I'm going to add brake coolers to my Miata, and I was wondering where the best place to put the inlets on the air dam are, aero vs function trade-off kinda thing? Yes, I know that any holes in the air dam decrease functionality of it, but cool brakes are happy brakes..

I was thinking of putting them where the red circle is, I'm guessing that has the lowest aero hit? Yellow might pick up less debris, though, I would guess green would have the highest aero drag and pick up the most junk..

Really, I have no idea obviously :)

The higher is likely better so you keep more pressure on the splitter.

I'd put it right above the splitter for more flow to the brakes.

so, offhand, I know that this car has acceptable brake cooling... for 20min sprint races (NMSA):

iirc, that's a 2.5" diameter inlet, and that position was largely determined by the structure behind the bumper, and the ease of running the tubing to the caliper... which I'd guess is probably going to be a greater determiner of where you'll end up putting it, than the actual aerodynamics.

something else to think about: I'd say you'd probably want it to be at the same height as the center of your radiator inlet. You might also think about 'building up' the outboard edges of the inlet so that it 'captures' the flow that is trying to go 'sideways' across the face of the bumper.

Thanks guys!

Looks like the car Buffalo posted is using the same kit I bought (https://www.good-win-racing.com/Mazda-Performance-Part/61-1717.html), so I'll probably go with that.

I'll keep my IR pyrometer nearby and see if I need to get more aggressive, like building up the outside edges (great idea!).

You could use a manometer to test a few different places to see where the highest pressure actually is. It's hard to know just by looking.

If you put the brake duct at the highest pressure location, you get the best cooling flow.

The great thing about the manometer is it measures differential in pressure between two vacuum lines. So put one end near the brake rotor to measure the pressure where the brake duct will 'exhaust', and put the other end on the front of the car at a planned 'inlet' location. Also, you can use the manometer for over and under the splitter to measure the difference in pressure that creates downforce, so you can see if the downforce measurably changes after adding the holes.

You might be surprised to find little difference or even negative pressure in some areas. No difference in pressure = no airflow, no matter how good the location looks.

I've got a manometer you can borrow for the cost of shipping, but I think I bought mine on eBay for like $20.

Yup, highest pressure location. I'm thinking that's going to be close to the splitter.

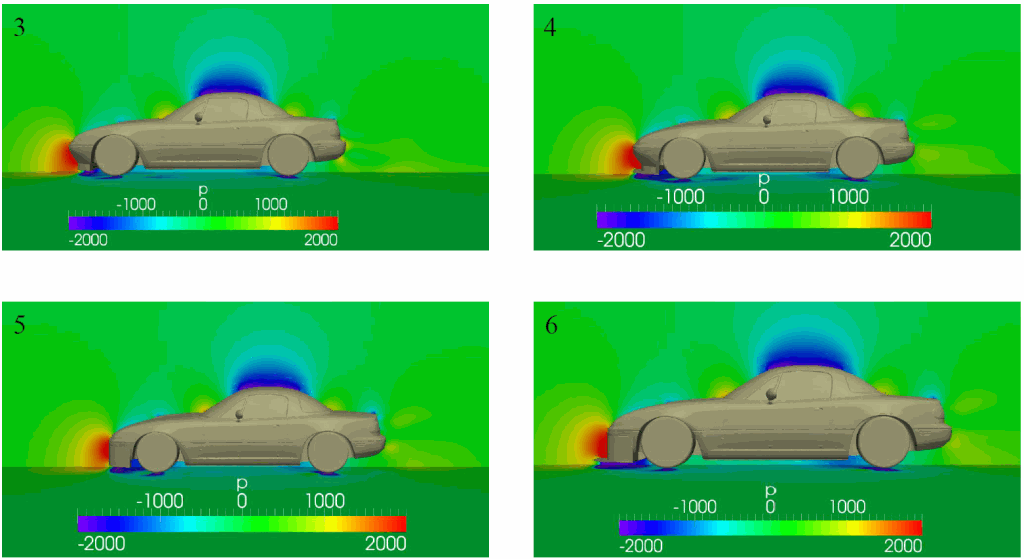

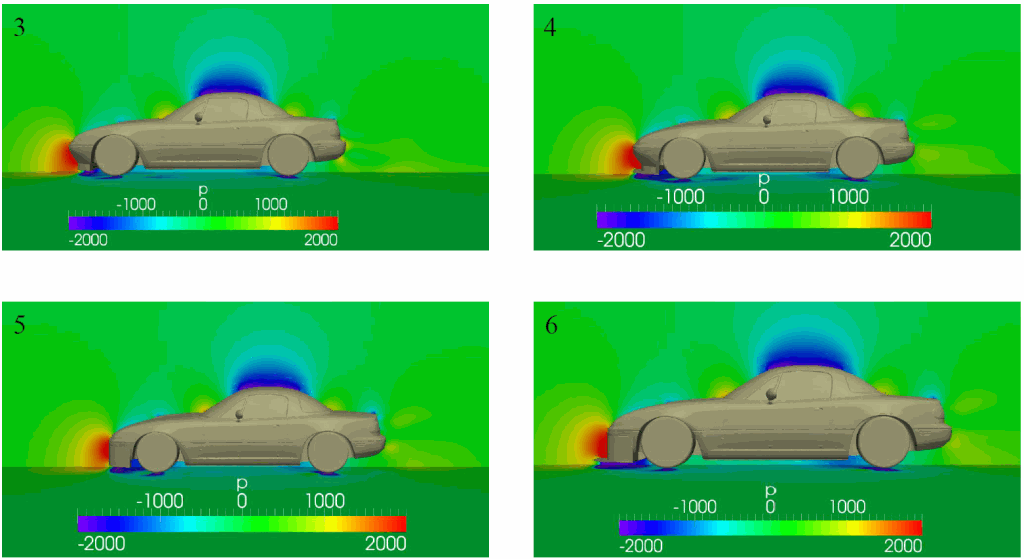

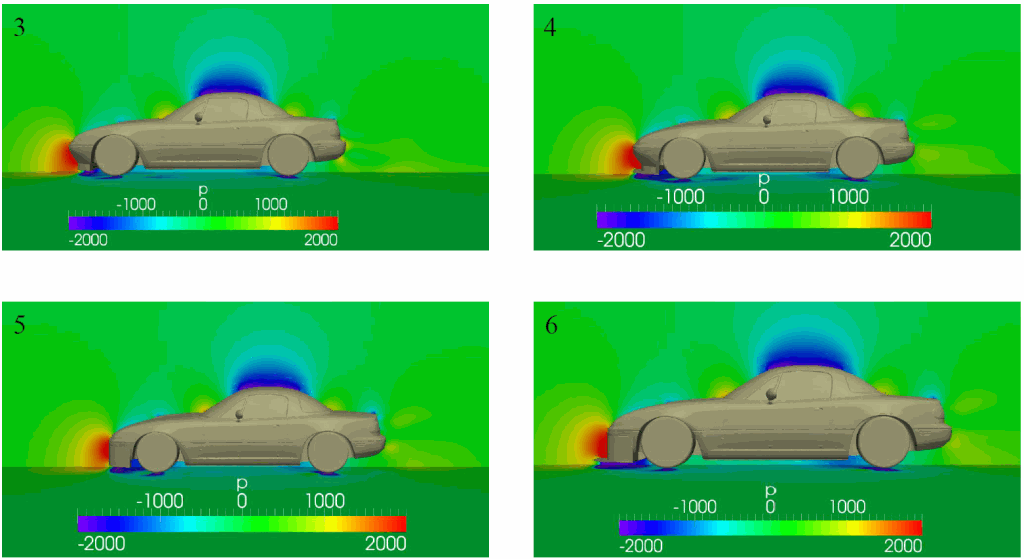

Edit: maybe not. Check this out. Your setup is #6. That's a pretty big happy zone.

Also, get a proper bellmouth for it. That'll improve efficiency.

I learned the hard way that 2.5" ducts may not be sufficient for Miata brake cooling if you're really working them hard, and switched to 3". That's a high power car on a high altitude track.

In reply to Robbie (Forum Supporter) :

one thing to keep in mind, when using the manometer, is you have to keep the tube port 'tangential' to the flow... so that the flow goes 'across' the open tube, similar to blowing a note over the top of a bottle.

another thing to keep in mind, is that an internal cooling flow... any internal cooling flow is dominated by 4 parts:

- The position and size of the opening

- The speed of the flow at entry

- The change in area of the 'tube'

- How low the pressure is at the exit compared to the pressure at the inlet.

Most of the time, grassroots people focus on putting the inlet at high pressure. But, you should also spend some time making sure to help as much air exit from the wheel well as possible... to help encourage that cooling air to leave, and in the process help draw more air in from the inlet. Otherwise, you'll end up with a bunch of hot stagnant air around the wheel, making your cooling duct (already inefficient because of the flexible tube) more inefficient.

Keith Tanner said:

Yup, highest pressure location. I'm thinking that's going to be close to the splitter.

Edit: maybe not. Check this out. Your setup is #6. That's a pretty big happy zone.

Also, get a proper bellmouth for it. That'll improve efficiency.

I learned the hard way that 2.5" ducts may not be sufficient for Miata brake cooling if you're really working them hard, and switched to 3". That's a high power car on a high altitude track.

Thanks Keith! I'm keeping ahold of that image for future use :)

Yeah, I was on the fence about the 2.5 vs 3" debate.. I've read a bunch of reviews and such, but for the forseesable future, I'm not increasing horsepower/decreasing reliability, so I decided that the 2.5 would work out okay for me.

I'm also slow and a pansy, so I'm pretty easy on brakes already. This is honestly more of a longevity mod and I'm trying to force myself to be harder on my brakes :)

Thanks for the offer, Robbie!

I think I'm good for now, as I don't plan on measuring it since I'm not ready to cut up/vent the fenders at this moment, although I have been meaning to pick up a manometer for various readings.

Good point from both you and Sleepy on venting/low pressure importance. It's certainly something to worry about in the future :)

Here's the full analysis: https://www.verus-engineering.com/blog/cfd-cases-4/post/air-dam-or-splitter-a-closer-look-12

The 3" is definitely a bigger pain in the butt. Full lock and big wheels means rubbing, which makes your hoses a consumable. It's something you do because you have to, not because it's easy to live with. That's why FM sells the 2.5" :) But they weren't enough for my use.

Yeah, that's understandable.. I'm guessing that I'll be making about 350 less HP than you did, so I'll be fine for a while..

Speaking of FM's gear, put together a kit to sell, I ended up buying from Goodwin some they had it all ready to go and I'm extremely short on time nowadays and I didn't have time to shop 3 or 4 other places to try to find 2.5" duct, or figure out how much I needed ahead of time..

When we offered complete kits with ducting, nobody wanted it because everyone had their own idea. Go figure.

And here I am doing the tech support ;)

Keith Tanner said:

When we offered complete kits with ducting, nobody wanted it because everyone had their own idea. Go figure.

And here I am doing the tech support ;)

Hah! Further evidence that we don't know what we want, but it sure as hell isn't whatever you're (for some value of you) is selling! :)

I looked at Goodwins site, looks like basically he sells the hose and the backing plates. We don't sell the hose. So yes, that's a reasonable thing for us to add to the product line. And maybe a nice 3D printed bellmouth inlet, hmm...

In reply to Keith Tanner :

Oooooohhh :). Now you're talking.. and make those bell mouths available separately :-p

Yeah, honestly the hose was what got me. I couldn't find a place on spruce to just get "some," I don't have the plates yet so I didn't know how much to order, and jegs & summit didn't have 2.5" available in their 10' boxes.

So I said screw it and just ordered from the guy who could give me a one-click solution. I did spend a day or so with it in my FM cart.

Keith Tanner said:

I looked at Goodwins site, looks like basically he sells the hose and the backing plates. We don't sell the hose. So yes, that's a reasonable thing for us to add to the product line. And maybe a nice 3D printed bellmouth inlet, hmm...

getting a proper 2.5" or 3" bellmouth would be awesome

Just as a conclusion to this thread, here's what I ended up with:

I will have a proper 2.5" bellmouth in hand as soon as I can get the printer time. It's 0.1mm smaller than the maximum size we can print...

Keith Tanner said:

I will have a proper 2.5" bellmouth in hand as soon as I can get the printer time. It's 0.1mm smaller than the maximum size we can print...

Awesome! I can't wait to see it!

where you placed the circles all of them will perform about the same. It should be noted that 3" brake duct can flow 133% more air than a 2.5.

I made some scoops for my brake ducts on my vette. Not the same thing at all but figured it would help a lot.

this is an old pic when I hadn't done much to the car but you can see the scoop in the former foglight hole

Keith Tanner said:

I will have a proper 2.5" bellmouth in hand as soon as I can get the printer time. It's 0.1mm smaller than the maximum size we can print...

So our printers are going flat out right now. We just ordered more that should increase our capacity by over 60%, maybe then I'll be able to get some time on the bed. It's killing me...

Keith Tanner said:

Keith Tanner said:

I will have a proper 2.5" bellmouth in hand as soon as I can get the printer time. It's 0.1mm smaller than the maximum size we can print...

So our printers are going flat out right now. We just ordered more that should increase our capacity by over 60%, maybe then I'll be able to get some time on the bed. It's killing me...

Yeah, that's always what happens when you start to add manufacturing capability...

Anybody know if repurposing my stock NB1 foglight holes for brake duct inlets is a waste on a mostly street driven car that (i hope) will do autocross and HPDE once in a while?

The foglights are gone, the bulbs are expensive and they suck