AutoZone sells various lengths of replacement stainless steel hard line with brass inverted flare union fittings for just a few bucks each. We picked up two lengths so we had enough fitting hardware to perform a splice.

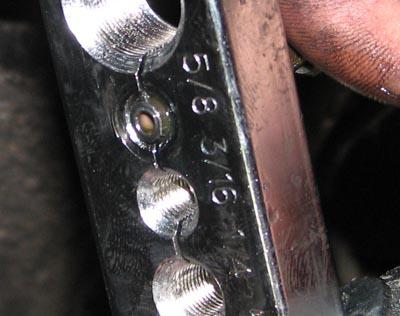

After cutting the stock brake line with a line cutter, we used a flare tool to give the line the proper shape for the inverted flare union fitting. Don’t forget to slide the flare union collar on the line before you flare it out, or you’ll be cutting again and starting over.

The stock brake line was pinched, but we were able to blow through it, so it might not have been the source of the problem. Still, removing it puts one less variable in the mix.

Connecting the OEM line to our aftermarket splice was simply a matter of tightening four flare union fittings.

We curved the replacement line so it follows nearly the same path as the segment it replaced.

We used an old car wash bottle and some of the same clear hose we use to bleed our brakes to siphon the brake fluid out of the master cylinder reservoir. This kept the spillage to a minimum when we removed the reservoir.

We found this Girling master cylinder at the local junkyard on a BMW 318is. It looked to be in better shape than our car’s master cylinder, it was easy to remove at the junkyard, and it cost just $6.

Just like we did with the fuel lines, we marked the brake lines going into the ABS unit with easy-to-read tape flags so we don’t get confused and cross anything up. The unique shape of the OEM lines would make messing up difficult, but backup plans are good.

Using a Torx-head socket we removed the ABS’s plastic shield, then we unplugged the big electrical connector and undid the brake lines. The big plug took some tugging, but it slides off vertically (don’t forget to remove the cable collar at its base first).

With the ABS pump and master cylinder replaced, we filled the reservoir with Motul RBF 600 brake fluid in the hopes that some of it would drain into the system while we swapped out the rear brake calipers.

Can you point to the old caliper? Now point to the remanufactured caliper. Hint: the really gross one is the old one.

Our refurbished rear calipers are so shiny they look almost out of place on the old rotors.

We used a Harbor Freight hand pump to get the bleeding process started; once the master cylinder had filled up, it was pushing fluid on its own and we were able to bleed the lines normally.

With our fuel delivery issue sorted out, the next big ugly box on our to-do list was the brakes. Specifically, we needed to eliminate the BMW’s tendency to apply increasingly severe rear brake line pressure to both rear wheels all by itself until the car could barely accelerate, even in first gear.

After experiencing the problem in competition and re-creating it under test conditions, we had a pretty good idea of what was going wrong. The rear brake line (it’s a single hydraulic line until it splits in two near the rear differential) was for some reason unable to release pressure, causing the rear pads to drag on the rotors. This manifested itself physically by making it feel like the parking brake was partly engaged, as the rear of the car would dip under acceleration from a stop and more gas than usually was necessary to get underway.

If we tried to drive through the problem, the pads would continue to drag, heating everything up. As the calipers and lines heated up, the fluid inside them expanded, increasing the pressure. When things were at their worst, the car would barely move. With enough momentum we could drive through the problem to a certain extent, but this had pretty catastrophic consequences for the poor rear brake pads as they were pushed well beyond their temperature limits.

Finding the source of the problem was the real trick. Essentially, it could be any one of the four major components that make up the brake system. Originally there could have been five sources, but we already removed our rear brake line pressure regulator at the NASA Championships, so all that’s left of our brake system is the master cylinder, the lines themselves, the ABS unit and the rear brake calipers.

Our rear brake calipers were gross, but we’d given them a field refurbishing at the NASA Championships and the pins slid and the piston compressed as they should. Also, the problem seemed symmetrical, so we felt it was unlikely that the rear calipers were simultaneously responsible. Still, our calipers were rusty and gross, so we got a set of refurbished calipers from Redline BMW for $65 each. One variable down.

Next we pondered the brake lines themselves. We found a dinged-in section of line when we were replacing our fuel tank. In our testing we determined that disconnecting the brake line fitting at the ABS pump relieved the pressure on the rear brakes and allowed the car to roll, so logic dictates that the problem was at the ABS pump or upstream of that, but we still didn’t like the idea of a crimped line, even if it was allowing fluid to flow freely. We picked up some replacement steel line at AutoZone. That’s another variable checked off.

Next on our potential list of culprits is the ABS unit. The first time we experienced the problem was at Summit Point just after some particularly heavy braking going into Turn 5. We were very likely engaging the ABS, and when we went to get back on the gas the tail end was locked up so hard we barely made it back into the pits at full throttle in second gear.

The factory service manual warns against tinkering with the ABS unit, but it didn’t really say anything about replacing it. Rennie at the aforementioned Redline BMW had an old 325i pump in his possession, so we figured making the swap was worth the trouble. There’s no guarantee that the new used pump is any better than our used used pump, but we’ll cross our fingers as this is the component we suspect the most.

The last potential culprit is the brake master cylinder. This little doodad goes for about $150 at the online retailers, so we were going to skip it on this first round. All that changed when we saw an engineless BMW 318is at the local junkyard with a fairly new looking Girling master cylinder. we ran home, grabbed our flare wrenches and sockets, and about 15 minutes and $6 later we had a replacement master cylinder. It even cleaned up prettier than our stock unit.

Short of replacing all the lines and buying a brand-new ABS unit, we’ve attacked this problem on all fronts with this recent bout of work. We though about doing things part-by-part in an effort to pin down the exact culprit, but bleeding brakes more than once seems like a hassle when you’re dealing with $6 used parts. Frankly, we don’t care if it was the ABS pump or the master cylinder as long as the new parts have fixed the problem.

View all comments on the GRM forums

You'll need to log in to post.