I just finished putting an aluminum flatbottom under the Daewoo and then got the car up to 80 ish mph. I was shocked how light it felt in the back. Honestly it was kind of scary how different it felt. Some of that might have been a wet road and some funny grooves in the concrete, but I've driven this stretch before in the wet and don't remember it being that way.

Is this all in my head or do I need to start thinking of a wing?

You have too much downforce in the front (vs. the rear) that's for sure...

Can you post pics of your new setup?

If you have a splitter that sticks out a lot, that is going to make a E36 M3-ton of downforce, you'd need a wing to balance that out. A balanced flat-bottom setup would be something like a very minimal splitter in the front and a big diffuser in the back.

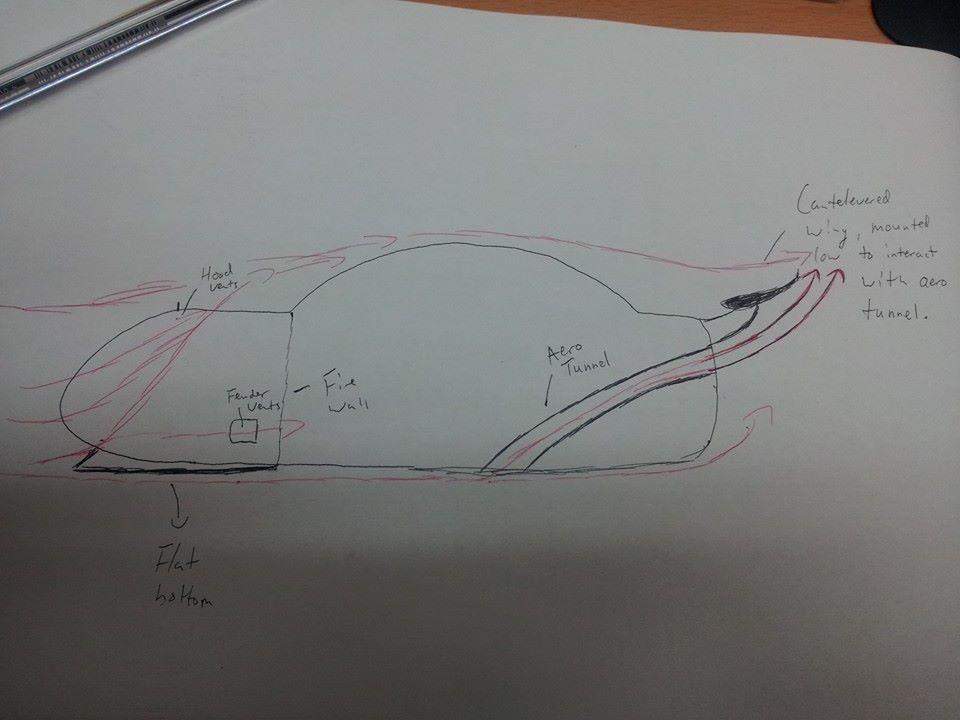

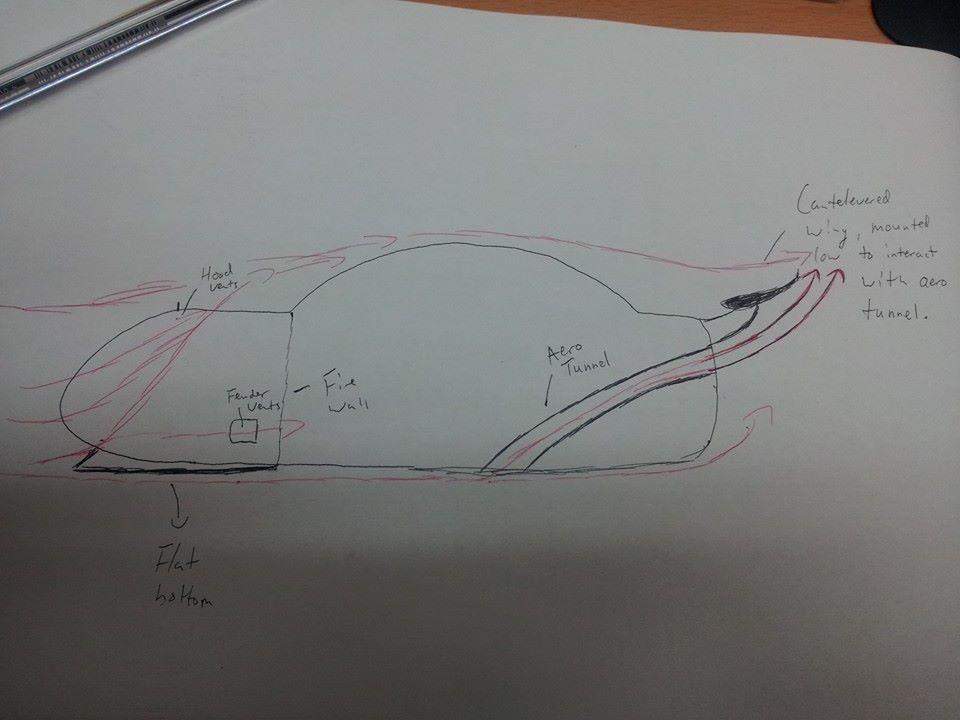

I'll get some pictures up soon. It has no splitter at all (for the moment), just a pretty good seal all the way from the bumper edge to the firewall. The air is forced to escape through my hood vents, fender vents, or down the tunnel currently occupied by my exhaust.

A setup like that would create some front downforce bias...at the very least you killed lift in the front and might still have some in the rear. I'd say you should make a diffuser now to balance it out, later you can link the front plate and diffuser with some sheet metal and add skirts to get more downforce in the center.

If you make the diffuser angle adjustable you can reduce its angle a bit if it creates any rear downforce bias. EDIT: You'll want to oversize it because when you get a full flat-bottom later, just having the smooth center will also boost front downforce.

Oh BTW here's an idea I came up with for splitter design...make it out of two plates bolted together with slots so they can slide apart and together, that way you can extend or retract the splitter to adjust front downforce. You'd want to get lots of overlap so that air can't pass through the slots.

Shaun

HalfDork

12/12/13 11:07 a.m.

I made as much of the bottom of my 96 civic flat as I could with coroplast and aluminum sheet and felt a very noticeable difference as well. Stuff like crosswinds have much less effect, your average 3% ish grade can be coasted down, MPG went a couple ticks to the good, and the car feels "lighter". I would hesitate to confirm that what you are experiencing is a noticeable shift in rear 'downforce' or overall downforce balance. Areo is complicated, 80mph is pretty slow for production sedans to be making downforce (if they make any anyways), and your new found slipperiness might just feel like a loss of traction. IMO you would need to test to really understand what is going on. Easier said than done I know. I got used to the difference in feel.

Well, I heard they make the rockin world go round.... so I'd say that would make a difference.

Pictures of the flat (fat) bottom girl in question.

http://bengarrido.com/2013/12/12/a-gallery-of-ghetto-modifications/

Yeah, I'd add more flat bottom to the car and to try and force all of the air out the back and under a diffuser.

Then add a rear spoiler/wing and a front splitter to improve balance and increase downforce. Be careful to not add too much drag since that can impact your top speed, the balancing act is to generate enough downforce to increase speed through the corners to offset any loss of speed on the straight sections.

With a FWD car, you probably still want to keep more downforce on the front, but not so much that it feels uncomfortable to drive at speed.

I race a flat bottom sports racer, so I've learned a little.

-

Add a big, honkin' plywood splitter. I'd let it stick out maybe 4" in front and a couple on the sides.

-

Add a big, honkin' wing on the back, "way up firm and high"

mtn

UltimaDork

12/12/13 3:23 p.m.

motomoron wrote:

I race a flat bottom sports racer, so I've learned a little.

- Add a big, honkin' plywood splitter. I'd let it stick out maybe 4" in front and a couple on the sides.

- Add a big, honkin' wing on the back, "way up firm and high"

Then trade it in on a '60 Chevy, and drive out past the corn where the woods get heavy

JFX001

UltraDork

12/12/13 4:31 p.m.

Somewhat outer-related...but those aero skirts found on semi trailers look like they would be a good source for material.

It's one of the reason an old beetle was so exciting as you hit 90mph. Heck yes it can make a huge difference. You just made the missing lower half of the airfoil, or wing.

Yeah you just created a parachute in the back. Maybe time to cut the rear bumper and see what happens.

I thought the title said Fatbottom = big difference. Geez, I could have told you that

foxtrapper wrote:

It's one of the reason an old beetle was so exciting as you hit 90mph. Heck yes it can make a huge difference. You just made the missing lower half of the airfoil, or wing.

That does make sense. I wonder how much of the effect I'm feeling isn't just downforce at the front but added lift at the rear?

This is sort of the master plan. I want downforce but I can't afford drag. Even with the best prepped engines I'm not going to get much over 200 hp in my target class and stay within the rules. Some of my competitors are going to be well above that (albeit with a weight disadvantage) and so I am trying to stick with devices that either improve drag or have minimal negative effects.

How about active aero? A wing on pivots tied to actuators on a 2 or 3 position switch linked to the brake peddle? Keith had a post about just this thing.

http://grassrootsmotorsports.com/forum/grm/active-aero/70768/page1/

Will you be cutting holes in the floor around the back seat area and ducting the air up to the bottom surface of the rear wing?

jere

HalfDork

12/13/13 4:19 a.m.

Couple of suggestions

It might help to put spats in front of the wheels (front and back) also. Try to get them the width of the tire or wider. If you can keep air from lifting the wheels off the ground, and instead put that force on the chassis you will have more traction.

If you have access to coroplast that would be great for the section after the engine bay all the way back.

Maybe run some angle aluminum in front the gap/hole where the control arms are too. Wheel wells seem to think they are parachutes as much as the rear bumper.

Also with that under-tray keep and eye on under hood temps. The oil and the transmission both tend to rely on air cooling.

jere wrote:

Couple of suggestions

It might help to put spats in front of the wheels (front and back) also. Try to get them the width of the tire or wider. If you can keep air from lifting the wheels off the ground, and instead put that force on the chassis you will have more traction.

If you have access to coroplast that would be great for the section after the engine bay all the way back.

Maybe run some angle aluminum in front the gap/hole where the control arms are too. Wheel wells seem to think they are parachutes as much as the rear bumper.

Also with that under-tray keep and eye on under hood temps. The oil and the transmission both tend to rely on air cooling.

Thanks for the advice. Do the spats have to be super strong or can I use relatively thin things like garden edging?

Not super strong but you don't want them to flop the wrong way...for example I've heard those garage door edging front lips turn inside-out at about 80MPH.

DaewooOfDeath wrote:

foxtrapper wrote:

It's one of the reason an old beetle was so exciting as you hit 90mph. Heck yes it can make a huge difference. You just made the missing lower half of the airfoil, or wing.

That does make sense. I wonder how much of the effect I'm feeling isn't just downforce at the front but added lift at the rear?

I disagree with those saying you've caused increased downward force at the front. You've done the opposite.

Previously, the air flowed very slowly along the underside of the car, caught up in the roughness of the car parts. It was essentially a wing in stall, and no lift was created, just turbulence. Possibly a little lifting from the pressure under the hood, but only a very few hundred pounds.

Now, there is a panel along the bottom, letting the air flow smoothly. Smooth air over the top, smooth air over the bottom. That's a wing. Longer travel rising up over the hood, lower pressure, so you get lift. Potentially a lot of lift.

How much lift? Depends on a number of variables, but as an example, remember the fun Nascar had when they went to smooth underbellies? Took quite a bit of upper wing design to counter the lift and hold the cars down.

The beetle I mentioned previously as an example was rather infamous for this because it had a rather smooth underbelly the full length of the car (well almost, the engine took a few feet at the very back, but eveb that was sealed). By about 90 mph a stock beetle would be starting to lift its front tires off the ground. Being young and bullet proof, I actually took my modified beetle to 100, maybe +100 mph. It was interesting watching the world as the front bobbed up and down several inches, and turning the steering wheel lock to lock did absolutely nothing. Before I splattered, I did have a lucid moment and somewhat mature thought, and slowed it down so I could again steer it. If I'd have had cutting brakes, I might now have though.

I get what you're saying, but then why do these guys bother building lift into their machines?

Isn't it a fluid dynamics law that higher speed is lower pressure and lower speed is higher pressure?

Step 1: make car really slippery.

Step 2: add back drag, but only in ways that produce down force when and where you want it.

Step 3: profit!