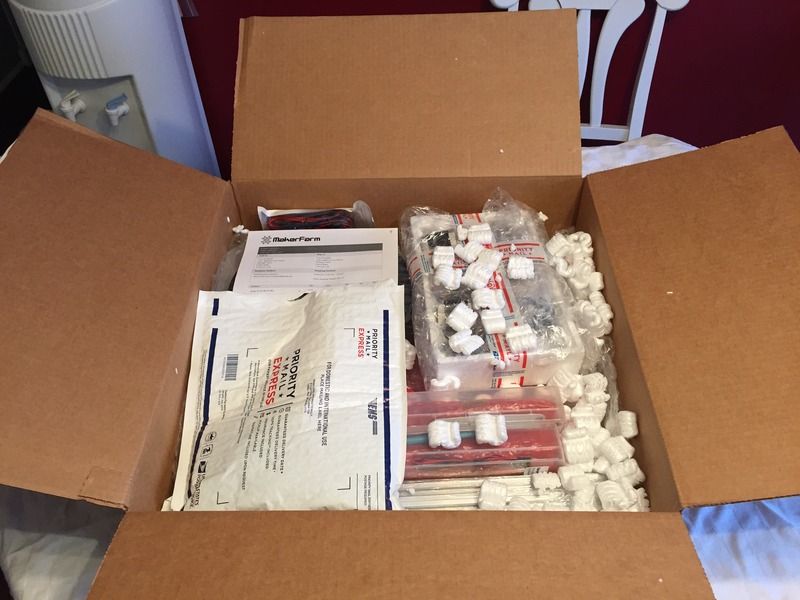

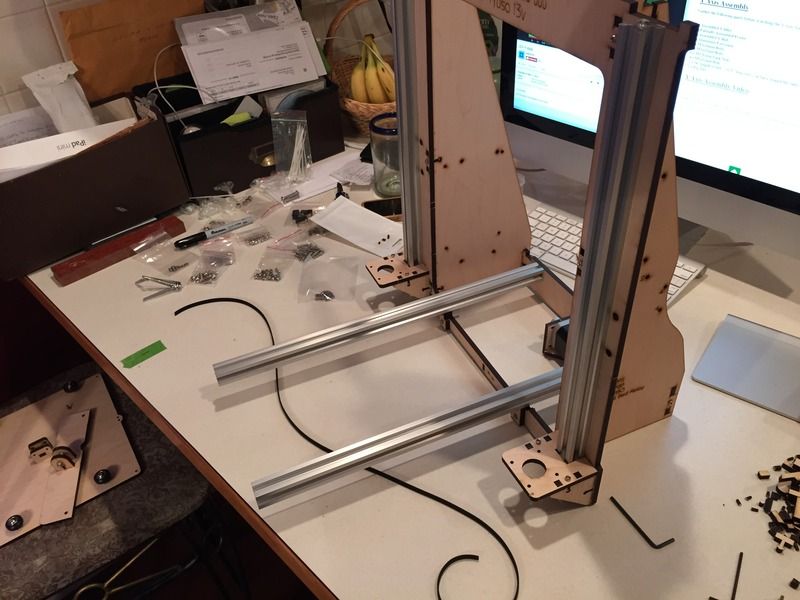

The world of 3D printers has finally hit the balance of quality/price for me to finally bite the bullet, and I've been asked to do a build thread, so here we go. After researching, and researching, and doing some research I decided on a Prusa-style printer. It uses Cartesian coordinates (X,Y, and Z, axis) with multiple motors and belts. This style has the print bed moving on the Y axis. Not my first choice because I could see a tall build falling over due to the movement? I guess we'll see. So, here's why I chose the model I did. I chose the Prusa 10 i3v because it has a 10X10X10 build envelope. That's bigger than all but a few, and at a much cheaper price than anything comparable. Most units ride on round rods with bushings for the movement. This one uses aluminum extrusions and tapered Delrin bushings for speed and accuracy. But there are two reasons that, together, were the deciding factor. Price and customer service. The printer is under $600, depending on how you outfit the printer. The other factor, customer service, was huge to me. Others have said that Colin at Maker Farm (www.makerfarm.com) is very responsive and knowledgeable. I've asked him 3 questions I think, one when I was deciding what unit I wanted, and twice during the build. He always gets back to me in a matter of a few hours, even in the middle of the afternoon on Saturday. That's huge. Colin is great. So, anyway, on to the build. What showed up on my door was a relatively small box full of fun and goodness.

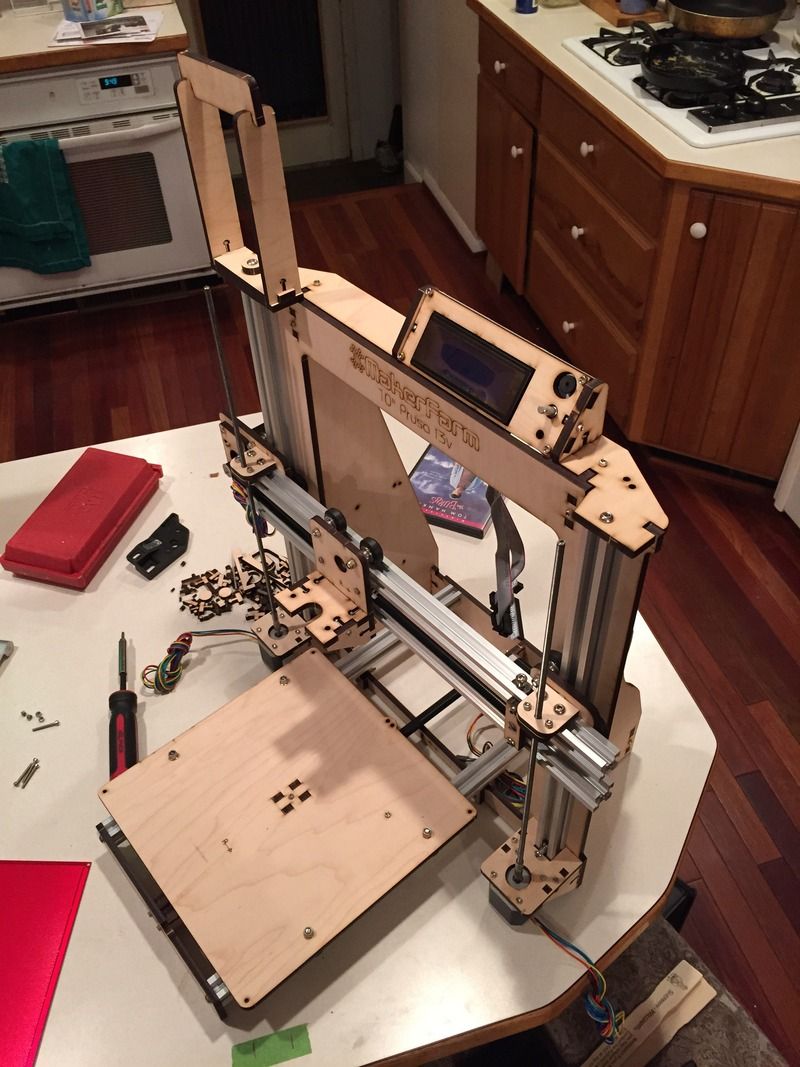

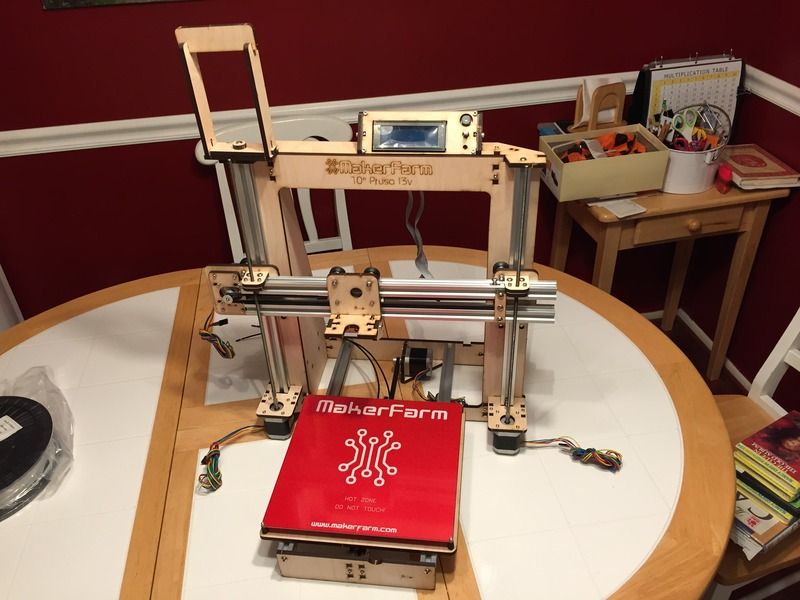

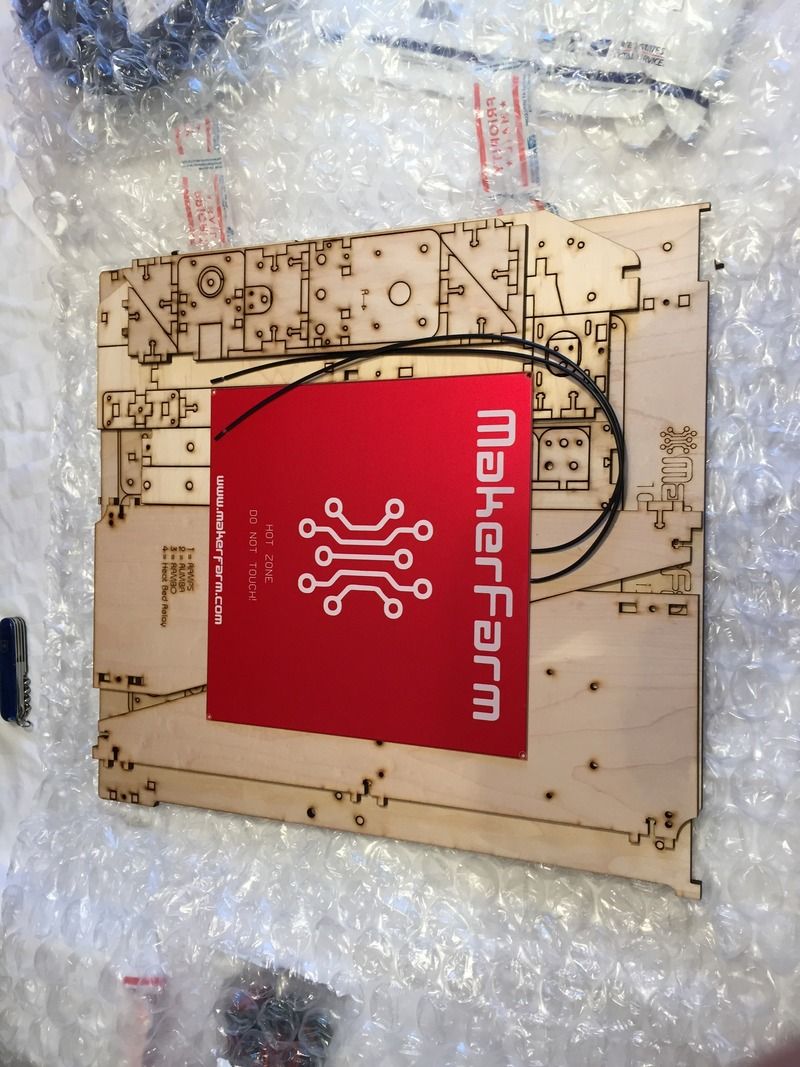

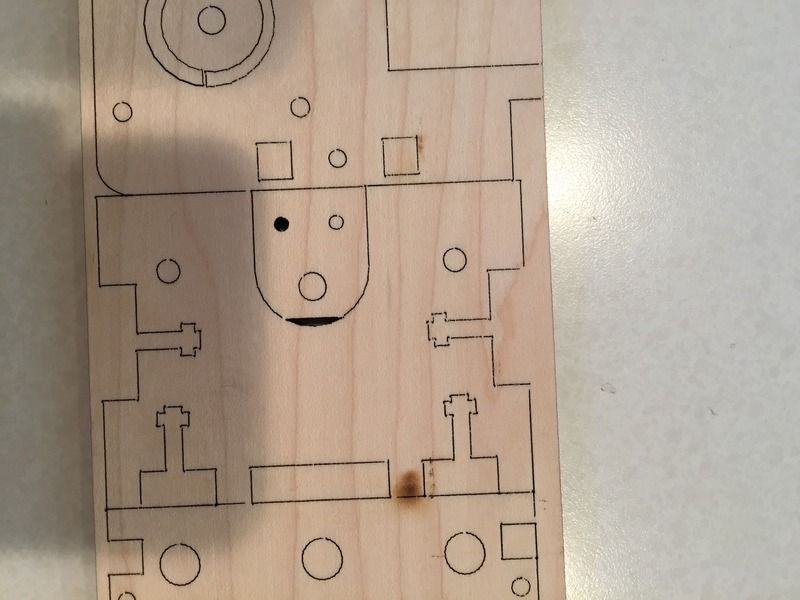

The frame of this unit is wood, birch plywood, with all the pieces laser cut with amazing precision.

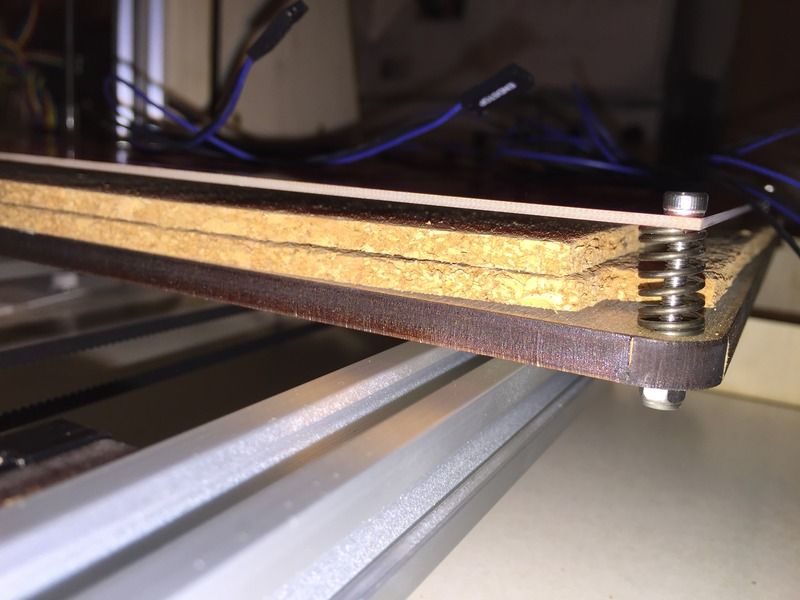

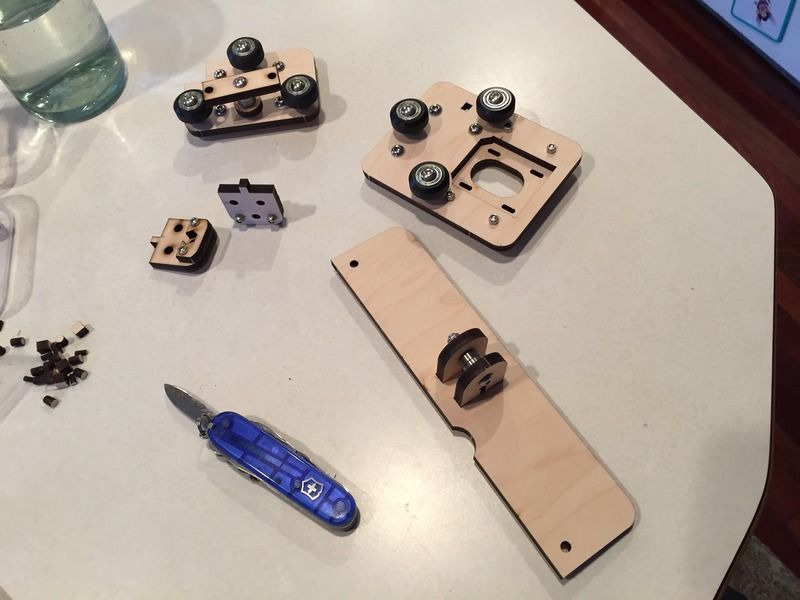

The frame of this unit is wood, birch plywood, with all the pieces laser cut with amazing precision.  The instructions are clear and concise, they are a series of videos actually. Each step has an accompanying video, that helps. I'm just realizing that I didnt take a ton of pictures, I was having too much fun putting it together. The engineering is great. Lots of parts can only go together one way, by design. Anyway, here's a few of the sub-assemblies from day one of the build.

The instructions are clear and concise, they are a series of videos actually. Each step has an accompanying video, that helps. I'm just realizing that I didnt take a ton of pictures, I was having too much fun putting it together. The engineering is great. Lots of parts can only go together one way, by design. Anyway, here's a few of the sub-assemblies from day one of the build.  The kit came on pretty much the worst weekend. I was busy and only had a few hours to fart around. More updates to come....

The kit came on pretty much the worst weekend. I was busy and only had a few hours to fart around. More updates to come....

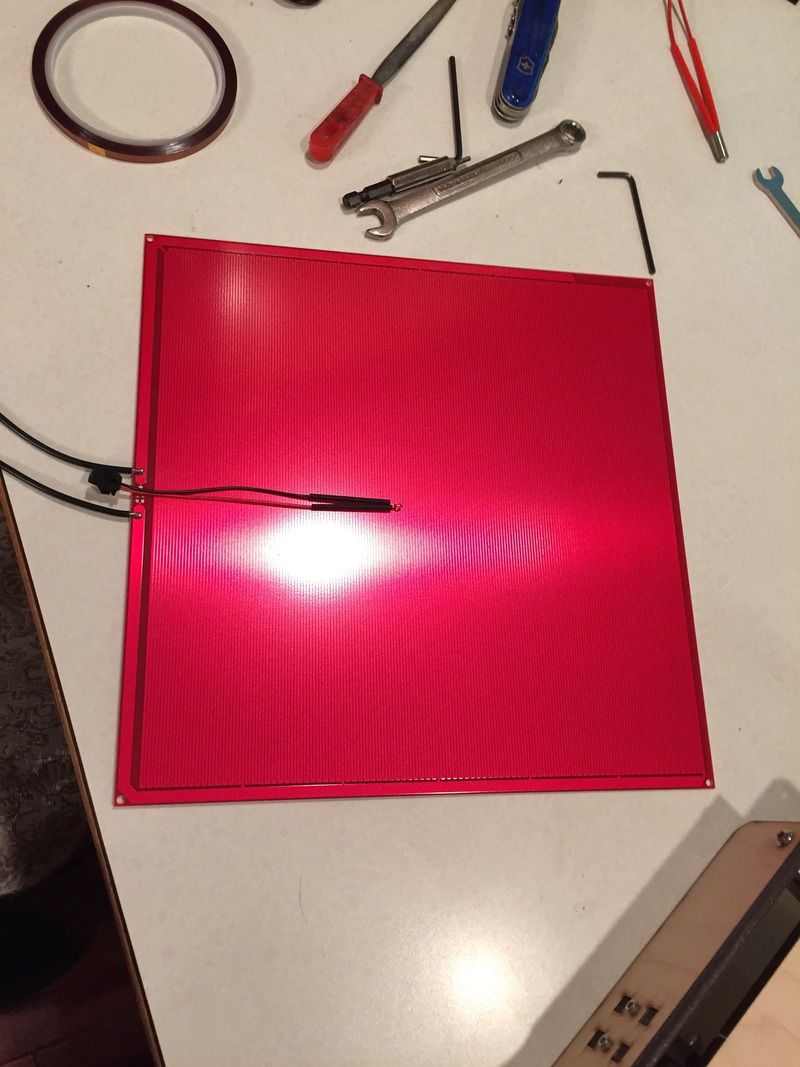

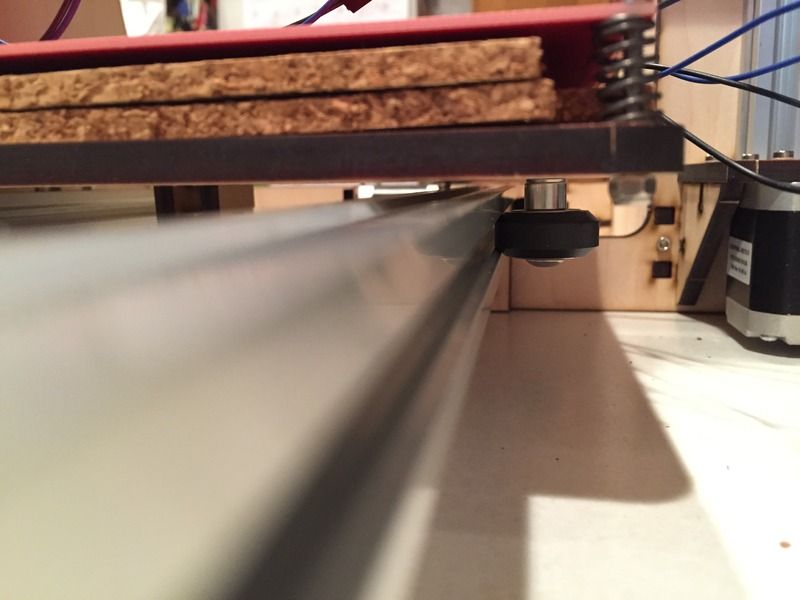

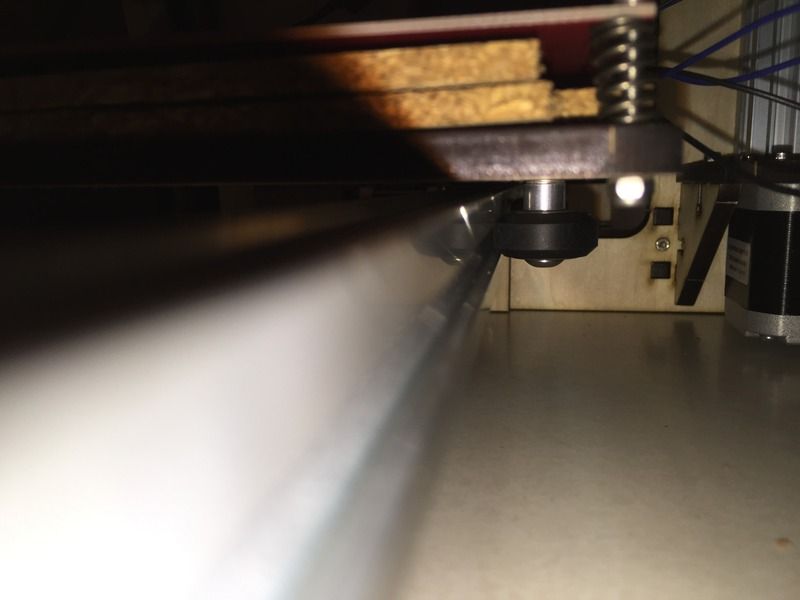

I don't know which picture is worse than the other haha.

I don't know which picture is worse than the other haha.