We had the stock drivetrain out of our 350Z, so now it was time to put the finishing touches on the drivetrain we’d be installing–a Chevy LS1 V8 we rebuilt ourselves and a brand new Tremec Magnum from American Powertrain.

First up: An oil pan. We left the stock F-body oil pan that our LS1 came with for its trip up to LOJ Conversions, but there was no way that would fit into our 350Z. Instead, we bolted on a LOJ 350Z oil pan. Since we were using their Ultimate Swap Kit to swap the engine into our 350Z, this was included in the kit. And it’s not just a normal pan, either: it boasts a 7-quart capacity with trap doors and a nice windage tray, which should help us keep oil in our engine on track.

Next: Knock sensors. Since we’d converted our Gen III LS1 to use a Gen IV electronics package, we wouldn’t be able to use the Gen III knock sensors located in the engine’s valley cover. Instead, we drilled and tapped the block for Gen IV knock sensors, which are located on the outside of each cylinder bank. Once the knock sensors were installed, we bolted the LOJ engine mounts on, too.

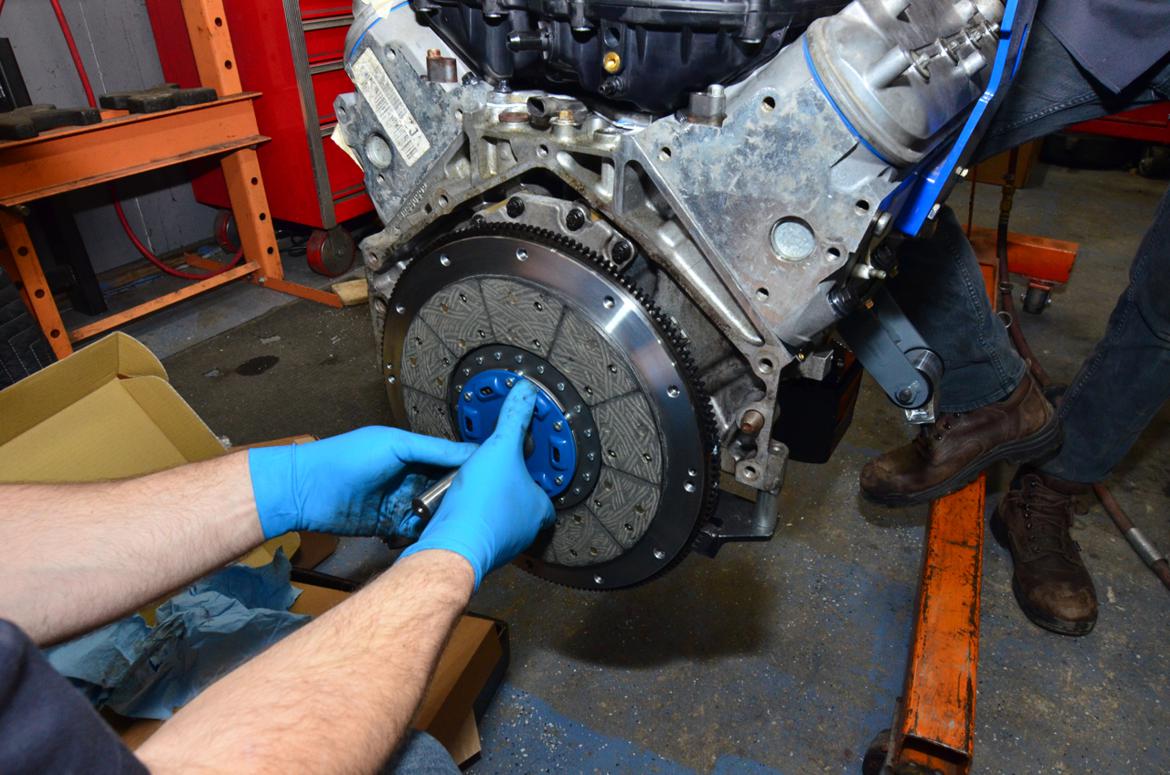

With that, the engine was officially ready to go in the car–we’ll cover the accessories and such later. Now, though, it was time to attach the transmission. We used a complete kit from American Powertrain, which included their clutch, steel lightweight flywheel, bellhousing, and all the odds and ends necessary to put it all together. Since our engine is mostly stock, we didn’t go crazy with the clutch, sticking to what’s known colloquially as a “stage one” setup. After shimming the hydraulic throwout bearing, we bolted the transmission to the engine.

One more step: The shifter. Our Tremec Magnum‘s shifter didn’t pop out in the right spot, so we used American Powertrain’s White Lightning shifter to put the shift knob in the correct spot.

Once the shifter was on, we were ready to put the drivetrain in the car.

View all comments on the GRM forums

You'll need to log in to post.