Castrol superclean and a wire brush. Then, use the por15 process. Metal ready, por, topcoat. That E36 M3 sticks like syphilis. The k frame of the duster was dpne in 1997 and still looks like the day i did it.

Castrol superclean and a wire brush. Then, use the por15 process. Metal ready, por, topcoat. That E36 M3 sticks like syphilis. The k frame of the duster was dpne in 1997 and still looks like the day i did it.

My only issue with Rust-Oleum (and implement paint in general) is that is seems to be hard within 60 days of painting. Maybe. Hardener is in my future I believe.

With POR-15 I'd be topcoating with something like Rust-Oleum anyway, right?

I did the TR4 frame with rustoleum - brushed on - it levels out nicely. Easy to touch up. The rustoleum spray bombs aren't nearly as good. If you go POR - like was said, it's not UV protected. If you topcoat it you need to get the topcoat on while it is still slightly tacky otherwise the topcoat tends to peel after a while.

APEowner wrote:Crackers wrote: Interestingly enough, Ford and Chevy small blocks have the same firing order. The cylinders are just numbered differently. In this case, the firing order is the identical, but the cylinders appear to be numbered differently. So even though the numerical sequence is the same, it does in fact have a different order. LOLThat's almost correct. There are two different reasonable firing orders for 90 degree v8 engines with cross plane cranks. Ford used both of the at one time or another. It seems like there are more because different manufacturers use a different numbering scheme.

IIRC, the Pontiac firing order is the exact reverse of the Chevy order... 2-7-5-6-3-4-8-1

Did I mention that I love the Grosh? Let's take the oil pan off. The pickup is gross, but the rest of the bottom end is shiny and pretty. And still stuck.

Took these three things and mixed up some magic goo and four pistons are upright and soaking.

Took these three things and mixed up some magic goo and four pistons are upright and soaking.

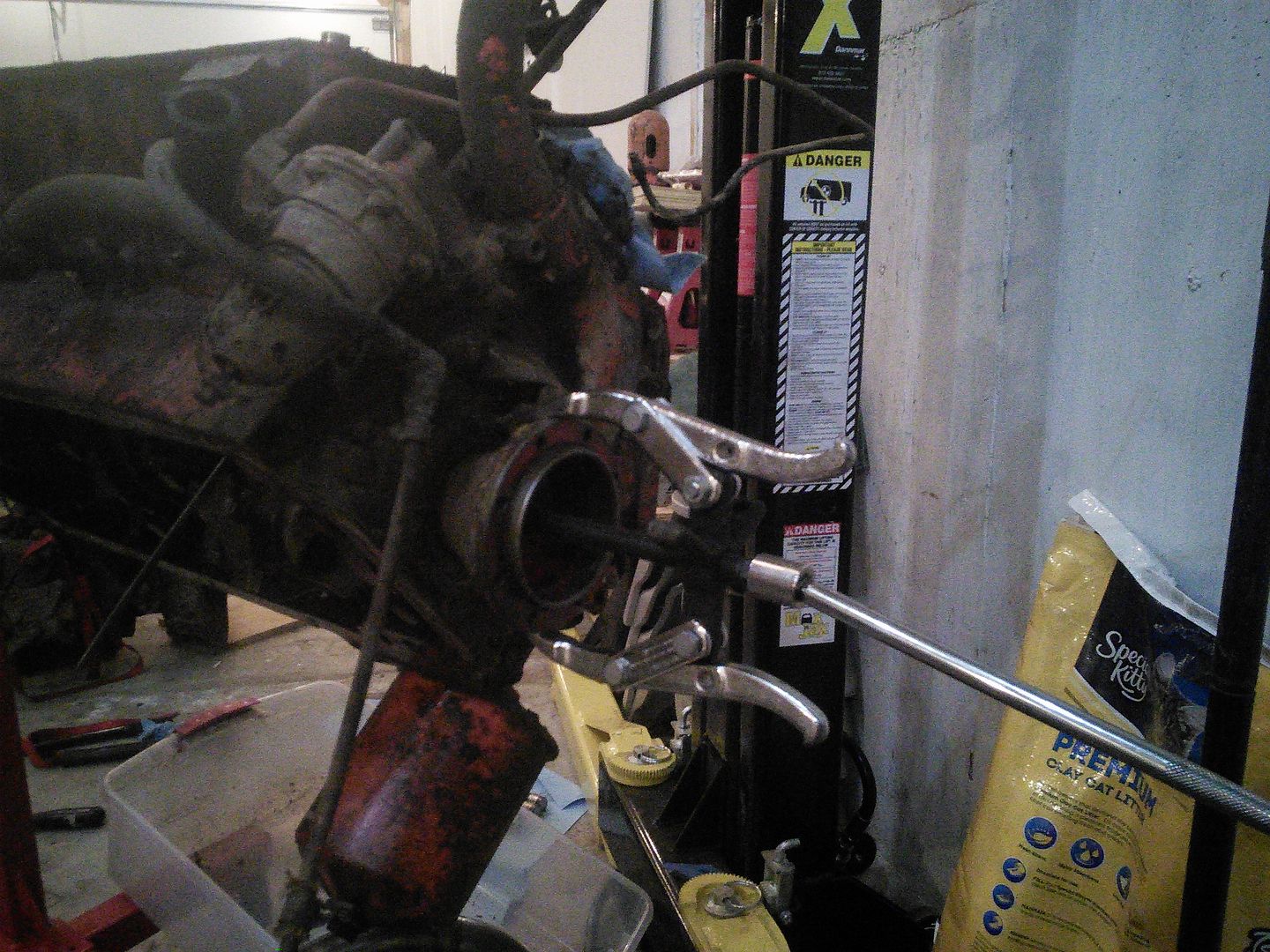

Then I remembered that I had a generic two jaw puller and I pulled the crank pulley.

Then I remembered that I had a generic two jaw puller and I pulled the crank pulley.

And then the timing case, though I didn't take a picture of that. I assume the idea now is to take the rod caps off, keep careful track of them (even though the caps and rods are numbered) pull the crank, continue keeping track of all the bearings too, and then see if I can drive the pistons out the bottom?

And then the timing case, though I didn't take a picture of that. I assume the idea now is to take the rod caps off, keep careful track of them (even though the caps and rods are numbered) pull the crank, continue keeping track of all the bearings too, and then see if I can drive the pistons out the bottom?

I'll try and remember to bring the real camera out tomorrow. I was having too much fun tonight to run inside and grab it tonight. ![]()

If the mileage is to be believed and based on what that bottom end looks like, you might be able to re-use bearings and all. It's certainly worth cleaning everything up, inspecting, and putting some plastigage in to check.

Also, actual numbers stamped on rods usually means overhauled already, and by someone relatively conscientious.

What does cleaning, boring, and cam bearing installation go for these days in Houston? Last time I had that much done to a big block mopar it was @$300 and done in two days. It's a pretty standard basic machine shop order, they should be able to quote you over the phone. (Usually you would magniflux too, but with the way the antifreeze looked I wouldn't bother unless you can be there when they do it to watch. Every engine rebuilder she see a magniflux once.)

There was some fairly nasty stuff in the bottom of the pan which then drained to the top of the motor when I flipped it over to take the oil pan off (didn't think that through) and then back out onto the floor when I tipped it down side down again. The part of the motor that didn't get covered in goo looks basically new. There is one little spot of light rust on one counter weight of the crank, smaller than a pea, everything else is clean. I'm feeling pretty good that the bores are the only potential bad spots.

About your frame cleanup. This isn't a whole answer...but it will probably also be useful in many other parts of the project:

For the last year or so I've been treating ANY rust I see with phosphoric acid. Purchased by the gallon at one of the local Low-Nard-Depot type places (though, I had to make a few stops...only one of them had it when I last looked). I'm pretty sure I've been told that this is basically what POR15's "metal prep" is.

I have purchased it by the gallon and applied using a spray bottle. I wear gloves...usually.

The cool thing about it is that, as far as I can tell...you don't have to top coat it. I'm using it basically to "arrest" rust that I find.

Living in Missouri, I have lots of rusty projects. I take comfort crawling around over and under a project and saturating the rusty parts with this stuff. It seems to not bother plastic, glass, or painted surfaces. (It did change the color of the paint on the '83 Suburban...but that paint is far from "high integrity.")

In reply to mazdeuce:

That's exactly how we had to disassemble the 350 in the Vette...except that without being able to rotate the crank there are some rod bolts that are inaccessible. After we pulled all the main caps, we used a punch on the head of the rod bolts + a large hammer to drive the pistons toward the deck, so it would rotate enough to get to other rod bolts.

Im my case the crank was free, but 3-pistons were really stuck.

Whichever pistons are stuck in their bores, drag the engine safely outside, stuff rags into those bores, soak with kerosene and light them on fire. By the time the kerosene and rags burn out, the piston will usually be freed up.

Tractor guys been doing that forever.

Cousin_Eddie wrote: Whichever pistons are stuck in their bores, drag the engine safely outside, stuff rags into those bores, soak with kerosene and light them on fire. By the time the kerosene and rags burn out, the piston will usually be freed up. Tractor guys been doing that forever.

and make sure to video it

Keep up the good work!

Oh and thanks for doing some of your work in the yard even though you have a stellar garage. It's good for the spirit of all those watching who think that they shouldn't play with stuff if they don't have a lab grade shop to work in.

Anyways for frame coating I used off the shelf Rustoleum semi-gloss black on the GMC and was very happy with the results. I wire wheeled off the large rust and just brushed the paint on over the rest. It dried pretty quickly in my cold garage and gave a fairly uniform coating. Not show car but way better than rust. Seems to be holding up quite well for how inexpensive it is as well. I like the brush vs. spray so you don't have to meticulously mask everything off so you don't have over spray everywhere.

Cousin_Eddie wrote: Whichever pistons are stuck in their bores, drag the engine safely outside, stuff rags into those bores, soak with kerosene and light them on fire. By the time the kerosene and rags burn out, the piston will usually be freed up. Tractor guys been doing that forever.

The method I read was to simply pour like half an inch of gasoline/oil mixture (heavy on the oil) in, no rags. I think the idea there is that the hot oil will penetrate down around the piston. Either way, they're a lot easier to take apart when they can rotate.

For chassis painting, I probably wouldn't be able to ignore the urge to just tear the whole front suspension apart for cleaning and painting.

Pete got five out. I got six. I win!

Incidentally, you can't punch these pistons out the bottom. The webbing for the block in the way. My camera did NOT want to take a photo down the bore by the way.

Incidentally, you can't punch these pistons out the bottom. The webbing for the block in the way. My camera did NOT want to take a photo down the bore by the way.

The crank is beautiful. The rod bearings are beautiful. The cam spins in the block like it's new. All of the lifters came out easily though I might need to polish one or two.

The crank is beautiful. The rod bearings are beautiful. The cam spins in the block like it's new. All of the lifters came out easily though I might need to polish one or two.

The six bores that I have empty of pistons look great. Ok, maybe not great, but not a deal killer yet. It's those two pistons and the potential damage that are holding me back. Any thoughts on using one of the commercial rust dissolvers on the bores? One of the pistons I'd be worried about pushing past the rust even if I could get it to move.

The six bores that I have empty of pistons look great. Ok, maybe not great, but not a deal killer yet. It's those two pistons and the potential damage that are holding me back. Any thoughts on using one of the commercial rust dissolvers on the bores? One of the pistons I'd be worried about pushing past the rust even if I could get it to move.

Throwing the micrometer in there gives me 3.86 inches or three about. 3.75 inch dingleberry hone, or is there a better option?

Does your fingernail catch at the top of the bore? If so a ridge reamer(three fingered assmy with a blade,spun slowly with a 1/2in ratchet) will rectify that and allow extraction of the two problem children.

In reply to mazdeuce: see what you can remove from the cylinder before punching out pistons, and then go for broke. It doesn't take much to make a ring stick, and looking at everything else, I think you'll be okay. As mentioned upthread, these aren't high performance German-engineered aluminum motors. Sometimes, you gotta use a big hammer...

You'll need to log in to post.