbo II engine, and theoretically having it lower is better for handling.

All of the above (plus emptying my interior of excess stuff) saved about 7lbs. And while it's unlikely to matter, incremental savings help to offset all the weight I've added over the past few years.

There are probably some other easier pickings too (smaller AGM battery), but in the meantime, I have some more weight coming in the mail. Hopefully it arrives soon so I can post about it.

Until next time :)

So, I realized I had actually written most of this post awhile back and never actually posted it. I ended up finishing it last night, but it is kind of hard to formulate all of the work in this update into one cohesive post. I am going to try and relay it in the order that makes most sense but I can’t help but feel it’s a bit unpolished. So if anything seems confusing, just remember that it probably made sense in July when I did it.

What does it take to get decent audio in an Rx7?

Someone I know asked me that awhile back, and my answer was that one needed to install 6 ½” components in the doors, tweeters on the door triangles, and a set of 8” subs in the shock towers (a proper box would be better but space is already limited).

This isn’t what I’d done though. I had installed 5 1/4” in the doors. This shouldn’t be a problem in and of itself, but the secondary problem was partial obstruction of the cone. I’ll get more into this later, but the long and short of it was that I needed to make some improvements to my speaker setup.

So join me for this quick two-hour project that spiralled into a multi-day effort spread over a couple weeks. Strap yourselves in for a long post.

I’ve ranted many a time about the deficiencies of the stock system, so I won’t go into them too much. The lack of bass is addressed pretty easily by sticking 8” subs in the shock towers:

I’d done that awhile back.

For proper vocals and clear instruments though, I needed door speakers. The stock 4” under-dash coaxials point down at your knees, so even if you upgrade them the poor placement and aiming is the real killer. Really the correct solution is component speakers with drivers on the doors and then tweeters on the triangles, aimed at head level.

S5 Rx-7s had optional door speakers, so a set of S5 door cards makes for a good starting point. These are what I have been using for a few years. Unfortunately the S4 door has the window track mount in a different location, so the driver can’t be installed in the optimal location and the cone is partially obstructed.

When I installed the 5 ¼” speakers, I thought the obstructed cone wouldn’t be too big a deal, but after driving around with them for awhile I really started to notice it. I ended up having to disable the crossover for the subwoofers so they would help with the vocals that were getting lost in the door (up above 400hZ even) and just living with the distortion.

But it was time to rectify my errors, and I decided to make things even harder by upgrading to 6 1/2” drivers. The 5 ¼” would probably be fine if the position were improved, but I decided to go big or go home. This meant locating the bigger speakers in the center of the door opening, and the window track mount would need to find a way to be okay with that.

Pulling off the door card, you can see my previous install:

You can see a few issues. The moisture barrier has come loose and was held on with tape, not to mention the 15 holes cut in it. I would need to replace them as part of this project.

The bigger issue though, is that water was clearly dumping onto the speaker. The driver’s side crossover (zip-tied to the back of that panel) was also wet, whereas the passenger side one was dry in the same position. More investigation would be required later, but wood is also a sub-optimal choice for this application. It works, but there are better options.

I also wanted to take the opportunity to neaten up the wiring for the power locks and the window relays. There are in-fact some crimps under that electrical tape, but not using a connector there just doesn’t sit right with me. The relays for the windows are also mounted in a poor place, and water has started to corrode the contacts. They would probably work fine for many years, but I’d rather do it right.

Starting with the new speakers:

Obviously they’re wider at the cone, but the coil and the frame at the back are also significantly beefier. I really like JBL speakers in terms of value for money. There is better out there, but at the price I am usually quite happy with them.

One thing I was kind of surprised by was that the frame is plastic. I know there are all kinds of different plastics, but when you pay decent money for speakers I would expect a metal frame. This is a non-issue, but just something I noticed. Either way, I got a good deal on these so I can live with it.

Looking at the back of the door card:

I had modified the leather insert from my old S4 door when I last assembled these panels, so you can see where I cut back the material for the driver. That would not be nearly enough for this application, but even if it was:

I had modified the leather insert from my old S4 door when I last assembled these panels, so you can see where I cut back the material for the driver. That would not be nearly enough for this application, but even if it was:

The door card itself has this sort of baffle-thing cast into it. Mazda obviously designed this around a 5 ¼” driver in the S5 location, so this simply won’t do. I then disassembled the entire door card:

One thing I should mention in case anyone else is in a similar situation:

One thing I should mention in case anyone else is in a similar situation:

The door vents are super fragile. You don’t need to remove them for this project, but in my case they were coming out so I could touch-up the vinyl panel. If you remove them, take the utmost care.

To be continued

I’d already removed the little speaker grill and set it aside. This is what the stock panel looks like without it:

You’ll notice that there are only three little tabs for the speaker grill, and everything else is excess. So that’s where I started:

And from the back side, I cut down the baffle and any other protrusions:

I also cut out those two mounting posts at the back. This didn’t turn out to be necessary, so if I were doing this again I would leave them. All they do is mount to the door insert, so I’m unlikely to miss them.

With those cut out, the next obstacle is the window track mount:

This presented an issue. Obviously I can’t just cut it out, because the window track would flop around. Secondary problem though is that it vastly extended the timeline, which is why this job spiralled way beyond how long I expected it to. But it’s better to do it right than to half-ass it, so I started working on relocating the mount.

This hole up above the existing mount presented an optimal location. The back was flat and it wasn’t in-use already. So I cut some mild-steel I had around and bent a new bracket, test fitting it 100 times:

I spent a long time getting the fitment right. This is not a part that I wanted to screw up, since finding another would be a pain and I wouldn’t have any windows while I waited. I also wasn’t sure how important the precise alignment of this track was, so I erred on the side of caution.

I spent a long time getting the fitment right. This is not a part that I wanted to screw up, since finding another would be a pain and I wouldn’t have any windows while I waited. I also wasn’t sure how important the precise alignment of this track was, so I erred on the side of caution.

I also took out the window glass before I tack-welded anything, since the spatter might melt the laminate and damage the glass.

After tacking the bracket on the track can come out. With the bottom bolt removed, the trim pulls back and this little clip thing is all that holds the top in. The track just pulls straight down.

To be continued.

I needed to remove the original track, but I didn’t want to be needlessly destructive in case I want to go back to stock (lol). So I ended up drilling out the spot welds and keeping the original bracket safe. Then I added some more tacks and painted it up:

Now I was ready to cut the door. It was at this point I realized maintaining the ability to reverse the window track modification didn’t make a lot of sense when I was about to slice a chunk out of the door panel, but hey, no need to cause wanton damage. Taking a saw to my car was bad enough.

Before:

After:

I know why I didn’t do this last time (nobody likes cutting their car), but honestly the amount of space it frees for the driver is just unreal. I absolutely should have done this the first time. I sprayed some black paint on the edge where I cut it for rust prevention. I did actually keep the parts I cut out, again, just in case I want to go back to stock…

While I waited for the paint to dry on the door, I worked on the vinyl of the door cards.

These are the original door cards that came with my car. Well, “original” since I don’t think anything on my car is actually original, but you know what I mean. They were maroon from the factory and had turned this ugly faded colour, which is why I wasn’t afraid to dye them black.

The Duplicolor Plastic & Vinyl dye worked well, but since these were the first part I did over 5 years ago, I had learned a few things about prep in the interim. There were two tiny spots (near the handle and near the vents) where some flaking occurred, so I set out to fix it.

I stripped back any loose dye, and then sanded the entire panels with 600 grit sandpaper. I didn’t want to sand too much or else the texture would be damaged, but then some places (particularly near the vent) were basically smooth already. This is probably part of why the flaking occurred. I also degreased them aggressively.

This is where that left the panels:

Ugly, but the surface is now prepped better. Some of the places I stripped back the dye were pretty shiny, which implies I didn’t degrease or sand them well-enough back in the day. I remember there was a LOT of Armor-All on there.

The vinyl dye sprays really strangely. If you spray a wet coat, the surface dries to a weird hazy look. I’ve discovered the best thing to do is dust the paint on there in many light coats. It takes a long time but provides the best results. After a couple days, I buffed the surface with a blue towel to even it out:

Before:

After:

To be continued

I had originally thought I would make the new speaker panels out of wood and varnish it, but the more I thought about it the less sense this made. There had to be better materials for this. The wood was still good for a mock-up though:

The black plastic thing is a prototype water-shield I made and 3D printed. I forgot to take pictures, but basically it acts like a hood on the back of the speaker to prevent any water landing on it from above.

You can see what I meant about clearance. The speaker still doesn’t want to be in the center of the opening. The door card also doesn’t sit as flat as it should, since the wood adds thickness.

It was at this point that I decided to toss out my earlier panels and start from scratch. They were built around the idea of getting something that took minimal door modifications and made it work, so I was fighting my own old designs.

Starting with some cardboard, I cut a new panel that used the same four mounting holes but covered the widest area possible. This left no air gaps and maximum space for the driver. At the same time, I also carefully contoured all of the edges so it sits as flush as possible against the door with minimal added thickness.

Then I offered the door card up to the panel again and traced out the available space:

The triangle is the opening of course, and the round circles are possible driver locations. This was definitely helping, and the next thing I was fighting was the opening in the speaker grille:

From the back, you can see Mazda only actually drilled any openings right over the 5 ¼” driver’s opening. I realized I could widen my options by drilling more holes. I removed the fabric, then popped it on the drill press and went to town:

As you can see, this allows for a much more optimal driver location. It can be pushed further forward while maintaining maximum free surface area. I originally wanted to reuse the factory material to cover the grill, but I found that it was faded and beginning to tear in a few places. I ordered some fresh fabric, and here is the comparison:

The pattern is very slightly different from OEM, but I can find a way to live with that.

I covered the grill with the new fabric. Using spray-adhesive, this was only a 5 minute job per side. I’m quite happy with the results. If you hold it up to the light you can see how much more opening it leaves me with:

But when installed, it looks OEM:

Well, except the pattern being slightly different. It’s not something anyone would normally notice. But I’ll notice…

Looking at the back, you can now see all of the available space we have:

To be continued

As far as materials, everyone seems to like MDF. Frankly, I don’t get it. The only thing worse than wood as far as moisture is MDF. They make a lot of sense indoors, but for a car door it seems like a poor choice unless you’re 100% confident in your vapour barrier. And well, you’ve seen my vapour barrier.

I saw some people talking about HDPE. I ordered some, but unfortunately I realized I would need it to be pretty thick before it was rigid enough. Probably around ½”.

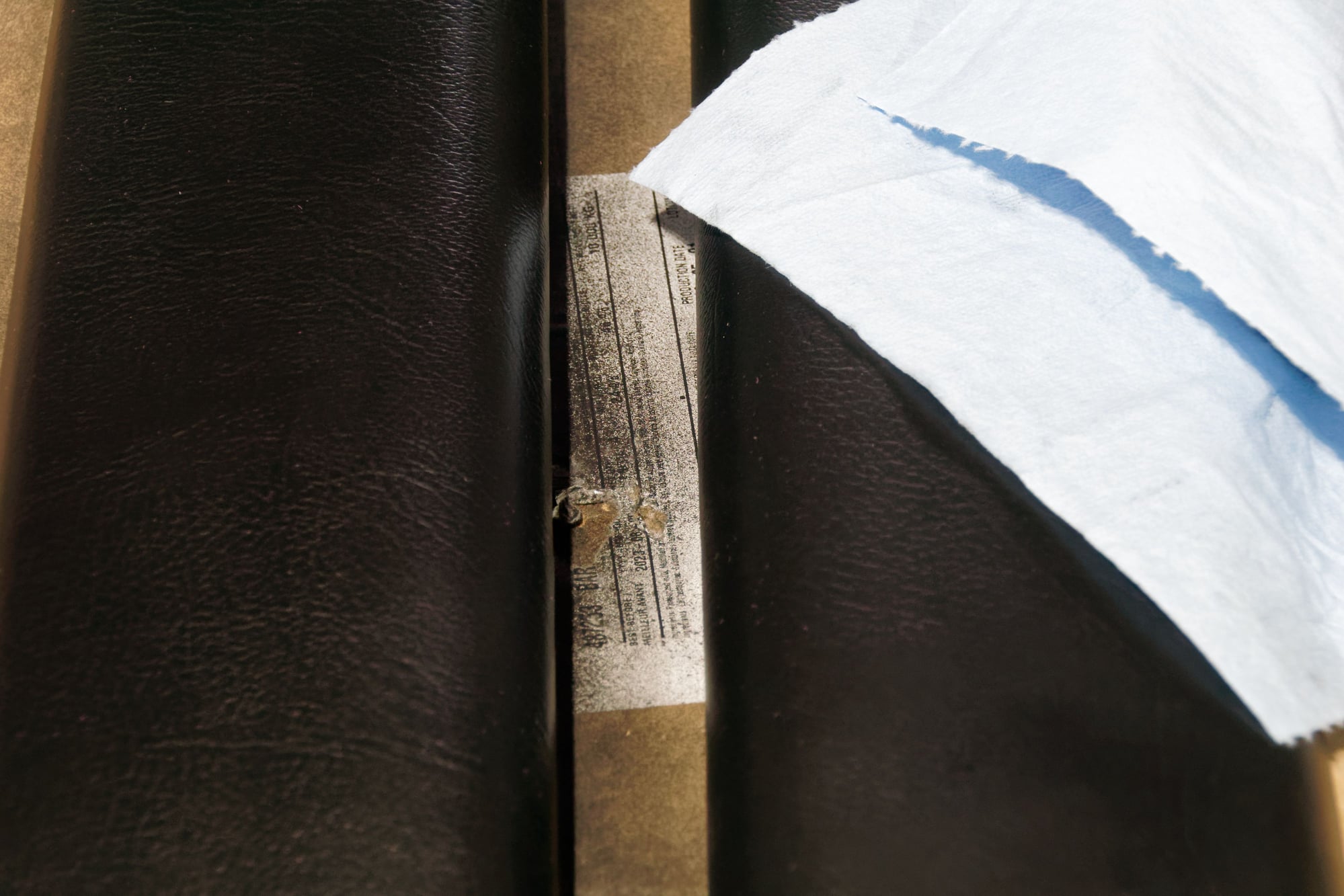

As I was getting ready to send the HDPE back I was talking about it with my dad, and he asked why I just didn’t use “the white plastic”. I asked what he was talking about, and it turned out we had a pretty sizeable flat piece of this white plastic stuff:

Neither of us knows what it is. He’s had it for years waiting to find a use for it. It’s got paper on one side (presumably to prevent scratches while working it).

And wouldn’t you know it, this stuff is perfect. It’s very rigid, easy to work with common woodworking tools, it’s waterproof, and the paper even prevented me from scratching it (not that it matters for this application).

It feels sort of like lexan, except that it cracks a bit more easily if you drill too aggressively. It also makes a weird smell when drilled.

I stripped the paper off by leaving the panel in warm water for awhile (I don’t want soggy paper inside my door), and this is what is left:

Neat! You can see what I meant about the contours here. Those let it sit further down in the stamped door panel, increasing clearance for the door.

You may also notice that the mounting holes for the speaker are really large. That’s because this bracket was included in the box:

I wasn’t going to use it initially. I don’t think I’ve ever actually used the mounting hardware included in a set, since they assume you have a wide flat surface to use and I have never found that to be the case.

However, when thinking about the plastic frame for the driver and the plastic panel, I figured the extra rigidity offered with the steel ring would be a good idea.

Installed. I’m quite happy with how it turned out, especially compared to the panel I made last time. We’ll come back to the speakers themselves in a minute.

It was time to reassemble the door cards. This is something I have discussed before, but I thought pictures may be interesting. First, this weather strip pops into the top of the vinyl and then the little tangs fold under to retain it:

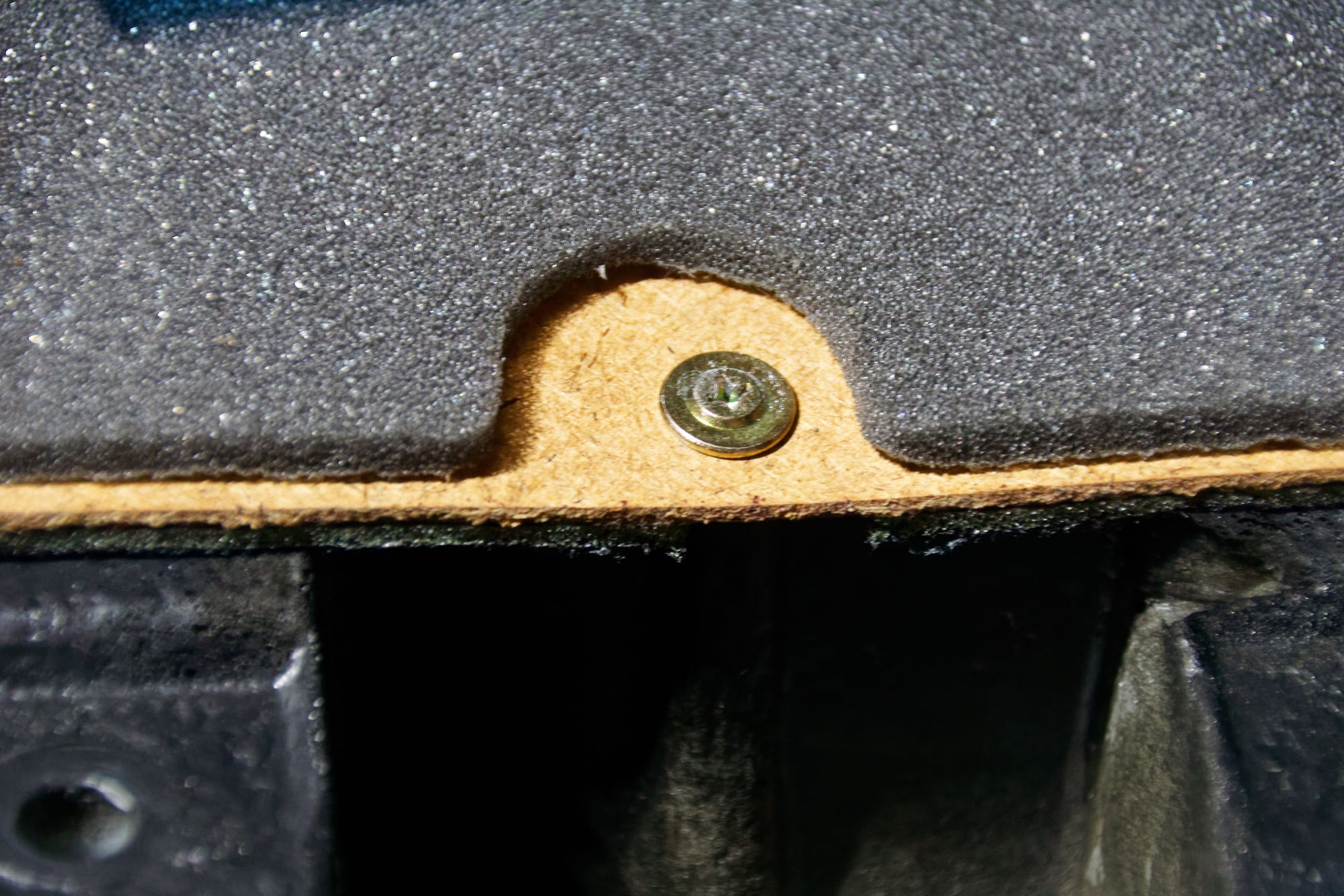

Then the insert can go in. It’s held in with these tiny little screws and washers.

I always end up with a few “extras” afterwards, but this time I made sure they all went back where they should. Well, I was two short. I’m going to have to dig around in my bins to try and find some spares (which I definitely have, someplace).

The handles goes on at the same time, and is held in the same way. Except that it also has these little post things, onto which a round washer-looking clip pops:

The best install tool is a small socket. There’s no great way to uninstall, so just get two thin screwdrivers and gently work it upwards if you’re in that position.

Next the vent goes in, but I decided to call it a night at that point. The next day I went out to continue the project, and disaster had struck:

I had been organizing all the hardware and whatnot for each door in a Ziploc bag, and overnight one of the bags fell from the box I had left it on and the vent face had shattered.

It’s my own fault for being careless with it. Now it needed to be fixed. I don’t have a spare black vent, and new ones aren’t cheap. I may still purchase one in the future, but for now I had a spare maroon vent face:

Well, it used to be maroon. This is what happens to maroon Rx7 interior parts with enough time and sun.

To be continued.

We’ll come back to the vent situation shortly.

One minor thing I wanted to fix was the door wiring. Keep in mind, everything worked fine. It just wasn’t very neat. The first and easiest thing to address was the connector for the power lock. I’m sure most of you are familiar with the Deutsch DT connector. If you aren’t, it’s a really easy to use and relatively affordable solution for waterproof connections:

You only need to crimp the terminals onto the wires, pop them into the back of the housing, and then insert the wedge-lock. Then you have a waterproof connection:

With that sorted out, the next thing to do was to replace the existing power-window relays with waterproof ones. These ones were pretty affordable on Amazon, and Amazon relays are just fine for a non-critical application. I had originally used two-position .250’ connectors to make the whole power-window relay setup plug and play, and those connectors were fine. So I ended up splicing downstream of those wires and using solder with adhesive-lined marine heat shrink tubing:

Apparently solder in automotive wiring is controversial, but I think it’s fine for this application. It’s a straight run of wiring with no bends, which will be well secured under the door panel for the rest of its life. I probably wouldn’t want to solder a joint in the middle of an engine harness that will flex around during install, but for terminals or straight runs it doesn’t worry me at all.

I wanted to mount them with a nut and bolt, but that put them in an awkward position uncomfortably near the window. Alternatively, they would fit on the interior side of the door, but then the door card wouldn’t sit right. So I settled for liberal zip-tie use in multiple locations:

I also can’t leave those gaping holes in the door seal, now can I? I hadn’t noticed any water ingress into the car, but water had definitely leaked into the door past the ancient window seals, so it might shorten the lifespan of the door card or cause mold.

The old seal was held on with bitumen. While I don’t like working with bitumen, it is still easier to deal with than double-sided tape. So I ordered a new bitumen roll:

Removing the old bitumen took a few hours and quite a bit of enamel thinner, but it ultimately came out clean.

There’s no great way to apply the new plastic sheet, because the moment it touches the bitumen it will not want to come off. So you really need to be sure before you press the sheet down. I saved myself some time by using the old sheet as a template, pre-cutting the holes for the power window connector and door latch rods, then installing the sheet onto it and shoving it into the hole in the door frame.

Then I rolled the new bitumen on. I followed the existing track, except for a detour around the new speaker panel. The panel seals to the door with foam, so I don’t need to worry about water leaking past. It looked like this:

And then I started from the corner near the speaker and worked my way around:

And there we go. After a bit of trimming it was ready for the door card. Speaking of which, where did the speaker placement end up?

Please forgive the obvious water spots on the lens.

Still not perfect, but about as close as I can get without visibly altering the door card. I might be able to go up ½” further and forward a little bit as well, but then there’s almost no frame behind the speaker panel for the foam to seal against. So this will have to be enough.

To be continued

Detouring back to the door card, it was time to inspect the door vent a bit further. There’s a small crack along the top, but it’s better than the other one. So I prepped and painted it with the same Duplicolor dye as I used on the door cards. Then I installed the black vent parts onto it.

The little vanes pop into these pivot point things:

Then the back housing clips on (nerve-wracking when the part is ~37 years old):

Then the little dial goes on, and it engages with the post for the innermost vanes:

And the vent is complete:

It’s not a 100% match to the OEM vent, but it’s fairly close:

And with that, I put the vents back into the door cards and reassembled. I tried to be gentle on install, but tightening the screws down into the vent plastic I did hear some splintering sounds. I’m thinking a new set of OEM vents should be on the short list…

Thinking about it, the door vent opening is actually a good location for a speaker. I think I remember Styx doing that on one of his FCs at some point. The only downside is that you lose the vent functionality.

Also, I feel like someone has mentioned this in the past, but it’s weird that FCs have the vent in the door. Most cars have the vent in the dash itself and then the door has a depression near the dash, but in our cars the door wraps around to the dash and the vent flows through. Neat.

I also zip-tied the crossovers inside the doorframe. No picture because I can’t take a picture inside a doorframe. I put them in locations where moisture wouldn’t reach them (I checked after it rained and they were dry) but I also put them in Ziploc bags and zip-tied them shut with the open end downwards. That should be acceptable as far as preventing water ingress.

The 5 ¼” speakers I was running before were a component design, and I had mounted the tweeters on the door triangles in these 3D printed pods. They were pretty good, but the silver ring on the tweeters bothered me. Conveniently the new tweeters seem to be identical, except that they’re all black.

I modified the 3D design and printed two new pods:

The barrels are an exact fit for the tweeters, so they just pop in, Then the entire thing mounts to the door triangle with two screws, and it pops onto the door:

Meanwhile the door card itself looks completely unmodified from the exterior:

And there we go. It’s all installed. It’s a bit underwhelming since I can’t actually demonstrate it for you, and the car looks almost no different from before. Except the black door inserts.

So, did it work? Well, sort of. The sound is definitely a vast improvement over my previous setup, but I still don’t find the vocals as clear as they should be. Cymbals and the higher range of the vocals are clear from the tweeters, but the real body of the human vocal range isn’t as present as I want. It’s not bad at idle, but when driving it lacks something. The subs can now be tuned with the crossover at a reasonable level though, and there is a good amount of punch coming from the doors that just wasn't there with the 5 1/4" drivers.

The next step would be a DSP and maybe some 4” speakers under the dash, but that’s a lot of expense to go to. I think before I make any further changes to the audio system, I’m going to replace the diff and subframe bushings (which are definitely bad) and minimize cabin noise while driving. I might find that I don’t actually need the extra speakers at all.

The door card inserts no longer match my maroon seats, but at some point I want to reupholster my spare GTU seats anyways and have an all black interior.

Until next time :)

Awhile back I stumbled upon a good deal for some factory Mazda comp control arm bushings. I wasn't really looking for them, but the price was too good to pass up at about $100 for complete front and rear.

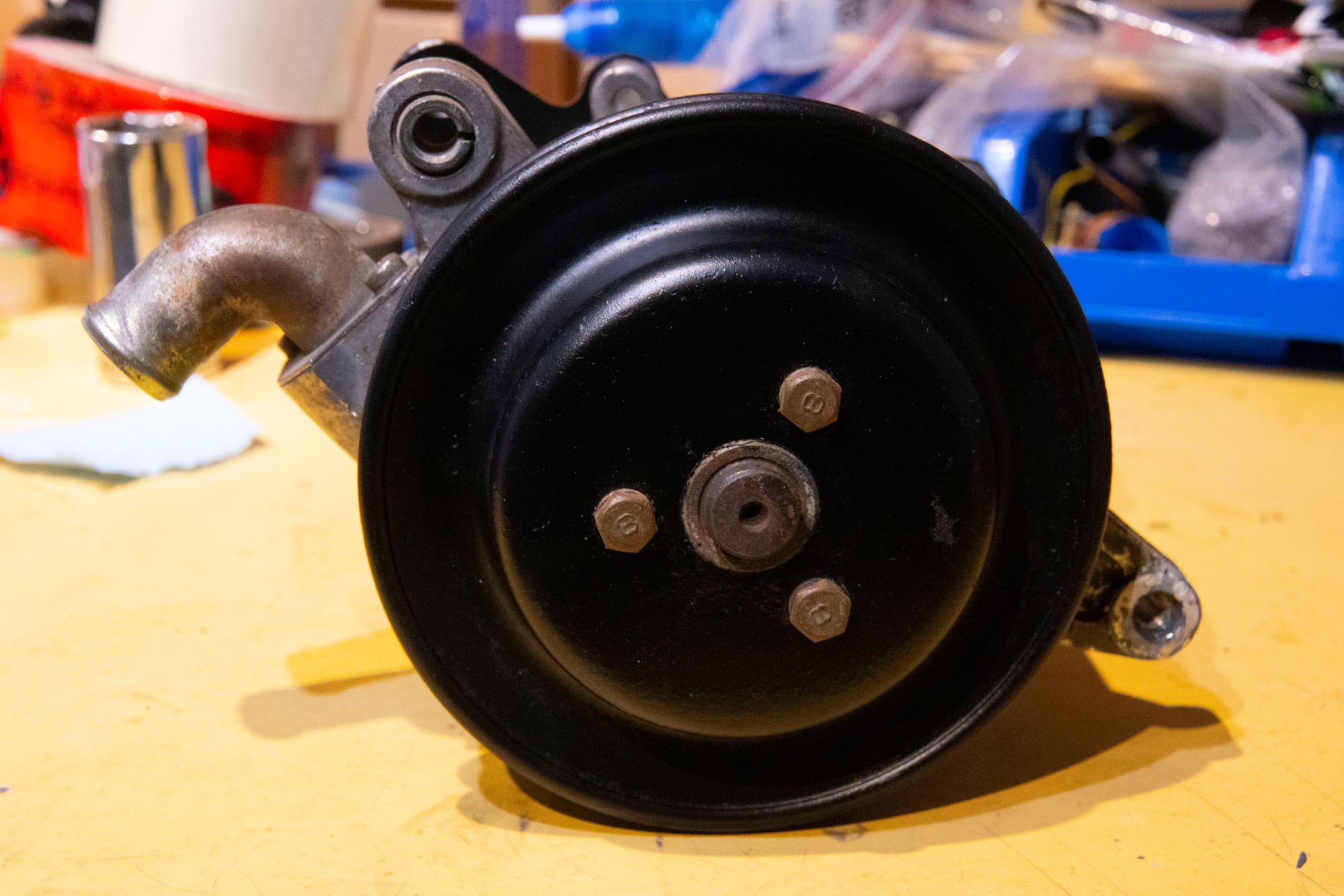

Turns out I didn't look at the pictures carefully enough, and I ended up getting a better deal than I had expected. It was a complete front control arm bushing set, but there were no rear control arm bushings. Instead, there was a set of Mazda comp differential mounts. An especially good deal since mine are 100% trashed.

I wasn't going to install them because I will be swapping to the Turbo II diff anyways, but then I did some thinking recently and realized I'd been neglecting some parts of the car and prioritizing getting all the parts I need to complete the swap. And sure, I want to complete the swap sooner than later. But until then I still want to enjoy driving the car. So I decided it was time to swap out my tired original diff mounts for the new set.

I had to evict my mum's Miata from the garage temporarily, since it's been raining for about a week here:

I guess that picture is a bit of a spoiler for the hood update, but I still haven't actually gotten around to doing the write-up yet. It took several months of putting in a couple hours at a time. My god, the sanding...

Anyways, I was going to just remove the diff, but then it became apparent that access was really tight. Trying to avoid removing the subframe would be a false economy, so I just spent the extra hour now and dropped the whole thing:

The motorcycle jack makes this a much easier job, although I should have put a couple planks under the diff to take up some space. The bottom of the diff sits higher when installed than the bottom of the subframe, so to get it to align properly for reassembly the diff needs to be slightly elevated.

But where's the diff in that photo you ask? Right here:

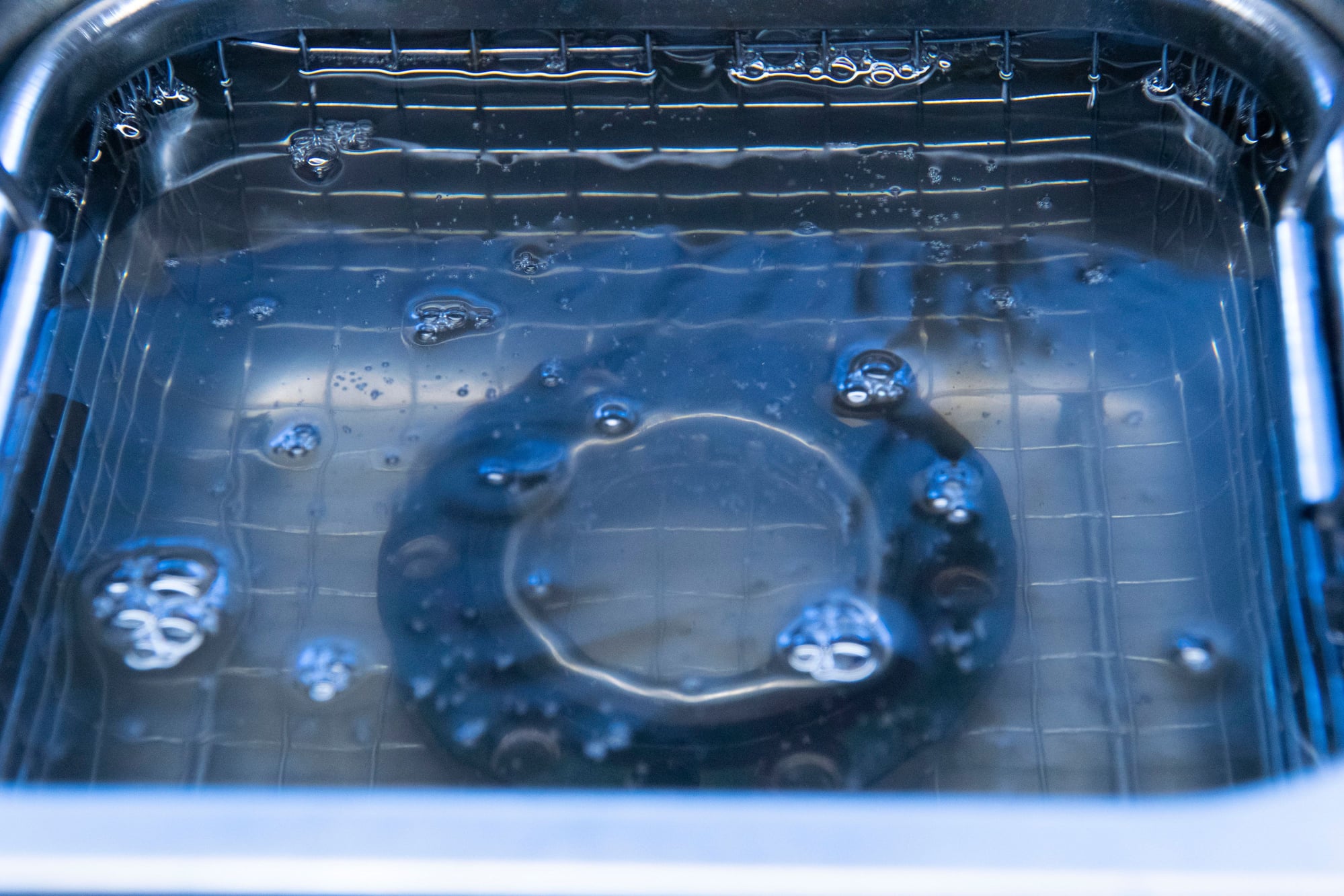

I drained the fluid and then flipped it over so I could remove the old mounts. Speaking of fluid, this is what came out:

It looked pretty good. Still clear like honey, and only a hint of metal dust in it. I was tempted to reuse it, but even though this diff is temporary I decided it deserved some fresh fluid. They don't grow on trees anymore.

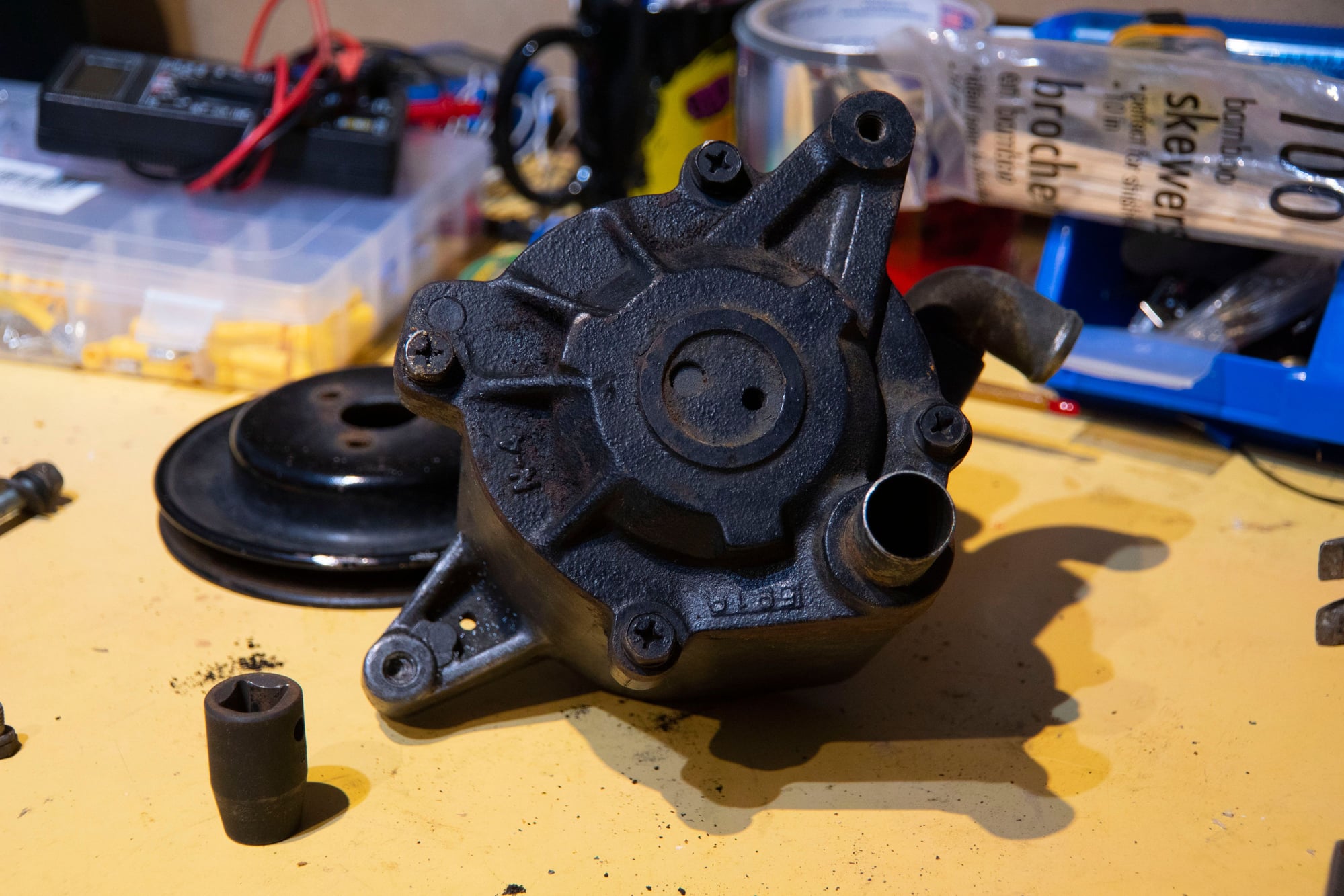

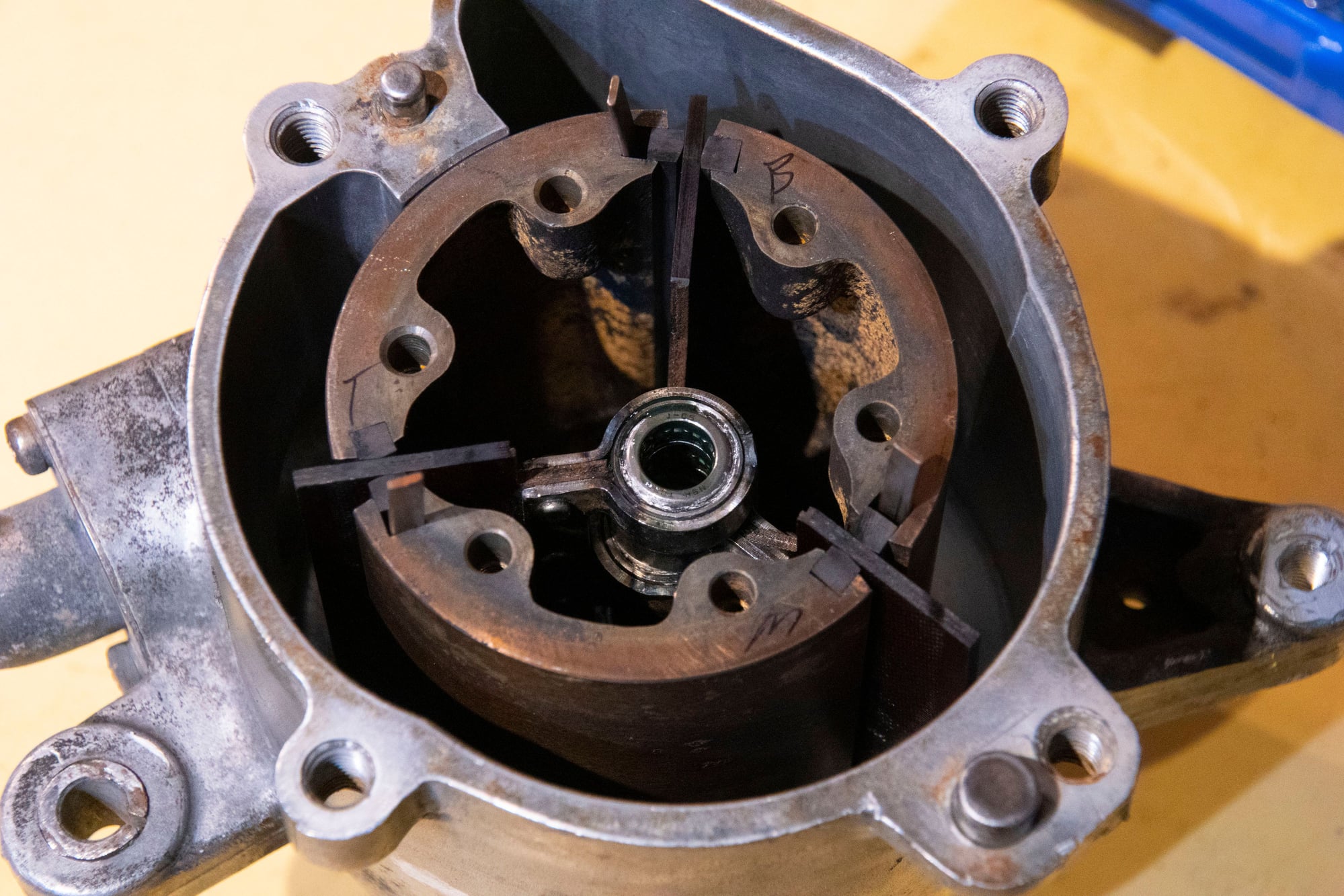

The mounts are pressed in from the upper side of the diff, so to remove them you need to push from the bottom side. Hence why I flipped the differential upside down:

It doesn't look so bad in this picture, but if you look closely you can see a lot of cracking on the rubber. That isn't terribly unusual (minor cracks form within a few years, in my experience) but when you look at the center sleeve you can see the rubber has started to separate from it. When I put a screwdriver in the center sleeve and pushed it around, it was also very very stiff. That's likely part of my road noise problem.

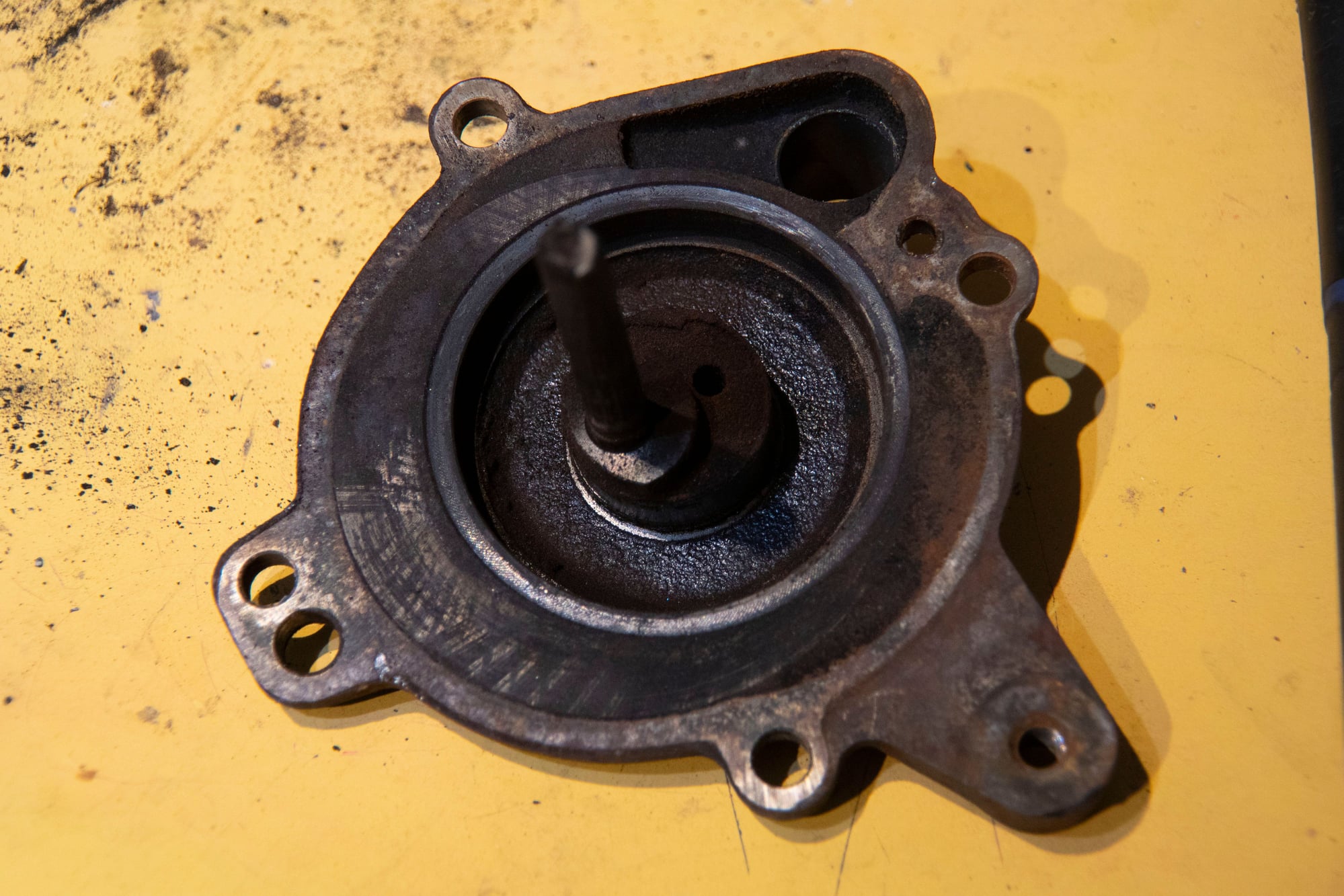

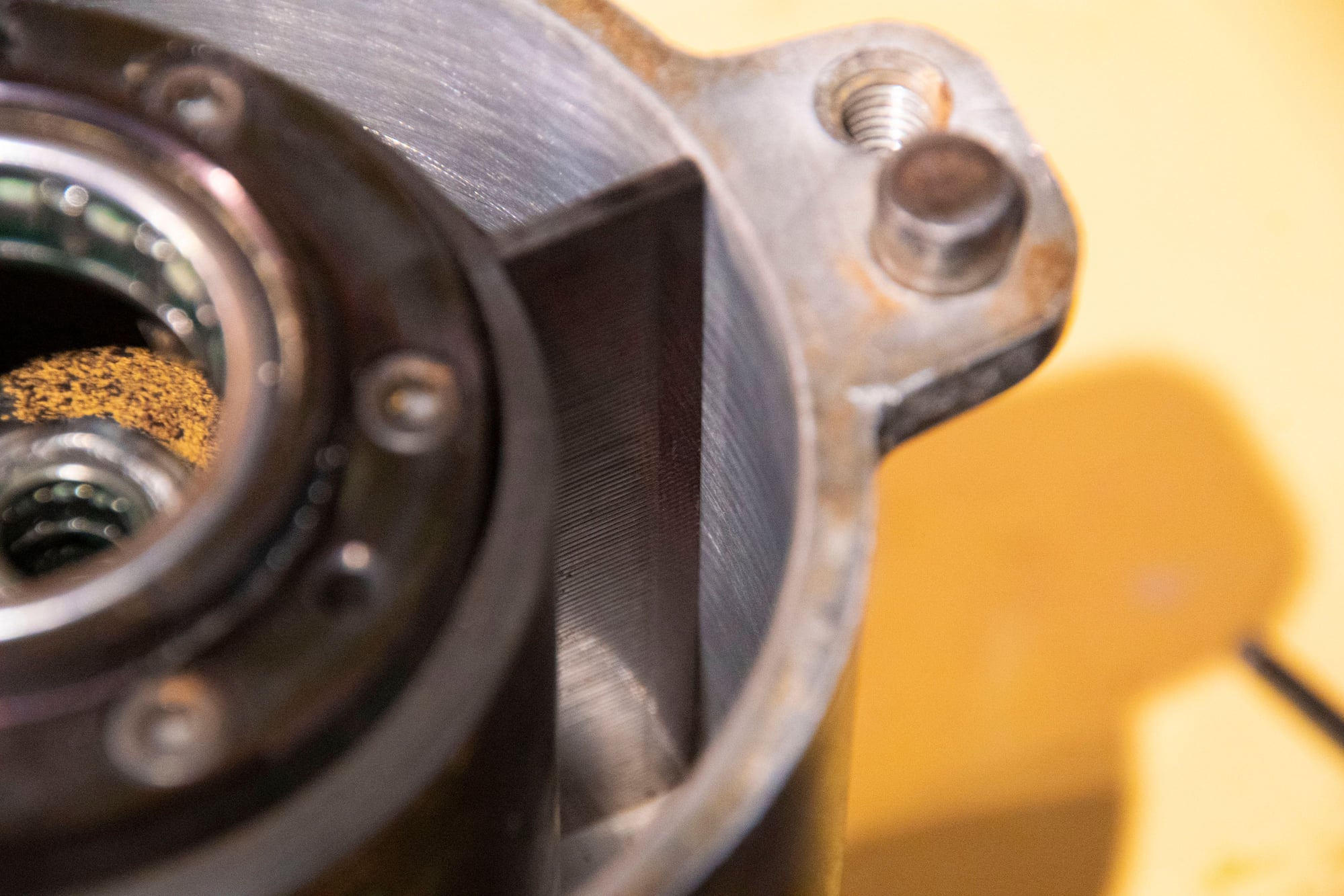

Drill a few holes in the rubber until the center sleeve falls out, then sawzall along one of the two seams in the bushing sleeve. Once you are most of the way through, use a chisel to hammer the sleeve inward until it loses tension and falls out:

The old bushings were so old it was like drilling plastic for the first 1/2" depth of the rubber. At the center it was kind of pliable, but the outside had basically no give.

I thought I remembered to take pictures of the new bushings before install, but I guess I forgot. Anyways, they look like the old except they have a slightly oblong shape. If you look at the old one in the above photo, you can see the outer sleeve is two-parts that form a whole cylinder. When not installed, these bushings have a 1-2mm gap between the sleeve halves. As you press them in this gap compresses and then the tension helps hold them in the diff housing.

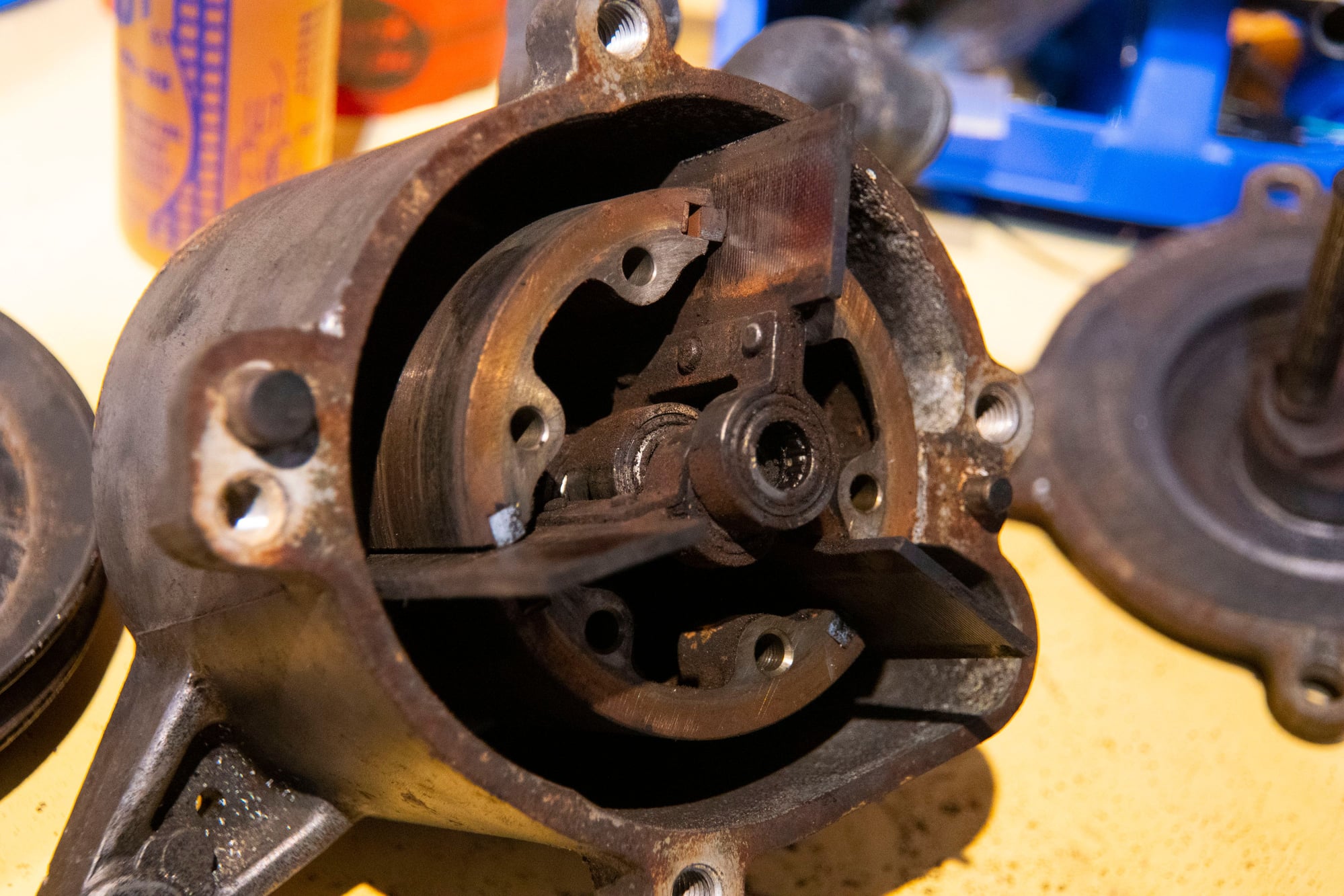

Speaking of presses, I don't have one. But what I do have access to is a very poorly-built log splitter:

It broke from the mere stress of me pushing it up a hill. I swear, this thing was originally welded together with a soldering iron...

Fixed. After that brief diversion I had to make some space. My brother's GS500 recently turned itself into a GS250, so I moved it aside and pulled the log splitter in to prevent working in the rain. The log splitter makes more torque now anyways...

I don't know what was more dangerous, my improvised log-splitter hydraulic press or the abysmal state of my garage.

To be continued

I had to spend a long time getting the spacing right. Actually, it wasn't that long a time, more like 5-10 minutes per side.

Basically the issue is that the diff needs to be tipped a little to fit the mount down into the valley of the log splitter, and then it also needs to be kept concentric to the nub in the middle of the moving side of the press. If the bushing isn't pushed in perfectly straight, it will want to skew sideways instead of pressing in. I just took it slow until I got it pressed most of the way in.

Fun fact, that big socket is the absurdly large 54mm flywheel socket. It's the perfect size to press the top of the bushing in, and then once it's 80% of the way installed the center sleeve will want to collide with the plank on the other side. Then flip the socket over and place it on the other side, and it will provide a pocket to let the diff mount push all the way home.

Other than the actual pressing of the mount, the other challenge is to make a flat surface for the splitter to press against. Turns out that's easily solved - if you put a plank in but oriented so it's cutting against the grain, the splitter won't want to cut through it. Conveniently the splitter bit (or whatever it's called) that I am using here is also pretty dull.

Once I got the first side installed, the other probably only took about 5 minutes. I was working alone, so the most challenging part was stretching my left thumb to start the motor while my left pinky was holding the dead-man switch, since my other hand was helping to hold the diff straight. Conveniently the people who designed the guard to prevent me from doing so were as lazy as the people who actually built the splitter, and I was able to do it without to much fuss.

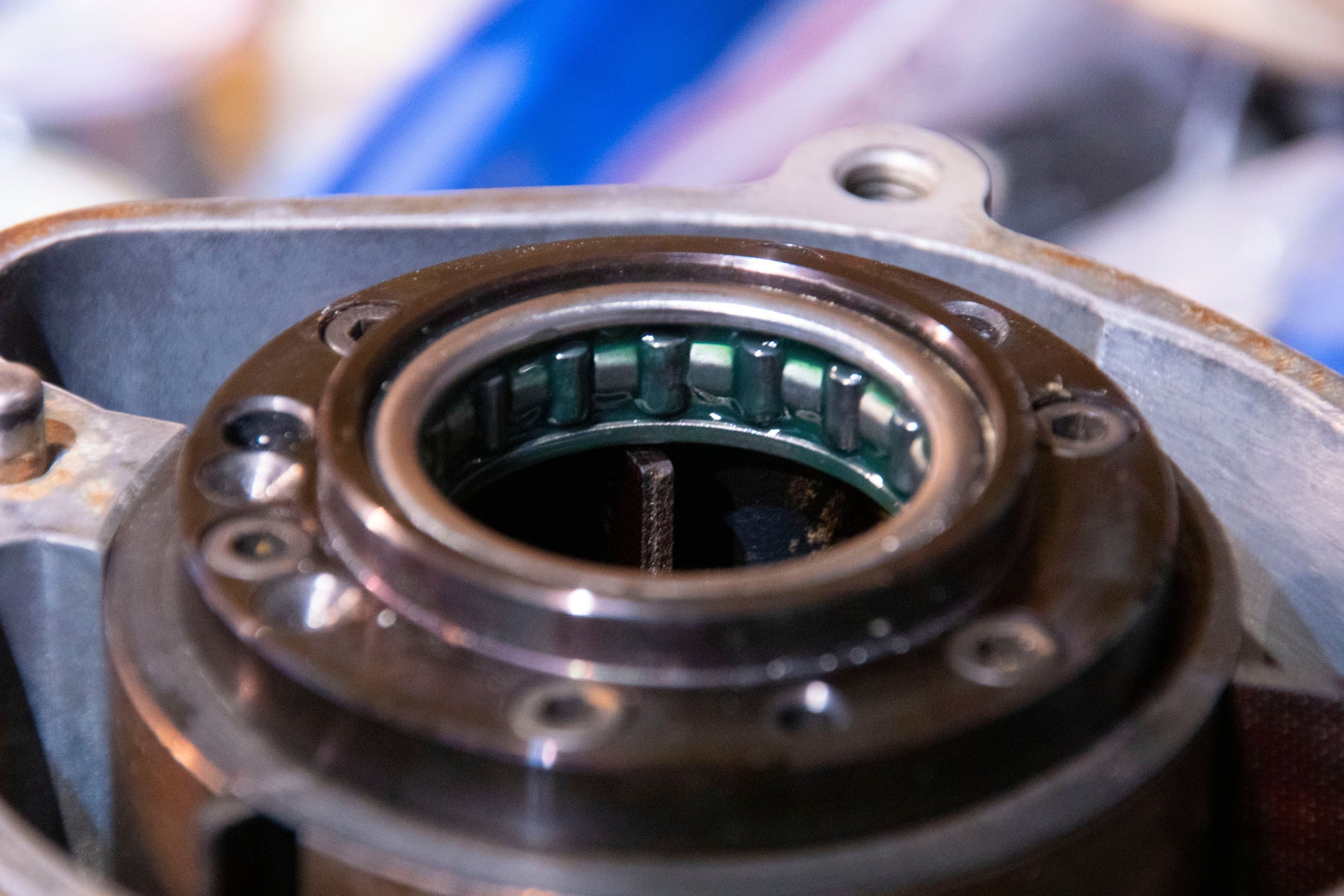

The new bushings installed:

It's weird, old bushings are somehow firmer than new but also allow more slop. I don't know how both are possible, but if these mounts are anything like the front mount I replaced last year, it will both improve ride quality and decrease slop.

Speaking of slop:

I thought the diff felt a bit weird lately. At some point the rear nut backed off and vanished, and the front one wasn't super tight either. Apparently new ones are $17 per from Mazda (!) and no parts stores around me have any in this size for some reason (M12 x 1.5, 10.9). I know a guy who sells all sorts of fasteners at really low prices, but he's about 40 minutes away. Conveniently he was near the Mazda dealership I would be visiting to pick up some other new parts:

Yup, those are my subframe bushings. They're also pretty stiff, and the rubber is separated all around from the sleeves. I don't know how much of a difference this makes to ride quality, but I intend to keep this car for a long time. I also don't feel like dropping the subframe again if I find the diff mounts didn't completely resolve the noise issue. So I sold a few more of my organs and went to the dealership to order two brand-new ones.

To be continued

The new subframe mounts came in from Mazda, so I went to pick them up. Pleasantly surprised that these were available next-day (in fact, less than 24 business hours since I ordered). I had disassembled the entire rear suspension in preparation:

Everything was in pretty good shape, surface rust aside. My homemade camber links are still smooth. I ended up swapping in another set of toe rods that I had around, purely because I felt like the joints were a bit smoother. It's unlikely to make a noticeable difference, but hey, I'm already here. Then it came time to remove the old bushings.

I started by drilling out the rubber like last time, but these mounts also have an additional inner sleeve that makes this difficult. So after drilling many holes (and snapping several bits, because titanium bits don't like to be pulled sideways), I put it in the log splitter and pressed the innermost sleeve out:

I then used a chisel to force the outer sleeve away from the subframe opening, and then worked my way around until it fell out. This was much more difficult than the diff mounts, and took over an hour per side:

Boy, my arms are tired from hammering.

Once again, they were in terrible shape. Not only was the rubber really stiff, but the outer sleeve was so rusty it had the consistency of one of those wafer cookies:

And it left a lot of crust inside the subframe:

I got all of it out by chipping away at it with a claw-hammer. Once I chipped it away, the inner surface was actually fairly smooth. Most of what you're seeing in there is mount remnants, not subframe.

I wire-wheeled everything clean, and then hit it with some black spray-paint. I expect it to rust again in the future, but I figured a thin coat of paint would mitigate the issue without interfering with the fit of the new mount.

You can see my alignment marks here. I'm not sure that it matters, but the mounts aren't actually pressed in straight. They have a slight outward angle. The differential mounts are installed with the split oriented longitudinally to the car, and I think in that application it would matter because the outer and inner sleeves have rubber between them in four locations, in an across-pattern. If the mount is rotated differently, it might absorb force differently. Or maybe I'm overthinking this whole thing.

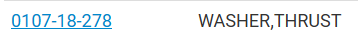

The new mounts:

You can see what I meant in the previous post about the split. When the mount is pressed in, that split closes:

I picked up some fresh hardware from my usual guy:

We'll talk about those big washers shortly.

To be continued

Second-generation Rx7s had a passive rear-wheel steering system from the factory. There are three bushings per side holding the hub assembly to the control arm. Mazda calls this a tri-axial floating hub, and the DTSS (dynamic toe suspension system, I think) causes these bushings to flex to cause slight toe-out on the inside wheel when turning (and toe-in on the outside wheel).

This system works, and I remember liking it a lot when I first had the car. It can however cause some vagueness as the system relies on the bushing being under load to start steering. So just when you feel the car starting to reach the limit, it kind of just continues to grip (until it doesn't).

The other problem is that these bushings are very old, and they no longer have the same stiffness they used to. So unless you want to buy brand-new hubs (the bushings are not sold separately), you need to delete them.

I thought about installing some DTSS deletes that I have had in a box for years, but first I thought I'd check the state of my current bushings. To my surprise, I already have DTSS delete bushings installed:

I don't recall ever deleting my DTSS, but then I did swap these hubs in when I did the 5-lug swap. So it's likely that they came with the hubs. I remember liking how DTSS felt when I first bought the car, and then being a bit less clear on whether I liked it the past few years after the 5-lug swap. I guess I have been driving without it for awhile without knowing.

I reassembled the rear suspension on the jack:

No, I didn't end up painting anything. I would like to make excuses as to why, but the truth is I just don't care that much how it looks anymore. It's under the car and it functions well, and I have some ideas that involve replacing the entire thing anyways. While the FC handles pretty well (even by modern standards), the rear suspension is kind of crude. Especially without the DTSS.

Without DTSS the spindle and trailing arm are basically acting as one unit. Like most trailing arm suspensions, it isn't terrible. It's just that it squats when you accelerate, and the toe and camber curves aren't ideal. In addition to that, I really don't like the front differential mount design:

Those are brand new nuts and lock washers. I only needed one, but decided to just get both.

Mounting the differential from the side like this is a really poor choice. First off, the mount is constantly in shear. Either the diff is shearing it downwards when at rest (admittedly not a lot, but it adds up) or when you accelerate the nose wants to move up and it shears upwards. This leads to shortened life, and allows a good amount of movement. I have a pinion snubber installed to mitigate this, but it's still a pretty lame design. Then as if that wasn't bad enough, the entire force of the differential moving up (ignoring the snubber for a moment) is placed on that tiny tab above the wide washer. If the differential moves too much (and you are making too much power) it can rip that tab, or rip the entire mounting flange off the subframe.

I don't think this will be an issue due to the snubber. I also don't make that much power (yet) or launch the car very frequently. But overall, the entire design of the diff mount and rear suspension in general kind of irks me.

I had an opportunity at my last job to see a lot of different Honda suspensions (none with diff installed though) and most of them use round bushings for all three mounts, and in orientations that place the mounts in tension / compression and not shear. I'd like to implement something similar.

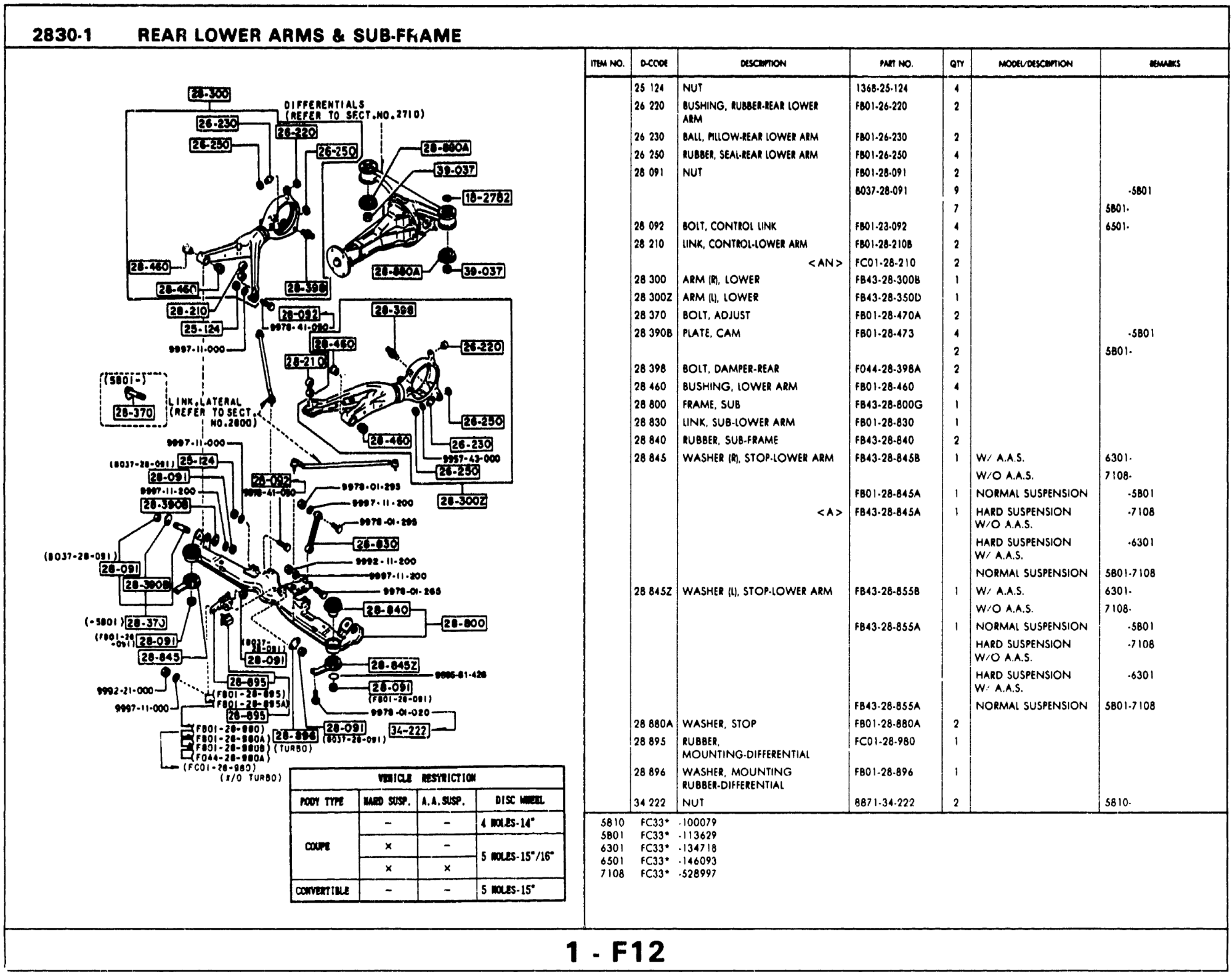

At this point in reassembly, I encountered a bit of a mystery. For some reason, I had an inkling that there should be a washer on top of the differential mount, like this:

The service manual makes no mention of this, though. I also can't find mention of it anywhere else. But still, I had a strange feeling that there needed to be a washer there. I dug and dug and dug, until I found the reason I thought that:

Aha! In the parts fiche:

18-2782 doesn't actually return any results on it's own. I didn't find it in the fiche, nor on Amayama. But after googling around awhile, I found this on another site:

EDIT: Even more interesting, I eventually did find the part on Amayama, but only in the diagram. Not searchable. The part number is also in a totally different font from the rest of the diagram, not listed on the right hand side, and hovering over the part / number does not pop up with the part info as it normally does for other parts.

"Thrust" also implies it's there for spacing and not to spread out the load. So that confirms it, there should be a washer there. Right?

Well, I'm not sure. I reinstalled everything and this is what I discovered:

Apologies for the poor photography, this was taken under the car with a flash.

The nut doesn't seem to get a lot of engagement with the additional washer. And this is without any sort of lock-washer either. The cup thing also has a wide gap between the rubber crown and the differential ear, so it seems like the washer isn't supposed to be there. Maybe the parts fiche was created before the part was removed from the design and not updated?

As if that wasn't weird enough:

The subframe mounts install fine, but the rubber contacts the subframe pretty firmly. I think they're supposed to contact, but this seems like a lot and doesn't allow even the slightest movement of the subframe mounts. This picture is without a lock-washer, so with a lock-washer the nut should end up right at the end of the threads.

To be continued

I did some more research, and I realized that not only does the FSM not list those two washers I added to the diff mounts, but it doesn't show any lock washers on the diff or subframe mounts either. Which makes sense, since I didn't remove any on disassembly.

So, I dropped the subframe assembly again and removed those two washers, then reinstalled to see what would happen. Turns out that without the extra washers, all four mounts align perfectly. What doesn't align perfectly is the camber link:

This link is necessary when you've installed lowering springs. The lowering springs end up causing negative camber, and you need this link to help pull that camber out. Shortening the link lifts the rear of the subframe closer to the body, and that tilt removes the camber. While looking at this link I realized that this heim joint probably doesn't do a great job of isolating vibrations, so I've made note of that and will need to find and modify my original link.

In my case, it won't align anymore. This photo was taken with the rear of the subframe jacked up as far as it would go, and there is a good 1" of gap still. This begs the question how it aligned in the first place.

To add to this, take a look at this photo:

You can see that the subframe has clearly been colliding with the body at the spot above the inner camber link. That's why there is exposed steel visible there.

Speaking of the inner camber link, I already have a set that are slightly shortened from stock. These are the second iteration. If you remember, I made these awhile back after my first attempt snapped when I went over a pothole.

I realized part of the reason it wouldn't align was the orientation of the jack caused the differential to hit the body, but I still ended up having to wind the adjuster out about 1/2" to get it to line up. It also occurred to me that the new subframe mounts might be causing it to sit at a slightly different height. This is actually almost certain to be the case considering how bad my old mounts were. So it might be that the camber link won't need to be wound out as far to achieve the same effect. Pure conjecture, but that's all I've got at this point.

Anyways, I reassembled everything and put the car back on it's wheels:

The camber doesn't seem to be that negative, if at all. Before I last got it aligned it was so bad I was getting obvious tread-wear issues and I could see the camber with the naked eye. Now when viewed from the side-profile, it looks pretty straight to me. I'll know more when I get it aligned.

The other thing I noticed is that for some reason the exhaust tips hang straight now. I've always followed the same method for installing the exhaust (hang everything, slip gaskets and fasteners in finger-tight, tighten in sequence front to back). It's unclear why it's hanging straight now when it didn't before, but it's a happy accident.

With snow on the ground and summer tires I didn't want to take a long drive. But it's insured year-round and the road was clean and salt-free, so I took a quick drive to the end of the road and back. The NVH from the rear is dramatically improved, and the car also launches much more smoothly. It's still too loud (exhaust drone), but this has gone a long way to improving some of the more fatiguing factors in driving the car for long periods.

One of the next things I ended up tackling was my exhaust. As a refresher, I was using a stock exhaust manifold, connected to a 2.5” downpipe welded where the pre-catalysts used to be, down to a v-band flange with some sort of stock replacement catalyst, going into a 3” expander through to a Racing Beat REV TII y-pipe and mufflers:

(This is an old picture from before the v-band when I was using a 3 bolt flange that leaked profusely)

The problems with this setup are manifold (Get it? Manifold? I feel like I may have made this joke before…):

- It’s ugly

- It’s rusty

- It drones at highway speeds

- The catalyst hangs low, reducing ground clearance

- The exhaust stinks like you wouldn’t believe

- I get a loud bang every time I shift at high RPM, and also on decel before the fuel cutoff kicks in.

- It will not flow enough once I swap the turbo engine in

I wanted to address all of these with a new center section, replacing that catalyst and adding a resonator to take out some of the drone. The downpipe will still be retained for now, but everything downstream would be ready for the turbo engine.

This was going to be a longer term project but I stumbled onto some good deals for a resonator, catalyst, and flanges. So I moved it up. I started with the following, all in stainless steel:

- 3” Vibrant Ultra-Quiet Resonator x1

- 3” Flowmaster 200 Cell catalyst (metallic core) x1

- 3” 90 degree elbow x1

- 3” V-Band clamps / flanges x3

- 5/16” and ¼” rod

I had the following goals:

- Make everything out of stainless so it would last a long time

- Increase ground clearance

- Eliminate drone

- Reduce the exhaust smell as much as possible

- Retain compatibility with the Racing Beat downpipe (without modifying it) should I want to use it in the future

- Add additional flanges to allow me to swap out the resonator / catalyst for straight pipe sections, in case I want to use it at a track later, or to replace them easily later without having to replicate curves.

First I removed the current catalyst, and the downpipe. Unfortunately the patient did not survive the surgery:

Apparently the all-thread hangers I made years ago were too much stress for the catalyst to handle and the welded on heat-shield was almost broken off. I tore it the rest of the way with my bare hands.

I also put aside the split-air tube and the downpipe. Normally the air pump sends air into the catalyst under certain conditions to improve emissions. This tube also has the nipple to provide pressurized exhaust to the aux port actuators. I have an idea to use the split-air tube with the new exhaust, but I have yet to actually implement it. I’ll talk about the actuators later on.

I do have the Racing Beat resonator that is intended to go in this location, but unfortunately it won’t work for me:

It’s intended to be used without a catalyst, but I want to run one. I like being able to take the car through a drive-thru without feeling bad for the workers, and I also like being nice to the environment when possible.

Using both a catalyst and a resonator requires a lot more planning, which I’ll get to shortly. One goal of mine was to retain compatibility with the rest of the Racing Beat exhaust by keeping my center section overall shorter than the resonator. This further complicates things.

The best way to start fabricating an exhaust would be to start by mocking up everything under the car. Unfortunately I couldn’t find a great way to do this. I don’t have enough jack-stands and jacks to get everything in the right place. So instead, I just started with what I knew would be hard points. I tacked the v-band flanges onto the resonator and the catalyst:

The idea is that the only parts of the pipe that will have curved sections are the parts that adapt between the Racing Beat exhaust and my custom section. I wanted the resonator and catalyst to remain straight with just flanges. This wouldn't end up panning out for the catalyst, but we'll get to that later

The space under the car requires that the pipe makes a bend in front of the y-pipe and the catalyst (now resonator) sits at an angle relative to the rest of the car. Here's the Racing Beat part for reference:

Then the pipe makes a smaller turn back towards the axis parallel to the car as it makes it’s way around the transmission crossmember. This sounds more complicated than it is, so pictures will make it more clear.

The y-pipe uses a 2 bolt flange. Fortunately I have this cut-off piece of the original pipe. I added a curved section and then the v-band flange was tacked onto the end of that:

I got the angle right on the second attempt. Basically found it was quicker to eyeball the measurements and tack it together for a test fit rather than to fumble around mocking everything up below the car.

I also had to address the hanger situation. One thing I observed from the Racing Beat resonator is that they used really sturdy hangers. They also had the hanger mount in two places creating a triangulated shape in the direction the exhaust wants to rotate. Meanwhile the crude hangers I welded onto the catalyst heat-shield years ago were not nearly as well thought-out. Even over a short length the hanger being welded in one place causes it to act as a lever and flex the weld. That could cause it to fatigue and snap, and also adds some flex to the whole hanger that might allow it to resonate weirdly. I’m no expert in physics (I was particularly poor at waves) but I imagine the vibrations transmitting through the exhaust at one frequency, and then bouncing unpredictably back because of flex in the hangers acting sort of like a double-pendulum and allowing it to interfere.

I’m probably overthinking this as usual. Point is, I wanted the hangers to be sturdy. So I measured carefully under the car and made some cuts in the rod to make one “main” hanger, and then added a support rod for the front to back axis and a support rod for the side to side. This left me with a pyramidal shape:

This should provide ample support, and the length of the “lever” part of the hanger is down to a couple of inches.

I tested and this setup is really sturdy. I can’t flex the hangers any noticeable amount by hand, which was not true of the previous ones.

Then I had to deal with the catalyst. I was hoping to keep it further back, but it became apparent early on that this wouldn’t be achievable without significantly modifying the y-pipe. So I had to push it a bit forward, which meant it no longer sat entirely under the heat-shielding that Mazda put in the transmission tunnel.

Would it cause an issue? No idea. But the transmission tunnel of the car already gets hot, so I didn’t want to aggravate the situation. I decided the best thing to do would be to add a heat-shield to the catalyst itself. Enter some 304 plate, two 304 M6 nuts, and aluminum sheet:

Even with just the two mounting points, it’s fairly sturdy and doesn’t rattle around. I also added an additional O2 bung here. That’s to allow a place for me to reinstall the split-air tube at a later date by welding on an M18 O2 spacer.

When selecting the catalyst I put a lot of thought into which one would serve my needs. I contacted a couple vendors and more than one told me they did not recommend a ceramic catalyst at all for rotary applications. Maybe it would be fine but I’d be reluctant to test it behind a turbocharger.

This Flowmaster catalyst has a stainless steel body and a 200 cell metallic core that should be resistant to clogging up or blowing out from the heat.

Mocking it up, I found that with the resonator in the right place the catalyst was at entirely the wrong angle. I kind of expected this, but I realized it was severe enough that modifying the downpipe would not be a good solution:

It is pointed right into the frame rail. So I ended up having to add some more of the curved pipe to the catalyst to achieve the angle I needed. Before:

After:

Then I mocked up the v-band flange, a 2.5” to 3” expander, and a cut section of the original pipe with the O2 bung to mate the two:

A bit ugly, but that entire forward section of the exhaust will be discarded soon anyways when I swap the engine.

To be continued.

With everything tacked I was ready to “finish weld” it.

I put that in quotes because I feel bad calling my work on this project “welding”. In short, it’s a combination of lack of skill and poor tools. My welder is a $300 special from Canadian Tire. It has four voltage settings (so you have to choose between “too hot” and “not hot enough”), the wire-speed varies audibly as I’m welding, and the settings required change drastically depending on temperature.

All that is to say that I was already starting from a poor foundation, and my lack of skill didn’t help. I’d actually made a small repair on the y-pipe in the past and found stainless quite easy to weld, but this time I ended up using too little current in an effort to not punch through the pipe.

This resulted in welds that looked like this:

The "Evil Energy" v-band came from Amazon. The logo is kind of ugly, but then it's hard to argue with $35 for all stainless bands and clamps compared to $100 from Vibrant. They work really well.

Predictably it looked terrible and leaked a lot when I did my first startup. So much so that I ended up grinding down all my welds for several hours and then rewelding everything a second time. I had to turn the welder to maximum power before I ended up getting a decent arc, and then after that the problem was mostly down to my method. The second pass didn't make it look much better, but it was gas-tight.

The back side of the weld was not protected by the shielding gas. Normally these parts should be back-purged with argon to prevent the back of the weld sucking in carbon, but without the equipment to do so I decided to compromise.

There are also two other factors that anyone considering a similar project should consider, which I failed to think about:

- Welding stainless too hot can compromise it’s anti-corrosion properties. Because I had to choose between too hot and too cold, I had to err on the side of too hot, and this has likely impacted the longevity of my exhaust.

- Stainless should be welded with pure argon, and I used 75% Argon 25% CO2. The stainless WILL weld fine with it, but the CO2 in the gas can allow carbon to get sucked into the weld and this will (again) compromise the anti-corrosion properties. I've used it for repairs on stainless before that seem to have lasted fine

Overall I doubt it will seriously matter. I might only get 10-15 years out of this exhaust rather than 30. By that time hopefully my skills will have grown and I can make an even better one.

With everything welded (again), the exhaust looks like this. Starting from the back is the small curved section, that rotates the resonator towards the passenger side, then the resonator itself:

After that, there is a small curved section rotating the catalyst back towards the driver's side (now running under / to the side of the transmission crossmember), and the catalyst itself with heat-shield:

And from there it’s just the original pipe.

Unfortunately I still have a slight leak from the flange where the manifold meets the downpipe (which might actually be the only original part of the car at this point). One or both of the flanges are warped. I did sand them down some, but frankly I just don’t want to fix this part. I have another manifold that might be better, but has bolts snapped off in all of the heat-shield mounts. I don’t really want to chase down another manifold or spend on a set of headers that will be replaced when I swap the engine, so for now I used some of the orange exhaust goo to mitigate the problem and will be ignoring the sound.

Speaking of ignoring the sound, a new set of shifter boots will help with that. I drove with the wrench shifter and no boots at all most of this autumn, and the rushing of the incoming air was lots of fun. Plus some leaves flew in, which added to the whole experience.

Honestly I could live with just having a gaping hole where the shifter comes through, except that the driveshaft is reachable through the hole at the right angle. I don’t want myself or a friend to lose some digits by absent-mindedly putting a hand in the wrong place, so I put the old boot back in while awaiting the new one.

The old boot is pretty crusty:

I found the cheapest source for these was Amayama, although it did end up taking about three weeks to reach my door. A perfectly valid trade-off when I’m not concerned about speed. The set comes with a new lower boot, middle boot, and upper boot. The middle and upper are identical, which made install a bit clumsy. I’m not sure whether it’s supposed to be that way or whether I received two identical parts by accident.

The lower boot was easy to remove because it was in such poor shape. Four bolts hold the little retaining plate in, and then the boot can be twisted inward until it pops free of the plate.

Here’s a comparison:

It was a bit tricky to wrestle the new one in, especially without removing the dash. The best way to do this would be to disassemble the shifter entirely and remove all the dash fasteners so it can be lifted up a bit, but it is possible to install without removing anything else.

Then I installed the middle and upper boots. The upper doesn’t sit very neatly since it’s identical to the middle, leading me to believe that maybe I wasn’t supposed to get two identical ones:

But it does seal, and it does dramatically reduce the noise while driving. So overall I’m happy with it. The wrench shifter started out as 50% joke, 50% not having a shift knob in the correct thread. I usually put the wrench shifter back in whenever the car is in a state of disrepair, but over the autumn months it's kind of grown on me. I'm still not sure how to integrate it with an interior that I try to keep mostly stock-appearing. I kind of want to put the 626 knob back in, but then the wrench feels super "clicky" and it's a lot of fun. Plus all my friends like it. I'm not sure where I'll land on this.

So what does the exhaust sound like? I took a short video to demonstrate:

Unfortunately it clipped the mic when I revved it, and it isn’t quite as bassy as real life, but it is a fairly good representation. The resonator made it a little quieter and removed some of the higher frequencies. It’s still quite loud when I wind it out, but idle and cruise are a lot better. I do still have a loud pop when I rev it high, but I think that’s something I’m going to have to live with. I might be able to tune out the popping on decel by playing with the DFCO transition point.

I was able to take a few test drives before the snow returned and the car is much more enjoyable to drive now. Not nearly as loud, and no exhaust stink rising through the shifter hole into the car. The only thing I have yet to test is whether the drone on the highway is gone.

Even from behind the car the stink of the exhaust is significantly, significantly reduced. I still need an air pump solution to help the catalyst survive longer but for now I’m quite pleased with the improvement. The catalyst sits much higher than before and only the heat-shield dips down below the frame rails, so I’ve also regained some clearance.

Lastly, the car feels like it makes more power at the top end. I’m thinking the original catalyst was clogged. Here’s an interesting picture I took:

I’d noticed this in the past and always chalked it up to being part of how the split-air tube works. I figured maybe the reason it goes all the way though the catalyst at an angle is that it has perforations to deposit the air evenly throughout the core, but then I don’t see any light coming through it even when I shine a flashlight. This leads me to wonder if the split-air tube is clogged (or mostly clogged). I know my auxiliary ports were working before. This means that there was at least some flow coming through that tube to drive the actuators.

Speaking of which, I am running with the aux ports zip-tied open for now (basically keeping the intake ports open 40 degrees later than normal at low RPM). I don’t love this solution (idle is noticeably worse and the car is a bit unhappy cruising below 3k now) but it will remain that way until I add in a better solution. Once I have the parts in-hand I should have a solution that improves the idle / emissions, and adds in improved aux-port functionality without a belt-driven pump or ACV. I think I also have a way to add some area under the curve in the 2500-4500 region too, but no promises until I can test it.

Love the effort here sir. For the Spray Vinyl/Plastic Dye go with SEM next time around. It sprays and lays MUCH nicer than the others out there. Pretty available online etc.

In reply to 84FSP :

I actually tested back to back and found the SEM did spray better and was more durable. But I liked the Duplicolor finish a bit better (less glossy) so I stuck with it.