In reply to GameboyRMH:

Do you have links to any articles that support you're saying? I don't doubt what you're saying, but the guy who has won the last 11 years in a row doesn't have any on his car and he had an aerodynamicist work on his aero package.

In reply to loosecannon:

Yup-I agree with Gameboy! There are a few things you can add to your design to create a more efficient design-including strakes!

Here's a link for the support you requested;

https://www.youtube.com/watch?v=3DIJMLrGz8Q

You can skip to 3:44 for answers, although I'd suggest checking out the whole video as his series are usually pretty good.

I also try to tell my friends to, if possible, never have a completely flat section between your front/rear axles! Yes, crazy talk, but this "flat floor" thing was an old rule regulation implemented in the 80's IMSA days when cars had 1500hp and OEM aero at their disposal.

If possible, you'd want to add "tunnels" between your axles to help promote laminar flow resulting in a more efficient low pressure zone feeding that diffuser. Also, if you still can, relocate those L-bracket attachments to the outside of your diffuser as they will cause that expanding air to detach and loose efficiency.

The slower you're going, the harder it is to keep that air attached (energized/working). With autocross on the slower end of autosports, it's paramount to keep that air attached. That's where spoilers are preferred over "wings" in the rear. Spoilers are high downforce/high drag devices, whereas downforce/drag can be better tuned in a wing. But all that doesn't matter that much because your autocross speeds are quite a bit lower than on a road course, so you're not fighting drag with more horsepower to overcome the deficit.

Now, I'm no engineer, but I stayed at a Holiday Inn last week!![]()

Another good video on diffuser strakes here:

It still doesn't cover the use of strakes to increase downforce at low speeds though, which is what I'm after. Mike Kojima mentions it here:

Can't remember where I originally learned that...but from what I remember, here is the effect you have from adding or removing strakes:

More strakes reduce the maximum downforce that can be generated but cause more downforce to be generated at low speeds, and make it more stable.

Less strakes maximize the amount of downforce that can be generated but reduce downforce at low speeds, and the downforce is less stable.

Not sure where your last post went! In any case, I wasn't trying to criticize what you've done-I just noticed a few things that would improve on your great work. For me, the angle aluminum was a concern because it was in the path of the expanding air.

It sounds like your rules set prohibits you from adding anything else, so the strakes thought is a non-starter (as well as the floor).

"Aero" can start having an effect at the speeds you're competing at- especially when you start combining elements to work in conjunction with each other (e.g. wing/spoiler energizing the diffuser).

Again, I didn't mean to sound critical. I definitely enjoy your work and seeing the updates!![]()

I needed a bead rolling tool for the intercooler piping, and made one: https://www.youtube.com/watch?v=4nYJPLaY8jw

I disassembled the diffuser and re-did it with the brackets and rivets on the outside so as not to disturb the airflow, and hit it with some PlastiDip

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_7245_zpslba33s9e.jpg.html] [/URL]

[/URL]

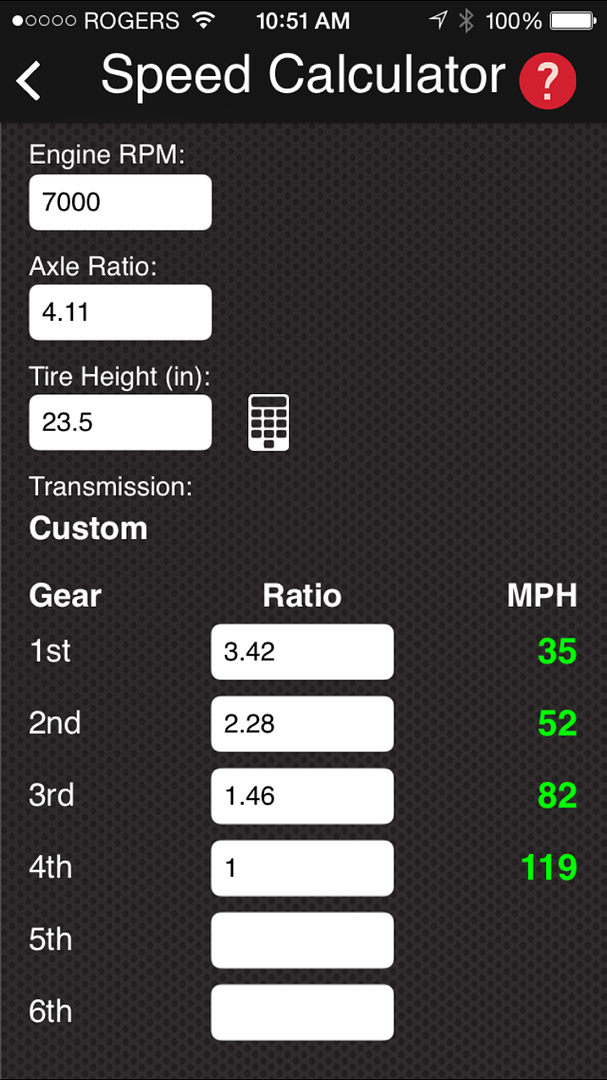

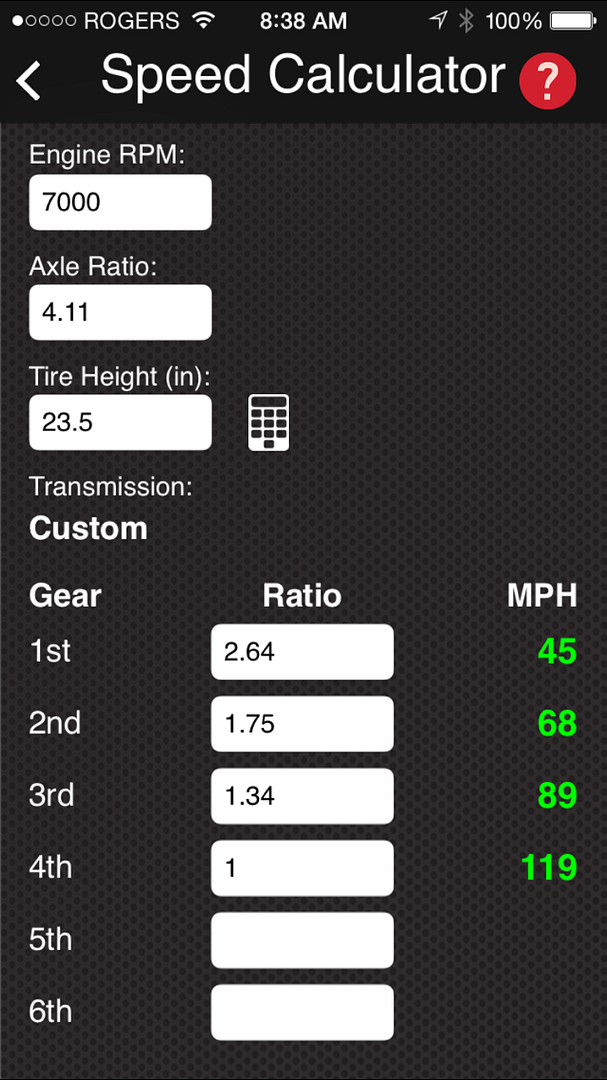

When I purchased my transmission, I thought the 82 mph in 3rd gear would be perfect for Nationals because most people agree that we hit 80 mph on the courses. However, I found out pretty quickly that 1st was a little low so we would start off in 2nd and use 2nd and 3rd only. There is a 30 mph spread between 2nd and 3rd and it would take a moment for the power to come up again. Also, several times on course, the car would either be redline in 2nd or lugging in 3rd. I looked at other available gears available for the Super T10 and found one that will work much better. It has a useful 1st gear that is good for 45 mph and a 23 mph spread to 2nd gear and another 21 mph spread to 3rd gear. This should result in better acceleration and more choices of gears on track. It was way cheaper to buy a new gearset than a new transmission so that's what I did. Attached are pictures from a speed calculator for the old gearset (3.42 first gear) and new (2.64 first gear) plus a picture of the actual gears.

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_6507_zpszfyabgfd.png.html] [/URL]

[/URL]

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_6447_zpsp0tfexai.png.html] [/URL]

[/URL]

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_7267_zps8hsmd8j9.jpg.html] [/URL]

[/URL]

That gear spacing sounds so much better. At what rpm are you getting full spool in the car? I would assume somehwere around 3250 or so.

Looking at the graph your splits from redline to next gear now put you right in the meat sitting 4500 & 5000 ish respectively. Before it was closer to 3k after a shift.

I'm late to the discussion, but the discussion on the diffuser design peaked my interest. First off, careful with what you see posted on youtube/ online resources outide of SAE articles when it comes to automotive aero. Diffusers in general are very complex devices and their operation isn't very intuitive.

What I would suggest is to run the diffuser as-is and use a qualitative test method to see if your flow is attached or not. You can do this using a technique called yarn tufting or by applying thinned colored oil to the surface of the diffuser. For the thinned oil method, apply thinned oil at the entrance of the diffuser. Then run the car in a straight line at the speed that you are designing for. Finally, bring the car into the pits and take pictures of the underside of the diffuser. if the oil streaks all the way from the point of application to the end of the diffuser, then the flow is attached in the diffuser at your test speed. If you see the oil streak stop at a certain point, then your flow is detaching off the diffuser at that point at your test speed. If you find separation, then add strakes until you find the amount that is necessary to stop separation. Also, your placement/size of your spoiler will affect the operation of your diffuser as well, and the amount of strakes you need. Unfortunately automotive aero is not a very intuitive thing, and the best way to go about it in a grassroots way is testing. Hope that helps.

Thinkkker wrote: That gear spacing sounds so much better. At what rpm are you getting full spool in the car? I would assume somehwere around 3250 or so. Looking at the graph your splits *from redline to next gear* now put you right in the meat sitting 4500 & 5000 ish respectively. Before it was closer to 3k after a shift.

Peak torque is at 4744 rpm and peak hp is at 5227 rpm. The torque rpm number seems pretty high for a turbo motor but that's what the dyno sheet says. From lunch to top speed, I was splitting that between 2 gears but now will be using 3, so it should result in better acceleration.

cheechthechi wrote: I'm late to the discussion, but the discussion on the diffuser design peaked my interest. First off, careful with what you see posted on youtube/ online resources outide of SAE articles when it comes to automotive aero. Diffusers in general are very complex devices and their operation isn't very intuitive. What I would suggest is to run the diffuser as-is and use a qualitative test method to see if your flow is attached or not. You can do this using a technique called yarn tufting or by applying thinned colored oil to the surface of the diffuser. For the thinned oil method, apply thinned oil at the entrance of the diffuser. Then run the car in a straight line at the speed that you are designing for. Finally, bring the car into the pits and take pictures of the underside of the diffuser. if the oil streaks all the way from the point of application to the end of the diffuser, then the flow is attached in the diffuser at your test speed. If you see the oil streak stop at a certain point, then your flow is detaching off the diffuser at that point at your test speed. If you find separation, then add strakes until you find the amount that is necessary to stop separation. Also, your placement/size of your spoiler will affect the operation of your diffuser as well, and the amount of strakes you need. Unfortunately automotive aero is not a very intuitive thing, and the best way to go about it in a grassroots way is testing. Hope that helps.

This is a great suggestion. I like the idea of tufts of yarn on the diffuser then taking video but the oil could work pretty nice, too.

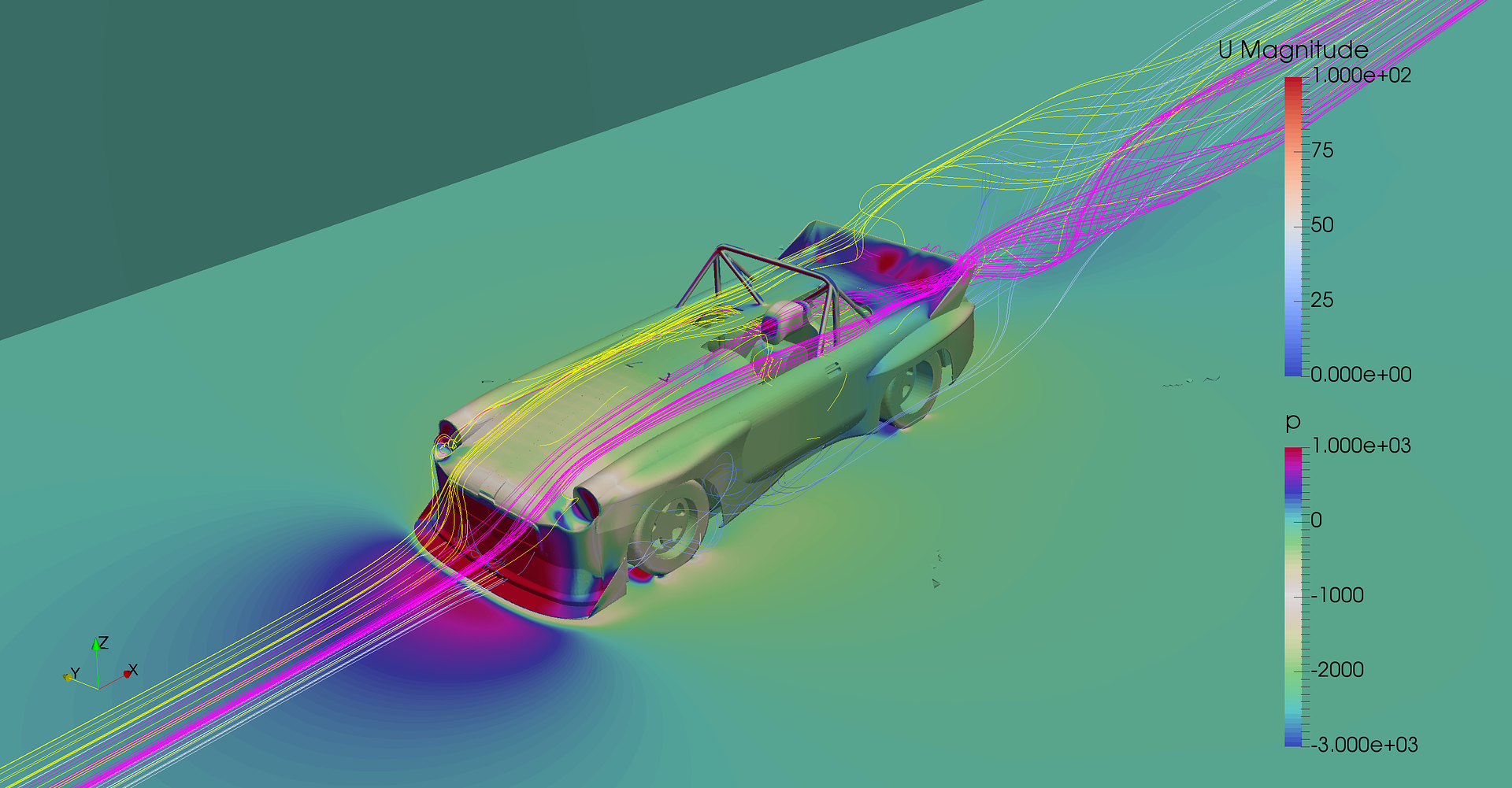

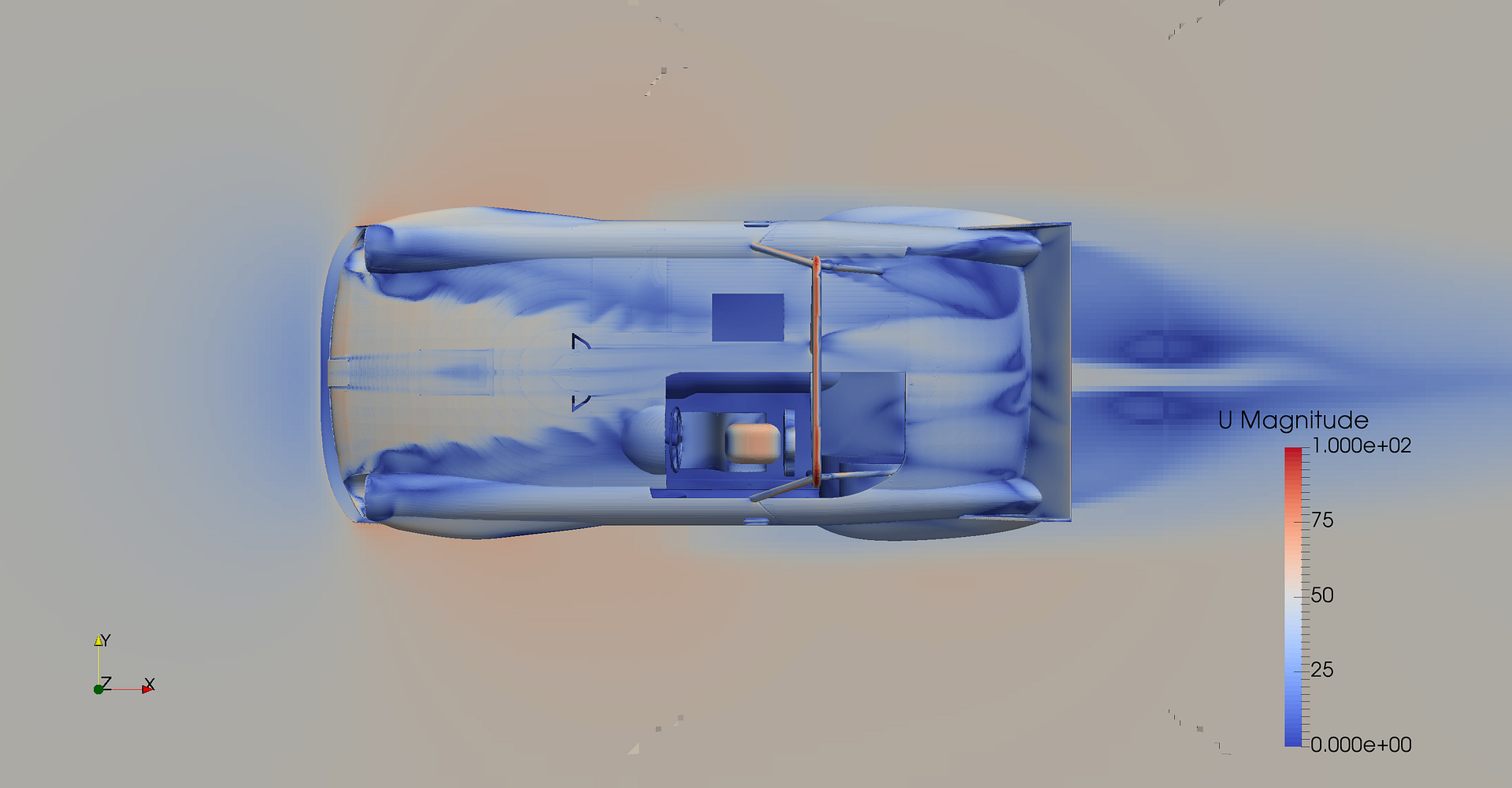

Update: My transmission has been sent off to a shop to get the new gears put in and I have hired Kyle from the Kyle Drives YouTube page to help me with the aerodynamics of the car. He is currently modelling the Pink Panther in 3D CAD so he can do a Computational Fluid Dynamics test on it. We Skyped for a while and he has looked over pictures and video of the car and has already given me some suggestions on what to do. Everything he has suggested is easy to do but he is going to do a CFD run before and after the changes to see how big the benefits are. He liked what he saw so far and I'm happy I have not made any big mistakes with the aero. Here is his YouTube page, and he is as friendly as he seems in the videos: https://www.youtube.com/channel/UCh3tzzP6n5b1EWcMUpiEhXg

Made a new cowl out of aluminum, video is attached

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_7528_zpsqxeqh5cb.jpg.html] [/URL]

[/URL]

https://youtu.be/FUNj-WbxCRk

In reply to loosecannon: Have been following along as 'becbgt' on mgexp. Did you go into greater detail on Ytube for the 2.4 ecm install/hookup/tune? To have the time, space, tools, skills....woof some day soon.

759NRNG wrote: In reply to loosecannon: Have been following along as 'becbgt' on mgexp. Did you go into greater detail on Ytube for the 2.4 ecm install/hookup/tune? To have the time, space, tools, skills....woof some day soon.

I don't know, there was a lot of time put into getting the 2.0 LHU running and most of it was really technical and boring. If you have an older 2.0 or 2.4 Ecotec, it's a lot easier. There are standalone wiring harnesses and tunes all over the place, but the LHU with the E39A ECM is too advanced for everybody. The car is done and now it's just fine tuning the handling and aero. I'll still get video of all the competitions I'm in and post those to YouTube so make sure you subscribe to my page https://www.youtube.com/channel/UCe50QeA3lG1KogAVpWraiIw

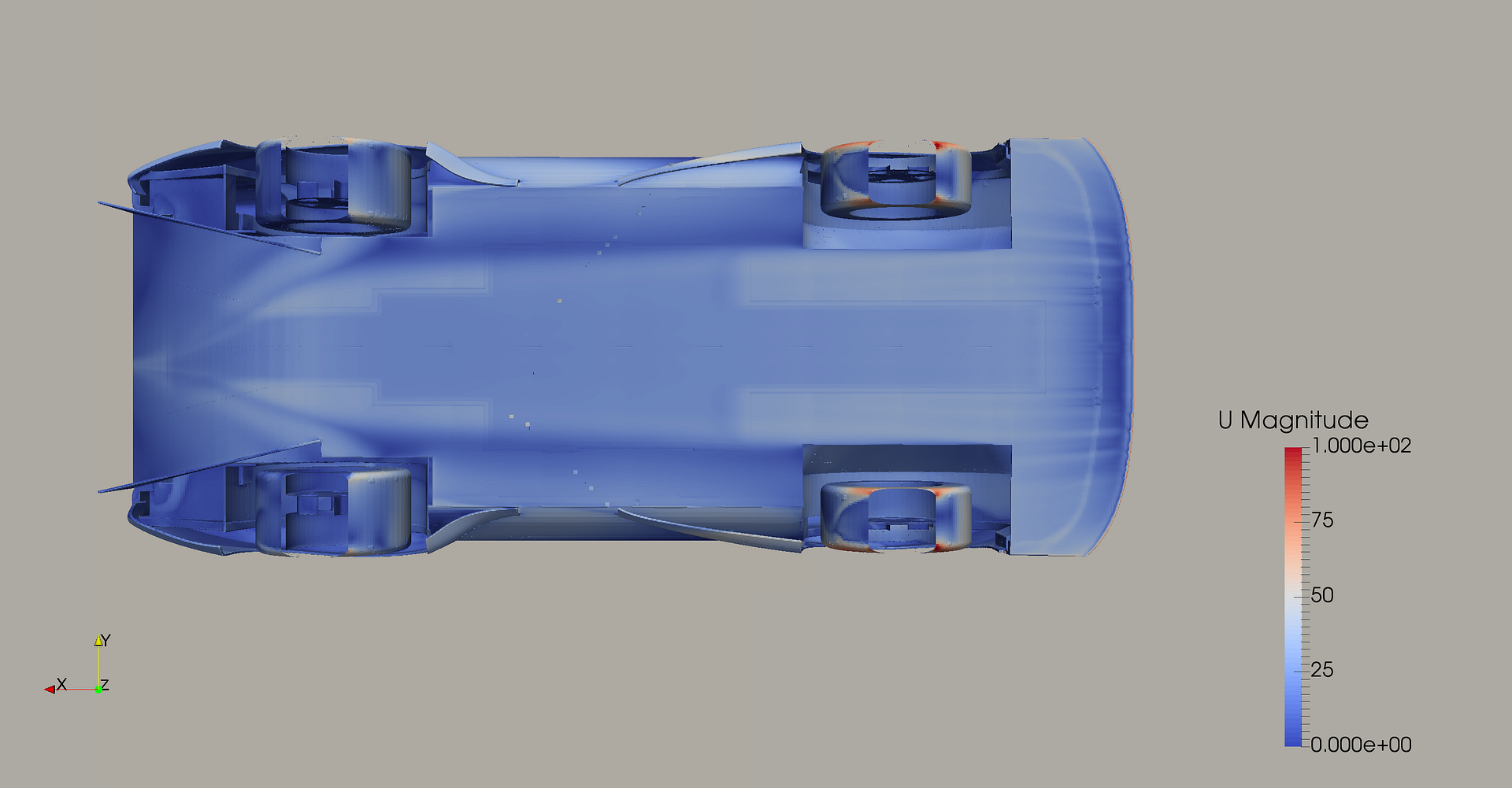

I have consulted with Kyle from the Kyle Drives YouTube page and hey, guess what? My rear diffuser is pretty good as it is and the CFD confirms it. To be perfect, it should be slightly narrower and slightly lower but no extra strakes required.

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/streamlines2_zpse73g05l0.png.html] [/URL]

[/URL]

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/Walvel2_zpsq9kuowoj.png.html] [/URL]

[/URL]

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/Walvel4_zpsd2gd8ac1.png.html] [/URL]

[/URL]

https://youtu.be/FUNj-WbxCRk

https://youtu.be/_qY1_gEXxHI

In reply to loosecannon: Not knowing the rules regarding body mods in EMod, would (if legal) front fender headlight covers that conform to the fender shape add any appreciable benefit to these purty pictures....er PinkP?

In the CFD simulations, have you tried simulating the aero changes with suspension movement or is it basically a stationary model in a wind tunnel?

In reply to GameboyRMH:

Stationary, costs go up fast when you start simulating different scenarios like pitch and roll

That explains why it's showing no strakes as being optimal - because it IS optimal in a wind tunnel, where there are no stability issues to worry about. To think in terms of design-by-example, consider this: Most of this year's WRC cars have diffusers, and from what I can find, it looks like all of those that do have plenty of strakes. Citroen even went to strakes after testing a strakeless diffuser on theirs:

In reply to GameboyRMH:

I will specifically ask Kyle about this when he gets back from consulting with one of the Formula 1 teams

In reply to loosecannon: Hey big thanks for the email/links (becbgt). Will view them soon,but this 80f temp and bluebird skies are callimg me out doors on the tractor. With this latest push, are vents/openings on the tops of the front fenders a possibility?

In reply to 759NRNG:

I hope it doesn't come to that. With the speeds I go, I doubt that more vents on top of the fender are necessary.

You'll need to log in to post.